hi,

@warrjon

did you inquire if truepoint could make them?

how hard is it to make the pivots?

id like to have a go.

I didn't ask True Point if they could make larger pivots although this would be possible.

It takes a lot of work to radius and polish the pivot and cup. I did it in the lathe but you could use a hand drill. The M4 setscrews need to have the flat cup radiused to suite the pivot.

To forge the radius in the cup I used a needle from a roller bearing as these are incredibly hard. I ground the radius on the needle screw the setscrew into the bottom of the round bar and hit it with a hammer.

Next step is to install the needle into a drill and burnish the setscrew. Polish with diamond paste to get a mirror finish. The better the finish the lower breakaway torque will be.

The donor carbide scribe and forge.

ok,i have a lathe and milling machine.

im trying to acheive a pair of these M3 thread,im slightly confused by the forge process?

edit, ah i get it now the forging is only to make the pivot cups.

im trying to acheive a pair of these M3 thread,im slightly confused by the forge process?

edit, ah i get it now the forging is only to make the pivot cups.

Last edited:

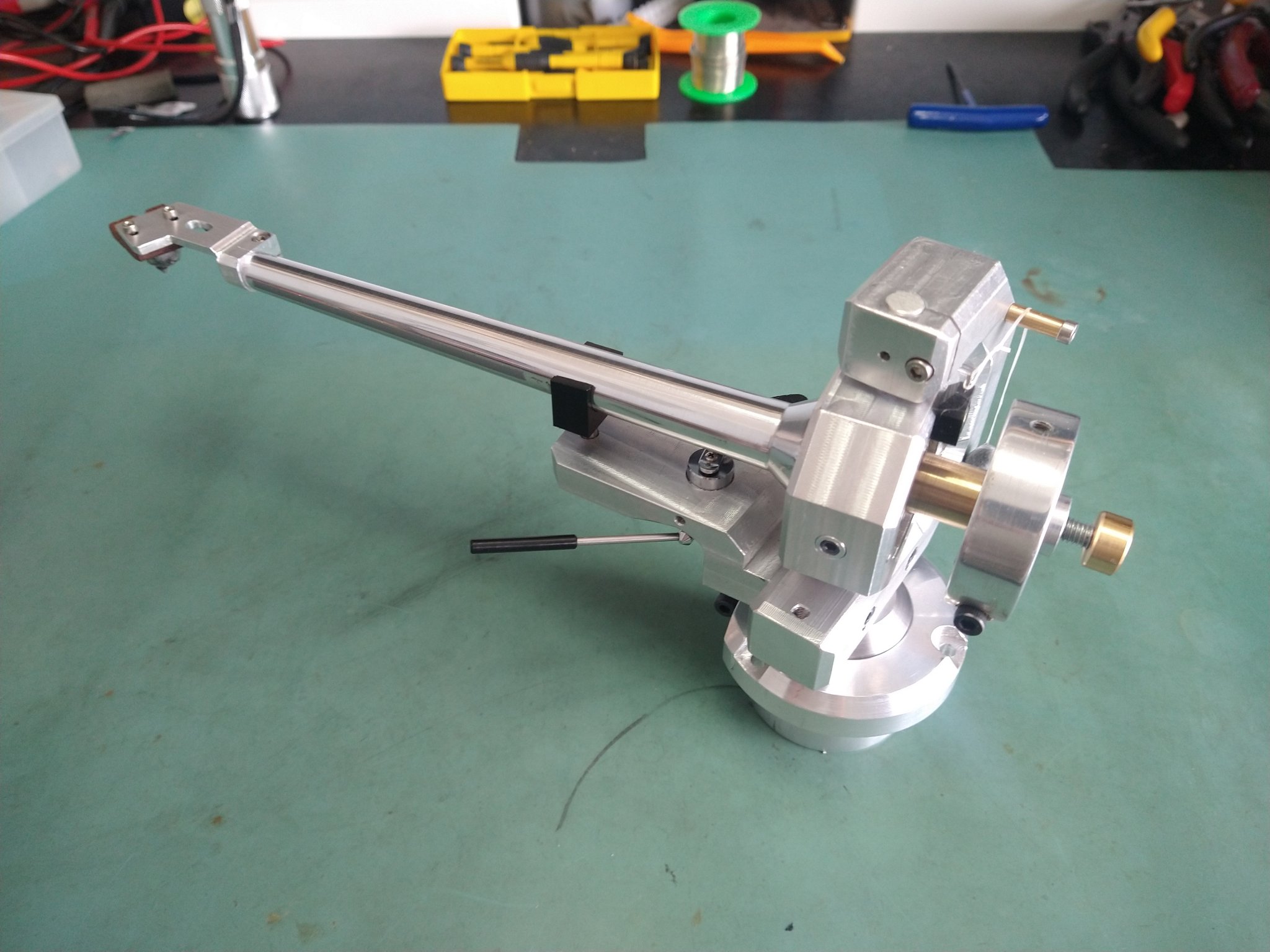

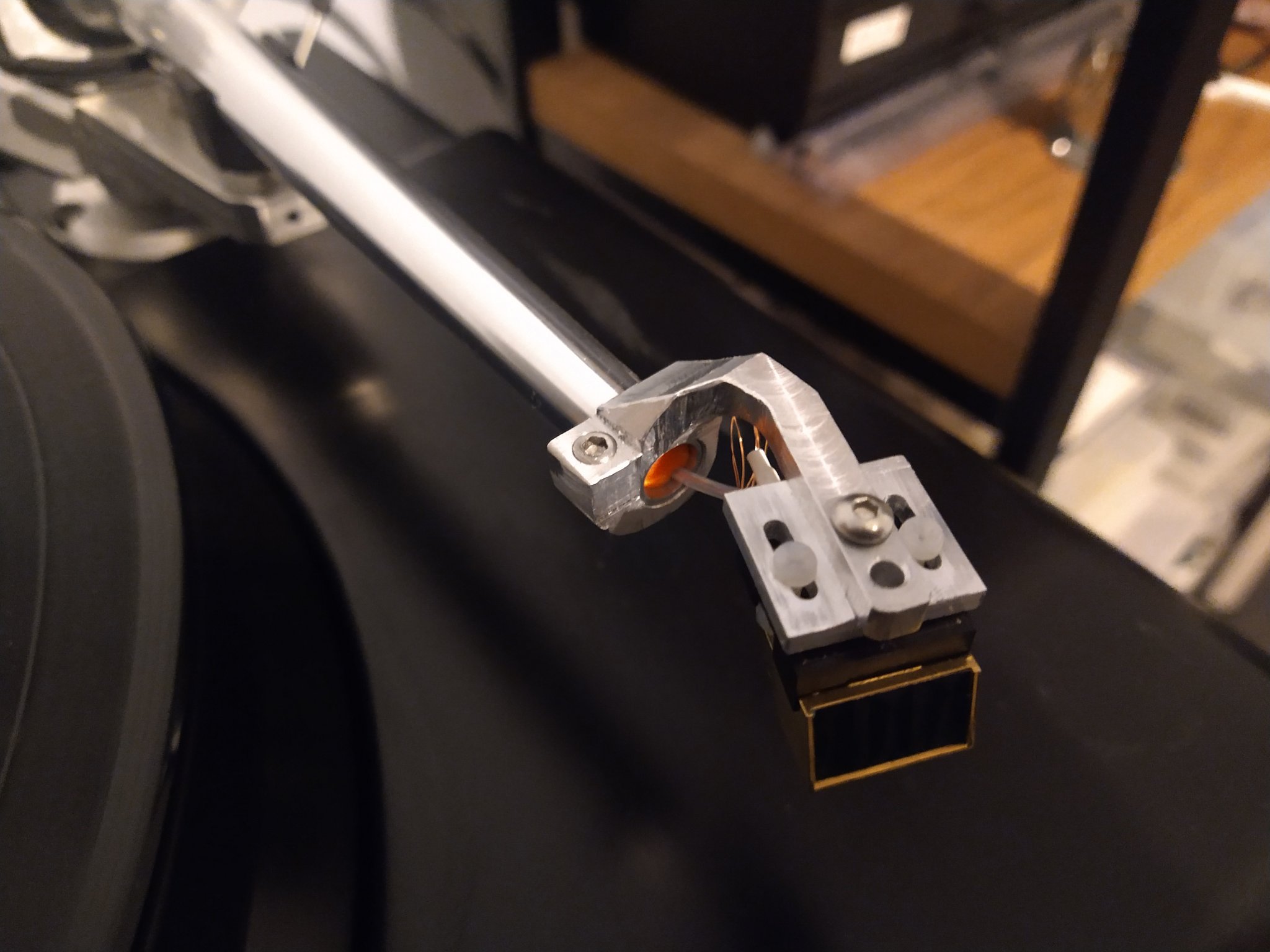

Here are a couple of pics of the arm. I've modified the headshell to make swapping cartridges quick and easy. You can see in the 2nd and 3rd pics there is a removable plate. The cart is aligned in the plate and can be removed and replaced without having to re-align.

just to update,i ordered 4 new pivots from trupoint,i'll post a photo when they arrive.

Which pivots did you end up buying

- Home

- Source & Line

- Analogue Source

- DIY 4 point pivoting arm