Follow this link http://www.stanford.edu/group/ctr/gallery.html and look down till you find "Flow over a Backward-Facing Step (Spanwise Vorticity)" near the bottom. I think it gives a good visualization of what is happening to the airflow over the pattern. That said it would seem to indicate that the training edge of the EnABL pattern should be a shape cut off going straight down. I would try coating just the leading edge to smooth the transition and not coating the trailing edge to give the sharp cut off.

Thanks Bud,

I'm not sure I can get to the dome, since it has a metal hexagrid over it and I'm not too keen on trying to do the inside of the dome. Should I do the ouside of the tweeter flange as shown below?

I'm not sure I can get to the dome, since it has a metal hexagrid over it and I'm not too keen on trying to do the inside of the dome. Should I do the ouside of the tweeter flange as shown below?

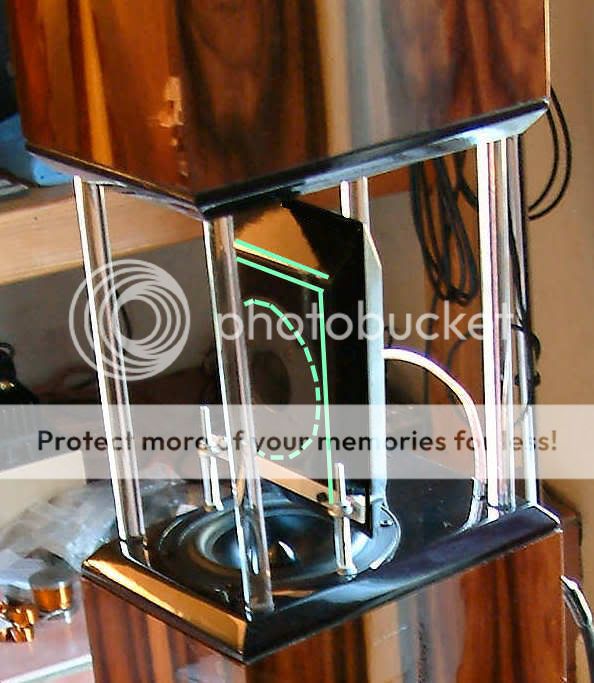

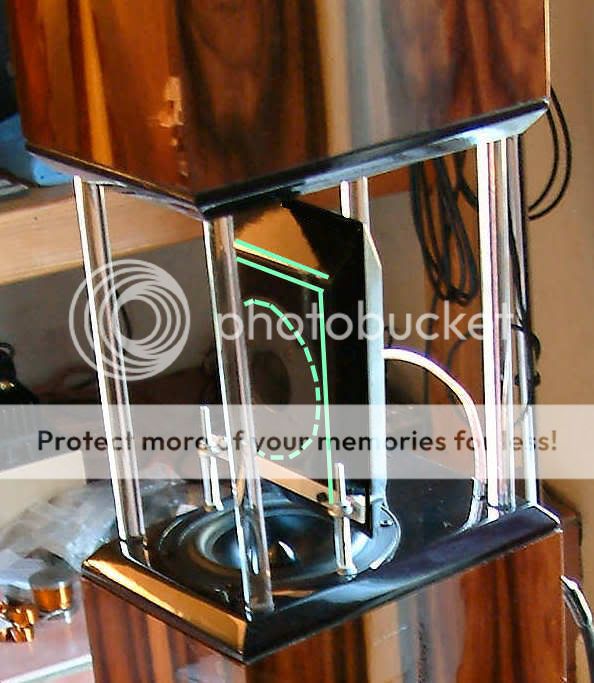

Here are a couple of photos of the EnABL treated Hemp FR8c that we played at RMAF. Done by yours truly in the hotel room. 😎

I did have much luck in my earlier experiments with calligraphy pens, so I've done 2 sets with brushes instead. Not the prettiest work you'll ever see, but it works. No glue drop on the dust cap (I do have it on my home drivers). No conformal coating, either. That will come.

The box is made of bamboo plywood and is really beautiful, the photos don't' do the color justice.

Planet10 Dave thinks that the cabinet face is a good candidate for the EnABL, too.

I did have much luck in my earlier experiments with calligraphy pens, so I've done 2 sets with brushes instead. Not the prettiest work you'll ever see, but it works. No glue drop on the dust cap (I do have it on my home drivers). No conformal coating, either. That will come.

The box is made of bamboo plywood and is really beautiful, the photos don't' do the color justice.

Planet10 Dave thinks that the cabinet face is a good candidate for the EnABL, too.

Attachments

Panomaniac,

These edges looks like intarsia, or I got too much Slivovitsa

Looks really good

Cheers,

Peter

These edges looks like intarsia, or I got too much Slivovitsa

Looks really good

Cheers,

Peter

panomaniac said:box design is from Planet10.... "Demetri"

http://www.planet10-hifi.com/boxes-fostex.html#demetri

dave

peterbrorsson said:These edges looks like intarsia,

It is actually the end grain of the bamboo ply... Chris is working up a set of Fonkens right now, i'm very interested to see how they turn out.

dave

Hi Dave,

That's what I mean, I call it plainly edges. Edge grain from now on then.

I assume it's a three-layer board. It's a pity that these kind of boards are so expensive here. Had my eyes on three-layer apple ply or cherry boards but price mounted (literary speaking) to 500 Euro a pair of bib's.

Cheers,

Peter

That's what I mean, I call it plainly edges. Edge grain from now on then.

I assume it's a three-layer board. It's a pity that these kind of boards are so expensive here. Had my eyes on three-layer apple ply or cherry boards but price mounted (literary speaking) to 500 Euro a pair of bib's.

Cheers,

Peter

planet10 said:

It is actually the end grain of the bamboo ply... Chris is working up a set of Fonkens right now, i'm very interested to see how they turn out.

Wow, they will probably look stunning knowing Chris's handywork.

I was thinking of mahogany ply for my next pair.

Jeff

Thanks Dave for the link. I was remiss in not posting it.

The bamboo end grain is very pretty and very unusual. I like it. Will have to have a pair for my living room. They'll fit just right with our tropical decor. The bamboo plywood we used has been caramelized, so it has a lovely honey brown color. In the photos I posted it looks too green. It's not.

Peter, we can't get Slivovitsa, here. Pity! So we just settle for "sugarcane juice." (Rum)

The bamboo end grain is very pretty and very unusual. I like it. Will have to have a pair for my living room. They'll fit just right with our tropical decor. The bamboo plywood we used has been caramelized, so it has a lovely honey brown color. In the photos I posted it looks too green. It's not.

Peter, we can't get Slivovitsa, here. Pity! So we just settle for "sugarcane juice." (Rum)

panomaniac said:.....

............we can't get Slivovitsa, here. Pity! So we just settle for "sugarcane juice." (Rum)

shall we change next year at the BAF ?

I've begun to experiment w/ some old drivers. Couldn't get the calligraphy pens to work well w/ Testors flat enamel model paint. The wide tips did fairly well, but the small tips for the center areas and small domes either wouldn't write or made blotches. So I switched to a brush: "000 Series 7 Finest Sable Winsor & Newton England". About the smallest brush I've ever seen. Now I can get those little dots!

Cheers, Jim

Cheers, Jim

Hi Jim,

Did you find the note buried in the avalanche rubble, of the preceding pages, about needing to burn the wax coating off of the pen tips? Also, using them, at least the A series, with the bent tip pointing down is much more satisfactory.

I just use the Rapidiograph pens for small dots, but I am used to them and have a huge number of tips.

Have fun.

Bud

Did you find the note buried in the avalanche rubble, of the preceding pages, about needing to burn the wax coating off of the pen tips? Also, using them, at least the A series, with the bent tip pointing down is much more satisfactory.

I just use the Rapidiograph pens for small dots, but I am used to them and have a huge number of tips.

Have fun.

Bud

dlneubec,

Almost all dome tweeter drivers can be disassembled without damage to the dome itself. Care and close peering through a set of magnifier flip down glasses is highly recommended though.

Your pattern locations are fine, though I would continue the horizontal pattern, on the triangular blocks, around the entire periphery.

Bud

Almost all dome tweeter drivers can be disassembled without damage to the dome itself. Care and close peering through a set of magnifier flip down glasses is highly recommended though.

Your pattern locations are fine, though I would continue the horizontal pattern, on the triangular blocks, around the entire periphery.

Bud

BudP said:Did you find the note buried in the avalanche rubble, of the preceding pages, about needing to burn the wax coating off of the pen tips?

Nope. Explains why they work better after a good wash in hot water.

I just use the Rapidiograph pens for small dots, but I am used to them and have a huge number of tips.

I have foud the 56 tip to be good for the little bits. For FE206/207, i use A3, A4, A5 and 56.

481 spots on a set of 206/207 with phase plugs... still have phase plugs to do.

dave

Attachments

481 spots on a set of 206/207 with phase plugs... still have phase plugs to do.

Spotted fervor indeed.....

Bud

planet10 said:

I have found the 56 tip to be good for the little bits. For FE206/207, i use A3, A4, A5 and 56.

I couldn't get the #56 tip to flow at all, even after thinning the paint. The wax coating that I see mentioned was probably the reason. I used a whittled down bamboo barbecue skewer for the tiny dots, actually worked ok. The A4 tip worked quite well. Thanks guys.🙂

Jeff

Am curious about the labour involved. Leaving aside any consideration of liscensing costs, unless somehow an automated procedure was developed, (obviously talking some sort of commercial factor here, not DIY) what would a treated driver cost above an untreated?

I have no figures, but I also wonder if the extra cost involved would make it beneficial to go to a 'higher' driver, in other words is the benefit given by the treatment still better on the lower driver than the untreated higher driver?

Hope that question made sense, and hope I haven't been rude.

I have no figures, but I also wonder if the extra cost involved would make it beneficial to go to a 'higher' driver, in other words is the benefit given by the treatment still better on the lower driver than the untreated higher driver?

Hope that question made sense, and hope I haven't been rude.

Jim Shearer said:Couldn't get the calligraphy pens to work well w/ Testors flat enamel model paint.

Yeah, same here. I didn't see the "wax off" post. Will give it a try.

Doing with a brush isn't bad, but I think I'll let my wife do it in future, she's good at that stuff.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- EnABL Processes