I had a wager with myself how long it would take for you to ask about the MFB 😀... what are the parameters of the special sensor coil...

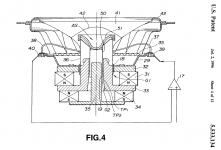

I think we discussed this previously that the sensor coil is operated in its own magnetic gap to minimize mutual coupling with the main drive coil.

It is a short coil / long gap arrangement to maximize linearity of the velocity feedback signal.

Pic and Patent attached.

BTW, if you ever start a thread on your MFB experiments send me a PM.

I don't often get over to the Subwoofer forum.

Attachments

My internet was down all day or I would have been here a lot sooner.

I tried the electrical tape gasket, it made no difference at all.

Then just for fun I tried something new. I put the tweeter together WITHOUT the metal frame that connects to the white wire. It made no difference at all.

I'm getting little shocks pretty regularly now from the black and red wire, but handling the white wire and the frame it connects to does nothing at all.

Admittedly, I don't really know what I'm doing here but it doesn't seem like the white wire or the metal frame it connects to has any voltage on it at all. Completely removing the frame removes any possibility of stray paths or voltage leakage, and the tweeter works without the white wire voltage at all, but seems a bit too quiet.

Again, I'm at a loss here.

I tried the electrical tape gasket, it made no difference at all.

Then just for fun I tried something new. I put the tweeter together WITHOUT the metal frame that connects to the white wire. It made no difference at all.

I'm getting little shocks pretty regularly now from the black and red wire, but handling the white wire and the frame it connects to does nothing at all.

Admittedly, I don't really know what I'm doing here but it doesn't seem like the white wire or the metal frame it connects to has any voltage on it at all. Completely removing the frame removes any possibility of stray paths or voltage leakage, and the tweeter works without the white wire voltage at all, but seems a bit too quiet.

Again, I'm at a loss here.

Hate it when that happens. 🙁

Completely removing the frame does not remove the leakage path from the diaphragm coating to the stator sitting on the coated O-ring. That is this leakage path that is allowing the tweeter to operate with just the red and black wires. You will know the leakage path has been successfully blocked when the ESL makes little to no sound with just the red and black wires. Then, if coating is still good from contact to diaphragm, hooking up the white wire will charge up the diaphragm for proper operation and you will hear much louder sound.

Before proceeding, lets take a step back and re-confirm that the HV power supply is still working.

It is possible that the internal 100M resistor has been damaged from all this testing and playing around.

1) With no music playing, connect DMM(1Mohm input impedance) between white wire and red wire.

2) Plug power cable in. If working, DMM should read 10 - 12 Vdc.

3) Unplug power cable; reading should quickly decay to 0Vdc.

Completely removing the frame does not remove the leakage path from the diaphragm coating to the stator sitting on the coated O-ring. That is this leakage path that is allowing the tweeter to operate with just the red and black wires. You will know the leakage path has been successfully blocked when the ESL makes little to no sound with just the red and black wires. Then, if coating is still good from contact to diaphragm, hooking up the white wire will charge up the diaphragm for proper operation and you will hear much louder sound.

Before proceeding, lets take a step back and re-confirm that the HV power supply is still working.

It is possible that the internal 100M resistor has been damaged from all this testing and playing around.

1) With no music playing, connect DMM(1Mohm input impedance) between white wire and red wire.

2) Plug power cable in. If working, DMM should read 10 - 12 Vdc.

3) Unplug power cable; reading should quickly decay to 0Vdc.

Last edited:

I've got 10.8 VDC between white and red with no music playing, it drops to 0 when unplugged.

I guess I'll try cleaning the new electrical tape gasket with rubbing alcohol but I was pretty careful when putting it on, and I put it on the stators, not on the O ring so I'm not sure how there could still be a leakage path.

I'll let you know what happens after cleaning.

I guess I'll try cleaning the new electrical tape gasket with rubbing alcohol but I was pretty careful when putting it on, and I put it on the stators, not on the O ring so I'm not sure how there could still be a leakage path.

I'll let you know what happens after cleaning.

I ended up taking out the electrical tape gaskets as they weren't doing anything.

Near the end of testing I finally did notice a small change when connecting the white wire but disconnecting it didn't do anything until I guess I discharged something by touching the red terminal, then the sound decreased a bit and increased again when the white wire was connected.

At that point I put it all back together again. The tweeter is definitely working but it's not working hard. Boosting 4 khz to 20 khz by about 6 - 10 db sounds a lot more natural to me but I can't measure as I don't have a mic at this time.

Maybe this is just supposed to be a very "warm" sounding speaker, I don't know. But I can't spend too much more time on it. I might repeat the procedure on the other one, not sure yet, as the experience has been a bit underwhelming.

Thanks for the help though.

Near the end of testing I finally did notice a small change when connecting the white wire but disconnecting it didn't do anything until I guess I discharged something by touching the red terminal, then the sound decreased a bit and increased again when the white wire was connected.

At that point I put it all back together again. The tweeter is definitely working but it's not working hard. Boosting 4 khz to 20 khz by about 6 - 10 db sounds a lot more natural to me but I can't measure as I don't have a mic at this time.

Maybe this is just supposed to be a very "warm" sounding speaker, I don't know. But I can't spend too much more time on it. I might repeat the procedure on the other one, not sure yet, as the experience has been a bit underwhelming.

Thanks for the help though.

Last edited:

the sensor coil is operated in its own magnetic gap to minimize mutual coupling with the main drive coil.

It is a short coil / long gap arrangement to maximize linearity of the velocity feedback signal.

bolserst, as always, has great answers and I'm much better informed. (I recently bought a dual voice coil driver to experiment with... when the weather cools here in the east)

BTW, ESL enthusiasts should consider that MF woofers might be especially suitable for pairing with panels because of their cleanliness of sound. One of the oldest questions in the ESL world is the proper pairing of low frequency cone drivers and ESL panels (or maybe of no importance, others might say).

B.

The motional feedback woofer holds no interest at all for me. I'm still of the opinion that any benefits of MF could be greatly exceeded by doubling the number of woofers instead of employing MF.

Want to buy these Sonys, Ben? I'm pretty sure the owner would sell them pretty cheap, he doesn't have much into them.

Want to buy these Sonys, Ben? I'm pretty sure the owner would sell them pretty cheap, he doesn't have much into them.

Re-reading all your test descriptions it still sounds like there is a leakage path somewhere pulling down the HV level...I just can't seem to identify it without having hands/eyes on, since I don't have first hand experience with it. I have read reviews of the speakers and the top end was never described as mellow or rolled off, so I don't think what you are experiencing is as it should be ....The tweeter is definitely working but it's not working hard. Boosting 4 khz to 20 khz by about 6 - 10 db sounds a lot more natural to me but I can't measure as I don't have a mic at this time.

Understand. Certainly not the best introduction to ESLs, trying to work on such an oddball tweeter design with no access to the important HV and step-up electronics or useful high-impedance instruments. We got close...just not quite there. Someday I hope to snag a pair of these to determine what was going on, and how best to repair them.But I can't spend too much more time on it. I might repeat the procedure on the other one, not sure yet, as the experience has been a bit underwhelming.

>>> Forgot to ask, did you ever try driving a piezo or dome tweeter from the tweeter amplifier upstream of the step-up transformer?

Last edited:

The thing that confuses me is that I thought the white wire and the metal frame it attaches to should have a LOT more voltage than anything else. The relatively low voltage black and white wires shock me but the white wire doesn't - not at all, not even a little bit. And I'm not sure how to interpret the meter reading but there's only low mV between the white wire and ground. Sorry if I sound like a broken record, I just don't get it.

I didn't try any tweeters at the bias block inputs yet. I will try that tomorrow. I really wanted to get this original tweeter working, and it really does sound nice with about 8 db boost.

I'm a bit worried that a normal tweeter cut in to the bias block inputs will be WAY too quiet. As it is, on the high voltage lines regular tweeters are already way too quiet. They piezo is the only one that gets anywhere near loud enough, and the piezo is actually a bit hot.

I'll let you know tomorrow when I try the low level inputs and some regular tweeters.

I didn't try any tweeters at the bias block inputs yet. I will try that tomorrow. I really wanted to get this original tweeter working, and it really does sound nice with about 8 db boost.

I'm a bit worried that a normal tweeter cut in to the bias block inputs will be WAY too quiet. As it is, on the high voltage lines regular tweeters are already way too quiet. They piezo is the only one that gets anywhere near loud enough, and the piezo is actually a bit hot.

I'll let you know tomorrow when I try the low level inputs and some regular tweeters.

Couldn't wait, I tried the low level inputs.

As a side note, they are dead serious about keeping people out of the bias block, in the service manual when it says it's replaced as a unit they are not kidding. It's got about 1/2 inch thick coating of what I assume is epoxy - it's black and shiny and rock hard. Only the top of the caps are sticking out through the coating. I had to cut the wires as even the input wire connector is embedded in the coating.

The piezo is now SCREAMING loud and even the regular tweeter is way too loud on those inputs. I grabbed the 62 ohm resistor I had on hand to pad it down and that got it into the right ballpark - an 8.2 didn't seem to have any effect so I went big. It's just an old 2 inch cone tweeter, maybe 90 db sensitivity I'm guessing. It doesn't sound very good but I can tweak it and try different tweeters too.

As a side note, they are dead serious about keeping people out of the bias block, in the service manual when it says it's replaced as a unit they are not kidding. It's got about 1/2 inch thick coating of what I assume is epoxy - it's black and shiny and rock hard. Only the top of the caps are sticking out through the coating. I had to cut the wires as even the input wire connector is embedded in the coating.

The piezo is now SCREAMING loud and even the regular tweeter is way too loud on those inputs. I grabbed the 62 ohm resistor I had on hand to pad it down and that got it into the right ballpark - an 8.2 didn't seem to have any effect so I went big. It's just an old 2 inch cone tweeter, maybe 90 db sensitivity I'm guessing. It doesn't sound very good but I can tweak it and try different tweeters too.

It all comes down to the high impedance nature of ESLs and their driving electronics.The thing that confuses me is that I thought the white wire and the metal frame it attaches to should have a LOT more voltage than anything else. The relatively low voltage black and white wires shock me but the white wire doesn't - not at all, not even a little bit. And I'm not sure how to interpret the meter reading but there's only low mV between the white wire and ground. Sorry if I sound like a broken record, I just don't get it.

Sony included a 100Meg resistor in series with the white wire and 30K in series with the red and black wires…all inside that impregnable bias block. Looking at your experience of tinkering, perhaps it was a smart move. If you had poked around touching wires going to the stators in a Quad, Acoustat, or Sound Lab ESL while playing music you would have been quickly jolted into cautiousness. So, just be careful with other ESLs when/if you work on them. They will fry meters, and burn holes in your finger tips like a taser.

The white wire does have >2kV on it, but with the 100Meg in series, as soon as you touch it you form a voltage divider and the majority of the voltage is dropped across the internal 100Meg resistor. If you could get in the bias block and touch the HV output upstream of the 100Meg resistor, it would give you a really healthy buzz.

Driving them with a low impedance source they were designed for and they work much better. 🙂Couldn't wait, I tried the low level inputs. The piezo is now SCREAMING loud and even the regular tweeter is way too loud on those inputs.

>>>To properly pad the piezo down, put a 30 ohm resistor across the piezo. Then, adding series resistance to lower level will not change the frequency response. (remember a piezo has an impedance that looks pretty close to a pure capacitance)

Comparing the sound of the ESL tweeter and the “regular” tweeters, you probably already noticed the clean nature of even the most basic ESL transducer. They can be quite addicting, even with their idiosyncrasies.

Last edited:

I'm going to ask the owner what he wants to do with these but I think it's a better bet to use the low level inputs and regular tweeters.

Now that I'm sure it isn't going to blow tweeters up I pulled out a couple of nicer ones to try. I'm using a Dayton RS28A right now and with a single series 22 ohm resistor it doesn't sound bad at all.

Dayton Audio RS28A-4 1-1/8" Aluminum Dome Tweeter

I'm going to have to get a mic before I can do much more than a series resistor, I don't like going blind. At this point I'm even having trouble figuring out which polarity is correct. I'm trying to listen for a reverse null and it just isn't there. So without a mic, the correct polarity is just a judgement call and I don't like not knowing. There's no point in trying to optimize the crossover when you don't even know which polarity is correct.

It's hard to say much on the topic of how clean the esl tweeter was compared to these other tweeters. I can say they definitely sound different, but they also have wildly different frequency response. Until that's equalized it's not wise to make judgment calls on other things. Even the diffraction profile of these different size and shape tweeters will give enough frequency response change to make the cause of different sounds unclear.

Now that I'm sure it isn't going to blow tweeters up I pulled out a couple of nicer ones to try. I'm using a Dayton RS28A right now and with a single series 22 ohm resistor it doesn't sound bad at all.

Dayton Audio RS28A-4 1-1/8" Aluminum Dome Tweeter

I'm going to have to get a mic before I can do much more than a series resistor, I don't like going blind. At this point I'm even having trouble figuring out which polarity is correct. I'm trying to listen for a reverse null and it just isn't there. So without a mic, the correct polarity is just a judgement call and I don't like not knowing. There's no point in trying to optimize the crossover when you don't even know which polarity is correct.

It's hard to say much on the topic of how clean the esl tweeter was compared to these other tweeters. I can say they definitely sound different, but they also have wildly different frequency response. Until that's equalized it's not wise to make judgment calls on other things. Even the diffraction profile of these different size and shape tweeters will give enough frequency response change to make the cause of different sounds unclear.

Last edited:

Probably the way to go for your situation, all things considered, if the owner is amenable.I'm going to ask the owner what he wants to do with these but I think it's a better bet to use the low level inputs and regular tweeters.

I guess a small planar ribbon might also work and keep the asthetics similar to OEM?

Beston RT002A Ribbon Tweeter

BTW, if I read the schematic correctly, the active HP filter is 3rd order @ 3kHz, so the exact front-to-back placement of the tweeter relative to the woofer may be important for avoiding a dip/peak at crossover.

Sure, for an apples-to-apples comparison you need to match level, response trends, and as much as possible cabinet diffraction.It's hard to say much on the topic of how clean the esl tweeter was compared to these other tweeters. I can say they definitely sound different, but they also have wildly different frequency response. Until that's equalized it's not wise to make judgment calls on other things. Even the diffraction profile of these different size and shape tweeters will give enough frequency response change to make the cause of different sounds unclear.

The inherent polar response difference would stay in the mix though.

But, that wasn’t what I was talking about.

I was just referring to the clean sound quality coming from the inherent low stored energy and lack of cone/dome/chassis resonances and reflections. It is noticeable even with disparate response and environments. It is most easily noticed when playing pink noise. Thru an ESL the noise sounds utterly flat with no hint of a tone in the mid or upper registers. Most if not all dynamic drivers have a tonal sound when playing pink noise, often different even between two of the same driver models.

...this reminds of the first time I got to go in the large anechoic chamber at work; so odd without the usual room reflections we are so used to.

Last edited:

I just put a link to this thread into the sub forum thread where dual voice coil motional feedback was recently hosted.

http://www.diyaudio.com/forums/subw...ack-dual-voice-coil-signal-3.html#post4784475

Ben

http://www.diyaudio.com/forums/subw...ack-dual-voice-coil-signal-3.html#post4784475

Ben

I have a Sony MHC-7900 system with Sony SA-H7900 speakers which are very similar to the SA-EX100 if I am correct. The system has been collecting dust at my parents place the past twenty-something years. I'd like to use them myself, but the tweeters in the SA-H7900s are very quiet, so a similar problem what has been discussed in this thread. I already checked if it was an equalizer problem and it was not. With a flat equalizer there is hardly any sound coming from the tweeters. This problem is also shortly discussed in this thread.

One speaker had barely any sound coming from the tweeter, the other is slightly louder but still very quiet. I took the speaker with the least sound apart and cleaned the tweeter (Sony 1-504-388-11) following this youtube video. I used dish soap to clean it. It made a small difference. The tweeter is now a bit louder, but still you have to put your ear very close to it to notice it. Breathing on it to moisten it does not make a difference on either side. Maybe it is still dirty, so I could use cleaning spirit to clean it, but I was hesitant not to damage it.

As far as I understand either the ESL foil is not conductive anymore or the high voltage circuit doesn't work. The fact that both speakers have the same problem makes me think that the foil is the problem, not the circuit. Unfortunately I can only measure DC voltages up to 600V, while the high voltage circuit is supposed to output a couple of kV I guess. For those that are interested, I found a service manual of this loudspeaker.

Does anyone know what to do? Are there still replacement parts available? I'd love to restore this system in it's old glory. Thanks in advance!

One speaker had barely any sound coming from the tweeter, the other is slightly louder but still very quiet. I took the speaker with the least sound apart and cleaned the tweeter (Sony 1-504-388-11) following this youtube video. I used dish soap to clean it. It made a small difference. The tweeter is now a bit louder, but still you have to put your ear very close to it to notice it. Breathing on it to moisten it does not make a difference on either side. Maybe it is still dirty, so I could use cleaning spirit to clean it, but I was hesitant not to damage it.

As far as I understand either the ESL foil is not conductive anymore or the high voltage circuit doesn't work. The fact that both speakers have the same problem makes me think that the foil is the problem, not the circuit. Unfortunately I can only measure DC voltages up to 600V, while the high voltage circuit is supposed to output a couple of kV I guess. For those that are interested, I found a service manual of this loudspeaker.

Does anyone know what to do? Are there still replacement parts available? I'd love to restore this system in it's old glory. Thanks in advance!

- Home

- Loudspeakers

- Planars & Exotics

- electrostatic tweeter repair Sony SA-EX100