After the n'th rebuild I also became slow as hell.... realy demotivated.. (it is not fun drilling 200 holes each time) but I am very happy tonight...

Nordic,

I feel your pain on the hole drilling, its never fun but its great when we are kindly rewarded with a better sounding project for all the hard work. Funny how demotivating some challenges can be, but then when it all comes together we are able to pick ourselves up from the dust with a clear mind 😉, good work on the lot, nothing is gained without some good ol blood,sweat,tears and little cursing for good measure.

Colin

I feel your pain on the hole drilling, its never fun but its great when we are kindly rewarded with a better sounding project for all the hard work. Funny how demotivating some challenges can be, but then when it all comes together we are able to pick ourselves up from the dust with a clear mind 😉, good work on the lot, nothing is gained without some good ol blood,sweat,tears and little cursing for good measure.

Colin

Nordic,

That's a very nice board, it has a good balance to it, congratulations and worth all the hard work!

I spend hundreds of hours on the pcb. It's ALWAYS worth it. Even little things like curvy tracks, precision hole diameters, careful placement to keep tracks always 1mm apart, thickest possible tracks, even component spacing - these things take a long time but once it's sent for manufacture there is no going back.....

As a general rule, for maximum longevity, and particularly when the cap is handling heavy ripple currents, I rate caps to no more than 80% max VW spec. This means max 50V for 63VW, no higher.

This is very conservative, and you can go higher where the cap does not withstand hefty charge cycle, but I'd not go over 90%, which is 57V on a 63VW.

Good job, you should be proud, this is not easy work,

Cheers,

Hugh

That's a very nice board, it has a good balance to it, congratulations and worth all the hard work!

I spend hundreds of hours on the pcb. It's ALWAYS worth it. Even little things like curvy tracks, precision hole diameters, careful placement to keep tracks always 1mm apart, thickest possible tracks, even component spacing - these things take a long time but once it's sent for manufacture there is no going back.....

As a general rule, for maximum longevity, and particularly when the cap is handling heavy ripple currents, I rate caps to no more than 80% max VW spec. This means max 50V for 63VW, no higher.

This is very conservative, and you can go higher where the cap does not withstand hefty charge cycle, but I'd not go over 90%, which is 57V on a 63VW.

Good job, you should be proud, this is not easy work,

Cheers,

Hugh

Nordic is a special man... a real hard worker, he never give up

There's no time to sleep for him.... his target is what makes him motivated.

Those last days i could see his behavior, he wake up and without coffee or anything he goes to work, a non stop worker, only stops when he feel pressure from his wife, or from me that goes asking him to stop and sleep a little.

He has a lot of energy and a very strong decisions...for him to the need to acomplish a mission is his main focus.

I found someone more decided than i am.... he has no limits to make efforts to reach something.

Finally he found a board he can trust and biasing point he likes...now he will be feeling good offering to us a good, reliable and guaranteed board.

I have to thank him very much, without his help, no way to me to have those nice boards to my dear amplifier.

A new amplifier born in Brazil...ahahahahaha.... the same number of parts... a matter of coincidence... i hope.

I am glad we decide not to show boards... at least we have delayed those things...of course not sure..but i have some suspections the amplifier is not so different compared to Precision.

The ones that will have boards will have the layout in front of their eyes..also the ones asked us...but clear published things, and so good forum as this one (and i love this forum) will allow copiers to start to work, and could give them all the hard work for free to copy..not fair... at least they will produce their own boards...the schematic was shown in Brasil, for a week only, now removed from Brazilian foruns, Orkut and Personal Blog.

People informed this amplifier can produce 8000 watts..and RMS!!!!.... terrible those things... se the quantity of power transistors, it is class AB, observe the transformer size... this cannot hold more than 1.5 Kilowatts of consumption...so, cannot produce more than 1 Kilowatt sound.

regards,

Carlos

There's no time to sleep for him.... his target is what makes him motivated.

Those last days i could see his behavior, he wake up and without coffee or anything he goes to work, a non stop worker, only stops when he feel pressure from his wife, or from me that goes asking him to stop and sleep a little.

He has a lot of energy and a very strong decisions...for him to the need to acomplish a mission is his main focus.

I found someone more decided than i am.... he has no limits to make efforts to reach something.

Finally he found a board he can trust and biasing point he likes...now he will be feeling good offering to us a good, reliable and guaranteed board.

I have to thank him very much, without his help, no way to me to have those nice boards to my dear amplifier.

A new amplifier born in Brazil...ahahahahaha.... the same number of parts... a matter of coincidence... i hope.

I am glad we decide not to show boards... at least we have delayed those things...of course not sure..but i have some suspections the amplifier is not so different compared to Precision.

The ones that will have boards will have the layout in front of their eyes..also the ones asked us...but clear published things, and so good forum as this one (and i love this forum) will allow copiers to start to work, and could give them all the hard work for free to copy..not fair... at least they will produce their own boards...the schematic was shown in Brasil, for a week only, now removed from Brazilian foruns, Orkut and Personal Blog.

People informed this amplifier can produce 8000 watts..and RMS!!!!.... terrible those things... se the quantity of power transistors, it is class AB, observe the transformer size... this cannot hold more than 1.5 Kilowatts of consumption...so, cannot produce more than 1 Kilowatt sound.

regards,

Carlos

Attachments

You see the interesting idea about the wind tunnel

To a Professional Standard 19 inches Rack mount, the front to bottom deep distance was not enought to a long heatsink...so they have used wind tunnel, this way you multiply by almost 3 the heatsink performance..and you see that three times this heatsink you can see into the picture...three times it's length is not possible into this enclosure, so..the back exausting fan will allow them to hold almost 1.5 kilowatt there.

The rounded enclosure to transformer can have a toroidal or two smaller standard squared transformers too (cheaper) and with round cover you will feel you have a toroidal inside...maybe.

I love this idea they use, i had that on mind for years long and i am happy my people are using this method, already used into foreigner amplifiers (long time already used)... you can reduce or almost remove the wind noises making your heatsink corners rounded to reduce turbulence or alike a blade to change wind direction, and fan using 8 volts voltage regulators will not be too much noisy, and will produce reasonable wind to cooling...you see the way heatsinks were assembled...very good!

Two heatsinks , one at the other one top... blades facing, fins facing..interesting, this constitutes something alike honey comb tunnel...nice!

regards,

Carlos

To a Professional Standard 19 inches Rack mount, the front to bottom deep distance was not enought to a long heatsink...so they have used wind tunnel, this way you multiply by almost 3 the heatsink performance..and you see that three times this heatsink you can see into the picture...three times it's length is not possible into this enclosure, so..the back exausting fan will allow them to hold almost 1.5 kilowatt there.

The rounded enclosure to transformer can have a toroidal or two smaller standard squared transformers too (cheaper) and with round cover you will feel you have a toroidal inside...maybe.

I love this idea they use, i had that on mind for years long and i am happy my people are using this method, already used into foreigner amplifiers (long time already used)... you can reduce or almost remove the wind noises making your heatsink corners rounded to reduce turbulence or alike a blade to change wind direction, and fan using 8 volts voltage regulators will not be too much noisy, and will produce reasonable wind to cooling...you see the way heatsinks were assembled...very good!

Two heatsinks , one at the other one top... blades facing, fins facing..interesting, this constitutes something alike honey comb tunnel...nice!

regards,

Carlos

Attachments

Hi Carlos

It happens I got five sinks of that shape on the shelf.

Hmmmm.

Is there one of those small PC fans on the back?

Regardos

JC

It happens I got five sinks of that shape on the shelf.

Hmmmm.

Is there one of those small PC fans on the back?

Regardos

JC

Nordic said:As for matching.... distortion will go down the closer it is matched...

For prototypes, I use a mix of transistors to make sure it is stable down to a worst case scenario... so you don't HAVE to match...

Matching transistors is mostly important, on a power amp, at the input. Using encased types as MAT02 and MAT03 should make a difference, if they can stand the voltage.

As Q5 and Q6 are higher voltage types and there's a 12v zener at the other end, the MATs can be used and should improve things if used.

Matching output devices is only advised if you don't put emitter resistors, and is very much used on MOSFET outputs as such. For bipolars and using .33 emitter resistors matching is not necessary.

What should be necessary is using same brand types, which in this "fake" times seems more and more difficult. In the USA you can buy directly from Onsemi, which should make things easier, but it's not easy for people like Carlos and me who live in Brazil.

JC Fardo said:Hi Carlos

It happens I got five sinks of that shape on the shelf.

Hmmmm.

Is there one of those small PC fans on the back?

There certainly is. Except if the bias is very low or the voltage is, which doesn't seem to be the case.

Those square tunnels at the back certainly house the fans.

I think they use standard PC supply fans

One to each channel.

take a look in this folder...the brochure.

http://www.etelj.com.br/etelj_audio/php/produto_especific_slim8000.php

Boys, those screws appearing into the top...the screw heads are shinning into my eyes and hardly bothering me....my God!.... how the could do such bad work like that?

We need urgently people with "style", "class"... elegance, as Jens Rasmussen and also Jan Dupont... the Danish people.

É uma cafonice louca esse painel.. dóimeu--- sódevêr.

This is not fine, have not class this panel and enclosure..a pain in my...my....my.... Heart!

Carlos

One to each channel.

take a look in this folder...the brochure.

http://www.etelj.com.br/etelj_audio/php/produto_especific_slim8000.php

Boys, those screws appearing into the top...the screw heads are shinning into my eyes and hardly bothering me....my God!.... how the could do such bad work like that?

We need urgently people with "style", "class"... elegance, as Jens Rasmussen and also Jan Dupont... the Danish people.

É uma cafonice louca esse painel.. dóimeu--- sódevêr.

This is not fine, have not class this panel and enclosure..a pain in my...my....my.... Heart!

Carlos

Attachments

Hope this link works:

http://www1.jaycar.com.au/productVi...&pageNumber=&priceMin=&priceMax=&SUBCATID=751

http://www1.jaycar.com.au/productVi...&pageNumber=&priceMin=&priceMax=&SUBCATID=751

Well done!

Well done!The time approaches for building. I'm still sourcing parts. Think that this time I might assemble on some plywood, for testing purposes. A proper case takes SO much time. Haven't decided yet if I'll go for two single 500/625VA or one 1000VA Toroidal T/F.

billabong.

You mean, you haven't checked which you can afford 😀

I would start with the heatsinks and transformers (if they are to share the case), then design the case from that point onwards...

Seeing as shipping is high and I can not find a wide enough sink locally I made a new plan... something I saw before in respected builders' amps...

Use two smaller heatsinks side by side, but they share the same heatspreader...

This way I can get a 10 x 40 x 4cm sink for less money than those conrad sinks... which are 7.5 x 35 x 4 I think, and still maintain a low profile case design. (cheaper).

It is time for me to do my first metal case... but it probably won't start before May... and may even take a few months as the transformers will probably be one month, sinks the next, output transistors from digikey the next and then the other small odds and ens and the PSU caps...and then the plates for the case, to spread it over a few pension payments.

One forum member kindly said they will send me some mica caps, so that is one thing less to budget for 😀

I would start with the heatsinks and transformers (if they are to share the case), then design the case from that point onwards...

Seeing as shipping is high and I can not find a wide enough sink locally I made a new plan... something I saw before in respected builders' amps...

Use two smaller heatsinks side by side, but they share the same heatspreader...

This way I can get a 10 x 40 x 4cm sink for less money than those conrad sinks... which are 7.5 x 35 x 4 I think, and still maintain a low profile case design. (cheaper).

It is time for me to do my first metal case... but it probably won't start before May... and may even take a few months as the transformers will probably be one month, sinks the next, output transistors from digikey the next and then the other small odds and ens and the PSU caps...and then the plates for the case, to spread it over a few pension payments.

One forum member kindly said they will send me some mica caps, so that is one thing less to budget for 😀

Billabong, I just picked up two fairly large metal amp cases from Dick Smith's for $29 each, not bad quality at all. They were reduced from $49 and have a black powdercoated steel chassis and a rack style 3mm aluminium front in anodised black, with the two handles like the old rack mount gear. The rear is also aluminium, and there's a moveable raw aluminium shelf inside for horizontal division. Also has rubber feet. I'm not sure if this was a limited time special...

Incidentally, I've just spent a two week tropical holiday in your State, up in Port Douglas and Palm Cove - about as far away from here we can go while still in Australia (over 6,000km). What a great place FNQ is! Seems we just missed the big rain... I see Port Douglas had half a metre yesterday...

I see Port Douglas had half a metre yesterday...

Cheers

Stuey

Incidentally, I've just spent a two week tropical holiday in your State, up in Port Douglas and Palm Cove - about as far away from here we can go while still in Australia (over 6,000km). What a great place FNQ is! Seems we just missed the big rain...

I see Port Douglas had half a metre yesterday...

I see Port Douglas had half a metre yesterday... Cheers

Stuey

Hey Stuey, show pictures to us.. those nice things

are welcome...you are into our crew, so, everything you buy and everything you make is interesting to all of us.

regards,

Carlos

are welcome...you are into our crew, so, everything you buy and everything you make is interesting to all of us.

regards,

Carlos

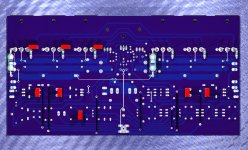

Hahah Carlos that is a render of V8 board, the final one was 8.1.

There is a slight diffirence in the grounding with the links to ground, going down now and not shareing the grounds of the outputs...

Parts layout is still the same

I will prepare some PDF's for you guys shortly...

There is a slight diffirence in the grounding with the links to ground, going down now and not shareing the grounds of the outputs...

Parts layout is still the same

I will prepare some PDF's for you guys shortly...

- Status

- Not open for further replies.

- Home

- Amplifiers

- Solid State

- Dx Precision, finally released... now debugged and better than HRII