It's highly questionable to use resonance frequency to estimate mass attached. What is the air mass attached?

400X microscope costs around $30.

If this is too much for you:

Can't you just bring your coated film to the store and check microscope they are selling...

400X microscope costs around $30.

If this is too much for you:

Can't you just bring your coated film to the store and check microscope they are selling...

@alexberg: I don't know if you are replying to me, but the method I posted has nothing to do with resonance. (my panels don't resonate at 18kHz 😛)

It uses the phase-lag/damping behaviour which a membrane has on a sound-wave. As you see in the formula only the mass is included, not something like a stiffness-factor. For resonance you need both!

For a lot of people this method means no extra cost at all (if you have an old oscilloscope somewhere)! And it's also possible to study the behaviour of other parts of the loudspeaker this way. (like for example the effect of the stator, a layer of cloth for or damping material)

It uses the phase-lag/damping behaviour which a membrane has on a sound-wave. As you see in the formula only the mass is included, not something like a stiffness-factor. For resonance you need both!

For a lot of people this method means no extra cost at all (if you have an old oscilloscope somewhere)! And it's also possible to study the behaviour of other parts of the loudspeaker this way. (like for example the effect of the stator, a layer of cloth for or damping material)

I agree, for resonance you need both.

Nevertheless, that is NOT easier/simple/cheaper to arrange then find a microscope.

What about HF stripe 2..5 cm wide, which is usually made of really thin film?

Do not we need the membrane dims to be >> wavelength to escape diffraction?

Secondly, you do not need to make sizable membrane... mounted on a frame just a little painted flake

Nevertheless, that is NOT easier/simple/cheaper to arrange then find a microscope.

What about HF stripe 2..5 cm wide, which is usually made of really thin film?

Do not we need the membrane dims to be >> wavelength to escape diffraction?

Secondly, you do not need to make sizable membrane... mounted on a frame just a little painted flake

I just used a painted flake... But you can also measure the weight of a membrane which is mounted.

As long as the piece of diaphragm is larger than +/-3 times the wavelength (5cm) this will be all right.

It also has the advantage of directly measuring the the weight, so you don't have to know the density of the dried coating.

Off course there are disadvantages, a measurement probably takes more time than a measurement with a microscope and the precision might not be as good as with a microscope.

(I'm not saying everybody should use this method, but it's nice to have several methods to measure something)

As long as the piece of diaphragm is larger than +/-3 times the wavelength (5cm) this will be all right.

It also has the advantage of directly measuring the the weight, so you don't have to know the density of the dried coating.

Off course there are disadvantages, a measurement probably takes more time than a measurement with a microscope and the precision might not be as good as with a microscope.

(I'm not saying everybody should use this method, but it's nice to have several methods to measure something)

I use a highly accurate Mettler milligram balance for measuring mass (it has a 0,1 mg reading). From the measured mass of part of the Mylar the total moving mass of the esl can be extrapolated. From the difference with/without coating the mass of the coating can be measured as well.

The total moving mass of an exl easily exceeds that of a dynamic tweeter by the way.

The total moving mass of an exl easily exceeds that of a dynamic tweeter by the way.

I wish I had that equipment 🙂

The moving mass is around 0.5g-1.0g for a 0.1 by 1m ESL unit. That doesn't seem to be much to me... How much is it for a dynamic tweeter?

But in practice it's not that much of a problem. A dynamic tweeters has a much larger excursion. A tweeters surface area is 4cm^2, the surface area of an ESL is easily 100x larger. So the dynamic tweeter has to move sqrt(100)=10 times as much, so it has to be 10^2=100 times lighter than the diaphragm to have the same amount of kinetic energy.

I guess it is heavier than 10mg...

The moving mass is around 0.5g-1.0g for a 0.1 by 1m ESL unit. That doesn't seem to be much to me... How much is it for a dynamic tweeter?

But in practice it's not that much of a problem. A dynamic tweeters has a much larger excursion. A tweeters surface area is 4cm^2, the surface area of an ESL is easily 100x larger. So the dynamic tweeter has to move sqrt(100)=10 times as much, so it has to be 10^2=100 times lighter than the diaphragm to have the same amount of kinetic energy.

I guess it is heavier than 10mg...

The moving mass of the scanspeak tweeter revelator D2905/990000 is stated as 0,45 gram.

Still there are many people who claim that the esl is much lighter than a dynamic speaker and therefor offers superior speed.

(Ofcourse you can't compare the two only by their mass as the radiating surface and the driving forces are completely different, that's another story.)

Still there are many people who claim that the esl is much lighter than a dynamic speaker and therefor offers superior speed.

(Ofcourse you can't compare the two only by their mass as the radiating surface and the driving forces are completely different, that's another story.)

An ESL can have as much excursion as a dynamic driver can if not more,Considering that I have reached the the excursion limits of my 3.25" wide panels with a D/S of .075" starting around 150hz to 200hz.

The total area of that panel is 204.435cm^2 (3.25" X 9.75").

Although I don't yet have a good scale I am sure that the mass is much less than .45 grams.

I use a .25 mil (6um) mylar with the Licron Crystal on my panels.

Just for what it is worth.

jer 🙂

The total area of that panel is 204.435cm^2 (3.25" X 9.75").

Although I don't yet have a good scale I am sure that the mass is much less than .45 grams.

I use a .25 mil (6um) mylar with the Licron Crystal on my panels.

Just for what it is worth.

jer 🙂

An ESL can have as much excursion as a dynamic driver can if not more,Considering that I have reached the the excursion limits of my 3.25" wide panels with a D/S of .075" starting around 150hz to 200hz.

The total area of that panel is 204.435cm^2 (3.25" X 9.75").

Although I don't yet have a good scale I am sure that the mass is much less than .45 grams.

I use a .25 mil (6um) mylar with the Licron Crystal on my panels.

Just for what it is worth.

jer 🙂

That will be true in case of your relatively small panels, but a modest fullrange will have more moving mass than the scanspeak (e.g. several grams as zweetvoetjes already mentioned).

B.t.w. I expect the ' speed' being independent on the size of the ESL-film as both the driving force and the mass are directly proportional to the size of the film and cancel in Newton's equation.

The moving mass of the scanspeak tweeter revelator D2905/990000 is stated as 0,45 gram.

Still there are many people who claim that the esl is much lighter than a dynamic speaker and therefor offers superior speed.

(Ofcourse you can't compare the two only by their mass as the radiating surface and the driving forces are completely different, that's another story.)

Can the D2905 play full range down to 300hz? No. If you want to compare a MC tweeter mass to an electrostatic, wouldn't it be a better comparison to compare the mass of equal radiating area, or at least compare the MC to a true ELS tweeter?

My point was about people claiming the moving mass of an esl being much lower compared to dynamic speakers. This is not true in case of fullrange esls compared with dynamic tweeters and both do want to produce the highest frequencies. You may compare the large esl with a woofer but the woofer doesn't need to be fast as it only takes care about the lows anyway. In fairness you may want to compare a small tweeter esl with a dynamic tweeter to prove that the esl is much lighter thus faster. But this makes little sense as cutting the size of an esl to the size of a tweeter doesn't make a faster thing as driving force is decreased with the same magnitude.

BTW

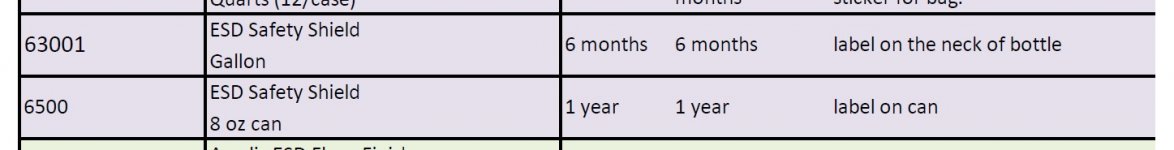

for the lazy ones there is 6500 in aerosol can. Not recommended by rep: "bottled is better" The smallest 6300 is 1 quart... 6400 even sticks to olefines (low surface energy plastics) such as PP and PE. Coating can be made extremely thin by dilution... Stretched coated Mylar to the break point: no flaking

Later,

Alex

P.S. 2 years so far so good.

Hello alexberg,

How long have you had your quart of 6300? Have you noticed any changes in its conductive properties?

I have had mine for 1 1/2 years now, and it no longer conducts.

I noticed the datasheet for the 6300 specifies a shelf life of only 3 months.

I contacted the company to get some clarification. Here is what I was told.

The particular type of acrylic polymers used in the 6300 coating are susceptible to bacteria once they are exposed to air in their liquid state. The product will “spoil” much the same way milk will spoil from bacteria exposure after a short period of time even if it’s kept cold. As the product "spoils" the resistivity increases until the the coating no longer conducts. However, once the liquid (while still “fresh”) is applied and dries to a film, it no longer is susceptible to bacteria.

The 3 month shelf life starts when the container is first opened.

Once opened, a 3-6month shelf life is typical depending on how much exposure to air it receives.

Unopened, it should last up to 1 year.

Mine is about 2 years old and no good as well...

In regard to shelf life it's the same you've posted, see attach.

Alex

BTW 2 years on the previous post was about the coating on membrane.

QUOTE

What is the preferred method of application in order to obtain the resistivity specified?

Flow coating may be ideal, but the lab technician prefers spraying. I suppose it depends on your situation. This coating was designed to be applied in a variety of ways. The viscosity is closer to water than paint so if you spray, use a fine tip nozzle rather than the type of nozzle found on a paint sprayer. Our chemist uses a HVLP sprayer with a 1.0 mm tip.

If painting, I’ve had luck with a foam brush rather than a bristle brush, but painting or brushing is not as ideal as spraying, dipping, or flow coating.

What is surface preparation procedure?

Cleaning the surface with isopropyl alcohol is ideal. Apply coating in environments between 15C- 24C with 30-40% RH.

What is the curing method?

The 6300 is an air-dry coating, so no special curing method is needed. The coating should dry to the touch in a couple of hours and 95% dry overnight (7 days for 100% dry). If you desire a force dry method, we recommend placing coated parts in an oven (80C – 90C) for 15-30 minutes. The parts can be preheated at 60C –79C for better coverage.

How to check if the adhesion is as claimed?

We do not have an official way of checking adhesion. A tape test should give you an indication of adhesion. Coat a sample of the substrate with the 6300 and allow to dry for a week (for a full cure). Cut two intersecting lines at a 30 – 45 degree angle (like an X) using a razor blade (or something similar). Cut through the coating down to the substrate. Use a hard metal straightedge to ensure straight cuts. Press adhesive tape in the center intersection of the X and remove the tape in a rapid motion. Inspect the area around the X for any coating removed.

Product is going to be applied to PETF. We’ve tested mainly on acrylic and polycarbonate, but we’ve also tested on glass, polyester webbing, PET, PVC, and PETG. I suspect reasonable adhesion on most materials except polypropylene, Teflon...

END QUOTE

In regard to shelf life it's the same you've posted, see attach.

Alex

BTW 2 years on the previous post was about the coating on membrane.

QUOTE

What is the preferred method of application in order to obtain the resistivity specified?

Flow coating may be ideal, but the lab technician prefers spraying. I suppose it depends on your situation. This coating was designed to be applied in a variety of ways. The viscosity is closer to water than paint so if you spray, use a fine tip nozzle rather than the type of nozzle found on a paint sprayer. Our chemist uses a HVLP sprayer with a 1.0 mm tip.

If painting, I’ve had luck with a foam brush rather than a bristle brush, but painting or brushing is not as ideal as spraying, dipping, or flow coating.

What is surface preparation procedure?

Cleaning the surface with isopropyl alcohol is ideal. Apply coating in environments between 15C- 24C with 30-40% RH.

What is the curing method?

The 6300 is an air-dry coating, so no special curing method is needed. The coating should dry to the touch in a couple of hours and 95% dry overnight (7 days for 100% dry). If you desire a force dry method, we recommend placing coated parts in an oven (80C – 90C) for 15-30 minutes. The parts can be preheated at 60C –79C for better coverage.

How to check if the adhesion is as claimed?

We do not have an official way of checking adhesion. A tape test should give you an indication of adhesion. Coat a sample of the substrate with the 6300 and allow to dry for a week (for a full cure). Cut two intersecting lines at a 30 – 45 degree angle (like an X) using a razor blade (or something similar). Cut through the coating down to the substrate. Use a hard metal straightedge to ensure straight cuts. Press adhesive tape in the center intersection of the X and remove the tape in a rapid motion. Inspect the area around the X for any coating removed.

Product is going to be applied to PETF. We’ve tested mainly on acrylic and polycarbonate, but we’ve also tested on glass, polyester webbing, PET, PVC, and PETG. I suspect reasonable adhesion on most materials except polypropylene, Teflon...

END QUOTE

Attachments

Mine is about 2 years old and no good as well...

In regard to shelf life it's the same you've posted, see attach.

Alex

BTW 2 years on the previous post was about the coating on membrane.

understood...the 2 years mentioned was for a cured coating.

Oh, and thanks for the additional application information.

Is it possible to mix Antistatik100 with elvamide? I used Antistatik 100 coating in my esl prototypes but surface resistance is little too low, about 10e7-10e8. Or should I just try elvamide coating?

I dont know what Antistatik100 is and how soulable it is with Elvamide.

I have tried a Swedish permanent antistatic and Staticide 6300 and they both mix well with Elvamide so you should be ok!

/R

I have tried a Swedish permanent antistatic and Staticide 6300 and they both mix well with Elvamide so you should be ok!

/R

The product you've mentioned is a topical oneIs it possible to mix Antistatik100 with elvamide? I used Antistatik 100 coating in my esl prototypes but surface resistance is little too low, about 10e7-10e8. Or should I just try elvamide coating?

So far I haven't had any issues with either formula.

Although I have the aerosol types.

I have had a can of the original formula since 2003 and it has been in freezing conditions out in the garage and I just shake it up good and it still worked.

The little panel that I had just got back running still has the original diagphram with the same coating on it since 2003.

So far I have the same results with the Licron Crystal type as a cured coating.

I have had that can for two years now on a couple of my diagphrams with no problems yet.

I haven't used it recently and according to Techspray there shouldn't be any problems with that formula either.

I will find out sometime shortly as I do need to replace the diagphrams on my little panels because of some burn holes and for a new build that I am planning.

I have not yet tried the stuff in a bulk container yet .

I don't recall any shelf life warnings in the Techspray info sheets.

jer 🙂

Although I have the aerosol types.

I have had a can of the original formula since 2003 and it has been in freezing conditions out in the garage and I just shake it up good and it still worked.

The little panel that I had just got back running still has the original diagphram with the same coating on it since 2003.

So far I have the same results with the Licron Crystal type as a cured coating.

I have had that can for two years now on a couple of my diagphrams with no problems yet.

I haven't used it recently and according to Techspray there shouldn't be any problems with that formula either.

I will find out sometime shortly as I do need to replace the diagphrams on my little panels because of some burn holes and for a new build that I am planning.

I have not yet tried the stuff in a bulk container yet .

I don't recall any shelf life warnings in the Techspray info sheets.

jer 🙂

Why would one expect that self-polymerizing one component varnish gonna be good forever? It's not saline...Hi

So the most stable and longest shelf life is still Licron?

Andrew

Seems that any hermetically sealed product is the proper one...

Water based product can be shipped by air - that was 1st decisive factor for me. Water based product dries much slower and I would never change such a convenience for a shelf life.

There are better materials as well - you would not like the price

On the other hand, also it's a stretch, would you use expired food?

- Home

- Loudspeakers

- Planars & Exotics

- ESL Diaphragm coating