Looks fantastic Alex, great workmanship, how many have you built now, which sounds best with different materials etc please?

mike

new carts vs L.C.s

Carlo can probably best comment in detail because he has a deeper perspective on both these alternative solutions.

Which is better? - equally i dont know! - Mike

Theoretically, the solution of the cart with both movements is better, more rigorous and elegant, but there are several contraindications, already talked about (bigger hor. mass - again a short arm as in usual LTA - bearings near the cartridge - difficult resonance grounding etc), so to answer seriously I'm trying to build my Corkscrew hypothesis. because making the 3 LCs I did some indigestion of parallelograms. Mike and Koldby are already working on them, with great results.

I'm now on the second carriage and the third corkscrew - the story continues, together with issues.

As for LC, my experience shows not only that the carriage must very light (hor. eff. mass) and frictionless - which is quite easy to do - but also that the sum of all the moving masses (carriage + cartridge + rails + parallelogram levers+ small parts) which, according to the known formulas, give vert eff mass, must be the minimum possible - which is difficult to achieve.

My posted videos on the 3mm warp of the first, quite heavy LC (alu + 8 balls bearings) vs LC Carbon (carbon + pentips, 26 gr) or vs LC prism (alu deeply enlightened, pentips, 33gr) show with great evidence the improvement reached

In my humble opinion one rail alone still weighs half of two

carlo

Carlo can probably best comment in detail because he has a deeper perspective on both these alternative solutions.

Which is better? - equally i dont know! - Mike

Theoretically, the solution of the cart with both movements is better, more rigorous and elegant, but there are several contraindications, already talked about (bigger hor. mass - again a short arm as in usual LTA - bearings near the cartridge - difficult resonance grounding etc), so to answer seriously I'm trying to build my Corkscrew hypothesis. because making the 3 LCs I did some indigestion of parallelograms. Mike and Koldby are already working on them, with great results.

I'm now on the second carriage and the third corkscrew - the story continues, together with issues.

As for LC, my experience shows not only that the carriage must very light (hor. eff. mass) and frictionless - which is quite easy to do - but also that the sum of all the moving masses (carriage + cartridge + rails + parallelogram levers+ small parts) which, according to the known formulas, give vert eff mass, must be the minimum possible - which is difficult to achieve.

My posted videos on the 3mm warp of the first, quite heavy LC (alu + 8 balls bearings) vs LC Carbon (carbon + pentips, 26 gr) or vs LC prism (alu deeply enlightened, pentips, 33gr) show with great evidence the improvement reached

In my humble opinion one rail alone still weighs half of two

carlo

Attachments

Last edited:

Mike,

I’ve made and tested three maquettes and four tonearms to order. Two of them were already given to the customers, and the other two are headed for testing.

Interestingly, the change to the sound is minimum, and, after listening to LC, the customers do not want to go back to their previous tonearms.

I’ve made and tested three maquettes and four tonearms to order. Two of them were already given to the customers, and the other two are headed for testing.

Interestingly, the change to the sound is minimum, and, after listening to LC, the customers do not want to go back to their previous tonearms.

Attachments

Mike,

I’ve made and tested three maquettes and four tonearms to order. Two of them were already given to the customers, and the other two are headed for testing.

Interestingly, the change to the sound is minimum, and, after listening to LC, the customers do not want to go back to their previous tonearms.

Great looking work Edouard, congrats.

Beautiful work and happy customers = success!

Please keep us all updated with your new work as well

mike

Alex wouldn't it make more sense to cantilever the arm mount so the vertical pivot sits over the spindle/label?

That way when tracking the largest warp at the record edge the cart would experience greater mechanical leverage when trying the lift the arm. Ie there would be a lower vertical leverage load on the suspension at the point of greatest warp.

Less visually elegant though...

That way when tracking the largest warp at the record edge the cart would experience greater mechanical leverage when trying the lift the arm. Ie there would be a lower vertical leverage load on the suspension at the point of greatest warp.

Less visually elegant though...

Hi sq225917

Maybe i don't understand the question: when designing the Lil Casey i used the parallelogram to prevent the carriage travel from altering the VTF. as it would happen with the type 1 lever used on pivoted TAs.

As known a parallelogram scale is indifferent to the position of the load, so its location is completely irrelevant.

What can be instead important is the length of levers, in order to reduce its angular motion on warps.

Let's face it, bringing the parallelogram above the spindle would not be particularly comfortable...

ciao - carlo

maybe Eduard could give the same answer

Maybe i don't understand the question: when designing the Lil Casey i used the parallelogram to prevent the carriage travel from altering the VTF. as it would happen with the type 1 lever used on pivoted TAs.

As known a parallelogram scale is indifferent to the position of the load, so its location is completely irrelevant.

What can be instead important is the length of levers, in order to reduce its angular motion on warps.

Let's face it, bringing the parallelogram above the spindle would not be particularly comfortable...

ciao - carlo

maybe Eduard could give the same answer

Sg225917,

I see you are unfamiliar with Lil Casey, so I recommend you start reading from comment number 2384 on page 239.

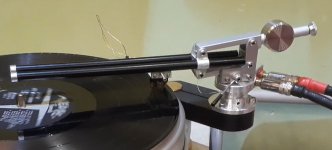

Carlo & Mike,

I had to redo the heavy version, since the pipe from a shop was not anodized inside, and the carriage did not move very well. I bought an arrow and made an elongated version out of it. Now I can replace 10” tonearm without drilling a new hole.

I see you are unfamiliar with Lil Casey, so I recommend you start reading from comment number 2384 on page 239.

Carlo & Mike,

I had to redo the heavy version, since the pipe from a shop was not anodized inside, and the carriage did not move very well. I bought an arrow and made an elongated version out of it. Now I can replace 10” tonearm without drilling a new hole.

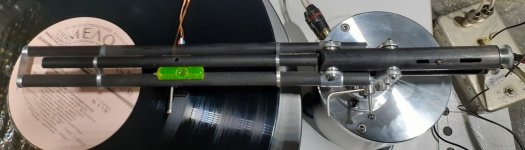

corkScrew RTA

This is what I am lazily building, together with many doubts. The new cart works very well, the corkscrew articulation seems promising (went back to disposable razor blade hinge), but i will have to check it on a disk to say something real. (measures + behavior).

So a complex construction of a - leveling + rotating + lifting base - is now in progress. As can be easily understood, not exactly for first timers*, not as much for the number of parts as for the required precision (carriage and vert. articulation)

carlo

*commendable exceptions excluded, of course.

This is what I am lazily building, together with many doubts. The new cart works very well, the corkscrew articulation seems promising (went back to disposable razor blade hinge), but i will have to check it on a disk to say something real. (measures + behavior).

So a complex construction of a - leveling + rotating + lifting base - is now in progress. As can be easily understood, not exactly for first timers*, not as much for the number of parts as for the required precision (carriage and vert. articulation)

carlo

*commendable exceptions excluded, of course.

Attachments

corkScrew RTA

This is what I am lazily building, together with many doubts.

That's beautifully executed work as always Carlo, definitely not for builders with really limited workshops i think.

I can see in the pictures a natty modified stylus balance, what's going on there please?

Mike

What would prevent the cartridge from tilting (one hinge goes up, the other down)? alighiszem

Perhaps the fact that there is only one hinge and the headshell hangs under its arching on warp's pushing; and even the tests done so far with different hinges.

But also I have a ton of doubts since the beginning #3762: that's exactly why I'm building it

I can see in the pictures a natty modified stylus balance, what's going on there please? Mike,

I'm afraid you'll see many changes before the end (especially thinking i'll have to make them) the ratio flexibility/verticality of movement on warps is the punctum dolens of the whole.

The variables are:

the razor blade - which I began to modify (<width <thickness); I would like to have 2 very narrow and thin ones.

the length - now reduced to the least for a steady verticality of the movement.

the width of the central "sandwich" attachment, which size influences the two aspects of the said ratio.

Currently the scale measurements say that the elbow-lever that characterizes the corkscrew cart works fine on warps up to 1.5 mm (almost no VTF variation) but after the increase becomes detectable.

carlo

Perhaps the fact that there is only one hinge and the headshell hangs under its arching on warp's pushing; and even the tests done so far with different hinges.

But also I have a ton of doubts since the beginning #3762: that's exactly why I'm building it

I can see in the pictures a natty modified stylus balance, what's going on there please? Mike,

I'm afraid you'll see many changes before the end (especially thinking i'll have to make them) the ratio flexibility/verticality of movement on warps is the punctum dolens of the whole.

The variables are:

the razor blade - which I began to modify (<width <thickness); I would like to have 2 very narrow and thin ones.

the length - now reduced to the least for a steady verticality of the movement.

the width of the central "sandwich" attachment, which size influences the two aspects of the said ratio.

Currently the scale measurements say that the elbow-lever that characterizes the corkscrew cart works fine on warps up to 1.5 mm (almost no VTF variation) but after the increase becomes detectable.

carlo

Currently the scale measurements say that the elbow-lever that characterizes the corkscrew cart works fine on warps up to 1.5 mm (almost no VTF variation) but after the increase becomes detectable.

carlo

Its impressive to have gained almost no VTF variation on 1.5mm warp with this mechanism, can you quantify detectable after that? is it enough to matter on a severe warp?

I feel that this is really angular displacement in the mechanism rather than vertical, so if you can double the levers you already have acceptable VTF variation on 3mm.................

Are you able to photo the cartridge alignment in warp tests and see it it stays vertical always, it may be that azimuth misalignment would be a worse disadvantage than vtf variation. mike

This morning i continued with ball bearing tests.

G10 ZRo2 balls start rolling more easily and run more quickly repeatedly on a sloped rail than Delrin, all at 5mm dia. ZRo2 is also more difficult to hold stationary on a level rail.

Then i wondered and looked up the density of the two, ZRo2 is around 3 times denser than Delrin, is that the reason why they roll better on a slope?

maybe i have to resort to a full cart resistance comparison..........mike

G10 ZRo2 balls start rolling more easily and run more quickly repeatedly on a sloped rail than Delrin, all at 5mm dia. ZRo2 is also more difficult to hold stationary on a level rail.

Then i wondered and looked up the density of the two, ZRo2 is around 3 times denser than Delrin, is that the reason why they roll better on a slope?

maybe i have to resort to a full cart resistance comparison..........mike

Are you able to photo the cartridge alignment in warp tests and see it it stays vertical always .... Mike

In a couple of weeks, hopefully; a month, or more - who knows. These things can only be properly tested under carefully controlled conditions, not by sensations. It's needed an almost final prototype, and I'm a methodical fellow.

VTF - perhaps less surprising than it seems: this mechanism uses 90% two conventional arms on blades (i.e. with very little friction) while the hinge only intervenes to maintain the alignment. And, as you know, it is springyness that makes VTF vary, not the CW.

Also consider that the "corkscrew" works like an elbow-lever (think of an object attached to a rope stretched horizontally; at first the effort to move it is practically zero but increases exponentially with the angle). Even a lateral displacement would practically irrelevant because the force is almost axial (and in any case the carriage would move)

I have modified the razor blade hinge (narrowed and thinned) so much that what I fear now is that it can tilt with the stylus drag; that's why I said I'll have to use two - but I'll start testing with this one.

carlo

My doubts more than on mechanics (I'm slowly understanding where they are and how to afford, but they need more precision than what i'm used to). lays in the ability of this type of TAs to manage the resonances with only the mass of the "floating headshell" as effectively defined by Koldby. Still remembering the awful sound of a fully decoupled cartridge

rolling balls - weight is strongly suspected, second their smoothness - imo

In a couple of weeks, hopefully; a month, or more - who knows. These things can only be properly tested under carefully controlled conditions, not by sensations. It's needed an almost final prototype, and I'm a methodical fellow.

VTF - perhaps less surprising than it seems: this mechanism uses 90% two conventional arms on blades (i.e. with very little friction) while the hinge only intervenes to maintain the alignment. And, as you know, it is springyness that makes VTF vary, not the CW.

Also consider that the "corkscrew" works like an elbow-lever (think of an object attached to a rope stretched horizontally; at first the effort to move it is practically zero but increases exponentially with the angle). Even a lateral displacement would practically irrelevant because the force is almost axial (and in any case the carriage would move)

I have modified the razor blade hinge (narrowed and thinned) so much that what I fear now is that it can tilt with the stylus drag; that's why I said I'll have to use two - but I'll start testing with this one.

carlo

My doubts more than on mechanics (I'm slowly understanding where they are and how to afford, but they need more precision than what i'm used to). lays in the ability of this type of TAs to manage the resonances with only the mass of the "floating headshell" as effectively defined by Koldby. Still remembering the awful sound of a fully decoupled cartridge

rolling balls - weight is strongly suspected, second their smoothness - imo

Last edited:

rolling balls - weight is strongly suspected, second their smoothness - imo

Carlo, thanks for all your response, i am also going to become (slightly!) more methodical and i propose now to undertake more rigorous tests.

I remember that you have previously suggested two forms of resistance analysis, one with a basic cable tie push test and the other with a more calibrated balance, could you kindly point to that information in the thread as i cannot find it, many thanks

Mike

Well, no doubt now, imho the Zro2 G10 balls are better than the Delrin ones, the cart has less friction (done the cats whisker tests) and the sound is better, a few details are apparent that i have not heard before and some good presence and rhythm, great bass lines etc, seems sad to get all excited about spheres of different materials, but no doubt it makes a difference......

mike🙂

mike🙂

It's great each time you make a small change that improves the sound.

I'm not surprised the Zro2 balls made a difference as they are harder and certainly more spherical than Delrin balls.

Next thing to look at is COM (centre of mass) and how it effects stability of the carriage.

Lowing the COM of my carriage made a huge improvement as it made the carriage far more stable.

I'm not surprised the Zro2 balls made a difference as they are harder and certainly more spherical than Delrin balls.

Next thing to look at is COM (centre of mass) and how it effects stability of the carriage.

Lowing the COM of my carriage made a huge improvement as it made the carriage far more stable.

Next thing to look at is COM (centre of mass) and how it effects stability of the carriage.

Lowing the COM of my carriage made a huge improvement as it made the carriage far more stable.

I never know if i am correct, but i feel the carriage is very stable because i have relatively wide spread spheres, next i will have a revised rail system with anodised rails that are in production at the moment.

After that i must correct my parallelograms vertical motion as it has VTF variation in warp and while it may not be causing a problem it makes me uneasy........it measures probably less than 0.1gram per mm of warp but i know its there! - so i need less springy hinges than the current mylar unless i change the configuration completely

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm