Allways there

Thanks Ger, i am looking forward to our next conversation.

Calvin i think had a bad experience with rhino, so many variables and i wish there were pics of his stats. the thing with rhino, if you make a mistake, i have something to take it back to plane metal in five minutes, so nothing is ruined.

I really need pics, this wil bug me all day long tommorow if i dont have something tonight, that should be obvious by now. Mavric

Thanks Ger, i am looking forward to our next conversation.

Calvin i think had a bad experience with rhino, so many variables and i wish there were pics of his stats. the thing with rhino, if you make a mistake, i have something to take it back to plane metal in five minutes, so nothing is ruined.

I really need pics, this wil bug me all day long tommorow if i dont have something tonight, that should be obvious by now. Mavric

Yes I agree,as I have never worked wih the stuff, you work with it all the time.

And it too was my conclusion that it may be an applicator error.

It is one thing to just spray it on something and another to spray it for a particular application as you have made a few test runs as well to dial in the right setting for your applicating system and this particular application.

Calvin, If you do get a chance,please do take some electrical tests as I am curious about the qualities of the material itself anyhow.

I had similar issues with my powder coater as well.

Like uneven thickness on one end due to fluidect behavior while curing in the oven to rolling the product up into a tube causing micro cracks in the coating.

Hopfully it will be something simple that you and your applicator can correct, too prove it to be a viable alternative coating method. jer

And it too was my conclusion that it may be an applicator error.

It is one thing to just spray it on something and another to spray it for a particular application as you have made a few test runs as well to dial in the right setting for your applicating system and this particular application.

Calvin, If you do get a chance,please do take some electrical tests as I am curious about the qualities of the material itself anyhow.

I had similar issues with my powder coater as well.

Like uneven thickness on one end due to fluidect behavior while curing in the oven to rolling the product up into a tube causing micro cracks in the coating.

Hopfully it will be something simple that you and your applicator can correct, too prove it to be a viable alternative coating method. jer

Last edited:

I agree as well, just wish i had a picture. mine looked well, ok, but it was a test. make sure youu use the "zoom in button" on the lower left, Calvin, did yours look anything like this? Ypu have me so curiuos, want to know what went wrong.

Kind regards, Mav

Kind regards, Mav

Attachments

Last edited:

keep posting,mavric, as I would to see start to finished in its entirety with no interuptions,too.jer

posting

I am sorry i have not been posting lately, my wife is very sick. So please do not erase anything, it takes alot of time to post pics with descriptions, still have around 100 more pics to go.

Ger, this is funny, got another flat screen, but my friend wants me to fix it, same problem, hmmm, I might have some extra income to help my wife(doctors) bills.

Gotta go, will try later will she can rest. Mav

I am sorry i have not been posting lately, my wife is very sick. So please do not erase anything, it takes alot of time to post pics with descriptions, still have around 100 more pics to go.

Ger, this is funny, got another flat screen, but my friend wants me to fix it, same problem, hmmm, I might have some extra income to help my wife(doctors) bills.

Gotta go, will try later will she can rest. Mav

Take care!

Dear Mav and partner,

I wish you both much strength and hope she'll be better soon.

Take care buddy.

All the best.

Audiofanatic

Dear Mav and partner,

I wish you both much strength and hope she'll be better soon.

Take care buddy.

All the best.

Audiofanatic

Tell her I said she better get better, and I hope she gets feeling better soon.

Give me a jingle later if you get the chance as I have some news too. jer

Give me a jingle later if you get the chance as I have some news too. jer

Very imortant!

Charlie used a beam spitter behind his panels. I used a 4" round 40" tall PVC in front of my stats, the dispersion is unbelievable, you take it away and it sounds so dirrectional, i will take a pic. ugly as heck, a pic is worth a thoussand words, just need anopther one. Mav

Charlie used a beam spitter behind his panels. I used a 4" round 40" tall PVC in front of my stats, the dispersion is unbelievable, you take it away and it sounds so dirrectional, i will take a pic. ugly as heck, a pic is worth a thoussand words, just need anopther one. Mav

Jer, you nailed the problem AGAIN, that buzzing is gone completely, chrystal clear. Thanks again, Mav.🙂

Good show,like I said "I don't know why it is like that" but I have feeling as to why but until I find out for sure I know that method works,I'm glad!

Now you can sit back and really enjoy those fabulous speakers that you have produced. Someday soon I will be able to do the same.Very very soon. jer

Now you can sit back and really enjoy those fabulous speakers that you have produced. Someday soon I will be able to do the same.Very very soon. jer

Jer, you nailed the problem AGAIN, that buzzing is gone completely, chrystal clear. Thanks again, Mav.🙂

Hey that's great news! What was causing the hum?

Hi Mavric,

Good to hear that you have solved the problem.

By the way, what exactly was the problem and how did you solve it?

Wachara C.

Good to hear that you have solved the problem.

By the way, what exactly was the problem and how did you solve it?

Wachara C.

Jer and I spoke and agreed it was a ground loop somwhere in my set up, isolated at the crossover. since it uses a computer cord and i have spares, simple suggestion was to pull the ground out of the plug, worked!

The downside is that i have no protection from thunder storms, so i put all my equip on a power strip and just unplug it when not in use.

I cannot describe how great these sound, my sweet spot will acoomodate at least three people before your db level and imaging didapates, i am still tring to bring home the RTA meter, just benn busy at work, which supecedes my memory, as work is hard to come by these days(thanks to obama).

A two week headache and a five minute fix, Jer, hats off to you my friend. I am rocking!!!Mavric

Thanks for the follow up.

The downside is that i have no protection from thunder storms, so i put all my equip on a power strip and just unplug it when not in use.

I cannot describe how great these sound, my sweet spot will acoomodate at least three people before your db level and imaging didapates, i am still tring to bring home the RTA meter, just benn busy at work, which supecedes my memory, as work is hard to come by these days(thanks to obama).

A two week headache and a five minute fix, Jer, hats off to you my friend. I am rocking!!!Mavric

Thanks for the follow up.

RTA meter

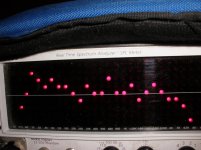

I have it now, Audio Control, have both RTA and SPL mic, trying to something with pink noise, any other suggestions??? i had a test cd, went to or above 20K and popped some fuses, no biggie, just cant watch the meter and clipping at the same time. here is a pick of white noise, i think, no label on the disk.

I have it now, Audio Control, have both RTA and SPL mic, trying to something with pink noise, any other suggestions??? i had a test cd, went to or above 20K and popped some fuses, no biggie, just cant watch the meter and clipping at the same time. here is a pick of white noise, i think, no label on the disk.

Attachments

I have it now, Audio Control, have both RTA and SPL mic, trying to something with pink noise, any other suggestions??? i had a test cd, went to or above 20K and popped some fuses, no biggie, just cant watch the meter and clipping at the same time. here is a pick of white noise, i think, no label on the disk.

I'm guessing that dip centered at the 630 hz band is the dipole cancellaton-- you probably have your crossover frequency set a bit higher than mine (275 hz). It will sound a lot fuller once you get that dipole cancellation EQ'd. Pushing a test tone to 20khz into ESL's will really tax the amps-- fortunately, actual music typically doesn't contain all that much energy in the highest octaves.

I have it now, Audio Control, have both RTA and SPL mic, trying to something with pink noise, any other suggestions??? i had a test cd, went to or above 20K and popped some fuses, no biggie, just cant watch the meter and clipping at the same time. here is a pick of white noise, i think, no label on the disk.

Hi Mavric,

You might try measuring just the ESL by itself, no woofer. Then measure the woofer by itself, no ESL. This should give you a clue if the dip around 630 is just the dipole roll off of the ESL, or an interaction between the woofer and ESL.

I'm not sure how you have your crossovers set up, but you might find that if you swap the phase of the woofer, the dip at 630 may fill in.

meter test

here are some base test, i am still trying to get the cross over adjested. there is a sharp roll off at or around 600 hz, @ 24db, the only problem is that these are old amps, 4 ohm MAX, clipping allerts go crazy when i put a little power( around 100watt, but the impiedence load?????) at very high frequency pops fuses. here are some pics of a traditional speaker a set up, notice there are ho high end, same song as a "conrrol".

here are some base test, i am still trying to get the cross over adjested. there is a sharp roll off at or around 600 hz, @ 24db, the only problem is that these are old amps, 4 ohm MAX, clipping allerts go crazy when i put a little power( around 100watt, but the impiedence load?????) at very high frequency pops fuses. here are some pics of a traditional speaker a set up, notice there are ho high end, same song as a "conrrol".

Attachments

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Planars & Exotics

- different ideas for ESL panels