The pole deflects under load but shows no signs of instability, cracking, or uncontrolled oscillation.

Carbon fiber is fine, until it isn't. It doesn't undergo plastic deformation under load before failure like metals experience. CF might be OK for a horn.

Using only half the original 24′ carbon pole, the system benefits from a significantly higher load margin — likely 3–5× the nominal safety factor, since we're working within the thickest and strongest sections of the pole. The moment arm is shorter, and the flexural stiffness higher, reducing the risk of dynamic failure.

Likely 3-5 times isn't a statement you are capable of defending if you ever end up in court.

Yes, re-entry horns are compromise, swapping length for frequency response. Besides halving length of the horn, no other benefits.I also had the impression that the folding was a compromise-laden way to simulate a longer horn with out taking up a longer space. Is that right, or does the folding have its own benefits?

I’m hoping to generate a lighter-weight horn design with comparable or slightly better frequency performance than the Goldwood GM-450PB, ...

I think you should accept advice from weltersys and buy TOA TU651/TH660 combos - they are better performer than yours JBL D250-X/Goldwood GM-450PB, with much more low frequency extension.My takeaways are to pay more for a better driver, one designed for midrange with a bigger coil, such as the B&C DCM420. Also to consider a folded horn, or perhaps a longer one

I am not aware of any commercial folded horns for B&C DCM 420, BMS 4592, BMS 4594, or available data for folded horn DIY printing.

Last edited:

Wrong takeaway.My takeaways are to pay more for a better driver, one designed for midrange with a bigger coil, such as the B&C DCM420.

A larger diameter coil does not mean more displacement, smaller diameter "PA" drivers have much more excursion potential which can offset the larger coil size.

A larger coil can handle more power, but at the low end, the driver's displacement limit, rather than power will limit output.

Each doubling of displacement allows +6dB more low end output.

Optimally, the horn length would be one wavelength long, 4.5 feet for 250 Hz.Also to consider a folded horn, or perhaps a longer one.

Folding reduces the volume the horn occupies considerably, and if the corner reflectors are correctly done, can allow good reproduction up to the acoustical bandpass limitations imposed on a driver capable of adequate excursion for loud lower speech range out put.

The potential to array with adjacent mouths and the acoustical LP reducing upper harmonic distortion are other benefits, but in general, folding high frequency horns is an acoustic compromise for volume and material conservation.I also had the impression that the folding was a compromise-laden way to simulate a longer horn with out taking up a longer space. Is that right, or does the folding have its own benefits?

I'm not saying they are the ultimate or best solution, but certainly the extra octave of extension makes them closer to covering the speech range with an available commodity.I think you should accept advice from weltersys and buy TOA TU651/TH660 combos - they are better performer than yours JBL D250-X/Goldwood GM-450PB, with much more low frequency extension.

I'd use horn loaded full range drivers rather than standard compression drivers for the low mid range, far more displacement for a given cost, but more design work.

EvenLouder should consider horn design from the bottom up, possibly using Ath.

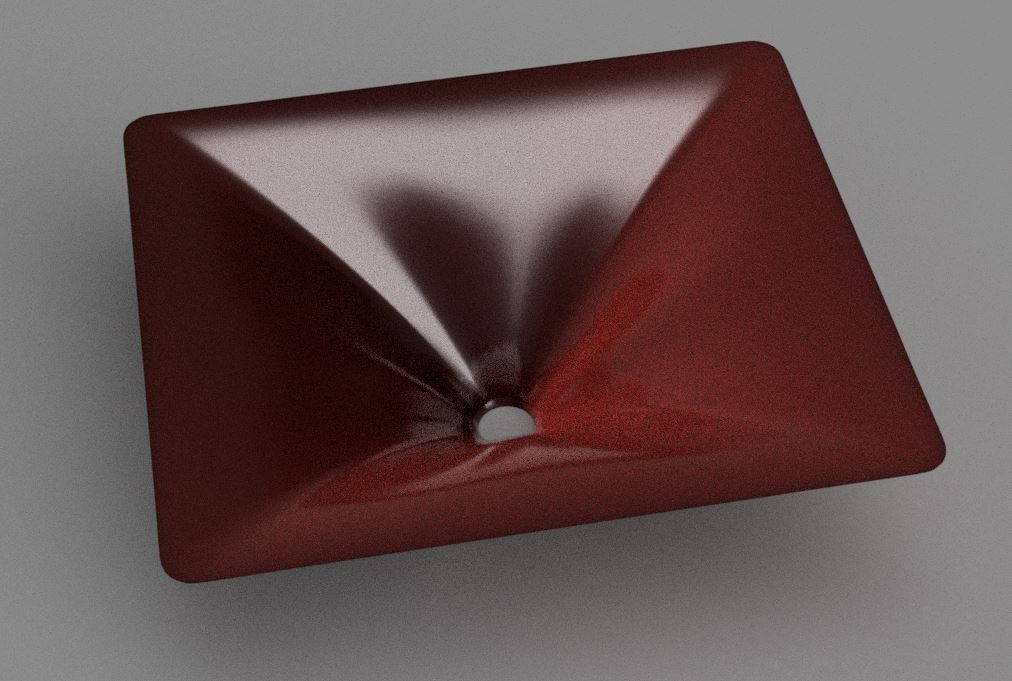

Ath is a piece of software for designing waveguides and horns. At the same time it makes it possible to easily simulate their acoustic behaviour by means of FEA (BEM) via ABEC/AKABAK tool.

Acoustic Horn Design – The Easy Way (Ath tool)

This is an associated thread for a waveguide generator called Ath (Advanced Transition Horn), version 4.

Ath is a piece of software for designing waveguides and horns. At the same time it makes it possible to easily simulate their acoustic behaviour by means of FEA (BEM) via ABEC/AKABAK tool.

The current Ath release is available at https://at-horns.eu

Thread milestones (last edited 26.12.2020...

This is an associated thread for a waveguide generator called Ath (Advanced Transition Horn), version 4.

Ath is a piece of software for designing waveguides and horns. At the same time it makes it possible to easily simulate their acoustic behaviour by means of FEA (BEM) via ABEC/AKABAK tool.

The current Ath release is available at https://at-horns.eu

Thread milestones (last edited 26.12.2020...

Art

Thanks for the corrections!

Is The TOA TU-651a good choice, even on the Goldwood GM-450PB smaller horns? the driver is affordable, and goes down to 150hz, and I wonder if they even bothered to test the Goldwood GM-450PB that low.

Regarding ATH it is a very exciting option, and I would love to explore it. I will admit the learning curve looks steep, and I have some fear.

If anyone is interested in working together on this, I have the CAD skills to thicken geometry and do the mechanical parts, but I think I am years from knowing enough about acoustics to operate that software. My DMs are open!

Is The TOA TU-651a good choice, even on the Goldwood GM-450PB smaller horns? the driver is affordable, and goes down to 150hz, and I wonder if they even bothered to test the Goldwood GM-450PB that low.

Regarding ATH it is a very exciting option, and I would love to explore it. I will admit the learning curve looks steep, and I have some fear.

If anyone is interested in working together on this, I have the CAD skills to thicken geometry and do the mechanical parts, but I think I am years from knowing enough about acoustics to operate that software. My DMs are open!

Yes, TU-651 is a good choice, but it can't go down to 150 Hz - absolute minimum is 250 Hz with a steep high-pass filter (3rd order) on a TOA TH660 horn. On a GM-450PB horn it will not go down that low, because of much smaller horn mouth and length.Is The TOA TU-651a good choice, even on the Goldwood GM-450PB smaller horns? the driver is affordable, and goes down to 150hz, and I wonder if they even bothered to test the Goldwood GM-450PB that low.

Interesting! Can I ask how that was determined?Yes, TU-651 is a good choice, but it can't go down to 150 Hz - absolute minimum is 250 Hz with a steep high-pass filter (3rd order) on a TOA TH660 horn.

The data sheet for the driver says

“Frequency Response: 150 Hz – 6 kHz”

And the frequency response graph seems to be 90dB at 200hz with the toa th-650 horn

Graph source:

Thoughts on Pressure Drivers for PA such as TOA TU-631 / TU-631M / TU-651 / TU-651M?

Hi Everyone,

I'm looking to buy some replacement pressure drivers (1 3/8" thread) to replace two damaged Vitavox GP1 pressure units and connect to the existing horn speakers that I have. This is for a temporary external public address set-up for a community fair.

I have heard that TOA is a very reputable company with decent products, and notice that they have several reasonably-priced drivers such as the TU-631, TU-651 and their corresponding constant-voltage equivalents, the TU-631M and TU-651M -...

Hi Everyone,

I'm looking to buy some replacement pressure drivers (1 3/8" thread) to replace two damaged Vitavox GP1 pressure units and connect to the existing horn speakers that I have. This is for a temporary external public address set-up for a community fair.

I have heard that TOA is a very reputable company with decent products, and notice that they have several reasonably-priced drivers such as the TU-631, TU-651 and their corresponding constant-voltage equivalents, the TU-631M and TU-651M -...

- AndyInBristolUK

- Replies: 4

- Forum: PA Systems

The data sheet for the driver says

“Frequency Response: 150 Hz – 6 kHz”

And the frequency response graph seems to be 90dB at 200hz with the toa th-650 horn

At 250 hz, the horn and driver combo will do about 102 dB, which is already down more than 10dB from it's peak output level. This will sound about half as loud, more or less. Around 175 hz, it's going to be about half as loud as it would be at 250 hz, about 92dB or so according to the chart.

Excursion goes up 4x every time the frequency is halved, assuming all else is held equal. At 1000hz, if you needed 0.08 mm excursion for a given sound pressure level, at 500 hz, it would be 0.32mm. At 250 hz, this would become 1.28mm. At some point the diaphragm is going to whack the phase plug or break.

I'd personally look for the best deal you can find on some neo magnet higher sensitivity fullrange drivers around 4". Buy as many as you can to array them vertically and hammer the FR into shape with dsp. I'd build the boxes out of 3/8" (front baffle) and 1/4" (back and sides).

The lower mids are critical to get right, as most of your speech intelligibility is based from 300 hz - 5k. Power handling will be great, so will overall sensitivity with a decent number of drivers.

The lower mids are critical to get right, as most of your speech intelligibility is based from 300 hz - 5k. Power handling will be great, so will overall sensitivity with a decent number of drivers.

Maybe even banana-shaped like a larger array?Buy as many as you can to array them vertically and hammer the FR into shape with dsp.

@Horneydude If the coverage needs to be vertically expanded, a curved array could be appropriate. The critical array height would need to be fairly long for a sensitivity boost all the way down to 300 hz, but it would alleviate the need for a separate LF driver, given the collective cone surface area is sufficient. A line with 16 to 20 drivers would be very capable of doing the job with decent low end cutoff. Thats about the surface area of a single 15" cone.

Below 250 Hz freq. response falls very steeply - that is where horn unloads the driver.Interesting! Can I ask how that was determined?

As @diyuser2010 pointed out, at such low frequency driver diaphragm may hit the phase plug if driven hard.

You need to look at the cut off frequency of the horn (Fc) as well as the driver response.Thanks for the corrections!

Is The TOA TU-651a good choice, even on the Goldwood GM-450PB smaller horns? the driver is affordable, and goes down to 150hz, and I wonder if they even bothered to test the Goldwood GM-450PB that low.

Below Fc, the horn response is useless for high power PA use, the driver's excursion goes up as output goes down, basically no more output than the driver with no horn.

The Goldwood GM-450PB (knock off of the JBL 2380 horn) says "cutoff (Fc) of 500Hz.

The 2380A horn, not the 4" dome diaphragm 2445 driver sets the low frequency limit, but with only .5mm 1 way excursion, a 2445 can't do much output down low, regardless of the horn's Fc.

Hornresp is probably better to start with, though the learning curve is still tough.Regarding ATH it is a very exciting option, and I would love to explore it. I will admit the learning curve looks steep, and I have some fear.

The easiest, but most limited in terms of driver selection is Celestion's Horn wizard:

https://celestion-horn.netlify.app/

In a matter of minutes you will be able to see how different horn expansions, profiles, and sizes result in different Fc, beamwidth, Di (directivity index) frequency response, and impedance curves.

That said, as I previously mentioned, horn loaded full range drivers rather than standard compression drivers for the low mid range are far more cost effective.

A $25 dollar "full range driver" has far more displacement capability than the $1000 dollar Celestion Axi2050, which only has a bit more displacement than the 4" diaphragm JBL 2445, 2450, etc.

Art

The GW horn mentioned doesn't do that well below 800 hz. I've used it with a few other large drivers ie. B&C DCX50, PRV D3220PH. It does OK with xover above 700 hz but doesn't load the driver lower than 500 hz, as Art already mentioned.

No one mentioned MEH ? I see it as the new trend - I haven't heard such design ( nor a kind of OP's proposal, megaphones excluded) and the 3D printers that allow for complex designs.

Mmmh...a MEH results at the end to be a box.

Mmmh...a MEH results at the end to be a box.

- Home

- Loudspeakers

- Multi-Way

- DIY Lightweight 5-meter tall Delay Tower PA System