Replacing a 30 year old electrolytic capacitor with a new one of any type is very likely to result in an improvement. Or at least a change in the sound. Electrolytics definitely change their characterizes over time as the electrolyte dries out.

But replacing newer capacitors of any type with a so called "better" type is a waste of time and money. I have seen no well controlled sound quality comparison tests to prove that there is any difference. Nor any measurements to show a difference. If someone can produce such a test it would be very interesting.

But short of a properly conducted valid test everything here is simply opinions, not facts. And those opinions are almost entirely driven by confirmation bias.

So I will say it here although I'm sure there will be lots of contrary comments, because confirmation bias is a very powerful thing.

"Replacing capacitors in crossovers with more expensive parts of the same value does not change sound from the speakers in any discernable way."

Why do the manufacturers of quality speakers use film caps in their designs? Please do the simple test by switching between a new bipolar electrolytic cap and a bog standard industrial polycarbonate/polypropylene cap in the filter of a tweeter and report back what you experience.

Of course differences between industry film caps and the gains of "audiophile" stuff is a question how much money one wishes to loose.

Last edited:

Once I had the opportunity to check the Jantzen superior caps vs the standard line. I connected satori Tweeter with only 2.2 uf cap connected and checked both with the 2.2uf superior and the 2.2uf standard Jantzen cap.

I really wanted the standard cap to sound the same with the superior, but it didn't.

Superior was better, hands down.

Does it worth the extra money?

For my cause, for only one 2.2uf cap per channel, sure it did.

Just my two cents.

I really wanted the standard cap to sound the same with the superior, but it didn't.

Superior was better, hands down.

Does it worth the extra money?

For my cause, for only one 2.2uf cap per channel, sure it did.

Just my two cents.

Cool.

Now that deserves testing; our ears are quite poor "microphones" compared to any modern Lab equipment,so if you find audible differences, (in principle I agree with your report) there must be measurable differences too.

Which ones? ..... let´s find them!!!!

Now that deserves testing; our ears are quite poor "microphones" compared to any modern Lab equipment,so if you find audible differences, (in principle I agree with your report) there must be measurable differences too.

Which ones? ..... let´s find them!!!!

Not really, measurements as troels gravesen says can be the same comparing a cheap pair of headphones and a true hi fi masterpiece, but do they sound the same?

Last edited:

Does anyone else use motor run polypropylene caps? The rectangular ones often come with a tab with a hole in for mounting.

Why do the manufacturers of quality speakers use film caps in their designs? Please do the simple test by switching between a new bipolar electrolytic cap and a bog standard industrial polycarbonate/polypropylene cap in the filter of a tweeter and report back what you experience.

Of course differences between industry film caps and the gains of "audiophile" stuff is a question how much money one wishes to loose.

Because electrolytics are known to degrade over time and film types don't. It's a more responsible thing to provide your customers with parts that don't change with age. That's the answer. No need to do a test.

Once I had the opportunity to check the Jantzen superior caps vs the standard line. I connected satori Tweeter with only 2.2 uf cap connected and checked both with the 2.2uf superior and the 2.2uf standard Jantzen cap.

I really wanted the standard cap to sound the same with the superior, but it didn't.

Superior was better, hands down.

Does it worth the extra money?

For my cause, for only one 2.2uf cap per channel, sure it did.

Just my two cents.

So do you really expect anyone else to trust your ears for what is obviously a completely uncontrolled and unscientific test? I certainly don't.

Nice story, but nothing more than confirmation bias in my opinion.

Cool.

... there must be measurable differences too.

Which ones? ..... let´s find them!!!!

Good luck with that. No one else seems to have been able to do it, yet.

Not really, measurements as troels gravesen says can be the same comparing a cheap pair of headphones and a true hi fi masterpiece, but do they sound the same?

This discussion has been primarily about whether more expensive capacitors make any difference. They don't.

But when you get into electromechanical devices such as speaker drivers and headphones it's an entirely different ball game.

Does that tell you anything?

About the effect of more expensive capacitors on sound? No. It tells you nothing about that subject.

Yes, that some people tend to trust the machines more than their ears

Smart people.

He's a salesman, what do you expect?I'm not put off so much by his style as by his actual comments.

I find it very hard to accept much of what he claims.

Okay for the sensible crowd, I bailed on building my own speakers because, while I can easy read factory data and do the calc's, I though I could not design a crossover without frequency response modeling of my exact drivers in the box. Can you design a crossover without studio testing?

Because electrolytics are known to degrade over time and film types don't. It's a more responsible thing to provide your customers with parts that don't change with age. That's the answer. No need to do a test.

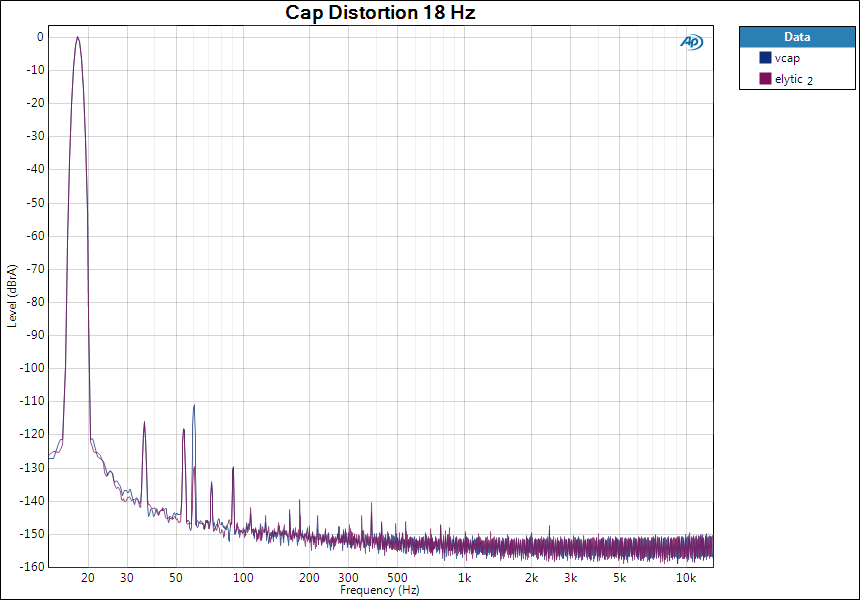

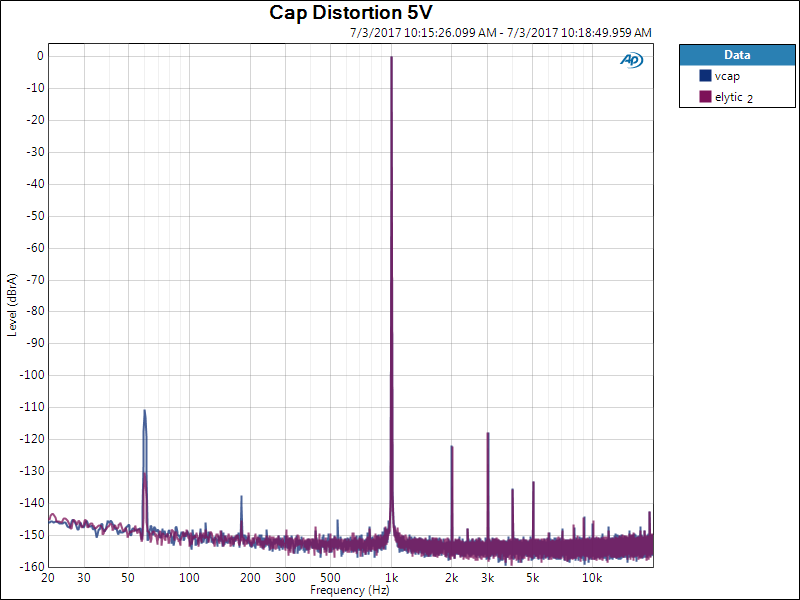

One objection to film caps in a woofer circuit (vs electrolytic) is due to their comparatively larger size making them more effective antennas for picking up mains noise. See here:

These measurements are made with 1uf caps.

Granted, it is pretty far down, but it might be worthwhile to provide shielding when using large films in a woofer crossover circuit when going to such lengths.

Last edited:

Okay for the sensible crowd, I bailed on building my own speakers because, while I can easy read factory data and do the calc's, I though I could not design a crossover without frequency response modeling of my exact drivers in the box. Can you design a crossover without studio testing?

No need to bail so soon. There is a big difference between building your own speakers and designing your own speakers.

There are plenty of readily available excellent DIY designs by people with the skills and experience to get it right. But trying to design a speaker yourself without the experience and testing equipment needed to perfect them is very difficult.

There is a wide range of complete kits available from Meniscus Audio, Madisound, Parts Express, and diysoundgroup. Prices range from a few hundred dollars to a few thousand. Lots to choose from. And there are also published designs where you have to purchase the components separately.

These DIY speaker builds represent tremendous value compared to buying commercially manufactured products. The cost to build my Piccolos was about $400. I'll put them up against any 2-way bookshelf commercial product costing 5 to 10 times that amount based on what I have heard in auditioning similar speakers in stores.

Last edited:

Where spending more on passive crossover components might be required:

Resistors - more of them to dissipate heat

Capacitors - finer tolerances especially if a part in the circuit (usually a notch of some kind) where +/-10% may cause 1 - 2 dB variation over a capacitor that is more or less bang on the value you need to optimise the notch

Capacitors - poly over electrolytic if you want to increase lifespan significantly (i.e. you want these around for 20+ years without touching them again). Chances are a driver / surround will die, tweeter tweeter ferrofluid dry up or you'll be sick of them and want something new anyway.

Inductors - sufficient gauge such that impedance doesn't rob the woofer of efficiency

Now. I'm not saying more expensive is better sounding. But more expensive usually improves quality / tolerances. In some cases this is warranted.

My current mains have a mix of electrolytics and polypropylene capacitors and iron core and air core inductors. I went with metal oxide resistors because of the marginal price differences and more accurate tolerances.

I'd highly recommend for new builders - just get electrolytics so you can "dial in" the values you need through listening and refinement. when a design settles, then splurge if your budget allows and conscience requires.

Resistors - more of them to dissipate heat

Capacitors - finer tolerances especially if a part in the circuit (usually a notch of some kind) where +/-10% may cause 1 - 2 dB variation over a capacitor that is more or less bang on the value you need to optimise the notch

Capacitors - poly over electrolytic if you want to increase lifespan significantly (i.e. you want these around for 20+ years without touching them again). Chances are a driver / surround will die, tweeter tweeter ferrofluid dry up or you'll be sick of them and want something new anyway.

Inductors - sufficient gauge such that impedance doesn't rob the woofer of efficiency

Now. I'm not saying more expensive is better sounding. But more expensive usually improves quality / tolerances. In some cases this is warranted.

My current mains have a mix of electrolytics and polypropylene capacitors and iron core and air core inductors. I went with metal oxide resistors because of the marginal price differences and more accurate tolerances.

I'd highly recommend for new builders - just get electrolytics so you can "dial in" the values you need through listening and refinement. when a design settles, then splurge if your budget allows and conscience requires.

Last edited:

Okay for the sensible crowd, I bailed on building my own speakers because, while I can easy read factory data and do the calc's, I though I could not design a crossover without frequency response modeling of my exact drivers in the box. Can you design a crossover without studio testing?

In short yes. For a "simple" 2 way you can get very close to real results through simulation on data not measured in your specific enclosure with your drivers.

What you need though is the following:

1. Using drivers of known consistency / batch quality.

2. Knowing the measurement conditions of the measurements you are using

You can then subtract the measurement conditions and "add in" your own (enclosure baffle step and diffraction). You can get very very close to actuals.

There's no "woo" or art in the above. It's about method and discipline. If you have good data, a good method and good tools. you'll get close to actual results. I'm not saying the results will be good. i.e. you could choose bad matching drivers, or have an unnatural target response meaning the result won't be good to your ears. This can equally happen with an actual measurement design approach too.

Obviously your own measurements are preferred (assuming you don't stuff up = bad input data, such as including reflections or using an uncalibrated mic with a +6dB gain above 1KHz etc....). But, not essential.

I don't see where there is any advantage over building a design that someone who has a lot more expertise has already created.

The only reason I can see for doing it yourself is if you have aspirations of becoming an expert speaker designer and are willing to go through the expense and many hours to get there over many years.

But for someone who simply wants to have an outstanding speaker in order to really enjoy listening to music the answer seems to be pretty simple. Build a proven design. And there are dozens of very good ones to choose from at all price levels.

Based on a lot of posts here I think that some people make up their minds first that they want to use a particular combination of drivers and there is no existing crossover over design for that combination. So they decide that they will go ahead and design a crossover themselves.

I seriously doubt that what they create will outperform existing DIY designs using different drivers. Yet we see many posts that start "I want to use a model X tweeter with a model Y woofer." Never mind that there is no easily found public crossover design. They think that despite a lack of experience they can easily design a great crossover themselves. That the software tools will do it all for them.

All you have to do is read how much time and effort the expert designers still need to apply to get speakers to sound outstanding. To tweak them. The software only gets you in the ballpark. Finishing requires a lot of experience that most people here don't have.

The only reason I can see for doing it yourself is if you have aspirations of becoming an expert speaker designer and are willing to go through the expense and many hours to get there over many years.

But for someone who simply wants to have an outstanding speaker in order to really enjoy listening to music the answer seems to be pretty simple. Build a proven design. And there are dozens of very good ones to choose from at all price levels.

Based on a lot of posts here I think that some people make up their minds first that they want to use a particular combination of drivers and there is no existing crossover over design for that combination. So they decide that they will go ahead and design a crossover themselves.

I seriously doubt that what they create will outperform existing DIY designs using different drivers. Yet we see many posts that start "I want to use a model X tweeter with a model Y woofer." Never mind that there is no easily found public crossover design. They think that despite a lack of experience they can easily design a great crossover themselves. That the software tools will do it all for them.

All you have to do is read how much time and effort the expert designers still need to apply to get speakers to sound outstanding. To tweak them. The software only gets you in the ballpark. Finishing requires a lot of experience that most people here don't have.

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Do Capacitors Matters - A $100± dollar upgrade