If such an area is increased three times more, then the bass will still be "caressing".To be clear, I am not talking about increasing sensitivity(SPL out for voltage in) but rather increasing maximum SPL output capability. For mid-HF range, the on-axis sensitivity of two panels will be essentially the same whether they are side-by-side, or stacked one behind the other.(again with the caveat that you need to keep spacing between the diaphragms to a minimum. For mid-HF you can adjust transformer design and gap to get most any sensitivity you are after. But, the max SPL is fixed by the area of the panels used since the available driving force per unit area is a fixed quantity for ESLs. Also, efficiency is kind of irrelevant with ESLs since it is so high that essentially all the power dissipated by the driving amplifier is due to the transformer and any crossover parts. In my experience, it is becomes difficult to get max SPL > 100dB unless you start narrowing the dispersion. Even segmenting the panel and using RC or LC transmission lines, you are still left with conflicting requirements resulting in compromises between max SPL and polar response. The Quad ESL63 is a case in point with a central disk of about 14cm diameter to reach 105dB.

I agree that(if domestically acceptable) the best path for woofing with dipole ESLs is increase the area as much as possible. But you may still reach the limit of your room size before target SPL. See example SoundLab ESLs with extra woofer panels. Even those used double diaphragms.

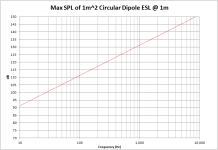

View attachment 1047772

This is because the ESL motor is very weak.

This construction will not give a real energy of the drum a priori.

Only an isobaric will give the desired effect. And then an isobaric with multiple membranes, but not two or three. I went through all this in practice, and not theoretically.

Good to know Havun. Thank you. Are the mid also sound ‘caressing’?If such an area is increased three times more, then the bass will still be "caressing".

This is because the ESL motor is very weak.

This construction will not give a real energy of the drum a priori.

Only an isobaric will give the desired effect. And then an isobaric with multiple membranes, but not two or three. I went through all this in practice, and not theoretically.

When we talk about isobaric, we are talking only about the low-frequency range.

Because only an isobaric is able to increase the pressure and, accordingly, the dynamics of the signal in this range.

In the range of medium and high frequencies, this is not required and can even spoil the situation.

Therefore, all this implies a two-way system where there will be a low-frequency radiator (isobaric) and a separate radiator for medium and high frequencies, which is not a problem for ESL.

The problem is only in the lower range where we want to replace a conventional speaker with a magnet and a lot of distortion with an electrostatic speaker with very low distortion and, accordingly, a very accurate sound in this range.

Because only an isobaric is able to increase the pressure and, accordingly, the dynamics of the signal in this range.

In the range of medium and high frequencies, this is not required and can even spoil the situation.

Therefore, all this implies a two-way system where there will be a low-frequency radiator (isobaric) and a separate radiator for medium and high frequencies, which is not a problem for ESL.

The problem is only in the lower range where we want to replace a conventional speaker with a magnet and a lot of distortion with an electrostatic speaker with very low distortion and, accordingly, a very accurate sound in this range.

It's very easy for an EML. For a unmounted unit or sealed box, just measure Rdc of the coil and the max impedance Rmax at resonance.The math can be done easily enough, although there is some approximation because of the radiation impedance. Best case would be to have the EML in a wall where the radiation impedance is well defined.

My preference is to either measure acoustic transmission at HF in open air ...

The Electrodynamic Damping is Rem = (Bl)^2/Rdc in Mechanical Ohms Ns/m.

If Rmax = 2 x Rdc, the Mechanical Damping Rm is equal to Rem. If it is 3 x Rdc, it half. If 11 x Rdc, it is 1/10.

The only caveat is with a multi-layer voice coil with very high inductance but even with a large PA unit with 4-layer VC, there is no problem. Everything else is out of the picture (including the Radiation Resistance at resonance which is simply added to the Mechanical Damping).

Why is this 'accurate enough'. It's cos in a well designed EML cone speaker, the majority of the damping should be Rem. For this you had better measure Bl directly (as Newtons/Ampere) rather than derive it from fancy stuff. It appears in loadsa other important stuff usually squared. The relative level of Rm vs Rem via this method is 'exact'

I was hoping you had a similarly simple method to measure Mechanical Damping for ESL

If your mean a Plane Wave Tube, you'll excuse me ROTFL. Mine at Calrec was not quite as long as Dip. Ing Wuttke's at Schoeps but we both found 'purely resistive' to be mostly BS. Not that they weren't useful for other stuff but mine at Calrec was taken apart soon after I left.or LF in a tube where the acoustic impedance is well defined and purely resistive.

Last edited:

50 N/m2 is 128dB spl. If this is Peak, then 125dB rms.- Driving force per unit area is a fixed and limited quantity for ESL (50-60 N/m^2) due to air breakdown limit,

With Bolserst's 4 x Soundlab panels taking up 60% of the room x-section in #356, this should be the case in most of the room 😱 ie you could be operating in the Near Field with big panel radiators in most (even Texan) rooms

Dem Texans have their women under control 🙂

EMLs are Mass Controlled so are usually Volume Displacement limited, rather than Force limited like an ESL. The 'linearity region' is sorta how much air it moves before it limits. There are also thermal compression effects which are audible but this is more the case at HFbut for EML (Planer Magnetic or Dynamic coil drivers) is the limit of the maximum Force determine by the amount of current the conductor trace or voice coil can take through it (power compression or damage) and also its linearity region of operation?

But it's possible to design even a small domestic EML speaker to not sound limited or compressed on music up to about 1000W/channel. My Powered Integrated Super Sub technology takes advantage of how we hear distortion to make small speakers sound like much bigger ones. Disco & PA speakers are a different matter.

Last edited:

Hi kgrlee, how did you get this value of 128dB and RMS 125dB? And at how many meters away from the speaker?50 N/m2 is 128dB spl. If this is Peak, then 125dB rms.

What do you mean by 'linearity region'?EMLs are Mass Controlled so are usually Volume Displacement limited, rather than Force limited like an ESL. The 'linearity region' is sorta how much air it moves before it limits. There are also thermal compression effects which are audible but this is more the case at HF

Great! then sounds like you have ~20 Rayl Mesh.Thank you. Yes, it is .003"

Looking back in your other thread: https://www.diyaudio.com/community/threads/isobaric-esl-alternative.364330/post-6487865][/url]

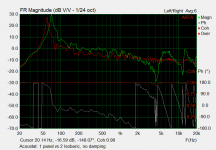

I see I had posted comments of what to expect measurement-wise with the thick felt between your panels, but never posted a set of quick-n-dirty undamped measurements I had taken of a friend’s Acoustat panels. These were near-field measurements about 2 inches from a location roughly 1/3 length, 1/3 width. First with just one panel, then holding the 2nd panel tightly behind the first. You can see the different things we have discussed in this thread...the increase in resonance frequency, the roughly 6dB boost in SPL, and the notches in the response due to the distance between the diaphragms. You should be able to measure something similar.

Using modeling techniques from an AES paper mentioned here: https://www.diyaudio.com/community/threads/superb-article-on-hf-esl-phenomena-imho.321111/post-5396518][/url]

You can see that theory matches the undamped isobaric response pretty well. I then added about 400Rayl of acoustic resistance between the panels to represent the thick felt you were using. The red curve was what I was describing in words in your other thread. (ie well damped LF response with roughly +/-3db ripples in the mid and highs. Using the 20 Rayl mesh front, back and middle should give you something midway between the undamped and the felt.

Also, don’t forget that the Acoustat has built-in LF boost to EQ the dipole roll-off. Since we are measuring near field, this tilts the response up at LF.

https://www.diyaudio.com/community/threads/open-cls-ii-stators-the-best-way-to-do-it.250559/post-3822064][/url]

I can post some directivity plots for you. Sounds like you are after 120dB @2m for a line source?- In order to achieve more SPL (120dB) how bad is the dispersion narrowing (beaming) gets?

Also, how low in frequency do you want the ESL to play? that will have a big impact on the directivity...the lower you want it to play 120dB, the worse the beaming.

Aaah…ok. You are talking about a measurement of just the resistive portion of the acoustic resistance at one frequency (resonance) with the assumption all other contributors to damping at resonance remain unchanged between the two measurements. I’m sure you are aware that mechanical damping is frequency and amplitude dependent as well as changing with the stiffness of the mounting method.It's very easy for an EML. For a unmounted unit or sealed box, just measure Rdc of the coil and the max impedance Rmax at resonance.

...The only caveat is with a multi-layer voice coil with very high inductance but even with a large PA unit with 4-layer VC, there is no problem.

https://www.diyaudio.com/community/...rporating-semi-inductance.329096/post-6010768

But with care in setup, and tightly stretched mesh, you can get a good approximate value for acoustic resistance at one frequency.

You could also just use the Semi-Le spreadsheet to read in the measurement impedance and calculate Rms for you even with high inductance coils.

https://www.diyaudio.com/community/...rporating-semi-inductance.329096/post-5964729

Yes, something similar can be done with ESLs, I’ll post details tomorrow.I was hoping you had a similarly simple method to measure Mechanical Damping for ESL

For LF (ie ka < 0.1) ?If your mean a Plane Wave Tube, you'll excuse me ROTFL. Mine at Calrec was not quite as long as Dip. Ing Wuttke's at Schoeps but we both found 'purely resistive' to be mostly BS.

Yes I do, matter of fact 125dB at 2m for a line source floor to ceiling. the lowest is 200HzI can post some directivity plots for you. Sounds like you are after 120dB @2m for a line source?

Also, how low in frequency do you want the ESL to play? that will have a big impact on the directivity...the lower you want it to play 120dB, the worse the beaming.

Brings back memories of discussing various methods of measuring unit parameters with Julian Wright of Celestion in da previous Millenium including how to mount and how to add mass. But I grovel in awe at your feat Steve 😱Aaah…ok. You are talking about a measurement of just the resistive portion of the acoustic resistance at one frequency (resonance) with the assumption all other contributors to damping at resonance remain unchanged between the two measurements. I’m sure you are aware that mechanical damping is frequency and amplitude dependent as well as changing with the stiffness of the mounting method.

https://www.diyaudio.com/community/...rporating-semi-inductance.329096/post-6010768

But with care in setup, and tightly stretched mesh, you can get a good approximate value for acoustic resistance at one frequency.

You could also just use the Semi-Le spreadsheet to read in the measurement impedance and calculate Rms for you even with high inductance coils.

https://www.diyaudio.com/community/...rporating-semi-inductance.329096/post-5964729

The acousitc resistance stuff was simply tightly stretched cloth glued to the chassis of EML cone speaker. Only at the resonant frequency.

BTW, the cabinet flexing stuff is well incorporated by my simple, 1 freq method if all you are after is a sealed box speaker response.

Though I've dabbled with both simple & esoteric simulation methods for unit & speaker design, my focus changed to how speakers behaved in room as this becomes by far the dominant factor (various caveats apply)

128dB spl is simply 20 x log10(50N/m2) referred to 94dB (1 Pascal spl) and is at the diaphragm. This is the pressure exerted by the diaphragm so is also the spl over most of it.Your calculation is for a 1m^2 piston in an infinite baffle.

For a circular 1m^2 dipole ESL, the maxSPL increases with frequency and only hits 128dB above 800Hz and would be extremely directive.

For an arrangement like your #356 where the panels take up most of the room's x-section, you are nearly 'propagating' a Plane Wave into the room so the spl doesn't drop much with distance. Hence my comments about operating in the Near Field. Room effects apply but usually help rather than hinder spl in this case

You can envisage large full range panels (no segmentation bla bla) making up the walls of your room propagating 'Plane Waves' over the whole frequency range ... and this would some nice properties for stereo too 🙂

Dis beach bum withdraws his inept claim and offers his nearly non-existent experience (and only in da previous Millenium) of ESLs as excuse 🙁 Most practical ESLs (outside Texas) would need segmentation bla blaMax spl isn't usually a problem with ESL mid & HF

Thank you for this information. So I take it you're aware I'm using the Acoustat X direct drive OTLs. I have them about 4' away from the back wall and I've installed the requisite resistors to defeat the wall effect compensation. Looking at your graph, my set up actually looks pretty good. I have a third set of panels I'm intending to add. Apparently the amps can handle up to 5 panels so I would have one with 4 and the other with 5...on each side. Where to drive that 5th panel is a question in terms of sensitivity as the amp finds it easier to drive with the more panels there are. Anyway, I was going to clad every panel front and back. Would that be overkill? I'm expecting a dynamic improvement, hoping for no change in response.Great! then sounds like you have ~20 Rayl Mesh.

Looking back in your other thread: https://www.diyaudio.com/community/threads/isobaric-esl-alternative.364330/post-6487865][/url]

I see I had posted comments of what to expect measurement-wise with the thick felt between your panels, but never posted a set of quick-n-dirty undamped measurements I had taken of a friend’s Acoustat panels. These were near-field measurements about 2 inches from a location roughly 1/3 length, 1/3 width. First with just one panel, then holding the 2nd panel tightly behind the first. You can see the different things we have discussed in this thread...the increase in resonance frequency, the roughly 6dB boost in SPL, and the notches in the response due to the distance between the diaphragms. You should be able to measure something similar.

View attachment 1048831

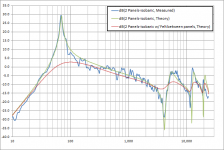

Using modeling techniques from an AES paper mentioned here: https://www.diyaudio.com/community/threads/superb-article-on-hf-esl-phenomena-imho.321111/post-5396518][/url]

You can see that theory matches the undamped isobaric response pretty well. I then added about 400Rayl of acoustic resistance between the panels to represent the thick felt you were using. The red curve was what I was describing in words in your other thread. (ie well damped LF response with roughly +/-3db ripples in the mid and highs. Using the 20 Rayl mesh front, back and middle should give you something midway between the undamped and the felt.

View attachment 1048832

Also, don’t forget that the Acoustat has built-in LF boost to EQ the dipole roll-off. Since we are measuring near field, this tilts the response up at LF.

https://www.diyaudio.com/community/threads/open-cls-ii-stators-the-best-way-to-do-it.250559/post-3822064][/url]

Understood, makes sense. And if the width of the ESL is narrower than the width of the room, then there'll be a diffraction effect that can cause side lobing and beaming.128dB spl is simply 20 x log10(50N/m2) referred to 94dB (1 Pascal spl) and is at the diaphragm. This is the pressure exerted by the diaphragm so is also the spl over most of it.

For an arrangement like your #356 where the panels take up most of the room's x-section, you are nearly 'propagating' a Plane Wave into the room so the spl doesn't drop much with distance. Hence my comments about operating in the Near Field. Room effects apply but usually help rather than hinder spl in this case

Wow! that is really loud. What is the application that you need this output capability?Yes I do, matter of fact 125dB at 2m for a line source floor to ceiling. the lowest is 200Hz

At that level, segmented panels may not be the best solution if trying to avoid them being too directional.

A better solution may be a curved panel, or a faceted panel like Soundlab.

I will include some example directivity plots of those as well, each with 125dB output down to 200Hz.

No I don’t think 20Rayl on each side would be overkill as far as damping.... I have a third set of panels I'm intending to add. Apparently the amps can handle up to 5 panels so I would have one with 4 and the other with 5...on each side. Where to drive that 5th panel is a question in terms of sensitivity as the amp finds it easier to drive with the more panels there are. Anyway, I was going to clad every panel front and back. Would that be overkill? I'm expecting a dynamic improvement, hoping for no change in response.

Rather than hoping for no change in response, consider measuring each step along the way.

I don't understand your comments about 4 and 5 panels on each side.

My recollection was that you were using 6 panels per side.(3 behind 3)

I’ll keep an eye out for updates in your Isobaric thread.

Weaker force applied over a large area, or stronger force over a smaller area results in the same level of radiated acoustic energy. I experimented with a woofer made from 2 panels (30cm x 180cm). Configuration 1 had the panels side by side (60cm x 180cm). Configuration 2 had the panels stacked one behind the other in isobaric configuration. When listening 3m away the two woofer setups sounded similar, but Configuration 1 sounded like it had slightly more bass output capability (louder and more dynamic) than Configuration 2. Measurements from the listening position confirmed the listening impression. I did not get the feeling that isobaric was required to achieve useful energy in the bass range, but it can be helpful if you are trying to keep the footprint small or aiming for SPL levels probably best left to EML woofers.If such an area is increased three times more, then the bass will still be "caressing".

This is because the ESL motor is very weak.

This construction will not give a real energy of the drum a priori.

Only an isobaric will give the desired effect. And then an isobaric with multiple membranes, but not two or three. I went through all this in practice, and not theoretically.

The radiation impedance for two panels side by side is twice that for two stacked panels. That means the membrane displacement for a given pressure at the surface, is half, and the resonant frequency is lower (70%) due to increased air mass attached to the membrane. So the bass response is slightly better for panels side by side, and the membrane displacement less.

- Home

- Loudspeakers

- Planars & Exotics

- Electrostats vs conventional drivers