The stators on both sides seem to be REALLY REALLY stuck to the diaphragm and I doubt I'll be able to get them apart without breaking the diaphragm. I don't think I'm going to try.

I'll clean up everything as well as I can and put it back together and see what happens.

I can't understand the translated text in the site you linked, but the white wire attaches to the central metal plate and from there I assume it charges the diaphragm. So the actual contact would be around the diaphragm edges? I'll clean that area up as well as possible (soap and water or maybe iso alcohol?) and put it back together.

I'll clean up everything as well as I can and put it back together and see what happens.

I can't understand the translated text in the site you linked, but the white wire attaches to the central metal plate and from there I assume it charges the diaphragm. So the actual contact would be around the diaphragm edges? I'll clean that area up as well as possible (soap and water or maybe iso alcohol?) and put it back together.

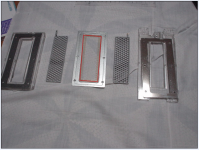

Correct. If you happen to have some DAG conductive graphite paint or the type you can get at auto stores to repair window defogger traces, you might try painting some of the diaphragm-to-metal plate contact areas to ensure conductivity at the joint as shown with red rectangle in pic....the white wire attaches to the central metal plate and from there I assume it charges the diaphragm. So the actual contact would be around the diaphragm edges?

Hmmm...but if you say you can't get the stators off the diaphragm, not sure if you will be able to get to this area.

Attachments

Last edited:

I did get the stators off, I did it very carefully with a very small sharp knife. The diaphragm is a lot stronger than I thought it would be.

I don't have graphite paint but what about dishsoap? What resistance readings should I be getting with leads about 1 cm apart?

I don't have graphite paint but what about dishsoap? What resistance readings should I be getting with leads about 1 cm apart?

I'm getting open circuit (infinite resistance) at all points on the diaphragm regardless of meter lead spacing.

Diaphragm will likely only be conductive on the side facing up in the attached pic.

Rather than using probes directly, results are usually better if you place two coins on the diaphragm close to each other to improved contact with the high resistance coating. Then put DMM probes on the coins. With this method, coatings usually measure in the 1M to 10M range, so make sure to use your highest resistance range on your DMM.

>>Your DMM only measures to 2Mohm, so it may or may not show conductivity even if the coating is good.

Soap is conductive, so if you could carefully paint a path between the metal plate and the perimeter of the diaphragm without getting any up on the upper surface of the O-ring where the stator plate goes, this should restore contact. Nice thing about soap is that it can easily be washed off if you screw up. The not nice thing about soap is that is can corrode metal that it is in contact with over time. Any chance that metal plate is stainless steel?

Rather than using probes directly, results are usually better if you place two coins on the diaphragm close to each other to improved contact with the high resistance coating. Then put DMM probes on the coins. With this method, coatings usually measure in the 1M to 10M range, so make sure to use your highest resistance range on your DMM.

>>Your DMM only measures to 2Mohm, so it may or may not show conductivity even if the coating is good.

Soap is conductive, so if you could carefully paint a path between the metal plate and the perimeter of the diaphragm without getting any up on the upper surface of the O-ring where the stator plate goes, this should restore contact. Nice thing about soap is that it can easily be washed off if you screw up. The not nice thing about soap is that is can corrode metal that it is in contact with over time. Any chance that metal plate is stainless steel?

Attachments

Last edited:

I got it cleaned up and back together and it seems to be exactly the same - working but incredibly quiet.

Still, connecting and disconnecting the white wire has no effect at all, and I don't see any spark at all when connecting and disconnecting the white wire. (The only time I saw it was when measuring stuff with the meter, I don't think I ever saw it when connecting or disconnecting the white wire.)

Maybe I'll take it apart again and coat both sides of the middle of the diaphragm with dishsoap - even with coins I still get infinite resistance at all points on the diaphragm.

What are you thinking at this point? I still don't think the bias voltage is working, do you still think it's a problem with the esl itself?

Still, connecting and disconnecting the white wire has no effect at all, and I don't see any spark at all when connecting and disconnecting the white wire. (The only time I saw it was when measuring stuff with the meter, I don't think I ever saw it when connecting or disconnecting the white wire.)

Maybe I'll take it apart again and coat both sides of the middle of the diaphragm with dishsoap - even with coins I still get infinite resistance at all points on the diaphragm.

What are you thinking at this point? I still don't think the bias voltage is working, do you still think it's a problem with the esl itself?

Yeah, I still think that it is likely either the diaphragm coating has completely lost conductivity or contact with the metal plate....I still don't think the bias voltage is working, do you still think it's a problem with the esl itself?

The chances of both bias supplies completely failing is very small.

Also, the Vdc measurements of the HV supply are as expected with your meter.

The chances of both diaphragms losing conductive with age, happens all the time with some other ESL brands(although I have no personal experience with the SONY ESL tweeters)

Just for testing purposes, you could coat the whole diaphragm with soap all the way to the metal plate. Use some mylar packing tape on the edges of the stator plate that will come in contact with the O-ring that has soap on it, or just don't put that stator in place. Either way, it will definitely make some sound if the HV supply is working.

Ok, I'll try soaping the diaphragms later.

In the meantime I've been experimenting with other tweeters. This thing is bizarre.

With regular tweeters the sound is way to quiet to match the woofer. With the piezo horn tweeter it's a bit too loud.

I tried to pad down the piezo a bit, resistors in normal ranges (up to 64 ohms) seem to have no effect at all. But I did notice that using MY BODY as a resistor works. Holding the speaker wire in my left hand and the tweeter terminal in the right hand I get maybe 6 db attenuation. Holding the wire in my left hand and touching the tweeter terminal with my right foot I get a few more db attenuation. I've never seen anything like this.

All this is just with the red and black wires.

Also, the red and black wires intermittently shock me. Most of the time there's no shock but every once in awhile sometimes there's a shock and sometimes even a spark. The sound is always consistent but the shock and spark are intermittent.

I don't know what to think of this thing.

Maybe I should forget about fixing it and instead put in a more regular tweeter instead, and hook it up somewhere before the bias board. If I were to do that, where would you recommend? Right at the bias board inputs?

In the meantime I've been experimenting with other tweeters. This thing is bizarre.

With regular tweeters the sound is way to quiet to match the woofer. With the piezo horn tweeter it's a bit too loud.

I tried to pad down the piezo a bit, resistors in normal ranges (up to 64 ohms) seem to have no effect at all. But I did notice that using MY BODY as a resistor works. Holding the speaker wire in my left hand and the tweeter terminal in the right hand I get maybe 6 db attenuation. Holding the wire in my left hand and touching the tweeter terminal with my right foot I get a few more db attenuation. I've never seen anything like this.

All this is just with the red and black wires.

Also, the red and black wires intermittently shock me. Most of the time there's no shock but every once in awhile sometimes there's a shock and sometimes even a spark. The sound is always consistent but the shock and spark are intermittent.

I don't know what to think of this thing.

Maybe I should forget about fixing it and instead put in a more regular tweeter instead, and hook it up somewhere before the bias board. If I were to do that, where would you recommend? Right at the bias board inputs?

If this is your first experience with the high-impedance world of ESLs, I can understand the confusion.I tried to pad down the piezo a bit, resistors in normal ranges (up to 64 ohms) seem to have no effect at all.

Since the black and red wires have 30K in series with the step-up transformer inside the bias block, adding resistance in series won't help much. The way to do it is with a shunt resistance from black to red. A 30K shunt will knock down the piezo output by -6dB; 10K shunt, by -12dB.

Correct. Hook up regular tweeter right at CN2 connection to the bias block.Maybe I should forget about fixing it and instead put in a more regular tweeter instead, and hook it up somewhere before the bias board. If I were to do that, where would you recommend? Right at the bias board inputs?

Note that there is a 3.3 ohm 5W resistor in series with these tweeter amplifier wires upstream of the protection relay.

Last edited:

Thanks very much for your help, I appreciate it. If soaping up the diaphragm helps I'll let you know, I'll probably do that tomorrow.

At low spl the piezo actually sounds quite nice and fairly balanced the way it is hooked up now. It's just at high spl that it wants to drill the ears, and that's probably just the infamous wild piezo freuqency response. I'm listening now at low spl and it's actually quite pleasant.

Is there any danger to leaving it hooked up like this long term? I can take it apart and attach at the bias block inputs but I'm worried that the spl will be radically different at that point before the step up transformer. Should I be worried about that? I think that's all I need to know and I can stop bothering you.

Thanks again.

At low spl the piezo actually sounds quite nice and fairly balanced the way it is hooked up now. It's just at high spl that it wants to drill the ears, and that's probably just the infamous wild piezo freuqency response. I'm listening now at low spl and it's actually quite pleasant.

Is there any danger to leaving it hooked up like this long term? I can take it apart and attach at the bias block inputs but I'm worried that the spl will be radically different at that point before the step up transformer. Should I be worried about that? I think that's all I need to know and I can stop bothering you.

Thanks again.

Correct. It is highly unlikely that you would ever get a spark from connecting up the white wire to its terminal even if diaphragm coating was perfect, since ESL tweeter has such small capacitance to charge. It is only when you go to connect the white wire with the red or the black wire that you might get a spark....connecting and disconnecting the white wire has no effect at all, and I don't see any spark at all when connecting and disconnecting the white wire. (The only time I saw it was when measuring stuff with the meter, I don't think I ever saw it when connecting or disconnecting the white wire.)

What piezo are you using? Most are plenty sensitive to keep up with typical woofers....Is there any danger to leaving it hooked up like this long term? I can take it apart and attach at the bias block inputs but I'm worried that the spl will be radically different at that point before the step up transformer. Should I be worried about that?

I would think hooking up before the step-up transformer will have a much better chance of matching levels with the woofer.

Not sure on the long term use with the piezo driven by the step-up transformer, but they are pretty robust and are getting 3rd order active crossover at about 2khz. I'd wager that as long as you used a shunt resistance to bring down the level in-line with the woofer you should be fine.

I have no idea what the piezo is. It was purchased at a Radio Shack about 25 years ago. It has a sticker on the horn body that says made in philippeans and on the back it says mexico in molded raised letters. The number 203 is stamped on the back as well. Other than that there's no identifying marks.

I was thinking about the dishsoap - I don't think it's going to do anything. The diaphragm has stickers on both sides to keep the stators from touching the diaphragm. If the diaphragm has completely lost it's coating and I can't coat over top of the stickers then the middle part will never be in electrical contact with the outside edges so it won't get the bias charge.

Anyway, if the inputs at the bias block drop the spl by more than a couple db the piezo will be too quiet and none of my regular tweeters will be anywhere near loud enough so I might have to shunt the red and white wire and use that. I'll try it all out asap.

I was thinking about the dishsoap - I don't think it's going to do anything. The diaphragm has stickers on both sides to keep the stators from touching the diaphragm. If the diaphragm has completely lost it's coating and I can't coat over top of the stickers then the middle part will never be in electrical contact with the outside edges so it won't get the bias charge.

Anyway, if the inputs at the bias block drop the spl by more than a couple db the piezo will be too quiet and none of my regular tweeters will be anywhere near loud enough so I might have to shunt the red and white wire and use that. I'll try it all out asap.

Your thinking is correct. Try the dish soap around the outer edge of the diaphragm, but inside the O-ring(stickers) that the stator sit on to see if that restores contact with the diaphragm coating. Only put the soap on the side I showed in post #45....I was thinking about the dishsoap - I don't think it's going to do anything. The diaphragm has stickers on both sides to keep the stators from touching the diaphragm. If the diaphragm has completely lost it's coating and I can't coat over top of the stickers then the middle part will never be in electrical contact with the outside edges so it won't get the bias charge.

If that doesn't work, you can try coating over the O-ring(sticker) and the center part of the diaphragm. Again, just on the one side. You should get sound out of the ESL even without that second stator in place. This would confirm that the issue is the coating.

OK. Now it is my turn to be forgetful about how high-impedance ESL drive systems work. I forgot that the piezo impedance is basically a capacitance like an ESL, but a much large capacitance...something like 0.1uF instead of 100pF. So, when driven be the step-up transformer it will be much reduced in level relative to what one might think. Also, the amplifier will see a highly capacitive load that it may not be happy driving at higher levels....if the inputs at the bias block drop the spl by more than a couple db the piezo will be too quiet and none of my regular tweeters will be anywhere near loud enough so I might have to shunt the red and white wire and use that. I'll try it all out asap.

If you want to use the system without the ESL tweeter, I think the best solution is to hook up a tweeter directly to the tweeter amplifier...upstream of the bias block. It could be either a piezo, or a dome tweeter, and should match level with the woofer fairly easily.

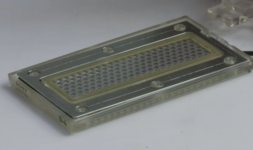

I coated the entire diaphragm except the O ring - the entire surface inside the O ring and everything on the outside of the O ring as well, all the way to the edges, as it appears the diaphragm material extends all the way across the entire metal frame. On the other side of the diaphragm I also coated everything inside the O ring, the entire radiating surface.

I put about one drop on each side on the radiating surface and spread it around until I read less than 1 million ohms with two coins.

It is now exactly the same - working but only loud enough to hear when the ear is within a couple of cm.

I'll take it apart one more time and coat right over the O ring just for fun, but won't that cause a voltage leakage? Maybe not enough to arc but more than ideal.

I'll report back shortly after I cover the O ring and test.

I put about one drop on each side on the radiating surface and spread it around until I read less than 1 million ohms with two coins.

It is now exactly the same - working but only loud enough to hear when the ear is within a couple of cm.

I'll take it apart one more time and coat right over the O ring just for fun, but won't that cause a voltage leakage? Maybe not enough to arc but more than ideal.

I'll report back shortly after I cover the O ring and test.

Remember, only coat over the O-ring on one side of the diaphragm, so you can leave the opposite side stator in place. You can test with just one stator in place, although it won't be as much output as with both in place....I'll take it apart one more time and coat right over the O ring just for fun, but won't that cause a voltage leakage? Maybe not enough to arc but more than ideal.

Mylar packing taping is great insulation, as is 3M foam tape. If you want to put the stator in place on top of the O-ring you coated over, you can use either as an insulator round the stator perimeter where it will contact the O-ring, before placing it down.

Well, I had it done before I saw this post. I'm getting good at this, 5 minutes to take apart, coat with dishsoap and reassemble. I did break a wire off last time, had to pause to solder that back on but it's a pretty quick process now.

3 drops of dishsoap this time, all on the side that the diaphragm contacts the metal frame that supplies the bias voltage from the white wire. I coated the whole side, inside the O ring, outside the O ring, and all over the O ring until I was reading less than 2 million ohms from the outside edge (outside the O ring) to the center radiating part.

Then I put it all back together and tested it. I didn't put any new gasket in between the voltage bias frame and the diaphragm.

The good news is that it works now. It's hard to say if it's as loud as it's supposed to be but I can clearly hear it from a distance and it blends well with the woofer. It isn't very bright sounding, maybe it could use a db or 2 (or 3) more, but it's working.

Should I take it apart again and put a gasket between the voltage bias frame and the diaphragm so the stator is not in direct contact with the dishsoap soaked O ring? Anything would work, I could even cut paper the shape of the O ring, the diaphrgm is sticky with soap now so it would stick. I'm not sure if I have mylar packing tape, I do have electrical tape and tuck tape and painter's tape.

Also, how long will the dishsoap last? Should I redo this with graphite powder for a longer lasting effect?

3 drops of dishsoap this time, all on the side that the diaphragm contacts the metal frame that supplies the bias voltage from the white wire. I coated the whole side, inside the O ring, outside the O ring, and all over the O ring until I was reading less than 2 million ohms from the outside edge (outside the O ring) to the center radiating part.

Then I put it all back together and tested it. I didn't put any new gasket in between the voltage bias frame and the diaphragm.

The good news is that it works now. It's hard to say if it's as loud as it's supposed to be but I can clearly hear it from a distance and it blends well with the woofer. It isn't very bright sounding, maybe it could use a db or 2 (or 3) more, but it's working.

Should I take it apart again and put a gasket between the voltage bias frame and the diaphragm so the stator is not in direct contact with the dishsoap soaked O ring? Anything would work, I could even cut paper the shape of the O ring, the diaphrgm is sticky with soap now so it would stick. I'm not sure if I have mylar packing tape, I do have electrical tape and tuck tape and painter's tape.

Also, how long will the dishsoap last? Should I redo this with graphite powder for a longer lasting effect?

Last edited:

Also I forgot to mention, it still makes no difference whatsoever if the white wire is connected or not. No difference at all in sound.

I got sound as soon as I connected red and black. Then I connected white and I was expecting it to get louder but it didn't it stayed exactly the same.

I got sound as soon as I connected red and black. Then I connected white and I was expecting it to get louder but it didn't it stayed exactly the same.

Last edited:

Also if I use more dishsoap will it make the esl tweeter louder? If a little is good a lot should be great, no? Just not sure what will happen when the resistance dips well under 2 million ohms and I'm not sure how these are supposed to sound in original condition.

We should all be welcoming just a guy to this ESL forum; he is a prolific contributor to the sub and other forums.

But.... I wonder if just a guy can explore for everyone's benefit (on the sub forum) the motional feedback woofer in this on-repair set? For example and just for starters, he could inform us what are the parameters of the special sensor coil since he is knowledgable about measuring such things. No doubt his observations on the overall benefits (or absence of benefits) of MF for this small woofer enclosed as it is would be helpful.

Ben

But.... I wonder if just a guy can explore for everyone's benefit (on the sub forum) the motional feedback woofer in this on-repair set? For example and just for starters, he could inform us what are the parameters of the special sensor coil since he is knowledgable about measuring such things. No doubt his observations on the overall benefits (or absence of benefits) of MF for this small woofer enclosed as it is would be helpful.

Ben

Last edited:

Yaye for sound! But, if you got sound as soon as connecting red and black wires, you have a short between stator and diaphragm coating. A short in ESL world would be anything < 10Mohm resistance. The ESL would be operating in single-ended unbiased mode which will be 6dB to 12dB quieter than the intended push-pull biased mode. White wire will make no difference because the HV will just be getting shorted to the stator.…The good news is that it works now. It's hard to say if it's as loud as it's supposed to be but I can clearly hear it from a distance and it blends well with the woofer. It isn't very bright sounding, maybe it could use a db or 2 (or 3) more, but it's working…I got sound as soon as I connected red and black. Then I connected white and I was expecting it to get louder but it didn't it stayed exactly the same

Yes, if you want to use the ESL with soap coating over the O-ring you will need to get an insulating gasket between the soap covered O-ring and the stators. Paper is gonna be too conductive for long term solution. Even PVC electrical tape is on the conductive end of insulators as far as ESL construction is concerned. But, I think it should work ok in this situation since the voltages involved are not particularly high. Alternatively, you could cut a spacer from the thin clear polycarbonate commonly used for blister packaging small items for sale.Should I take it apart again and put a gasket between the voltage bias frame and the diaphragm so the stator is not in direct contact with the dishsoap soaked O ring? Anything would work, I could even cut paper the shape of the O ring, the diaphrgm is sticky with soap now so it would stick. I'm not sure if I have mylar packing tape, I do have electrical tape and tuck tape and painter's tape.

If dish soap is dried thoroughly with a hairdryer, it will last a long time. I have some ESLs using diluted(2-to-1) Ivory dish soap that are coming up on 16yrs and still going strong. The main drawback of soap is the added mass rolling off the top end. Soap is pretty heavy as far as coatings go, and the slight tackiness attracts dust over time. So you want to try and keep the coating as light as possible. Anything with < 100Mohm coating resistance and there is no benefit as far as increased SPL. Also, be aware that it can corrode metal it is in contact and eventually lose conduction. I got around this by using a DAG graphite bridge between the soap coating and metal HV contact.Also, how long will the dishsoap last? Should I redo this with graphite powder for a longer lasting effect?...if I use more dishsoap will it make the esl tweeter louder? If a little is good a lot should be great, no?

Graphite powder tends to be a bit messy, and difficult to ensure no unwanted leakage paths. Also, not sure how to get conductivity over/under the O-ring. I guess Ideally you would replace entire diaphragm and coat properly. Could then use thin VHB foam tape for the O-ring spacers between diaphragm and stators.

Last edited:

- Home

- Loudspeakers

- Planars & Exotics

- electrostatic tweeter repair Sony SA-EX100