I would require a hardware and software change to the SG4, but you could do it manually by adding a switch to ground to pin 2 of both output chip amps on the MA3D. When pin 2 is at ground, the chip amp is disabled and the outputs are high impedance and the motor should turn freely by hand. You would have to open this switch before exiting standby and close the switch before entering standby mode.

Hi!

Does anyone know where to buy I2C interface board with PCF-8574A chip?

I've already bought a few unspecified ones on amazon.

Where should be either 8574 or 8574A. But they all ended up without A.

Does anyone know where to buy I2C interface board with PCF-8574A chip?

I've already bought a few unspecified ones on amazon.

Where should be either 8574 or 8574A. But they all ended up without A.

Why do you specifically need the 'A' variant? The latest version of the SG4 chip, v1.05, (in stock) works with both the 8574 and 8574A.

Yes? I bought chips from Seth Hensel in October. And I have chips version 1.04.

Therefore, I need 8574A. Can I try desoldering 8574 chips from existing I2C boards and installing 8574A in their place?

Therefore, I need 8574A. Can I try desoldering 8574 chips from existing I2C boards and installing 8574A in their place?

I would think that would work. I also couldn't find the A version but am using 1.05 v firmware and it works fine.Yes? I bought chips from Seth Hensel in October. And I have chips version 1.04.

Therefore, I need 8574A. Can I try desoldering 8574 chips from existing I2C boards and installing 8574A in their place?

Please PM to me. I can't apparently due to newbie restrictions..The latest version of the SG4 chip, v1.05, (in stock) works with both the 8574 and 8574A.

Have done.Please PM to me. I can't apparently due to newbie restrictions..

Hi to all,

Is here somebody who can fix my SG-4 or MA-3D, I don't know which is bad. Digital board is not lightin no more and motor is not turning.

I will pay to someone to fix it because I'm not in electronicks, somebody else built the boards for me.

Thanks in advance,

Ben

Is there really nobody who can help. Comon people, please. If my request is against forum rules, please say so.Hi to all,

Is here somebody who can fix my SG-4 or MA-3D, I don't know which is bad. Digital board is not lightin no more and motor is not turning.

I will pay to someone to fix it because I'm not in electronicks, somebody else built the boards for me.

Thanks in advance,

Ben

I will send my controler to you to fix it and when is done, just tell me know how much I owe you.

Please help! I can't listen to my LP's and that hurts.

Thanks to Pyramid and the forum members for my inspiration and guidance to upgrade my TD125 MkII. I thought I would share my long journey. Started with stock Thorens TD125 MkII and removed motor, all control electronics, and optical systems. Replaced the motor with AA-BLWS-231S motor, along with SG-4 (v1.05) and MA-3D amplifier to drive the motor. You will see in the pictures that I put the turntable in a new plinth and built a separate box for all the electronics with a pull-out drawer to expose the control. I also designed an optical reflective sensor under the TD125 sub-platter, looking at the strobe pattern on the sub-platter. I then designed an Arduino based frequency measuring and display module to monitor and display the frequency of the signal coming from the optical sensor. If the turntable is turning at 33.33rpm then the signal from the optical sensor/stobe pattern will be 120Hz. The software integrates for 4 seconds then displays the frequency and the turntable rpm. All the electronics operate from a 30W-15V power supply. I also machined a new tonearm bronze mounting plate and Delrin tonearm board for the SME 3009 Series II Improved tonearm. The tonearm was completly rebuild and rewired by SME Tonearems in Toronto, Canada. You will also notice the labels which I had custom made. The first picture is the completed turntable.

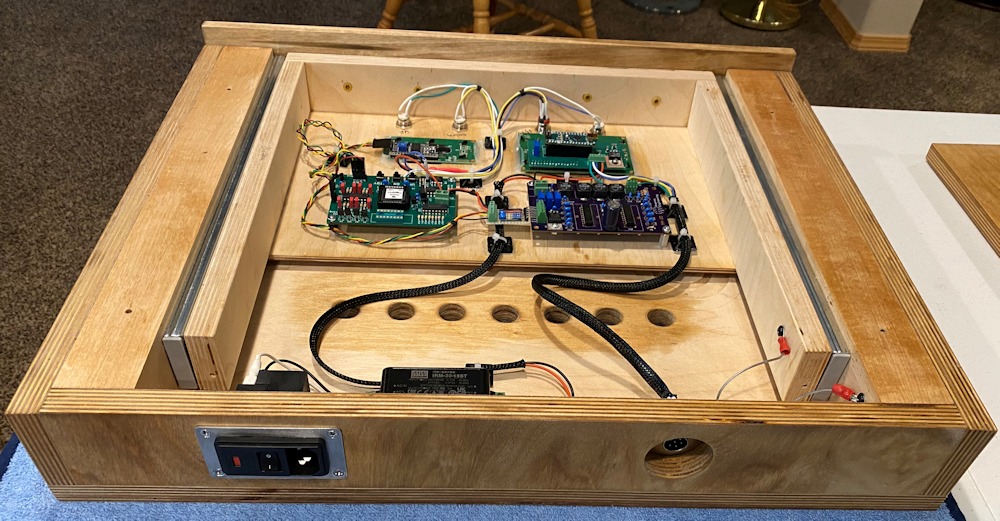

This is the control electronics looking at the bottom of the control box.

The control box from the top & front.

The view of the control buttons and displays with drawer opened.

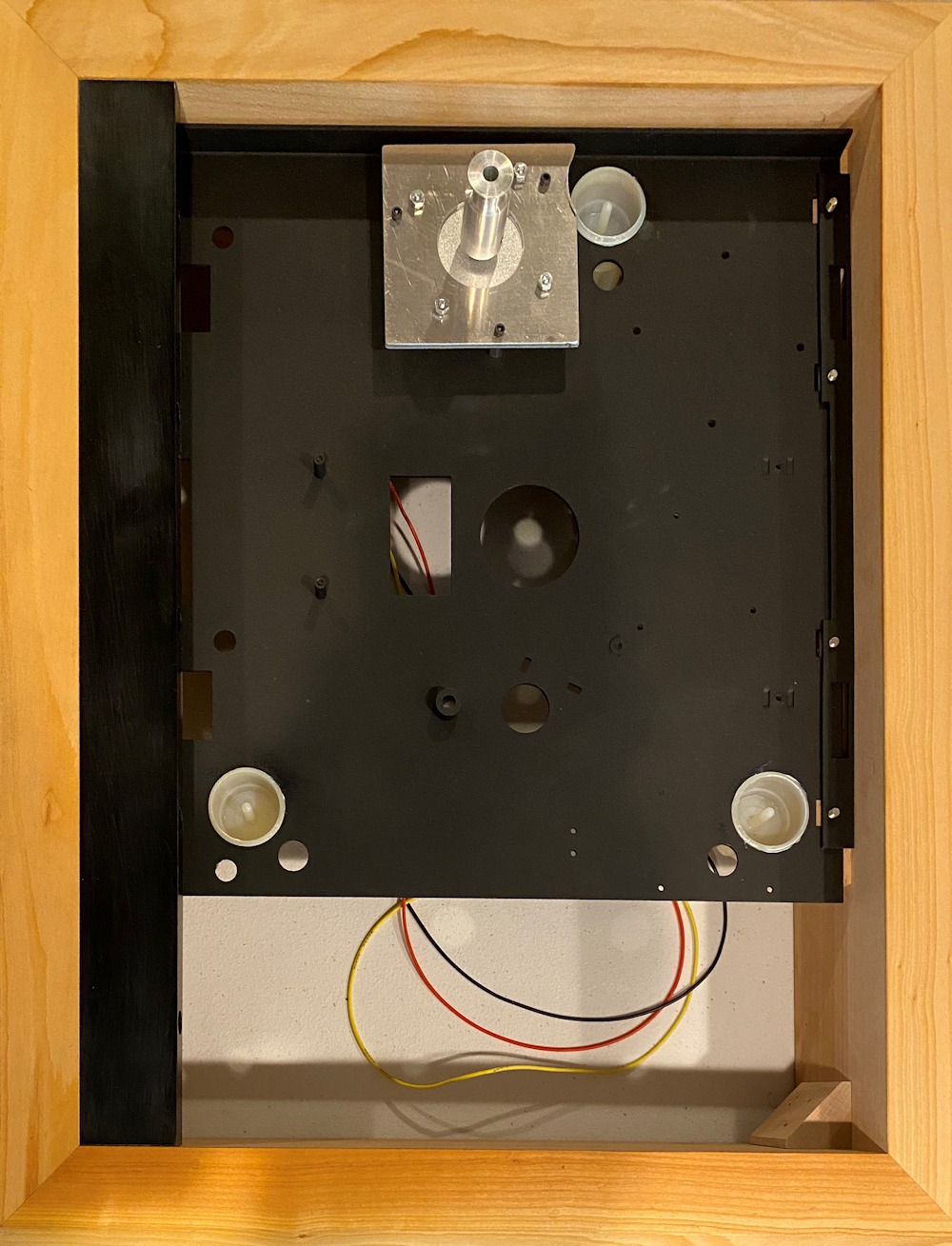

The new plinth and the TD125 sub-chassis and the AA motor and new pulley.

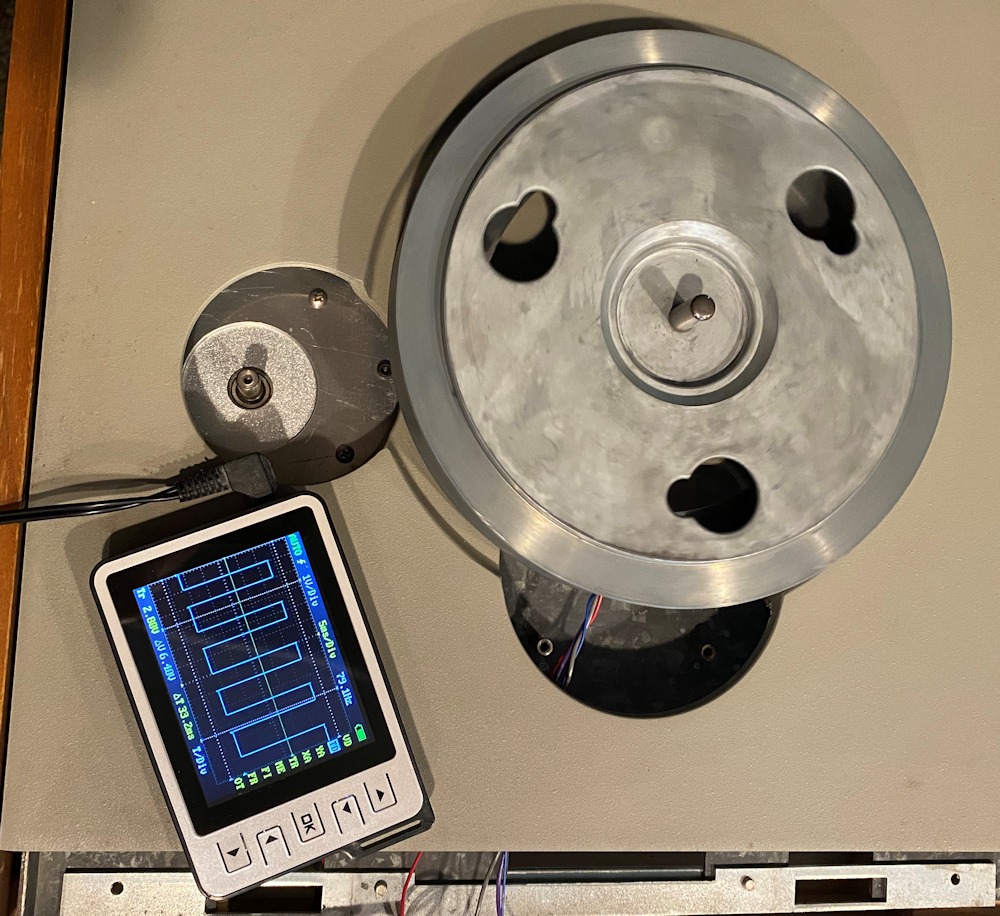

The completed system operating.

This is the control electronics looking at the bottom of the control box.

The control box from the top & front.

The view of the control buttons and displays with drawer opened.

The new plinth and the TD125 sub-chassis and the AA motor and new pulley.

The completed system operating.

Hi pcneal,

Was there a problem with the original motor? PM me please.

I have one with a bent shaft (I didn't do it).

-Chris

Was there a problem with the original motor? PM me please.

I have one with a bent shaft (I didn't do it).

-Chris

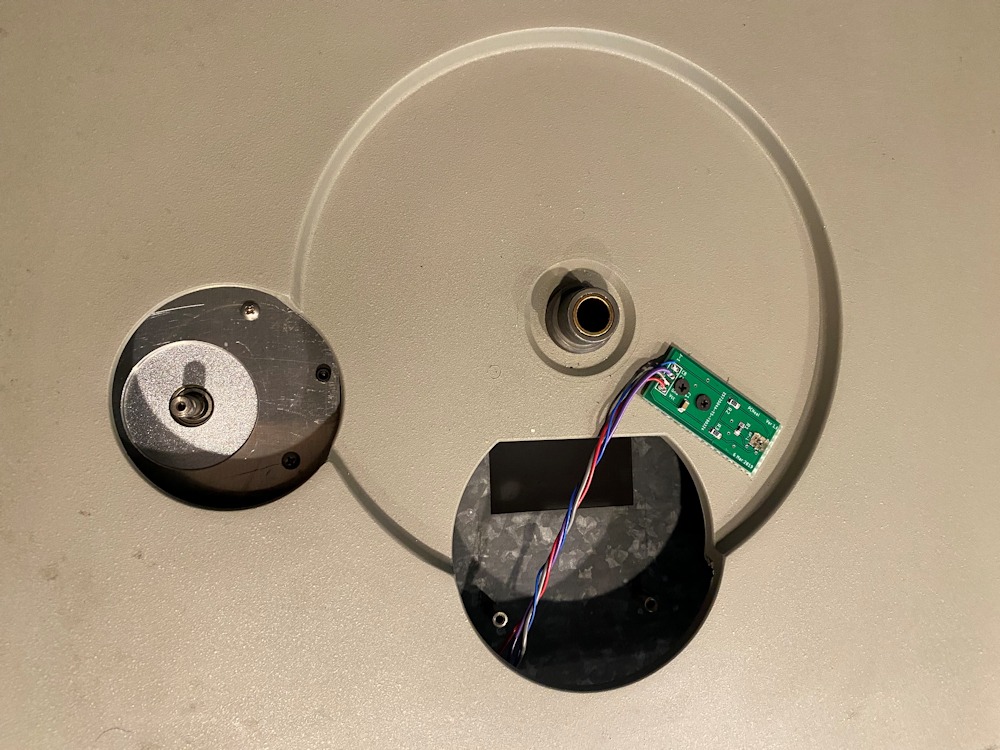

I inadvertenly omitted the picture of the optical sensor.

The sensor output displayed on minature o-scope.

The sensor output displayed on minature o-scope.

Chris,Hi pcneal,

Was there a problem with the original motor? PM me please.

I have one with a bent shaft (I didn't do it).

-Chris

I have used 3 of the BLWS-231S motors and all have been perfect.

-Parris

- Home

- Source & Line

- Analogue Source

- DIY 4 Phase Sinewave Generator for Turntable Motor Drive