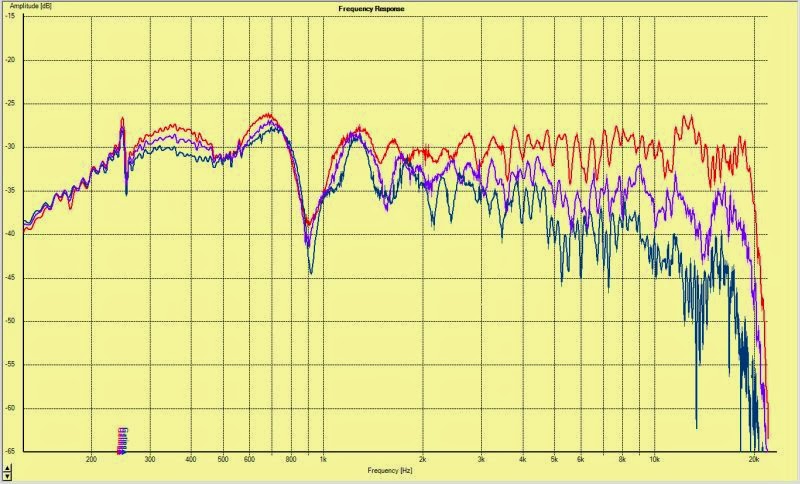

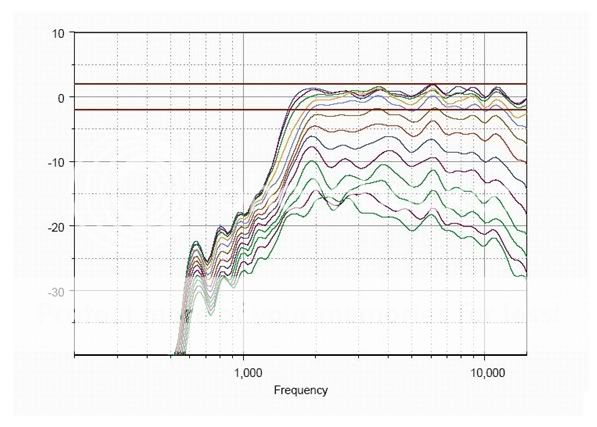

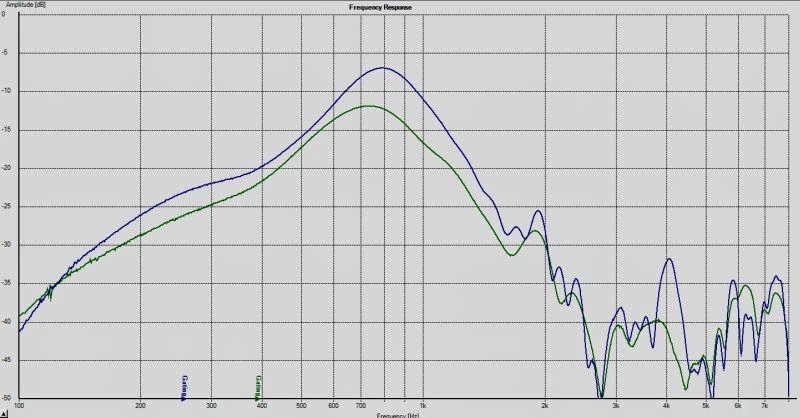

^^ Here's a polar measurement of this Synergy Horn from yesterday.

After working for a bit, I discovered the dip in the lower midrange was due to a reflection in the room. Basically I live in an apartment so I have to measure speakers indoors and choose my gates carefully.

This presents a catch-22; I can pull the speaker away from the walls, and get a clean measurement above 2khz. Or I can put the speaker in the corner, eliminate half of the reflections, and get a clean measurement below 2khz. It's not possible to do both, unfortunately, with such a small room.

Here's a polar measurement from today. Same speaker, but measured in a corner. Trying to replicate the effect of mounting in the corner of a car, under the dash.

The response of the midranges is a lot better now that the baffle is larger. That extends the F3 and smooths out the response.

As usual, it's really tricky to get the octave from 1khz to 2khz correct in a Synergy horn, but this is fairly close. Project isn't finished, just getting it to the point that it's listenable.

Well I decided to nuke the Pyle Synergy horn. Here's why:

1) The horn is narrow, but it's also deep. Due to that, it was basically impossible to aim it. If I turned it even ten degrees I couldn't reach the clutch pedal.

2) I spent a day listening to it off axis, and it just sounds really wonky. This is one of my big grips with car audio horns; they have massive pattern flip. When a horn has pattern flip, it's really hard to get it to sound natural. For instance, it might measure well on axis, but you move 30 degrees off axis and the response looks horrible.

So I started over again, this time with another Pyle horn, the JBL knockoff from Zilch's Econowave speaker.

At top is the Pyle waveguide from the Econowave, at bottom is the PH714S

From the side, it's clearly much smaller

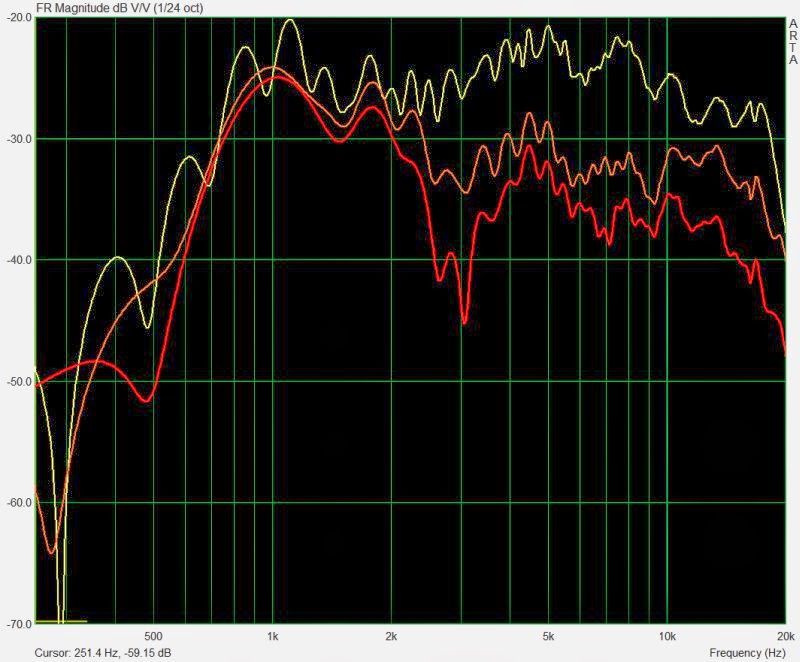

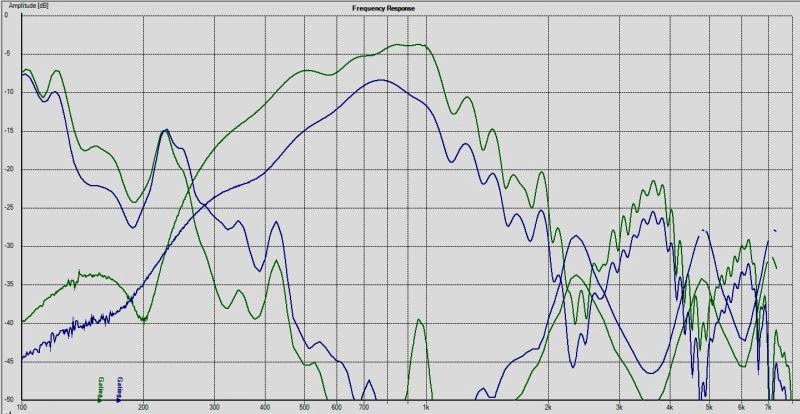

Here's a quick comparison of their polar response, as a Synergy horn. The first measurement is the Econowave waveguide. Second is the PH714S. The first one has no EQ whatsoever; the second one was carefully tweaked for hours. The first one has a bandpass filter on the mids and a highpass on the tweeter, but no EQ at all. In the measurements I notice a few things:

1) The PH714S has directivity that narrows as you go higher in frequency. Basically the beamwidth is frequency dependent

2) The waveguide from the Econowave also narrows at high frequency, but the beamwidth is relatively consistent.

But the main thing, by far, is that the Econowave waveguide is small enough that I can aim it.

1) The horn is narrow, but it's also deep. Due to that, it was basically impossible to aim it. If I turned it even ten degrees I couldn't reach the clutch pedal.

2) I spent a day listening to it off axis, and it just sounds really wonky. This is one of my big grips with car audio horns; they have massive pattern flip. When a horn has pattern flip, it's really hard to get it to sound natural. For instance, it might measure well on axis, but you move 30 degrees off axis and the response looks horrible.

So I started over again, this time with another Pyle horn, the JBL knockoff from Zilch's Econowave speaker.

At top is the Pyle waveguide from the Econowave, at bottom is the PH714S

From the side, it's clearly much smaller

Here's a quick comparison of their polar response, as a Synergy horn. The first measurement is the Econowave waveguide. Second is the PH714S. The first one has no EQ whatsoever; the second one was carefully tweaked for hours. The first one has a bandpass filter on the mids and a highpass on the tweeter, but no EQ at all. In the measurements I notice a few things:

1) The PH714S has directivity that narrows as you go higher in frequency. Basically the beamwidth is frequency dependent

2) The waveguide from the Econowave also narrows at high frequency, but the beamwidth is relatively consistent.

But the main thing, by far, is that the Econowave waveguide is small enough that I can aim it.

Here's some new measurements. There have been a few changes since my post eleven days ago:

1) I've switched out the JBL compression driver for a Celestion CDX1-1425. The JBL is probably a little better, and definitely a better buy, but I only have one. Also, by using the Celestion I was able to shrink the depth of the horn a little bit, by removing the screw on throat.

2) The measurements I posted on 3/13 I was using one dipole midrange. Now I am using two dipole midranges and a sealed midrange. By combining dipole and sealed I should get a cardioid response. One thing that I'm doing which is a bit odd is that my midranges aren't identical. I am using one closed back Pyle midrange, and two dipole 3" midranges. This might seem a bit odd, but I basically did this because it's easier to build. The Pyle is already a closed back mid, so I don't have to hassle with sealing off the basket. Also, one five inch midrange generates about as much output as two 3" drivers with one watt.

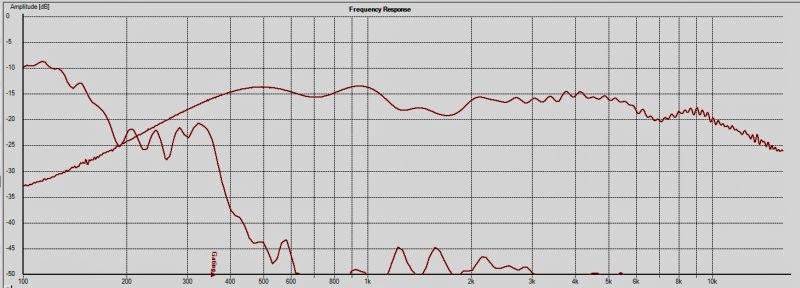

Here's the frequency response of the device with just the dipole mids and the compression driver. (IE, the Pyle isn't running.) This is a super basic setup; there is a first order xover on the compression driver, no xover whatsoever on the mids, and no attempt to EQ or match the levels. Basically just to see if I'm 'in the ballpark.'

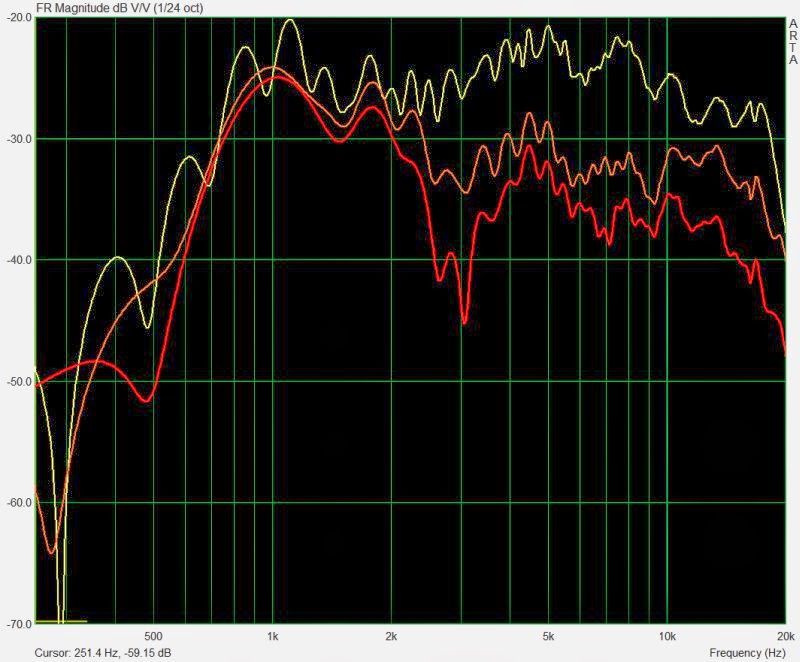

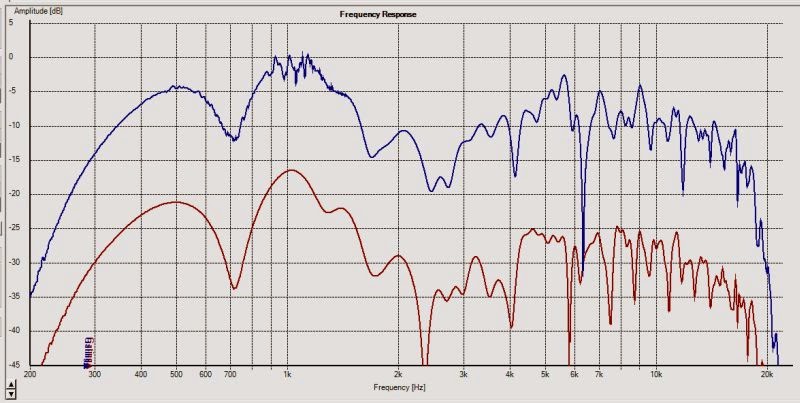

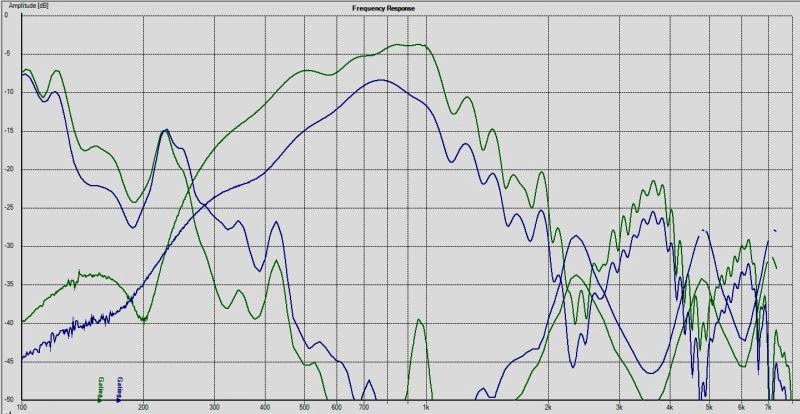

Here's another measurement, this time with the Pyle 'in the mix.' The top measurement is *without* the Pyle. Bottom measurement is *with* the Pyle. We see the output level of the mids has gone up by three decibels.

Here's the individual response of the cardioid midrange array* and the tweeter. Again, no attempt to make things smooth or to make them match, just a simple first order filter on the compression driver to keep it from blowing up.

* the cardioid midrange array is one Pyle closed back midrange and two Dayton NS91 in a dipole.

Here's another measurement showing the individual responses of the cardioid array and the tweeter. The difference here is that it's using a passive filter on the compression driver and no electronic filters whatsoever. Basically I tried this because I might go passive just to reduce the number of amps I have to use. Jury is still out - I <3 my miniDSP but I'm not too thrilled about wiring up three amps in the car.

The green line is the combined response, but raised by 10dB. Even with a crossover filter that's a whopping two components it's +/- 5dB from 400hz to 15khz. And I could easily get that to +/- 3dB with some EQ.

1) I've switched out the JBL compression driver for a Celestion CDX1-1425. The JBL is probably a little better, and definitely a better buy, but I only have one. Also, by using the Celestion I was able to shrink the depth of the horn a little bit, by removing the screw on throat.

2) The measurements I posted on 3/13 I was using one dipole midrange. Now I am using two dipole midranges and a sealed midrange. By combining dipole and sealed I should get a cardioid response. One thing that I'm doing which is a bit odd is that my midranges aren't identical. I am using one closed back Pyle midrange, and two dipole 3" midranges. This might seem a bit odd, but I basically did this because it's easier to build. The Pyle is already a closed back mid, so I don't have to hassle with sealing off the basket. Also, one five inch midrange generates about as much output as two 3" drivers with one watt.

Here's the frequency response of the device with just the dipole mids and the compression driver. (IE, the Pyle isn't running.) This is a super basic setup; there is a first order xover on the compression driver, no xover whatsoever on the mids, and no attempt to EQ or match the levels. Basically just to see if I'm 'in the ballpark.'

Here's another measurement, this time with the Pyle 'in the mix.' The top measurement is *without* the Pyle. Bottom measurement is *with* the Pyle. We see the output level of the mids has gone up by three decibels.

Here's the individual response of the cardioid midrange array* and the tweeter. Again, no attempt to make things smooth or to make them match, just a simple first order filter on the compression driver to keep it from blowing up.

* the cardioid midrange array is one Pyle closed back midrange and two Dayton NS91 in a dipole.

Here's another measurement showing the individual responses of the cardioid array and the tweeter. The difference here is that it's using a passive filter on the compression driver and no electronic filters whatsoever. Basically I tried this because I might go passive just to reduce the number of amps I have to use. Jury is still out - I <3 my miniDSP but I'm not too thrilled about wiring up three amps in the car.

The green line is the combined response, but raised by 10dB. Even with a crossover filter that's a whopping two components it's +/- 5dB from 400hz to 15khz. And I could easily get that to +/- 3dB with some EQ.

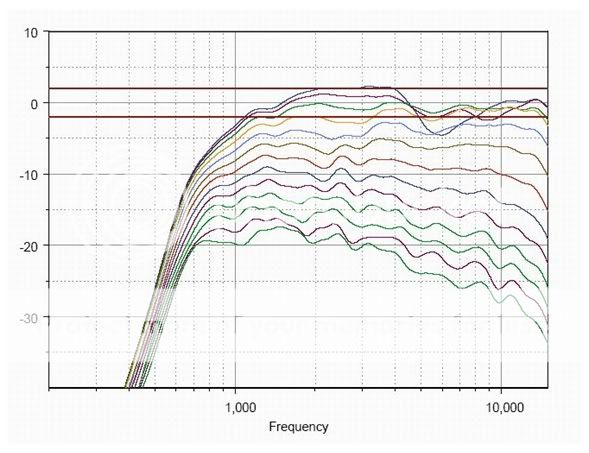

Here's some updated polar measurements. This measurement is on axis, 22.5 degrees off axis, and 45 degrees off axis. It uses a cardioid array of one Pyle PDMR5 (sealed) and two Dayton NS91s in a dipole. Compression driver is the Celestion CDX1-1425 and the waveguide is Pyle's clone of JBL's PT waveguide. (Same one as the Econowave.) The passive crossover is two components (a cap and a resistor) and I'm using a miniDSP for EQ.

For comparison's sake, here's Earl Geddes' measurement of his 12" OS waveguide, similar to my reference speakers at home (Gedlee Summa)

Here's Earl's measurement of the Pyle waveguide. My Synergy version of the same waveguide goes a lot lower, but suffers from a dip in the midrange. Hopefully I can fix that with some tweaks to the geometry.

I have one of the Synergy horns running in my car, and it sounds good, but it's making a buzzing noise when I crank up the power. Here's what might be causing this:

1) The Dayton midranges have a lot of excursion; the cone might be running into the wooden mounting plates

2) The midrange taps might be too small

3) The amp might be running out of power

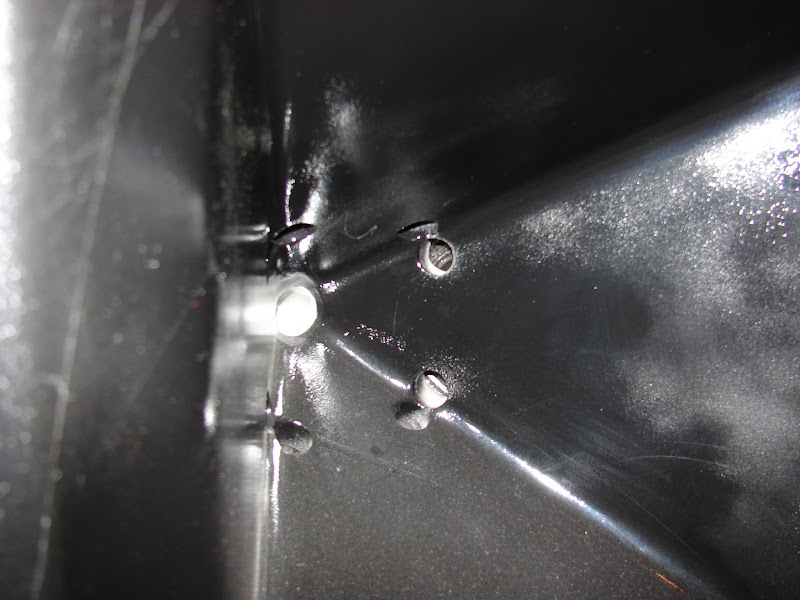

Here's a picture of the Lambda Unity horn. To me, it looks like each midrange is using 3/4" holes that are about an inch deep.

Here's what my midrange taps look like. They're about the same area, but a different shape. I'm stuffing the ports to make them less 'visible' to the compression driver.

Here's some quick calcs of how much displacement my drivers have:

1) My Pyle PDMR5 has 0.0064 liters of displacement (64cm^2 cone, 0.1cm of xmax)

2) My Dayton NS91s have 0.0150 liters of diplacement (30cm^2 cone, 0.5cm of xmax)

So it looks like the midrange taps might be the problem. Though the Dayton midranges are one quarter the size of the Pyle midranges, they have 2.5 times the displacement, due to the high xmax. And I think the 5mm that they're rated for is insanely conservative; I can physically push the cone almost an inch out of the basket, so I wouldn't be surprised if the "real" xmax is closer to 12mm.

So it looks like I need to make those midrange taps bigger, at least for the Daytons. The Pyle seems to be fine. This is actually the first time I've run into this problem, I've never built a horn that produced so much midrange that it would buzz.

1) The Dayton midranges have a lot of excursion; the cone might be running into the wooden mounting plates

2) The midrange taps might be too small

3) The amp might be running out of power

Here's a picture of the Lambda Unity horn. To me, it looks like each midrange is using 3/4" holes that are about an inch deep.

Here's what my midrange taps look like. They're about the same area, but a different shape. I'm stuffing the ports to make them less 'visible' to the compression driver.

Here's some quick calcs of how much displacement my drivers have:

1) My Pyle PDMR5 has 0.0064 liters of displacement (64cm^2 cone, 0.1cm of xmax)

2) My Dayton NS91s have 0.0150 liters of diplacement (30cm^2 cone, 0.5cm of xmax)

So it looks like the midrange taps might be the problem. Though the Dayton midranges are one quarter the size of the Pyle midranges, they have 2.5 times the displacement, due to the high xmax. And I think the 5mm that they're rated for is insanely conservative; I can physically push the cone almost an inch out of the basket, so I wouldn't be surprised if the "real" xmax is closer to 12mm.

So it looks like I need to make those midrange taps bigger, at least for the Daytons. The Pyle seems to be fine. This is actually the first time I've run into this problem, I've never built a horn that produced so much midrange that it would buzz.

Did you play it without the fuzz stuffed into the ports?

I'm going to try the following:

1) I'm going to enlarge the ports, and measure it

2) I'm going to measure it with and without fiberglass in the ports

3) I'll also try something a little less restrictive than fiberglass, like polyfill and reticulated foam

I'm reluctant to "un-block" the ports because it really seems to clean up the response of the compression driver. If you look at my measurements, the response above 2khz is nearly as good as Geddes measured with the same waveguide, sans holes.

Also, there's a pretty good chance it's just physically whacking into the mounting plate. I noticed that if I put my finger on the backside of the cone the buzzing stops. So doing that may act like a physical 'brake' stopping it from hitting anything.

Now, obviously I could just high pass it. But if I do that my F3 will be around 500hz. And I think I can get down another octave if I deal with the buzz. Also, the cardioid midbass sounds really lovely.

Here's more pics of the horn coming together. I've been reinforcing it with fiberglass. It's rather amazing how much vibration can be generated by three drivers on an ABS horn.

I've had some issues from generating noise from cloth-covering ports, is why I asked. Though, that was with covering the woofer ports with too-dense cloth.

I've had some issues from generating noise from cloth-covering ports, is why I asked. Though, that was with covering the woofer ports with too-dense cloth.

It turns out the reason for the buzzing was quite boring:

It was just plain ol' distortion.

Here's what I think happened:

1) The Dayton NS91 has a ridiculous amount of xmax. Something like 25mm.

2) The driver is only rated for 5mm

3) My hypothesis is that the motor is *capable* of much more excursion than it's rated for, but it's rated for 5mm because distortion goes through the roof if you exceed that. Basically a normal overhung driver can't physically move that far, so distortion doesn't go nuts. But take an NS91 and stick it in a dipole, and it will move into a very high level of distortion.

Either that, or it's just smacking into the horn mounting plate. But I don't think that's the case, because I can stop the buzzing by physically putting my finger on the woofer when it's playing at high levels. If it was smacking the mounting plate, then touching the *back* shouldn't stop the buzzing. So I think it's the high excursion that's causing issues.

I measured the distortion in Holmimpulse and it was clear as night and day, note how it goes through the roof at 400hz. And this measurement is *after* I added a highpass. Before I had a high pass in the mix, my F3 was around 200hz but the octave between 200hz and 400hz was pure distortion.

Long story short, I added a high pass using the miniDSP and the problem disappeared for the most part. I still need to get this sorted out though, because the driver is physically capable of going down to 200hz, but only at low volumes. The excursion just goes nuts otherwise.

Last edited:

Assuming you are writing about the ND91, it has only 5.1 mm Xmax, a lot for a 3.5". If you see it moving over 10.2 mm peak to peak, just under 1/2", it is exceeding Xmax, and distortion will rise rapidly with more excursion.It turns out the reason for the buzzing was quite boring:

It was just plain ol' distortion.

Here's what I think happened:

1) The Dayton NS91 has a ridiculous amount of xmax. Something like 25mm.

2) The driver is only rated for 5mm

3) My hypothesis is that the motor is *capable* of much more excursion than it's rated for, but it's rated for 5mm because distortion goes through the roof if you exceed that.

"25mm peak" is likely a peak to peak Xlim (Xmech) rating, excursion in excess of that (just under one inch) may cause damage to some part of the driver.

If you are hearing (or measuring) much distortion (buzzing) at excursions below Xmax, it may be from a bent frame causing the voice coil to rub, your observation that you can stop the buzzing by physically putting a finger on the woofer is consistent with a bent frame, a bent frame is consistent with your construction techniques.

If the driver primarily buzzes at one frequency, but not others, a dragging coil is likely. Buzzing is quite annoying, distortion from simply exceeding Xmax not so much.

Unscrew the driver(s) and run it open air, you may find the buzz goes away (if the frame un-warps), as long as it is under around 10.2mm peak to peak movement.

That said, open air or open back, the driver probably will exceed Xmax with only around 10 watts, nine volts or so.

Attachments

Last edited:

It took literally days of experimentation to get to the bottom of the distortion problem, but I think I figured it out:

It's the ports.

Here's some background on the issue:

I've built a whole pile of unity horn type devices, going all the way back to 2006. 90% of the time, I use very small midranges. Typically about 2" in diameter.

Due to the small midranges, I could use small midrange taps. So I didn't have to hassle with any significant peaks or dips due to the mids, or major diffraction off of the taps.

This time around, I'm using much, much larger ports, because the mids are larger.

I stuffed the ports, because it seemed like this should offer the best of both worlds. If you fill the chamber and the port, the material will absorb high frequencies. So any sound from the compression driver that makes it into the ports will simply get filtered out. The fiberglass will *also* absorb highs from the midranges, but that's fine, because we don't need them to play high.

So far, so good, right?

Unfortunately I didn't realize how much air those mids need to move, and my measurements indicate that stuffing the ports with fiberglass increases distortion in a huge way.

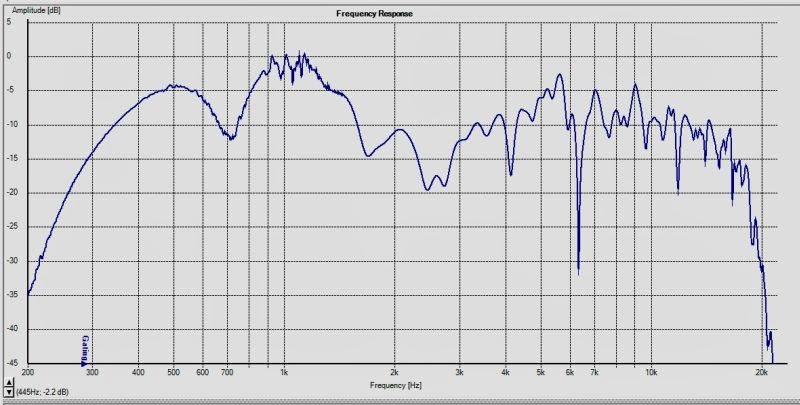

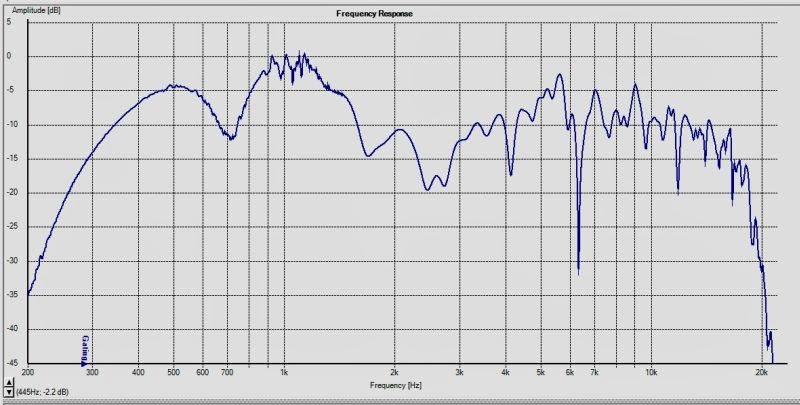

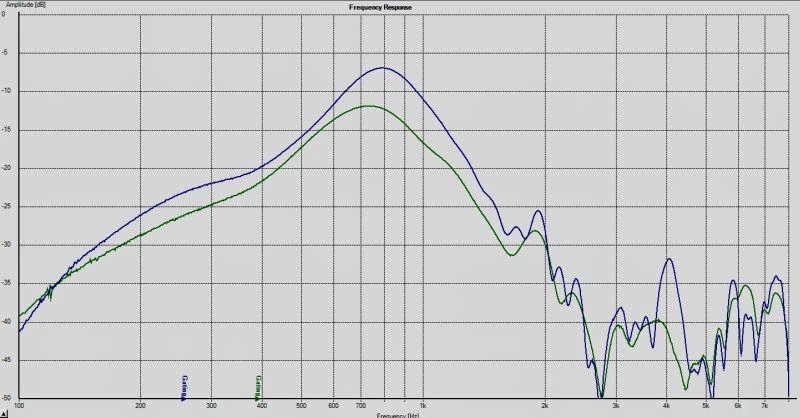

^^ Here's the response of the Pyle midranges with no xover or eq, with and without fiberglass in the ports.

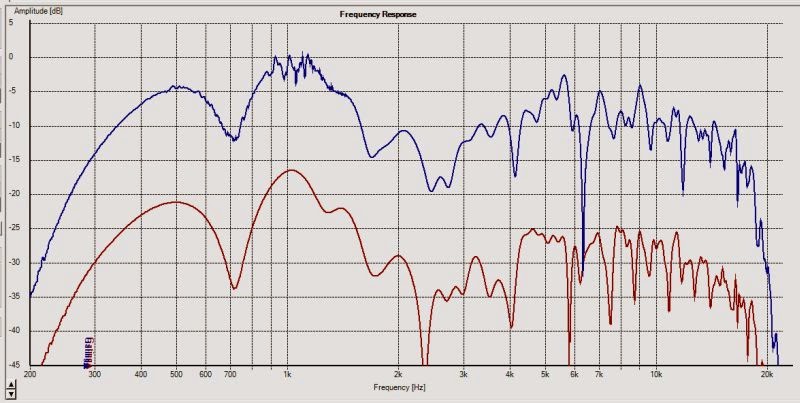

Here's the response of the Dayton ND91 mids, with and without fiberglass in the ports. Again, no xover or EQ. (I failed to save the file that shows the distortion, but it's a little bit better than the Pyle iirc.)

Below 500hz, the increase in distortion is particularly noticeable. At some frequencies, the output is down by eight decibels while the distortion is UP by eight decibels. That means that if you had to increase the power to compensate for the lack of output, your distortion level would go up by at least sixteen decibels! OUCH.

Here's the things that make me think the buzzing sound I was hearing was caused by the stuffed ports:

1) I was hearing the buzzing from both speakers, in varying degrees. This would seem to rule out a bad driver. (I literally put my ear up the individual drivers, and all were exhibiting it to one degree or another.)

2) A couple of days ago I thought the buzzing was due to the driver physically smacking into the mounting plate. But when I touched the Dayton ND91 cone, the buzzing stopped. If it was smacking the plate, touching the cone wouldn't stop that. But it WOULD reduce the excursion, which would reduce the volume of air moving through the port. And I believe the distortion problem is due to two things. First, the volume of air. Second, that the airflow is reduced by the presence of fiberglass.

So stuffing the ports with fiberglass is a colossally bad idea, in fact it looks like the shape of the ports probably has a larger effect on the midrange clarity than the location of the ports. (Within reason of course.) IE, we've been having long discussions about the perfect spot to put the midrange taps, when the *shape* of the midrange taps is pretty darn important too.

Here's the best paper I've seen on port distortion:

11094

It's the ports.

Here's some background on the issue:

I've built a whole pile of unity horn type devices, going all the way back to 2006. 90% of the time, I use very small midranges. Typically about 2" in diameter.

Due to the small midranges, I could use small midrange taps. So I didn't have to hassle with any significant peaks or dips due to the mids, or major diffraction off of the taps.

This time around, I'm using much, much larger ports, because the mids are larger.

I stuffed the ports, because it seemed like this should offer the best of both worlds. If you fill the chamber and the port, the material will absorb high frequencies. So any sound from the compression driver that makes it into the ports will simply get filtered out. The fiberglass will *also* absorb highs from the midranges, but that's fine, because we don't need them to play high.

So far, so good, right?

Unfortunately I didn't realize how much air those mids need to move, and my measurements indicate that stuffing the ports with fiberglass increases distortion in a huge way.

^^ Here's the response of the Pyle midranges with no xover or eq, with and without fiberglass in the ports.

Here's the response of the Dayton ND91 mids, with and without fiberglass in the ports. Again, no xover or EQ. (I failed to save the file that shows the distortion, but it's a little bit better than the Pyle iirc.)

Below 500hz, the increase in distortion is particularly noticeable. At some frequencies, the output is down by eight decibels while the distortion is UP by eight decibels. That means that if you had to increase the power to compensate for the lack of output, your distortion level would go up by at least sixteen decibels! OUCH.

Here's the things that make me think the buzzing sound I was hearing was caused by the stuffed ports:

1) I was hearing the buzzing from both speakers, in varying degrees. This would seem to rule out a bad driver. (I literally put my ear up the individual drivers, and all were exhibiting it to one degree or another.)

2) A couple of days ago I thought the buzzing was due to the driver physically smacking into the mounting plate. But when I touched the Dayton ND91 cone, the buzzing stopped. If it was smacking the plate, touching the cone wouldn't stop that. But it WOULD reduce the excursion, which would reduce the volume of air moving through the port. And I believe the distortion problem is due to two things. First, the volume of air. Second, that the airflow is reduced by the presence of fiberglass.

So stuffing the ports with fiberglass is a colossally bad idea, in fact it looks like the shape of the ports probably has a larger effect on the midrange clarity than the location of the ports. (Within reason of course.) IE, we've been having long discussions about the perfect spot to put the midrange taps, when the *shape* of the midrange taps is pretty darn important too.

Here's the best paper I've seen on port distortion:

11094

Last edited:

John,

So what did you find on the shape of the ports? What works best?

I wish I knew! I am inclined to believe that flaring the inside should help, similar to what Danley does.

One thing that sucks is that I didn't realize the effect on distortion and frequency response was so significant. It really behooves me to keep all the ports identical. And I haven't been doing that; I just use a dremel to flare it out, which makes it hard to keep everything consistent.

An externally hosted image should be here but it was not working when we last tested it.

Here's some pics of the SH25, gives a good idea of the port shape they're using

Member

Joined 2009

I'm doing my own experiments with a small driver in a chamber with pretty disappointing results so far.

Port shape is indeed a tricky business when trying to optimize both low and high end extension. I don't have any data worth of mention at this point but I have a suggestion to minimize your labor. Build the driver chamber out of wood but then use modeling clay to shape the port. Try different shapes to find out what factors affect the sound.

Port shape is indeed a tricky business when trying to optimize both low and high end extension. I don't have any data worth of mention at this point but I have a suggestion to minimize your labor. Build the driver chamber out of wood but then use modeling clay to shape the port. Try different shapes to find out what factors affect the sound.

PB/John-

Beveling the holes seems to be a way to shorten the effective port lengths without using thin walls. My HornResponse models usually seem to want short ports.

It looks like DSL uses round ports for midrange rather than oval or square or teardrop.They used oval for some woofer ports. I wonder what the tradeoffs are?

Beveling the holes seems to be a way to shorten the effective port lengths without using thin walls. My HornResponse models usually seem to want short ports.

It looks like DSL uses round ports for midrange rather than oval or square or teardrop.They used oval for some woofer ports. I wonder what the tradeoffs are?

PB/John-

Beveling the holes seems to be a way to shorten the effective port lengths without using thin walls. My HornResponse models usually seem to want short ports.

It looks like DSL uses round ports for midrange rather than oval or square or teardrop.They used oval for some woofer ports. I wonder what the tradeoffs are?

There's some hints on my threads about the Paraline.* Basically the source of the sound is going to happen at a point in the horn that's large enough for the wavelengths to form. For instance, 1350hz is ten inches long. So there's no physical way for a wave to form in a port that's 1" in diameter. It simply won't fit. So it's just air moving through a duct, with no possibility to form that wavelength.

A rule of thumb might be about one third of a wavelength, so for 1khz, that means that 1khz will 'form' at a point about 2-3" ahead of the compression driver.

Personally, I like the long skinny taps because it keeps them from encroaching on the vertical and horizontal axis. In a horn with straight walls, like the Danley horns, the walls will extend the port and I imagine it would reduce turbulence.

Basically you want this:

not this:

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

I wish these waveguides were for sale. Those creases would be a great place to hide the midrange taps.

* the threads "sunshine" and "square pegs" on this forum

That JBL pinched cheek horn can probably be approximated by sculpting a PVC sheet with a heat gun and suspending a 4 cable cross with a weight to pinch the creases.

Or sculpt it on modeling clay and pour a plaster negative cast to make a positive fiberglass horn.

Or sculpt it on modeling clay and pour a plaster negative cast to make a positive fiberglass horn.

DSL uses a variety of port shapes for mid range, some could be described as teardrop, oval, or sausage shaped.It looks like DSL uses round ports for midrange rather than oval or square or teardrop.They used oval for some woofer ports. I wonder what the tradeoffs are?

The sausage or teardrop shapes allow more port area in the corners of the horn where they have less adverse affect on the high frequency response.

Attachments

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Edge of No Control