@Celsius, it would be better if you do 7 primaries, where the first and last have 3 layers each and the 5 inner ones have 6 layers each. This way leakage inductance is minimized. Secondaries have 3 layers each. Cannot do this trick starting and finishing with a secondary, unless you change the design.

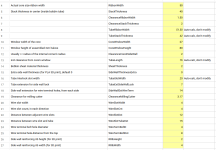

I have done the calculation starting from the core size and estimated a hand-made coil former but I don't know if a standard coil former will be ok.

I have considered 78 mm layer width and 22 mm total height (including the insulators). If your coil former is different need to take it into account.

I have done the calculation starting from the core size and estimated a hand-made coil former but I don't know if a standard coil former will be ok.

I have considered 78 mm layer width and 22 mm total height (including the insulators). If your coil former is different need to take it into account.

EDIT: sorry you need to do 2 layers for the first and last primaries and 4 layers for the inner 5 primaries. Total 24.

Celsius, If you meant the feeling of subjectively better high frequency response for nanocrystalline core, that is something else. But if talk about subjective sound perception, we need to clarify it in the discussion. Otherwise, a reader might get confused, where in this example, high frequency response is mostly understood as the bode plot of the transformer.

50AE: But maybe amorphous core has a similar response, this is theory but I know you have tried nanocrystalline core as well, please what has been your experience?

LinuxGuru, I only show that I read, for me Core material are important only for timbre, all cores correctly design have a good bandwidth for humans.

HIB have a very good timbre

Amorphous the same

Nano Cristalline also

We are speaking about small details maybe the same difference between Guarneri, Cremona and Stradivarius,

but here I see that theory is the winner. I do not know why Finemet was developed.

HIB have a very good timbre

Amorphous the same

Nano Cristalline also

We are speaking about small details maybe the same difference between Guarneri, Cremona and Stradivarius,

but here I see that theory is the winner. I do not know why Finemet was developed.

For sure not for audio transformers 😀 .I do not know why Finemet was developed

Finemet (nanocrystalline) is developped being high permeability, low loss material as an alternative for the older well known materials like permalloy.

Permalloy (in different grades) has nickel as main material content. Nickel as raw material is rather rare and therefore much more expensive.

Law of economics play their role.

maybe was used in audio by same esoteric properties 🙂

this is why I think this is a good thread, we can read different opinions about sound with this core

this is why I think this is a good thread, we can read different opinions about sound with this core

For high-efficient low-loss switching power supplies and inverters (e.g. wind/solar), often as replacement for ferrite.I do not know why Finemet was developed.

@Celsius, primary have so high number of turns that on frequencies of several KHz+ core is almost out of equation. Coil design and Eddy current loss matters much more for HF response, unless you use junk iron from scrapyard.

BTW the eddy current. I've just received nanocrystalline C-cores and confirmed my assumptions - cutting makes winding strips shorted. Cut surface look like solid metal.

I remember that vacuumschmelze with their C-cores performed some kind of pickling process to break this shortcuts but I can't find it now.

Yes, cut C-cores are always shorted at the cutting, including HiB-C cores. This decreases permeability to some extent. It is easily tested using the probes of a DMM ohmmeter across the cut surface.

It can be somewhat remedied by etching the surface, for example by applying hydrochloric acid. I have tested this successfully. If the cores are to be glued by anaerobic glue, some of them contain etching agents that do a 2 in 1 job.

It can be somewhat remedied by etching the surface, for example by applying hydrochloric acid. I have tested this successfully. If the cores are to be glued by anaerobic glue, some of them contain etching agents that do a 2 in 1 job.

I've made quick test with 40 turns without gap because I need to order custom bobbins for this CC-400 cores (already decided to this size).

Measured inductance 10,00mH.

AL value= L/N^2 =6250

Core relative permability

ur = AL * LFe / 0.4 * Pi * AFe

from manufacturer

LFe=30.6cm

Afe=11.15cm2

so ur = 13650

with 1000 turns theoretically L=6,25H

with 3000 turns 56,25H

Also I need to check B-H curve because I have to be sure that they sold me NC not amorph cores 😉

Measured inductance 10,00mH.

AL value= L/N^2 =6250

Core relative permability

ur = AL * LFe / 0.4 * Pi * AFe

from manufacturer

LFe=30.6cm

Afe=11.15cm2

so ur = 13650

with 1000 turns theoretically L=6,25H

with 3000 turns 56,25H

Also I need to check B-H curve because I have to be sure that they sold me NC not amorph cores 😉

Yes its nano because amorphous will have mu around 1200 - 2500 only. When nano and amorph C-cores immersed into the glue and cut, permeability drops sharply.Also I need to check B-H curve because I have to be sure that they sold me NC not amorph cores

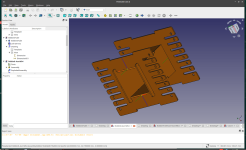

I made a freeware bobbin design tool with FreeCAD where you can enter dimesnions and get source files (DXF/SVG/PDF/STL), ready for milling, laser cut or 3D print. Need some spare time and few days to make a video instruction on Youtube.I've made quick test with 40 turns without gap because I need to order custom bobbins for this CC-400 cores (already decided to this size).

Attachments

Awesome! Can you share this?I made a freeware bobbin design tool with FreeCAD where you can enter dimesnions and get source files (DXF/SVG/PDF/STL), ready for milling, laser cut or 3D print. Need some spare time and few days to make a video instruction on Youtube.

Yes, in a few days, need to make video manual on Youtube.Awesome! Can you share this?

while we're on the subject of the bobbin - does bobbin material (dielectric constant) makes any siginificant difference? FR4 has value 3.9-4.7, PTFE about 2 but probably isn't as strong as FR4

I don't think capacitance 1st layer - core will make any significant difference in this particular case. Go with 2.0 - 2.5mm FR4.while we're on the subject of the bobbin - does bobbin material (dielectric constant) makes any siginificant difference? FR4 has value 3.9-4.7, PTFE about 2 but probably isn't as strong as FR4

Effective capacitance depends on the voltage between core and the first layer. If the first layer is a primary layer with high ac potential the dielectric properties of the bobbin are worth considering but you can forget about teflon, pure teflon is too soft, and with the high amount of glassfiber needed to make it mechanical usable it will loose the dielectric advantages. Look at polypropylene or polystyrene instead. Those have better dielectric properties, but offçourse they can not compete with the mechanical or thermal properties of FR4.

It just came to me, If you know how to make a bobbin out of a flat panel, you could make the sideplates out of sturdy FR4 and use the translucent part of a CD case (polystyrene, Dk ~2.7) for the inner parts that are against the core and hold it all together.

It just came to me, If you know how to make a bobbin out of a flat panel, you could make the sideplates out of sturdy FR4 and use the translucent part of a CD case (polystyrene, Dk ~2.7) for the inner parts that are against the core and hold it all together.

Last edited:

- Home

- Amplifiers

- Tubes / Valves

- Design of C-core nanocrystalline GM-70 output transformer