First many thanks to cats squirrel for his work on this subject. Not just cats squirrel, we need more science investigation on this subject. A material engineer who is also a turntable audiophile to conduct research and analysis.

How To Become A Material Engineer - Zippia

guys, I appreciate your comments on this thread.

How To Become A Material Engineer - Zippia

guys, I appreciate your comments on this thread.

thanks for the thanks.

BUT, I am not a Material Engineer! I do test materials according to accepted test methods. But my scientific understanding and experience is not in material science. However, the field of the sciences has commonality, meaning the philosophy of science applies, regardless of a particular field of study. 🙂

BUT, I am not a Material Engineer! I do test materials according to accepted test methods. But my scientific understanding and experience is not in material science. However, the field of the sciences has commonality, meaning the philosophy of science applies, regardless of a particular field of study. 🙂

Hello All,

I have been reading this thread with great interest. When I build my 4 phase sine wave / 3 phase class D BLDC motor project I had no idea that Pyramid and I both had early model scouts. This project has inspired me to take the next step and build my own plinth, so if you all will indulge me, may I ask the following questions.

1. How did you decide on the thickness of the layers? What would happen if the center MDF layer was thinner or thicker than the Corian layers? Or if the Corian was bonded using the VHB tape with no MDF layer at all? Would that be closer to a true CLD design?

2. Could I use fiberglass resin on the MDF instead of the CPES? I am assuming that the glue is meant to make the tape bond better, but is there also another reason to use a penetrating sealer?

3. I am going to use a PVC platter and bearing from a Galibier Serac turntable. It is much thicker than the Scout's acrylic platter. Do you have any advice on a riser armboard to mount an Origin Live (Rega style) arm?

Thanks,

Russell

I have been reading this thread with great interest. When I build my 4 phase sine wave / 3 phase class D BLDC motor project I had no idea that Pyramid and I both had early model scouts. This project has inspired me to take the next step and build my own plinth, so if you all will indulge me, may I ask the following questions.

1. How did you decide on the thickness of the layers? What would happen if the center MDF layer was thinner or thicker than the Corian layers? Or if the Corian was bonded using the VHB tape with no MDF layer at all? Would that be closer to a true CLD design?

2. Could I use fiberglass resin on the MDF instead of the CPES? I am assuming that the glue is meant to make the tape bond better, but is there also another reason to use a penetrating sealer?

3. I am going to use a PVC platter and bearing from a Galibier Serac turntable. It is much thicker than the Scout's acrylic platter. Do you have any advice on a riser armboard to mount an Origin Live (Rega style) arm?

Thanks,

Russell

Hello All,

I have been reading this thread with great interest. When I build my 4 phase sine wave / 3 phase class D BLDC motor project I had no idea that Pyramid and I both had early model scouts. This project has inspired me to take the next step and build my own plinth, so if you all will indulge me, may I ask the following questions.

1. How did you decide on the thickness of the layers? What would happen if the center MDF layer was thinner or thicker than the Corian layers? Or if the Corian was bonded using the VHB tape with no MDF layer at all? Would that be closer to a true CLD design?

I used material that was available rather than machining or using custom material thickness. Probably the easiest way to answer your question is "try it and measure your results".

2. Could I use fiberglass resin on the MDF instead of the CPES? I am assuming that the glue is meant to make the tape bond better, but is there also another reason to use a penetrating sealer?

CPES is thinner than alcohol so it soaks in readily without changing the outside dimension of the MDF. CPES makes the MDF dimensionaly stable with temp and humidity and may add to damping. As you noted, VHB tape bonds better to CPES than it does to bare wood or MDF.

3. I am going to use a PVC platter and bearing from a Galibier Serac turntable. It is much thicker than the Scout's acrylic platter. Do you have any advice on a riser armboard to mount an Origin Live (Rega style) arm?

Corian machines very well; I drilled and tapped mounting holes for the Jelco tonearm.

Pyramid,

Thanks for your response. I will follow your advice and try a few panels before making a final decision. I was just looking into the VHB tape and it looks like 3B sells quite a lot of different versions of it.

Could you tell me the part number for the VHB tape and where you purchased it?

Russell

Thanks for your response. I will follow your advice and try a few panels before making a final decision. I was just looking into the VHB tape and it looks like 3B sells quite a lot of different versions of it.

Could you tell me the part number for the VHB tape and where you purchased it?

Russell

I used 3M type 5925P; it's wide and thin. I bought it on-line some time ago. Just Google it and you can find distributors.

Pyramid,

Can you confirm that this is 5925 (25 mil) vs 5952 (45 mil)?

5925 (with or without the P) seems to only be available in 1" rolls.

I will continue my search.

Russell

Can you confirm that this is 5925 (25 mil) vs 5952 (45 mil)?

5925 (with or without the P) seems to only be available in 1" rolls.

I will continue my search.

Russell

Authentic 5925 is pretty dear and hard to find in 2" rolls, but it is out there. Definitely a lot more than $111 for 72 yds. Maybe $360 or more

I found this on Ebay:

(5pcs.) VHB 5925 DOUBLE SIDED FOAM ADHESIVE SHEET ( 3 5/8 in X 6in ) .025 thick | eBay

The seller purchased 1000 sheets at a auction and is not 100% that they are authentic, but I've taken the chance to purchase some to test. I will report back on them.

I've also found a vendor of a competing product called AFTC Silver Tape. The gentleman I spoke with over the phone, Andrew Machover at TAPE-RITE CO, seemed to know his stuff about the different types of VHB tapes. The recommended tape most similar to 5925 is 5336. It is closer to 4936 or RP25 according to Andrew. I'm not sure how different they are vs 5925, but the price is $36 for a 1" by 36 yd roll. 2" or larger is just the multiple times the 1" price.

If this info is useful to anyone, please let me know. I'll try to document my build as it goes along.

I found this on Ebay:

(5pcs.) VHB 5925 DOUBLE SIDED FOAM ADHESIVE SHEET ( 3 5/8 in X 6in ) .025 thick | eBay

The seller purchased 1000 sheets at a auction and is not 100% that they are authentic, but I've taken the chance to purchase some to test. I will report back on them.

I've also found a vendor of a competing product called AFTC Silver Tape. The gentleman I spoke with over the phone, Andrew Machover at TAPE-RITE CO, seemed to know his stuff about the different types of VHB tapes. The recommended tape most similar to 5925 is 5336. It is closer to 4936 or RP25 according to Andrew. I'm not sure how different they are vs 5925, but the price is $36 for a 1" by 36 yd roll. 2" or larger is just the multiple times the 1" price.

If this info is useful to anyone, please let me know. I'll try to document my build as it goes along.

Measured and Remeasured

Pyramid,

Good thread you've started!

Cats Squirrel,

Thanks for recommending that AD Accelerometer a while back. I've finally put it to good use.

I confess there's been a lot of mistakes and rework over the last few weeks. Hopefully what I'm about to post is accurate.

Here's a good video that I believe was posted buy Earl Geddes aka Gedlee. (Sorry to Earl and the creator if I got that wrong).

Constrained layer damping | Audio Science Review (ASR) Forum

Note that this link starts about 35 minutes into a video on speakers.

There's a few Oscilloscope shots that give an idea of what to expect from Constrained layer damping. There's also a recommendation for a two part goop that's meant for the job - but that's not what I've used so far.

More shortly...

Pyramid,

Good thread you've started!

Cats Squirrel,

Thanks for recommending that AD Accelerometer a while back. I've finally put it to good use.

I confess there's been a lot of mistakes and rework over the last few weeks. Hopefully what I'm about to post is accurate.

Here's a good video that I believe was posted buy Earl Geddes aka Gedlee. (Sorry to Earl and the creator if I got that wrong).

Constrained layer damping | Audio Science Review (ASR) Forum

Note that this link starts about 35 minutes into a video on speakers.

There's a few Oscilloscope shots that give an idea of what to expect from Constrained layer damping. There's also a recommendation for a two part goop that's meant for the job - but that's not what I've used so far.

More shortly...

The jig

The final use is a Turntable plinth, so I mostly tested pieces that were about 18 to 20 inches in length. The widths were around 2.5 to 4.3 inches. Maple flooring, MDF, Birch plywood, Panzerholz are among the pieces tested.

The viscous layers tried were GreenGlue (from HomeDepot), an Underwater Butyl tape, Duct Seal and a couple of stretchy latex adhesives.

When I suspended the pieces and hit them with a Golf ball, the lowest resonances were typically 200 hz, 350 hz or so. Later, I placed the test pieces on the Concrete Basement Floor with audio points supporting the ends. Hopefully I just attached a photo of the jig.This typically lowered the first resonance peak by half (100 hz to 250 depending on the materials).

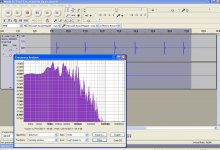

The grey piece on the left is a guide. I slide 5 or 6 glass marbles down the incline to strike the test piece. The mass of tape and wires near the middle of the panel is the Accelerometer. Audacity collects the pulses in an old PC.

Now, did that file attach?

The final use is a Turntable plinth, so I mostly tested pieces that were about 18 to 20 inches in length. The widths were around 2.5 to 4.3 inches. Maple flooring, MDF, Birch plywood, Panzerholz are among the pieces tested.

The viscous layers tried were GreenGlue (from HomeDepot), an Underwater Butyl tape, Duct Seal and a couple of stretchy latex adhesives.

When I suspended the pieces and hit them with a Golf ball, the lowest resonances were typically 200 hz, 350 hz or so. Later, I placed the test pieces on the Concrete Basement Floor with audio points supporting the ends. Hopefully I just attached a photo of the jig.This typically lowered the first resonance peak by half (100 hz to 250 depending on the materials).

The grey piece on the left is a guide. I slide 5 or 6 glass marbles down the incline to strike the test piece. The mass of tape and wires near the middle of the panel is the Accelerometer. Audacity collects the pulses in an old PC.

Now, did that file attach?

Attachments

Collecting the measurements

It was not such a good idea to do this in front of the Beer Fridge. Lost some of my marbles underneath.

Hopefully, this is a valid method (comments please)... Here's a shot of six pulses collected in Audacity. I selected a window that engulfs the lot, then hit "Analyze" then "Spectrum". A window pops up showing the FFT results.

The "Export" button allows the FFT data to be saved off - and I did.

Then, I window around one pulse and zoom in to see the length of a pulse. In this case the target was a piece of maple flooring on it's own (no damping). The ringing disappears from view after about 0.13 seconds. CLD does improve on this in most cases.

It was not such a good idea to do this in front of the Beer Fridge. Lost some of my marbles underneath.

Hopefully, this is a valid method (comments please)... Here's a shot of six pulses collected in Audacity. I selected a window that engulfs the lot, then hit "Analyze" then "Spectrum". A window pops up showing the FFT results.

The "Export" button allows the FFT data to be saved off - and I did.

Then, I window around one pulse and zoom in to see the length of a pulse. In this case the target was a piece of maple flooring on it's own (no damping). The ringing disappears from view after about 0.13 seconds. CLD does improve on this in most cases.

Attachments

Some test results

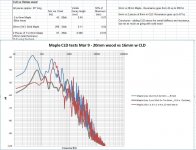

The first picture is a screen grab from an Excel sheet.

The heavy blue line is the 21" x 3.5" x 3/4" piece of Maple flooring by itself - no damping. The first resonance peak is at 126 hz.

The Green line is "GreenGlue". It's a product that's meant for CLD on two panels of drywall. Two pieces of similarly sized Maple flooring were lightly gooped up, and clamped for about 12 hours. In Earl's video, he comments that the viscous layer should be a thin as possible.

The GreenGlue has reduced the first resonant peak by about 8 db. That doesn't seem like much, but a knuckle tap reveals a much more dead sound from the CLD'd combination.

The next shot is a single Marble hit with the Green glue CLD. Now it disappears from view in about 0.05 seconds.

The graph also plots similar tests for an Underwater tape called "Versatape" (Black trace). One side is self adhesive, the other side is Contact cement.

The brown trace is GB Ductseal from Home Depot. It's meant for sealing Electrical boxes and coduits. This particular brand stays pliable for years. Another one by Thomas and Betts tends to dry out.

There's also two stretchy Latex products in there ( Yellow trace and light purple trace). They don't appear as effective. However, I had to use 2.5" wide flooring for those. Bad science perhaps.

If anyone is interested, I'll try to post results for different woods for the layers. It's work in progress, so may take a while. Suggestions welcome.

Hugh

The first picture is a screen grab from an Excel sheet.

The heavy blue line is the 21" x 3.5" x 3/4" piece of Maple flooring by itself - no damping. The first resonance peak is at 126 hz.

The Green line is "GreenGlue". It's a product that's meant for CLD on two panels of drywall. Two pieces of similarly sized Maple flooring were lightly gooped up, and clamped for about 12 hours. In Earl's video, he comments that the viscous layer should be a thin as possible.

The GreenGlue has reduced the first resonant peak by about 8 db. That doesn't seem like much, but a knuckle tap reveals a much more dead sound from the CLD'd combination.

The next shot is a single Marble hit with the Green glue CLD. Now it disappears from view in about 0.05 seconds.

The graph also plots similar tests for an Underwater tape called "Versatape" (Black trace). One side is self adhesive, the other side is Contact cement.

The brown trace is GB Ductseal from Home Depot. It's meant for sealing Electrical boxes and coduits. This particular brand stays pliable for years. Another one by Thomas and Betts tends to dry out.

There's also two stretchy Latex products in there ( Yellow trace and light purple trace). They don't appear as effective. However, I had to use 2.5" wide flooring for those. Bad science perhaps.

If anyone is interested, I'll try to post results for different woods for the layers. It's work in progress, so may take a while. Suggestions welcome.

Hugh

Critical Frequency for Maple?

Hi Cats Squirrel,

I'm hoping you have a reasonable guess about these questions...

What would be the Critical Frquency for 3/4" (19mm) Maple?

When I combine two layers in CLD, should it now be considered 1.5 inches for the purposes of Fc?

Is the Analog Devices Accelerometer likely to pick up anything that might indicate what Fc is? (I think you said it's a calculation only).

Would a better Accelerometer pick up anything?

Thanks,

Hugh

thanks for the reference, will read it soon as...

On the question of thickness. The usefulness (goodness) of the material will depend quite a lot on its thickness. The thicker the plinth panel the higher the fundamental (and all harmonic) frequencies, which may mean higher modal densities and more of a problem with resonances. The critical frequency will come down, above which all resonances will be heard! Also the region between the fundamental frequency and critical frequency will be reduced, even nullified, meaning there will be no losses due to mass! And as thickness increases, mobility goes down but mechanical impedance goes up, so transfer of vibrations to the plinth (or arm to arm board) will be drastically reduced.

For Panzerholz, somewhere between 15mm and 25mm thickness would be ideal.

Hi Cats Squirrel,

I'm hoping you have a reasonable guess about these questions...

What would be the Critical Frquency for 3/4" (19mm) Maple?

When I combine two layers in CLD, should it now be considered 1.5 inches for the purposes of Fc?

Is the Analog Devices Accelerometer likely to pick up anything that might indicate what Fc is? (I think you said it's a calculation only).

Would a better Accelerometer pick up anything?

Thanks,

Hugh

Tape Thickness

Hi rsritchey,

Do you know off the top which of the tapes you mention would be the thinnest one? I ask because it seems that thinner is more effective for CLD according to some. I tried it with the Green Glue and it seems to be true.

Hugh

Authentic 5925 is pretty dear and hard to find in 2" rolls, but it is out there. Definitely a lot more than $111 for 72 yds. Maybe $360 or more

I found this on Ebay:

(5pcs.) VHB 5925 DOUBLE SIDED FOAM ADHESIVE SHEET ( 3 5/8 in X 6in ) .025 thick | eBay

The seller purchased 1000 sheets at a auction and is not 100% that they are authentic, but I've taken the chance to purchase some to test. I will report back on them.

I've also found a vendor of a competing product called AFTC Silver Tape. The gentleman I spoke with over the phone, Andrew Machover at TAPE-RITE CO, seemed to know his stuff about the different types of VHB tapes. The recommended tape most similar to 5925 is 5336. It is closer to 4936 or RP25 according to Andrew. I'm not sure how different they are vs 5925, but the price is $36 for a 1" by 36 yd roll. 2" or larger is just the multiple times the 1" price.

If this info is useful to anyone, please let me know. I'll try to document my build as it goes along.

Hi rsritchey,

Do you know off the top which of the tapes you mention would be the thinnest one? I ask because it seems that thinner is more effective for CLD according to some. I tried it with the Green Glue and it seems to be true.

Hugh

Maple thickness and Fc

It seems a little vain to be quoting myself.

I was able to get an answer via google for Maple thickness.

Wood, Panel and Structural Timber Products - Mechanical Properties

Plugging the Density and Modulus values into the Fc formula, it looks like 3/4" (20 mm) is not in the ballpark. It's more like 6mm. More rework.

No matter. The 20mm Maple tests were to see which Viscoelastic materials work.

Hi Cats Squirrel,

I'm hoping you have a reasonable guess about these questions...

What would be the Critical Frquency for 3/4" (19mm) Maple?

When I combine two layers in CLD, should it now be considered 1.5 inches for the purposes of Fc?

Is the Analog Devices Accelerometer likely to pick up anything that might indicate what Fc is? (I think you said it's a calculation only).

Would a better Accelerometer pick up anything?

Thanks,

Hugh

It seems a little vain to be quoting myself.

I was able to get an answer via google for Maple thickness.

Wood, Panel and Structural Timber Products - Mechanical Properties

Plugging the Density and Modulus values into the Fc formula, it looks like 3/4" (20 mm) is not in the ballpark. It's more like 6mm. More rework.

No matter. The 20mm Maple tests were to see which Viscoelastic materials work.

CLD vs Thicker wood

I can't see anything on the Accelerometer that convinces me I'm seeing Fc. Do you suppose that exiting the panels with sound would show anything? Maybe with a Microphone on one side?

Here's another chart showing what CLD seems to do on thinner pieces of Maple. (I'm not making the plinth from Maple, this is just material on hand).

All pieces are about 20 inches in length. The Blue trace is 6 mm thick maple. The brown trace is 20mm maple. Notice how the first resonant frequency goes way up.

The grey trace is (2) 8mm pieces (18mm total thickeness) with a thin layer of Ductseal pressed in between for Constrained Layer damping. This makes the pulses decay more quickly than wood alone.

It also raises the resonance a bit (vs. 6mm piece alone), but likely not as much as a solid piece would have. So, minimal effect on the first resonance and overall stiffness.

I'm guessing the effect on Fc would also be less than increasing panel thickness. Thoughts anyone?

Hugh

I can't see anything on the Accelerometer that convinces me I'm seeing Fc. Do you suppose that exiting the panels with sound would show anything? Maybe with a Microphone on one side?

Here's another chart showing what CLD seems to do on thinner pieces of Maple. (I'm not making the plinth from Maple, this is just material on hand).

All pieces are about 20 inches in length. The Blue trace is 6 mm thick maple. The brown trace is 20mm maple. Notice how the first resonant frequency goes way up.

The grey trace is (2) 8mm pieces (18mm total thickeness) with a thin layer of Ductseal pressed in between for Constrained Layer damping. This makes the pulses decay more quickly than wood alone.

It also raises the resonance a bit (vs. 6mm piece alone), but likely not as much as a solid piece would have. So, minimal effect on the first resonance and overall stiffness.

I'm guessing the effect on Fc would also be less than increasing panel thickness. Thoughts anyone?

Hugh

- Home

- Source & Line

- Analogue Source

- DIY CLD Plinth Design--A measured Approach