Sorry, couldn't see the pic in your post.

Here's a scrap of red oak bare, and with 1 quick wipe of maloof.

I'm def going to use this the next oak project I do.

I always liked the way oak stains myself.

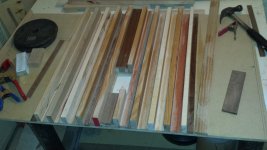

I have some red in the mix. I posted a picture back a couple posts. I wasnt clear on that so Ill take over the apology. I will update tomorrow or next.

I've used "Danish Oil" a lot. Very good.

Depends entirely on the wood and what your intended result needs to be.

Test first, finish the final piece later...

I also like "Waterlox" which is a polymerized linseed oil based finish.

For super gloss, "Gym Lox".

These are both solvent based.

Personally I do not like poly finishes, they always look plastic...

The hard wax with a buff can be excellent on woods like Rosewood, fwiw.

Open grain woods and closed grain woods need different approaches.

Maple/Cherry, closed - Oak, Mahagony, open.

_-_-

Depends entirely on the wood and what your intended result needs to be.

Test first, finish the final piece later...

I also like "Waterlox" which is a polymerized linseed oil based finish.

For super gloss, "Gym Lox".

These are both solvent based.

Personally I do not like poly finishes, they always look plastic...

The hard wax with a buff can be excellent on woods like Rosewood, fwiw.

Open grain woods and closed grain woods need different approaches.

Maple/Cherry, closed - Oak, Mahagony, open.

_-_-

I've used "Danish Oil" a lot. Very good.

Depends entirely on the wood and what your intended result needs to be.

Test first, finish the final piece later...

I also like "Waterlox" which is a polymerized linseed oil based finish.

For super gloss, "Gym Lox".

These are both solvent based.

Personally I do not like poly finishes, they always look plastic...

The hard wax with a buff can be excellent on woods like Rosewood, fwiw.

Open grain woods and closed grain woods need different approaches.

Maple/Cherry, closed - Oak, Mahagony, open.

_-_-

I agree about the plastic look of some poly, so I currently use wipe-on only (very thin coat) and a satin sheen.

Thanks for the Waterlox tip. I'll have to try it, but it's really expensive!

Whatever you decide, I'd get a scrap piece, and run a test on it to see how it comes out.

In a previous project, I tried a few different combinations to see which I liked the best. Some different oils, shellac and lacquer.

Agree that poly can look plastic, a common complaint for it.

If you want a furniture grade finish, you could try a danish oil, than a lacquer finish over that. You can get lacquer in gloss, semi or satin finishes, depending on preference. You can get spray cans of lacquer, best for small jobs. Otherwise you'd need a sprayer.

I used deft lacquer in the blue cans. If their color scheme is the same, the blue is the "real" lacquer. Green was water soluble stuff. Lacquer is very flammable so I would do it outside, side of my house.

Sand with very fine grit sandpaper in between coats. I would use a few light coats.

Good luck

Randy

In a previous project, I tried a few different combinations to see which I liked the best. Some different oils, shellac and lacquer.

Agree that poly can look plastic, a common complaint for it.

If you want a furniture grade finish, you could try a danish oil, than a lacquer finish over that. You can get lacquer in gloss, semi or satin finishes, depending on preference. You can get spray cans of lacquer, best for small jobs. Otherwise you'd need a sprayer.

I used deft lacquer in the blue cans. If their color scheme is the same, the blue is the "real" lacquer. Green was water soluble stuff. Lacquer is very flammable so I would do it outside, side of my house.

Sand with very fine grit sandpaper in between coats. I would use a few light coats.

Good luck

Randy

I'm not for the plastic look myself. A couple of the water based stains get a deep lush consistent coverage on tight grains like maple. I don't know why that is, does it seep into the grains better than oil bases? I've had oil stains that almost rubbed right off and have such poor penetration in spots while taking really well in others.

I liked using the water base then a coat or two of low gloss shellac to seal it. It looks quite nice but doesn't compare to the danish oil finishes I've seen. It almost seems too easy to achieve a professional looking finish with the stuff.

I bought a clear watco spray bomb to test once the humidity lets. I wasn't always happy with spray on clears in the past but I have not tried the watco brand. Some of them tend to dry matte and look unprofessional. I was thinking if I do do multi finishes that will be less likely to leach opposed a thinned brush on clear.

Thanks for the pointers. I will absolutely test everything prior to committing.

I dampened grains here to accentuate them but it looked nicer in person.

I liked using the water base then a coat or two of low gloss shellac to seal it. It looks quite nice but doesn't compare to the danish oil finishes I've seen. It almost seems too easy to achieve a professional looking finish with the stuff.

I bought a clear watco spray bomb to test once the humidity lets. I wasn't always happy with spray on clears in the past but I have not tried the watco brand. Some of them tend to dry matte and look unprofessional. I was thinking if I do do multi finishes that will be less likely to leach opposed a thinned brush on clear.

Thanks for the pointers. I will absolutely test everything prior to committing.

I dampened grains here to accentuate them but it looked nicer in person.

Attachments

They're putting Watco in a spray can??

Doubt that it is actually Watco, since the gov't doesn't like us to spray VOCs at all.

Best buy the can...

You can buy powedered Analine Dyes (use gloves and respirators) and dye the Watco if you like. The dyes are sold by pro woodworking sources, and maybe online these days. I've done that, it works gangbusters.

Heck you can dye the Waterlox or almost any other finish with that stuff.

_-_-

Doubt that it is actually Watco, since the gov't doesn't like us to spray VOCs at all.

Best buy the can...

You can buy powedered Analine Dyes (use gloves and respirators) and dye the Watco if you like. The dyes are sold by pro woodworking sources, and maybe online these days. I've done that, it works gangbusters.

Heck you can dye the Waterlox or almost any other finish with that stuff.

_-_-

Ah, looks like they've merely "expanded" the scope of the vintage brand name - that's lacquer...

Another great brand of finishing products is Mohawk

Lacquer Aerosols, Waterborne Stains, Leather Cleaners & More - Mohawk Finishing

I've used their M102-320 and 335 aerosols on small projects with great success. They are a petro-chemical based VOC product with all the neceesary warnings and precautions - ventilation, respirator mask, etc., but IMHO this category of clear top coat beats any water-based / urethane material for natural look, and yes I've tried more than a couple of the latter type- both OTC consumer and industrial /commercial types.

Lacquer Aerosols, Waterborne Stains, Leather Cleaners & More - Mohawk Finishing

I've used their M102-320 and 335 aerosols on small projects with great success. They are a petro-chemical based VOC product with all the neceesary warnings and precautions - ventilation, respirator mask, etc., but IMHO this category of clear top coat beats any water-based / urethane material for natural look, and yes I've tried more than a couple of the latter type- both OTC consumer and industrial /commercial types.

The Waterlox (allegedly) Original MSDS:

https://www.waterlox.com/images/products/Product-MSDS-TB-5284.pdf

https://www.waterlox.com/images/products/Product-MSDS-TB-5284.pdf

You guys are lucky. I live in Cal, and we can only use low emissions finishes now.

So very restricted in what we can use, and they have reformulated so that some of the new formulas that meet the regulations are not as good.

I think I had good luck with oil, then shellac than lacquer.

Just shellac over oil looks nice too, but shellac won't protect as well. But for something like a speaker maybe good enough.

Randy

So very restricted in what we can use, and they have reformulated so that some of the new formulas that meet the regulations are not as good.

I think I had good luck with oil, then shellac than lacquer.

Just shellac over oil looks nice too, but shellac won't protect as well. But for something like a speaker maybe good enough.

Randy

Try your Sherwin-Williams dealer. They carry real lacquer in their "commercial finishes" department.

Try three coats of Danish Oil, the last two being clear. The first could be clear, or coloured.

See what that looks like.

See what that looks like.

Try three coats of Danish Oil, the last two being clear. The first could be clear, or coloured.

See what that looks like.

Close to my original idea that I will stay with with or without a tint. That I may experiment with or just choose one and go with it.

The audio table that was finished danish/clear looked so brilliant in its simplicity of design being understated with big chunky pieces with what looked like 3/4" round overed surfaces that showcased the beautiful grain patters in the black walnut. Gosh it sounds like Id make love to it with all this gushing. But seriously though it wreaked of quality that was part in thanks to the finish. And it was indeed low gloss thats more in my cup of tea as well.

Try three coats of Danish Oil, the last two being clear. The first could be clear, or coloured.

See what that looks like.

Yep, like that a lot.

A good tip is to wet sand with 400 or 600 while the oil is wet.

Much good advice here but a lot of generalities as well. Finishes colored or clear need to be specific to the wood species as well as usage.

Open pored woods like Pine and Oak and even Cherry tend to splotch with oil-based stains, even "clear" Watco, as Lionseed oil increasingly darkens whatever wood it touches over time. These need pre-treatment with sealers sold as "conditioners" at home centers.

I'm not familiar with water based "stains" mentioned to do a good job on Maple; perhaps these are actually dyes like Quality Wood Finishing Supplies since 1994 - Homestead Finishing Products Transtint which may be mixed with either water or alcohol. I prefer the alcohol dilute which is easier to control. Homestead has excellent tutorial-like info from Jeff Jewitt, a well-known conservator.

I find that Sherwin-Williams "Wood Classics" satin varnish is just excellent on Walnut or Cherry over a few 1 1/2 lb. cut coats of Amber Shellac. The shellac helps bring out the color of the wood and reduces splotching. I pad on the shellac whether as a base or a topcoat and apply the varnish, surprisingly, with a foam brush.

On exotics like the Padauk used for my 45 amp it's straight shellac: 12 coats over as many days. The first 4 3 lb. cut lightly sanded with 250 Garnet just to level then 0000 steel wool for the next 4 and 4 more of 1 1/2 lb. After a month, paste wax applied and buffed with a micro fibre cloth.

The Walnut mono-blocks are 2 coats of 1 1/2 lb. cut of amber shellac to bring out the color then 4 coats, each one sanded with 250 then 400 grit garnet, Wood Classics Satin finish. After a month, the varnish is waxed using a pad of 000 steel wool dipped in mineral spirits, squeezed out of the excess and used to apply Minwax paste wax buffed with the micro fibre cloth.

Open pored woods like Pine and Oak and even Cherry tend to splotch with oil-based stains, even "clear" Watco, as Lionseed oil increasingly darkens whatever wood it touches over time. These need pre-treatment with sealers sold as "conditioners" at home centers.

I'm not familiar with water based "stains" mentioned to do a good job on Maple; perhaps these are actually dyes like Quality Wood Finishing Supplies since 1994 - Homestead Finishing Products Transtint which may be mixed with either water or alcohol. I prefer the alcohol dilute which is easier to control. Homestead has excellent tutorial-like info from Jeff Jewitt, a well-known conservator.

I find that Sherwin-Williams "Wood Classics" satin varnish is just excellent on Walnut or Cherry over a few 1 1/2 lb. cut coats of Amber Shellac. The shellac helps bring out the color of the wood and reduces splotching. I pad on the shellac whether as a base or a topcoat and apply the varnish, surprisingly, with a foam brush.

On exotics like the Padauk used for my 45 amp it's straight shellac: 12 coats over as many days. The first 4 3 lb. cut lightly sanded with 250 Garnet just to level then 0000 steel wool for the next 4 and 4 more of 1 1/2 lb. After a month, paste wax applied and buffed with a micro fibre cloth.

The Walnut mono-blocks are 2 coats of 1 1/2 lb. cut of amber shellac to bring out the color then 4 coats, each one sanded with 250 then 400 grit garnet, Wood Classics Satin finish. After a month, the varnish is waxed using a pad of 000 steel wool dipped in mineral spirits, squeezed out of the excess and used to apply Minwax paste wax buffed with the micro fibre cloth.

Attachments

Last edited:

Bill I find oak very easy to stain without conditioner, one of the easiest in fact, ash also very easy. Maple and birch can be blotchy and they would be considered tight grain wood. Think of wood as a handful of drinking straws, some wood have a variety of size strays the larger ones suck up more stain faster and darken quicker.

You can make your own conditioner to partialy seal the pores prier to staining 1 part boiled linseed to about 8 parts varsol/paint thinner.

When using shellac i never mix it stronger then 1 1/2-2lb cut and if it isnt to humid can apply it all in one day one coat after another only waiting a hour or so when i need to sand or scrap between coats.

You can make your own conditioner to partialy seal the pores prier to staining 1 part boiled linseed to about 8 parts varsol/paint thinner.

When using shellac i never mix it stronger then 1 1/2-2lb cut and if it isnt to humid can apply it all in one day one coat after another only waiting a hour or so when i need to sand or scrap between coats.

Solids are of course quite difference from veneers, but I do a lot of the latter with Cherry and walnut, find they both take stains or "clear" lacquer / post catalyzed conversion varnish ( ML Campbell Krystal) quite nicely.

- Status

- Not open for further replies.

- Home

- Design & Build

- Construction Tips

- Danish oil plus a clear?