Hi High

The PVB I encounter as a seepage from a Laminate Glass is is usually quite hard to the Touch but will trim reasonable easy to clean a glass edge.

If a String of it is trimmed off it will usually roll up rather that break, so I will assume this is an elastic type of property, I have a very vague recollection that a trim off can be stretched, but the memory is very distant of experiencing this.

The PVB I encounter as a seepage from a Laminate Glass is is usually quite hard to the Touch but will trim reasonable easy to clean a glass edge.

If a String of it is trimmed off it will usually roll up rather that break, so I will assume this is an elastic type of property, I have a very vague recollection that a trim off can be stretched, but the memory is very distant of experiencing this.

John,

Ok, maybe I'd best let my test piece cure a little longer and see if it gets harder. Thanks.

Hugh

Ok, maybe I'd best let my test piece cure a little longer and see if it gets harder. Thanks.

Hugh

Do you recall what solvent they used for glass? I'm not assuming it will work for Acrylic, but may as well know about it.

I know when Float Glass Lamination is cut, the Old Tradesmen would Diamond Scribe and and Break the Glass and use Methylated Spirits to treat the PVB Layer to make it separate.

JohnnoG, Cats Squirrel,

At the moment, I'm having more success in having PVB stick to Acrylic using Nail polish remover (Acetone) rather than Isopropanol. But, a question about the method of dissolving it...

If I drop a little bit of powder into quite a bit of Nail Polish remover, it very quickly forms a gummy blob. I crush it a few times and soak for about 30 seconds, then apply it to the Acrylic. I place the mdf on top and lightly clamp overnight.

The cured PVB is quite elastic.

Does it seem like I have it right?

Hugh

don't use acetone, it will dissolve the acrylic. Use warm propanol (IPA, propan-2-ol). Warm by putting a bottle containing some of the alcohol in warm water. Add about 20% by weight of the PVB, and agitate to dissolve.

I'm surprised that Fc is so high for a 38mm panel. Is that due to the 3 layers?

Hello Hugh,

yes the Fc does seem very high. The calculations for three layer laminates is extremely complex, and obviously, from the result quoted, doesn't work in this instance. I re-programmed my spreadsheet with a simpler set of equations, and got 877 Hz as a result. That seems more like it. But I'm not sure how accurate it is. But it seems to work with single material calculations.

Here is a table I produced by actual measurement and by calculation, and managed to ascribe most of the resonant modes, except for one. But that one was close to the critical frequency!

assigned modal frequencies by cats squirrel,

assigned modal frequencies by cats squirrel, I don't know why F2,1 is so far out, but it happens quite often! These results were not carried out on a laminate, just a single material.

Last edited:

don't use acetone, it will dissolve the acrylic. Use warm propanol (IPA, propan-2-ol). Warm by putting a bottle containing some of the alcohol in warm water. Add about 20% by weight of the PVB, and agitate to dissolve.

Ok, I'll give that a try later. The trial adhesion from Acetone is firming up as it cures. It seems to take more than a day.

Hi Deadhead,

PU = Polyurethane - right? Thanks, I agree as an adhesive it's very good. I'll post some test results later. I've tried Lepages "PL" which sets up very hard.

I've also tried one by Sika that's an Elastometer, but still fairly stiff. If I can find another that stays soft I'll give it a go too. Suggestions are welcome, but it seems the brands in Canada differ from those in the UK.

PVB is looking like it may be similar to the Sika.

So far, an Acrylic/Silicone by GE is looking like it may be a good combination of soft elastometer and decent adhesive.

Hugh

PU = Polyurethane - right? Thanks, I agree as an adhesive it's very good. I'll post some test results later. I've tried Lepages "PL" which sets up very hard.

I've also tried one by Sika that's an Elastometer, but still fairly stiff. If I can find another that stays soft I'll give it a go too. Suggestions are welcome, but it seems the brands in Canada differ from those in the UK.

PVB is looking like it may be similar to the Sika.

So far, an Acrylic/Silicone by GE is looking like it may be a good combination of soft elastometer and decent adhesive.

Hugh

A Polysulphide Silicone is becoming less common as there are other Silicones becoming available that will offer the same attractive properties that the Polysulphide Silicon has offered.

This Silicone has been commonly used on the Perimeter Seals of a double glazed glass unit. It has very good properties in relation to keeping adhesion if submerged in water and will maintain the Gas in a gas filled cavity for the expected period offered by a manufacturer.

As a material with properties that are separated from the usual used Sealants, when used in the construction under discussion it might have a property that offers a improved interface ?

This Silicone has been commonly used on the Perimeter Seals of a double glazed glass unit. It has very good properties in relation to keeping adhesion if submerged in water and will maintain the Gas in a gas filled cavity for the expected period offered by a manufacturer.

As a material with properties that are separated from the usual used Sealants, when used in the construction under discussion it might have a property that offers a improved interface ?

A Polysulphide Silicone is becoming less common as there are other Silicones ....

As a material with properties that are separated from the usual used Sealants, when used in the construction under discussion it might have a property that offers a improved interface ?

Hi John,

You'll see from what I'm about to post that I'm leaning towards soft adhesives. Is Polysulphide Silicone one of those? Is GE MaxStretch a Polysulphide Silicone? (Not sure I understand).

When I first mentioned I was using adhesives for windows, I actually meant the ones intended to stick to the outside Vinyl frames rather than the glass.

Hugh

Effects of adhesives

A few weeks back, I had a "good" idea. It could easily be more of a naive idea, but here goes....

I'm finding that the 100mm square panels don't tell the whole story, especially when it's layers. Their resonances are higher than the full sized plinth.

It's looking like I'll be using some existing 12mm acrylic for a plinth, but I'll try testing the materials using some old 3mm (1/8") Acrylic from a storm window. It's weathered for more than a decade, so some of the properties are no longer typical.

The test pieces are 4.5" (115 mm) square. The layers are 1/8" (3mm). It's like a plinth built 1/4 scale. In my mind, this allows the resonant frequencies to be lower and (perhaps) be a partial mimic of the full sized plinth. I doubt that it's a scaled representation of Fc though.

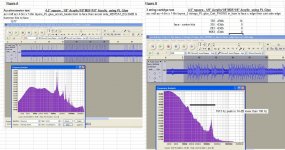

Figure A in the attached is a 4.5" square sandwich of 1/8" Acrylic/ 1/8" MDF / 1/8" held together with Lepage's PL "Construction adhesive. It's a Polyurethane that sets up fairly stiff when it cures. The accelerometer is hot glued to the center of the string-suspended panel. Figure A shows the spectrum from Audacity after several hammer taps to the opposite face (in the center).

There's a spike of over 20dB at 1577 hz. (Bryan, I did test the Accelerometer on a speaker to see if it can read this high - it can). The very narrow width indicates it's a poorly damped spike. I was wondering if this could be Fc, or something just above Fc where the damping is poorer.

In Figure B, an old Magnetic cartridge is held against the same panel. As Cats Squirrel pointed out, the response to the peak (now 1613 hz) is suppressed. But, in this particular example, that peak is about the same as a few other resonances - 293 and 335 hz. As a reference point, it's just 14 dB lower than the response at 100hz.

Our hearing is more sensitive at 1613 hz than at 100 hz. If this was a real plinth, I suspect the 1613 hz peak might be audible, or a “colouration” at the very least. (In fairness, if I showed other examples where the panel is struck in other locations, it's much less dramatic. I’m picking an extreme example.)

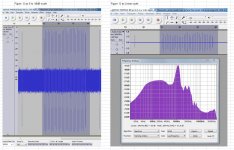

Figure J is one of the Acrylic panels intended for the real plinth ( 1/2" (12mm) x 18" x 14"). The panel shows a variety of nasty, narrow peaks at 655 hz and above. I suspect that one or more of these would also be high and poorly damped if a hard glue like Lepages PL or Epoxy was used between the layers. I'm hoping the rest of these tests demonstrate a way to cope using softer adhesives. I haven't built the real plinth just yet, so take it with a grain of salt.

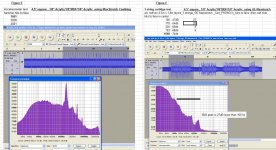

Figure C is an Accelerometer test on the same Acrylic/MDF/Acrylic layers with Greenglue in between. (The corners had to be bolted as the Acrylic is slightly warped and green glue is not really an adhesive.) Note that the main peak is now at 1107. The height is lower and the bandwidth is wider from the improved damping.

There may be a penalty in the lower frequencies. There's now a wide hump centered at 252 hz. I expect that the lower frequencies are still well damped (> 0.4 =DF as a guess).

Figure D is the corresponding Cartridge output through a phono stage. The peak is now 1155 hz. It's now 22dB below the 100 hz mark (black line). It's also a wider peak compared to figure B, suggesting it's better damped which will make it diminish faster.

Figure E and F are show the effect of GE MaxStretch as the adhesive. It's labelled as "Elastomeric". It also recovers slowly when stretched, suggesting it is also Viscoelastic - just not sold for that purpose.

In figure F, the resonant peak at 1648 is fairly wide - good damping.

Particle Board (aka Chipboard in the UK) with Maxstretch is used in Figures G and H. The width of the peak (1167 hz) in Figure G looks like the best of the lot.

The cartridge output in Figure H has a corresponding peak at 1110 hz. It too appears to be wide and well damped. It’s peak is 26dB below the 100 hz line.

I wonder if I should try a (quarter scaled) panel using Greenglue, Chipboard and Acrylic as well.

For the real plinth with 12mm Acrylic, I'm leaning towards 12mm Chipboard (Particle Board in North America) and the MaxStretch caulking - so far.

Hugh

A few weeks back, I had a "good" idea. It could easily be more of a naive idea, but here goes....

I'm finding that the 100mm square panels don't tell the whole story, especially when it's layers. Their resonances are higher than the full sized plinth.

It's looking like I'll be using some existing 12mm acrylic for a plinth, but I'll try testing the materials using some old 3mm (1/8") Acrylic from a storm window. It's weathered for more than a decade, so some of the properties are no longer typical.

The test pieces are 4.5" (115 mm) square. The layers are 1/8" (3mm). It's like a plinth built 1/4 scale. In my mind, this allows the resonant frequencies to be lower and (perhaps) be a partial mimic of the full sized plinth. I doubt that it's a scaled representation of Fc though.

Figure A in the attached is a 4.5" square sandwich of 1/8" Acrylic/ 1/8" MDF / 1/8" held together with Lepage's PL "Construction adhesive. It's a Polyurethane that sets up fairly stiff when it cures. The accelerometer is hot glued to the center of the string-suspended panel. Figure A shows the spectrum from Audacity after several hammer taps to the opposite face (in the center).

There's a spike of over 20dB at 1577 hz. (Bryan, I did test the Accelerometer on a speaker to see if it can read this high - it can). The very narrow width indicates it's a poorly damped spike. I was wondering if this could be Fc, or something just above Fc where the damping is poorer.

In Figure B, an old Magnetic cartridge is held against the same panel. As Cats Squirrel pointed out, the response to the peak (now 1613 hz) is suppressed. But, in this particular example, that peak is about the same as a few other resonances - 293 and 335 hz. As a reference point, it's just 14 dB lower than the response at 100hz.

Our hearing is more sensitive at 1613 hz than at 100 hz. If this was a real plinth, I suspect the 1613 hz peak might be audible, or a “colouration” at the very least. (In fairness, if I showed other examples where the panel is struck in other locations, it's much less dramatic. I’m picking an extreme example.)

Figure J is one of the Acrylic panels intended for the real plinth ( 1/2" (12mm) x 18" x 14"). The panel shows a variety of nasty, narrow peaks at 655 hz and above. I suspect that one or more of these would also be high and poorly damped if a hard glue like Lepages PL or Epoxy was used between the layers. I'm hoping the rest of these tests demonstrate a way to cope using softer adhesives. I haven't built the real plinth just yet, so take it with a grain of salt.

Figure C is an Accelerometer test on the same Acrylic/MDF/Acrylic layers with Greenglue in between. (The corners had to be bolted as the Acrylic is slightly warped and green glue is not really an adhesive.) Note that the main peak is now at 1107. The height is lower and the bandwidth is wider from the improved damping.

There may be a penalty in the lower frequencies. There's now a wide hump centered at 252 hz. I expect that the lower frequencies are still well damped (> 0.4 =DF as a guess).

Figure D is the corresponding Cartridge output through a phono stage. The peak is now 1155 hz. It's now 22dB below the 100 hz mark (black line). It's also a wider peak compared to figure B, suggesting it's better damped which will make it diminish faster.

Figure E and F are show the effect of GE MaxStretch as the adhesive. It's labelled as "Elastomeric". It also recovers slowly when stretched, suggesting it is also Viscoelastic - just not sold for that purpose.

In figure F, the resonant peak at 1648 is fairly wide - good damping.

Particle Board (aka Chipboard in the UK) with Maxstretch is used in Figures G and H. The width of the peak (1167 hz) in Figure G looks like the best of the lot.

The cartridge output in Figure H has a corresponding peak at 1110 hz. It too appears to be wide and well damped. It’s peak is 26dB below the 100 hz line.

I wonder if I should try a (quarter scaled) panel using Greenglue, Chipboard and Acrylic as well.

For the real plinth with 12mm Acrylic, I'm leaning towards 12mm Chipboard (Particle Board in North America) and the MaxStretch caulking - so far.

Hugh

Attachments

I'm very concerned by the amount of noise in your results. What voltage are you running your accelerometer at?

Bryan,

That particular Accelerometer board has a built in regulator. So, it accepts 4.5 V (3 AA cells) and knocks it down on the board, so I don't actually know. Guessing 3v.

The display you see in the background is in dB. It happens to be on the 0-60 db scale which does make it look noisy. I'll repost a could of those results at 0-48dB or linear.

Hugh

That particular Accelerometer board has a built in regulator. So, it accepts 4.5 V (3 AA cells) and knocks it down on the board, so I don't actually know. Guessing 3v.

The display you see in the background is in dB. It happens to be on the 0-60 db scale which does make it look noisy. I'll repost a could of those results at 0-48dB or linear.

Hugh

Hi Bryan

My suggestions are offered as I am aware you are measuring properties of the constructions that are being produced.

I am sure you have sealant/adhesives that are totally fit for purpose and your choice of a material that can offer a flexion when cured is showing this.

My additional suggestions are more leaning toward the idea that if one was trialled it might show a measurement that is seen as an improvement.

The Polysulphide Silicone is used in locations where movement of materials is expected to happen, so it will have a flexion.

The most flexion Silicone I know off is a Butyl Rubber based Silicone, it will have a bounce back/memory property when cured and pressure is applied to the surface.

My suggestions are offered as I am aware you are measuring properties of the constructions that are being produced.

I am sure you have sealant/adhesives that are totally fit for purpose and your choice of a material that can offer a flexion when cured is showing this.

My additional suggestions are more leaning toward the idea that if one was trialled it might show a measurement that is seen as an improvement.

The Polysulphide Silicone is used in locations where movement of materials is expected to happen, so it will have a flexion.

The most flexion Silicone I know off is a Butyl Rubber based Silicone, it will have a bounce back/memory property when cured and pressure is applied to the surface.

I'm very concerned by the amount of noise in your results. What voltage are you running your accelerometer at?

I had a good look at gains, etc. Audacity somehow decided to work with the "Microsoft mapper" instead of the "direct" setting from much earlier. I'll repeat a couple of those measurements later.

Hugh

- Home

- Source & Line

- Analogue Source

- DIY CLD Plinth Design--A measured Approach