Stuey,

The smaller glass tube is the arm lift.

Colin

Ahhhh! Thanks.

I thought you were doing it direct from the headshell...I did wonder how easy that would be. 🙄

Is it possible that the effect is really more of just the difference between the static coefficient of friction and dynamic coefficient of friction. Once the arm starts to slide it slides VERY well, but getting it to slide takes a little bit of effort. This happens on both axis. So in effect what you are really doing is presenting a very rigid cartridge mount "like the cuter head" which appears to have a large mass during the transients. But during warps it recovers quickly due to it having a very low mass and low dynamic friction coefficient.

Just thinking out loud here, but besides having an optimum static friction coefficient, I would think it to be beneficial to have the static friction forces equal in both the horizontal and vertical axis for best channel separation and balanced transient responses. This may explain why this design not only performs as well as it does but also sounds best with the sealed bearings without the grease removed.

Just thinking out loud here, but besides having an optimum static friction coefficient, I would think it to be beneficial to have the static friction forces equal in both the horizontal and vertical axis for best channel separation and balanced transient responses. This may explain why this design not only performs as well as it does but also sounds best with the sealed bearings without the grease removed.

Is it possible that the effect is really more of just the difference between the static coefficient of friction and dynamic coefficient of friction. Once the arm starts to slide it slides VERY well, but getting it to slide takes a little bit of effort. This happens on both axis. So in effect what you are really doing is presenting a very rigid cartridge mount "like the cuter head" which appears to have a large mass during the transients. But during warps it recovers quickly due to it having a very low mass and low dynamic friction coefficient.

Just thinking out loud here, but besides having an optimum static friction coefficient, I would think it to be beneficial to have the static friction forces equal in both the horizontal and vertical axis for best channel separation and balanced transient responses. This may explain why this design not only performs as well as it does but also sounds best with the sealed bearings without the grease removed.

SG,

Good thinking. I was heading in that direction when I mentioned static friction relative to difficulty in setting tracking force with a balance. You have really cut to the heart of what makes these LT arms perform so well. I think we need to redefine Hi-End for phono arms. Tonight I was experimenting with tracking force weights. My carriage weight is at 32.5 grams including cartridge and counterweight. Started with tracking force up around 2 grams. Records were playing well and I stopped backing off when I hit 1.1 grams. I'm sure I can go even less than that. One of the records was a recording of the African Sanctus. A high point on the record is a drum interlude featuring every imaginable drum, big, small and very much bigger. The arm tracked that without batting an eyelash at 1.1 grams. AMAZING!!!!! Sounded great everywhich way. I can't get over what this arm can do.

BillG

Should be what I meant to say was......haha, but yes sgregory, what I was getting at with groove modulation vs static and.dynamic friction of the bearing assembly. And to think that I almost got flamed.just for having this idea to begin with 😀

Although difficult to set in a static condition, tracking weight is still critical imho since it sets the coils, or magnet, within the gap. Too much or too little and you introduce non-linearities in the output signal which is distortion. Very good question though as to how much is just right....I think the rules change a little with this design.

With Denon 103r mine weighs in at 26 grams with stylus guard minus wire.

I have no doubt that this arm will work well. I do have a TriPlanar arm with Lyra Kleos cartridge on my main system. I can guarantee if it works as well as I think it will, I will try a shoot out.

With Denon 103r mine weighs in at 26 grams with stylus guard minus wire.

I have no doubt that this arm will work well. I do have a TriPlanar arm with Lyra Kleos cartridge on my main system. I can guarantee if it works as well as I think it will, I will try a shoot out.

Tonearm gliding on ferrofluid

Since I have an aversion to ball bearings I made thoughts on how I could make without them. The idea was a cushion of ferrofluid on which the tonearm can glide and which is held in place by four magnets.

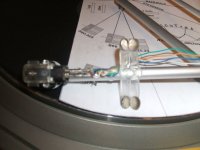

I built a proof of concept. On the first picture you can see the four magnets (sorry for the poor focus).

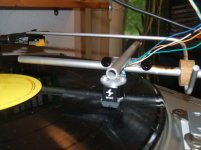

On the second picture the magnets are wetted by the ferrofluid.

The tonearm worked as devised. I could write about ink dark silence and opening up of the soundstage, but I am not a subjectionist.

I can make no statements on long term stability. The ferrofluid must be of high quality, not the kind which evaporates fast. Those sold for educational or entertainment porposes do not qualify, only the type which is used in speaker coils.

I suppose the magnets dampen effectively any vibrations in the horizontal plane through the eddy currents induced in the aluminium wand.

Since I have an aversion to ball bearings I made thoughts on how I could make without them. The idea was a cushion of ferrofluid on which the tonearm can glide and which is held in place by four magnets.

I built a proof of concept. On the first picture you can see the four magnets (sorry for the poor focus).

On the second picture the magnets are wetted by the ferrofluid.

The tonearm worked as devised. I could write about ink dark silence and opening up of the soundstage, but I am not a subjectionist.

I can make no statements on long term stability. The ferrofluid must be of high quality, not the kind which evaporates fast. Those sold for educational or entertainment porposes do not qualify, only the type which is used in speaker coils.

I suppose the magnets dampen effectively any vibrations in the horizontal plane through the eddy currents induced in the aluminium wand.

Attachments

Ummm... what do the magnets do??

Looks like ur floating on the silicone base of the ferrofluid??

Did try this with just flat pucks?

Looks like ur floating on the silicone base of the ferrofluid??

Did try this with just flat pucks?

Are you able to adjust VTA.? looks pretty high to me .....

You can make an arm work with a plastic tube but it is only really suitable for proof of concept and even then I would not recommend it. I think Doug built one with a PVC rube. The problem is way too much friction the plastic is way too soft. You need the tube to be hard as possible harder than your bearing material so the bearing wears and not the tube. Best regards Moray James.

What about a tube made of delrin or polycarbonate Moray ... ?

Tonearm gliding on ferrofluid

The magnets hold the ferrofluid on the four corners of the tonearm slide.

I do not quite grasp what you mean by flat pucks - if you mean the magnets, yes, they are simple disks.

Ummm... what do the magnets do??

Looks like ur floating on the silicone base of the ferrofluid??

Did try this with just flat pucks?

The magnets hold the ferrofluid on the four corners of the tonearm slide.

I do not quite grasp what you mean by flat pucks - if you mean the magnets, yes, they are simple disks.

oh, so your magnets hold the ferrofluid to themselves and then slide??

How long before the ferrofluid slides off and/or gets spread across the rod?

How long before the ferrofluid slides off and/or gets spread across the rod?

Are you able to adjust VTA.? looks pretty high to me .....

That is not my tonearm. I just posted links found on the internet. But you can contact the Flickr member or post question on the comments section. I agree with you that the VTA does appear to be too high.

Neat idea, atleast with Ferro fluid heat won't be an issue 😀. Otoh , bearings if good wont be a noise issue with a well designed carriage and good bearings. Plus the mechanical coupling is good for the bass retrieval and oomph, which can often be a weak point apparently with air bearings. Though if videos of it in action can be posted it would be fabulous 🙂

Colin

Colin

Tonearm gliding on ferrofluid

Exactly.

A very small amount of the ferrofluid gets spread on the rod, the bulk of it remains around the magnets. Alas, as I wrote I can not make any statements on long term stability.

On the weekend I try to make a video.

oh, so your magnets hold the ferrofluid to themselves and then slide??

How long before the ferrofluid slides off and/or gets spread across the rod?

Exactly.

A very small amount of the ferrofluid gets spread on the rod, the bulk of it remains around the magnets. Alas, as I wrote I can not make any statements on long term stability.

On the weekend I try to make a video.

A very small amount of the ferrofluid gets spread on the rod, the bulk of it remains around the magnets.

From the picture it looks like you use aluminium.

As aluminium are paramagnetic some of the ferrofluid will stick to the surface..

Why not use a diamagnetic material?

From the picture it looks like you use aluminium.

As aluminium are paramagnetic some of the ferrofluid will stick to the surface..

Why not use a diamagnetic material?

Good idea! It was just a proof of concept I built with was at hand.

Good idea! It was just a proof of concept I built with was at hand.

a liquid bearing works yes but it goes against the whole purpose of Bo's design which is to make the are as rigid as possible, this design permits motion in all planes. Motion of the arm equals loss of information. Best regards Moray James.

There's some math required in here.

What the math would indicate is if the velocity of the stylus motion via the suspension was sufficient to overcome the inertia of the mass of the arm via the lever that ends with the counterweight.

What the math would indicate is if the velocity of the stylus motion via the suspension was sufficient to overcome the inertia of the mass of the arm via the lever that ends with the counterweight.

a liquid bearing works yes but it goes against the whole purpose of Bo's design which is to make the are as rigid as possible, this design permits motion in all planes. Motion of the arm equals loss of information. Best regards Moray James.

"Rigidity" means high friction and greater effective mass. Not my cup of tea.

"Rigidity" means high friction and greater effective mass. Not my cup of tea.

How does rigidity equate with friction and mass?

I am talking about in the bearing/carriage assembly. The carriage in Bo's design is totally free to travel in the horizontal plane but it has resistance to the carriage moving forwards and backwards that is the rigidity I am referring to. Allowing the arm to rock bounce or move other than in the horizontal plane and in a limited range forwards and backwards will diminish performance. If you are not following this perhaps it would help to read the Cantus thread where I posted a number of comment which Bo made so that you can better understand the design concept. Hope this helps Best regards Moray James.

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm