Take to a motor repair shop and have it vacum varnish impregnated.

It is possible to DIY with a pressure cooker, but a SWAT team may show up on your doorstep.

It is possible to DIY with a pressure cooker, but a SWAT team may show up on your doorstep.

Take to a motor repair shop and have it vacum varnish impregnated.

It is possible to DIY with a pressure cooker, but a SWAT team may show up on your doorstep.

Ok, thanks that's an idea. But i live in Portugal and don't know anything about motor repair shop's... are you talking about a mechanic 1:1 cars? Maybe not...

I should do it myself because i can squeze the metal parts on the transformer by hand and the hum goes 50% less, so i could try these next things... (advice me if any is wrong or bad, or ok...)

-I read somewhere to spray it with epoxy spray paint... what parts am i spraying? Can spray the inside of it? Or only the outside? Those wires inside tremble/shake and they make the iron board's ratlle, because if i squeze the metal parts it hums 50%less.

-Put on the hole of the wood speaker (where the amp rack sits) a car audio dampening material like Stinger Road Kill or Dynamat for the vibration hum not pass to much for the woofer cabinet...i notice hum coming from the speakers... the hum could be a 50hz hum that is a subwoofer frequency...??

-Maybe spray it or brush it with varnish myself... All the inside i can and the outside? (metal pieces outside?)

-Put a wood piece each side on the transformer and bolt it till the max i can to sequeze the metal pieces for not rattle to much. And glue the bolts/screws with RC glue locticte blue or red to secure it because of the vibration!

-Use an insolatium varnish air drier...like this:

-Maybe all of that. That should make it 50% less rattle hum?

Or any more ideas....

Last edited:

We used to soak in polyurethane varnish (as in dangle them on a string) transformers (mainly SMPS and TV line components but normal mains ones too ) to try and quiet them. Heat the transformer first in an oven (say to 60C) and then flood it. As it cools and contracts it will tend to pull the varnish into the gaps. Leave it submerged for several minutes. No guarantee of success though but worth a try. Spraying or painting won't do a thing.

We used to soak in polyurethane varnish (as in dangle them on a string) transformers (mainly SMPS and TV line components but normal mains ones too ) to try and quiet them. Heat the transformer first in an oven (say to 60C) and then flood it. As it cools and contracts it will tend to pull the varnish into the gaps. Leave it submerged for several minutes. No guarantee of success though but worth a try. Spraying or painting won't do a thing.

Ok, i will hack it then! I am desesperate so i will do anything. I wonder why Samson sells this this way? Maybe because the speakers are half the price of Mackie's! And being PA audio it doesn't matter... but this is used on a home! 🙂 where silence is the goal!

So what do i have to grab the transformer out:

-Remove those screws on the metal frame and and stick with the yellow plastic on hand only for dipping on varnish?? But the what about the cables? can't hooven them? or can being 60ºc? melting the plastic?

Or just remove all the assembly with the 4 screws on the botton, and dip the transformer with the metal plates on varnish?

Thanks already!

60C shouldn't harm anything. It will be designed to run at temperatures well over that at full load. Just undo the bolts that secure it to the chassis and tie a bit of string through one of the holes to dangle it.

60C shouldn't harm anything. It will be designed to run at temperatures well over that at full load. Just undo the bolts that secure it to the chassis and tie a bit of string through one of the holes to dangle it.

ok, i will remove the 4 screws and remove the plug's of the wires from the board.

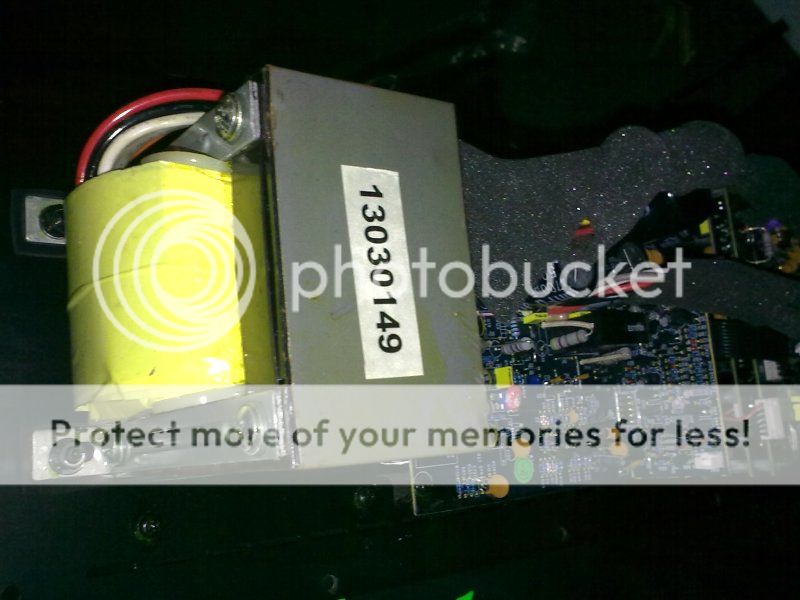

So i will have the same thing of the picture less the motherboard.

In the wooven how much time should i leave in there at 60c? (the plug's may melt?)

And how much time to submerge it on the varnish?

And after the swim pool how much time to cure it on the air, before i put it again on the motherboard?

Ok, thanks!

Well this viedos shows it all....

Build an electric transformer (DIY) - YouTube

Now i understand. And mine on the Samson seens like that!

And where is the epoxy or varnish? on the transformer wire? It will shake for sure, right?

anyway... i should have in hand just that like the video on the end put it on the hooven and then dip in on varnish.

Any ideia of the varnish? Polyertane, why?

Build an electric transformer (DIY) - YouTube

Now i understand. And mine on the Samson seens like that!

And where is the epoxy or varnish? on the transformer wire? It will shake for sure, right?

anyway... i should have in hand just that like the video on the end put it on the hooven and then dip in on varnish.

Any ideia of the varnish? Polyertane, why?

Polyurethane is probably as good as any (tough and not to brittle) and leave it submerged for several minutes. Then just let it dangle and drip dry. Upside down is probably best as the varnish wont cover the mounting brackets. When you refit it, scrape the mountings so that any earthing is preserved. You can use it as soon as it stops dripping.

60C is a ball park figure. Nothing should melt at that temperature but remember many domestic ovens will overshoot the set temperature by a large amount. 60C on an oven could well go nearer 100C and then cut off and cool back down to around 40 before it cuts in again.

60C is a ball park figure. Nothing should melt at that temperature but remember many domestic ovens will overshoot the set temperature by a large amount. 60C on an oven could well go nearer 100C and then cut off and cool back down to around 40 before it cuts in again.

Polyurethane is probably as good as any (tough and not to brittle) and leave it submerged for several minutes. Then just let it dangle and drip dry. Upside down is probably best as the varnish wont cover the mounting brackets. When you refit it, scrape the mountings so that any earthing is preserved. You can use it as soon as it stops dripping.

60C is a ball park figure. Nothing should melt at that temperature but remember many domestic ovens will overshoot the set temperature by a large amount. 60C on an oven could well go nearer 100C and then cut off and cool back down to around 40 before it cuts in again.

So for the oven how many minutes should i let the transformer in there?

On the varnish bucket i should let it soak 30 mintues? allright?

Can i do this 3 times for better or is a waste of time? and heating the first layer of varnish is not a godd idea?

Peel off the tape covering the windings (per your pic?) without damaging them. It's prob been varnished once already as you might see, so you are adding to it.

You can prob have a small amount of water separately in the oven as a gross indicator of temperature (I assume).

You can prob have a small amount of water separately in the oven as a gross indicator of temperature (I assume).

"It's prob been varnished once already "

I doubt it.

Most shops that rewind electric motors have the capacity to vacuum varnish.

Heat, combined with pressure, can do it at home.

An alternate method:

http://www.diyaudio.com/forums/tubes-valves/143932-cheap-easy-vacuum-impregnation.html

I doubt it.

Most shops that rewind electric motors have the capacity to vacuum varnish.

Heat, combined with pressure, can do it at home.

An alternate method:

http://www.diyaudio.com/forums/tubes-valves/143932-cheap-easy-vacuum-impregnation.html

So for the oven how many minutes should i let the transformer in there?

On the varnish bucket i should let it soak 30 mintues? allright?

Can i do this 3 times for better or is a waste of time? and heating the first layer of varnish is not a godd idea?

Its hot enough when you can't hold it for more than a couple of seconds. You can soak it for as long as you want but give it enough time for the varnish to penetrate.

Its hot enough when you can't hold it for more than a couple of seconds. You can soak it for as long as you want but give it enough time for the varnish to penetrate.

Ok, for the heat then.

I can leave it for a night in varnish soak?

Now one last question. For not wasting any more money right now i have at home 2liters of wood varnish. This varnish is for garden wood's. Can i use it for the transformer, or should look for the polyetane type because the transformer is metal?

My only concern is the cables because i do not know if all are plug's, maybe i have to cut some and ultimatly solder back. Not a easy job for a newbie on those things... but we will see.

-I see a plug here, but need to know the other cables if they have plugs...and need to get rid of the foam! (FIRE on oven)

The transformer should be quieter on the end.... i guess. Part of the rattle hum desapear if i squeze by hand the metal parts on the transformer, so i have faith!

Let me know about the wood varnish is a good solution or total bad for metal! 😀

Last edited:

I don't know if "wood varnish" would be OK or not tbh. Sorry.

I asked that because googling it with images "polyurethane varnish" gives me bottles of pictures of that "polyurethane varnis" with wood with brush's!

https://www.google.pt/search?q=poly...wICgBw&ved=0CAkQ_AUoAQ&biw=1024&bih=601&dpr=1

Polyurethane is for wood... but I didn't/don't know if there is any other kind of "wood varnish" that may not have been suitable.

Just get it dipped and hung up to dry 😀

Just get it dipped and hung up to dry 😀

And by experience it should be quiter then, after that soak?

By this pic... i see that it got already varnish...on the metal plates secruing it...

right?

I got 2 speakers of those and all since day one brought new, make the hum of transformer (mechanical hum).

By the next week i will do the soak on varnish, let it cure for one day, and then test it.

Since i identified the problem i have high hopes that solves at least 50% of the hum.

The dc trick with caps an bridge did noting on the ac cable...🙁

By this pic... i see that it got already varnish...on the metal plates secruing it...

right?

I got 2 speakers of those and all since day one brought new, make the hum of transformer (mechanical hum).

By the next week i will do the soak on varnish, let it cure for one day, and then test it.

Since i identified the problem i have high hopes that solves at least 50% of the hum.

The dc trick with caps an bridge did noting on the ac cable...🙁

Last edited:

Ok, wife today was not home until 23.00h so when i arrived from work, the first thing was atacking the Samson Active Speaker, Lol!!

-Screwed the board out...

-Removed the transformer, it was easy!

-Cooked it at 60ºc about 25minutes

-And now it's soaked on varnish for about 15minutes.

In the next 15 minutes i will remove it.

Any opinion for a second coat, or not? Not necessary or could be good? Or worse?

An if a second coat is good, do i have to cook it on the oven again when dry?

Tanks for all 😱

I maked a video of the transformer hum... it's uploading now....

-Screwed the board out...

-Removed the transformer, it was easy!

-Cooked it at 60ºc about 25minutes

-And now it's soaked on varnish for about 15minutes.

In the next 15 minutes i will remove it.

Any opinion for a second coat, or not? Not necessary or could be good? Or worse?

An if a second coat is good, do i have to cook it on the oven again when dry?

Tanks for all 😱

I maked a video of the transformer hum... it's uploading now....

Last edited:

Ok, now the transformer is out of the soup varnish 😀 , dipping out and air hanging...

And the video is this...

300 Watts rms transformer mechanical hum - YouTube

-I guess the camara did not record the 50hz sound of the mecanichal hum, because on the video it's hard to notice... but in real person it's upsetting....

And the video is this...

300 Watts rms transformer mechanical hum - YouTube

-I guess the camara did not record the 50hz sound of the mecanichal hum, because on the video it's hard to notice... but in real person it's upsetting....

Last edited:

- Home

- Amplifiers

- Solid State

- DC filter