Just had a quick glance at your facebook profile. Wow! with quality like that you don't need to find a market. It will find you!

If anyone tells me that the Chinese high end hasn't quite arrived yet. I say too late.

Oh yes it has! I mean it in the nicest way but if this is what happens when you get "bored". I hope you do so on a regular basis.

I want some of that gear just to look at it! Very impressive.

If anyone tells me that the Chinese high end hasn't quite arrived yet. I say too late.

Oh yes it has! I mean it in the nicest way but if this is what happens when you get "bored". I hope you do so on a regular basis.

I want some of that gear just to look at it! Very impressive.

Last edited:

I'm just a small time hobbyist/freelance, I have a bad habit of doing odd stuffs that people normally don't do. And so recently I been reading on the basic method of making paper. Still wondering what kind of the liquid mixture they use with the paper pulp.

Still haven't got the time to test out Honeycomb inductors on loudspeaker crossover even though I have the winding machine for it which end up winding for my fullrange VC.

Still haven't got the time to test out Honeycomb inductors on loudspeaker crossover even though I have the winding machine for it which end up winding for my fullrange VC.

Last edited:

hmmm paper

On that note I had a friend in Melbourne who designed speakers with active electronics and featured Feastrex drivers handling the meat of most of the audio spectrum. Sent them on loan to an audio show in Shanghai. When they came back they didn't sound quite the same. Turns out the paper on the boutique drivers had become hydroscopic. So to me a critical aspect would be how to prevent this by treating the paper without sacrificing the exqusite tone that so many love on a great fullranger. Tannoy I believe use a multi ton press on the pulp to compress the fibres. A local manufacturer of PA gear did some research at Melbourne University. He found that the density of modern cellulose pulp didn't match the denser cellulose pulp used on vintage drivers.

On that note I had a friend in Melbourne who designed speakers with active electronics and featured Feastrex drivers handling the meat of most of the audio spectrum. Sent them on loan to an audio show in Shanghai. When they came back they didn't sound quite the same. Turns out the paper on the boutique drivers had become hydroscopic. So to me a critical aspect would be how to prevent this by treating the paper without sacrificing the exqusite tone that so many love on a great fullranger. Tannoy I believe use a multi ton press on the pulp to compress the fibres. A local manufacturer of PA gear did some research at Melbourne University. He found that the density of modern cellulose pulp didn't match the denser cellulose pulp used on vintage drivers.

This he deduced was the reason for so many guitarists preferring the tone of a vintage speaker. The slower growth rate of the vintage wood that produced the pulp. Me thinks paper isn't the answer but as Voxative employ wood veneer that they claim is 100 times stiffer than paper pulp. If you do go paper I would suggest a hybrid of hemp carbon fibre & pulp from vintage salvaged wood. Stick that in a 200+ ton press and find your own propriety moisture stabilising formulation. The paper manufacturers keep their formulations a closely guarded secret.

Unfortunately.

On that note I had a friend in Melbourne who designed speakers with active electronics and featured Feastrex drivers handling the meat of most of the audio spectrum. Sent them on loan to an audio show in Shanghai. When they came back they didn't sound quite the same. Turns out the paper on the boutique drivers had become hydroscopic. So to me a critical aspect would be how to prevent this by treating the paper without sacrificing the exqusite tone that so many love on a great fullranger. Tannoy I believe use a multi ton press on the pulp to compress the fibres. A local manufacturer of PA gear did some research at Melbourne University. He found that the density of modern cellulose pulp didn't match the denser cellulose pulp used on vintage drivers.

On that note I had a friend in Melbourne who designed speakers with active electronics and featured Feastrex drivers handling the meat of most of the audio spectrum. Sent them on loan to an audio show in Shanghai. When they came back they didn't sound quite the same. Turns out the paper on the boutique drivers had become hydroscopic. So to me a critical aspect would be how to prevent this by treating the paper without sacrificing the exqusite tone that so many love on a great fullranger. Tannoy I believe use a multi ton press on the pulp to compress the fibres. A local manufacturer of PA gear did some research at Melbourne University. He found that the density of modern cellulose pulp didn't match the denser cellulose pulp used on vintage drivers. This he deduced was the reason for so many guitarists preferring the tone of a vintage speaker. The slower growth rate of the vintage wood that produced the pulp. Me thinks paper isn't the answer but as Voxative employ wood veneer that they claim is 100 times stiffer than paper pulp. If you do go paper I would suggest a hybrid of hemp carbon fibre & pulp from vintage salvaged wood. Stick that in a 200+ ton press and find your own propriety moisture stabilising formulation. The paper manufacturers keep their formulations a closely guarded secret.

Unfortunately.

Last edited:

That is sad for an expensive driver cone turning that way. But untreated paper always sound the most natural. I seen people go to the extend of painting varnish or lacquer on fostex. but that introduce more weight to the cone.

Yes indeed I have washi paper from Japan, they do have the tendency to absorb environmental moisture easily. Thats why there is another paper which I was looking at called Lokta, which is durable and resistance to enviroment.

https://en.wikipedia.org/wiki/Lokta_paper

Environment is changing especially the weather, no doubt the quality of the pulp production getting effected by it.

But I have seen veneer without lacquer or varnish will get moldy.

Maybe pure carbon fiber cone for fullrange 😀

If I going the route in producing my own paper, that means I have to design the mold too.... 😱

Yes indeed I have washi paper from Japan, they do have the tendency to absorb environmental moisture easily. Thats why there is another paper which I was looking at called Lokta, which is durable and resistance to enviroment.

https://en.wikipedia.org/wiki/Lokta_paper

Environment is changing especially the weather, no doubt the quality of the pulp production getting effected by it.

But I have seen veneer without lacquer or varnish will get moldy.

Maybe pure carbon fiber cone for fullrange 😀

If I going the route in producing my own paper, that means I have to design the mold too.... 😱

LOL! Me thinks if anybody can find that magic formulation for fullrange cone material I'm replying to that person right now.

I will try & dig up the paper R&D from that PA & Guitar speaker guy for you & pm you. Lokta sounds promising & interesting. High altitude and lattitude trees & shrubs tend to be slow growers forming the denser cellular structure you seek.

I will try & dig up the paper R&D from that PA & Guitar speaker guy for you & pm you. Lokta sounds promising & interesting. High altitude and lattitude trees & shrubs tend to be slow growers forming the denser cellular structure you seek.

The problem with paper is the modern methods of production that rely heavily on solvents & acids & they tend to eat themselves slowly over time. That is why many pages on books a few decades old tend to yellow & disintegrate. Hemp fibre production tends to avoid those manufacturing techniques or not need them.

Traditional paper making methods tend to avod this but are labour intensive. Carbon fibre is excellent but the only one that seems to have mastered it's sonics is Audax. As I see from your loudspeaker taste for your multi way speakers you would tend to agree. The best sounding Scanspeaks are cabon/pulp hybrids.

Sourcing vintage wood for pulp is a finite dwindling resource.

Lokta is a renewable that might indeed supply you what you need.

Being highly regulated by the Nepalese Authorities supply in any quantity might still be an issue. Other possibilities are Papyrus, Banana fibre & don't laugh Nomex. I also see you are a Mundorf fan. Me too Lastly apologies for thinking you were Chinese when you are from Singapore.

Traditional paper making methods tend to avod this but are labour intensive. Carbon fibre is excellent but the only one that seems to have mastered it's sonics is Audax. As I see from your loudspeaker taste for your multi way speakers you would tend to agree. The best sounding Scanspeaks are cabon/pulp hybrids.

Sourcing vintage wood for pulp is a finite dwindling resource.

Lokta is a renewable that might indeed supply you what you need.

Being highly regulated by the Nepalese Authorities supply in any quantity might still be an issue. Other possibilities are Papyrus, Banana fibre & don't laugh Nomex. I also see you are a Mundorf fan. Me too Lastly apologies for thinking you were Chinese when you are from Singapore.

Last edited:

I love threads like this!

Do you know how you can plot the BxL (x)-curve in FEMM? If not, since you already have a coil in the simulation, just click the area-tool (next to the line tool) in the view-module and click the coil. Then select the integratl tool, and you can get the Lorentz force as absolute in R and Z-directions. So if you move the coil by moving the actual geometry in the drawing, you can run several simulations to get the force-plot.

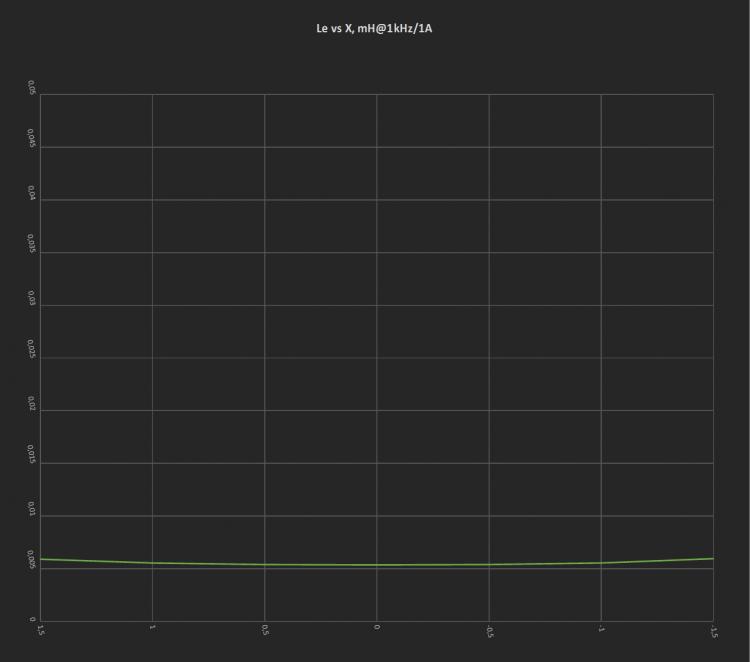

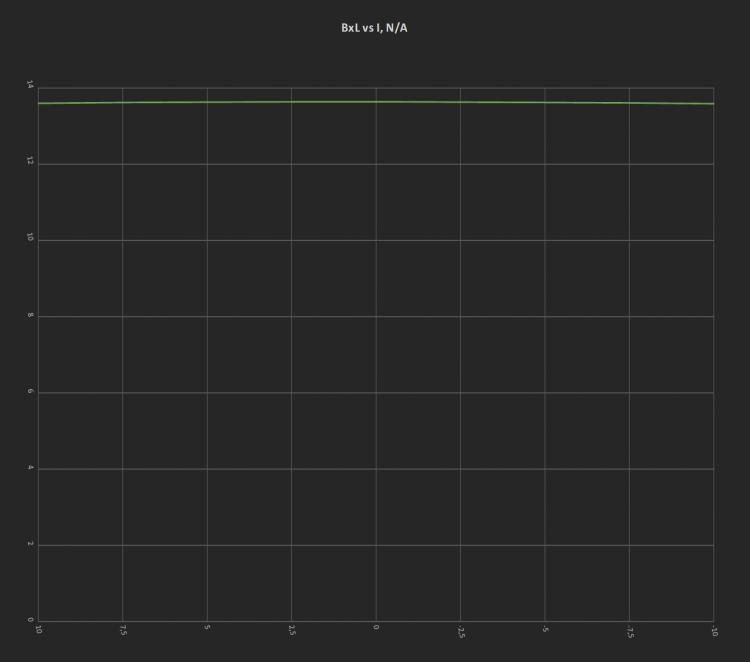

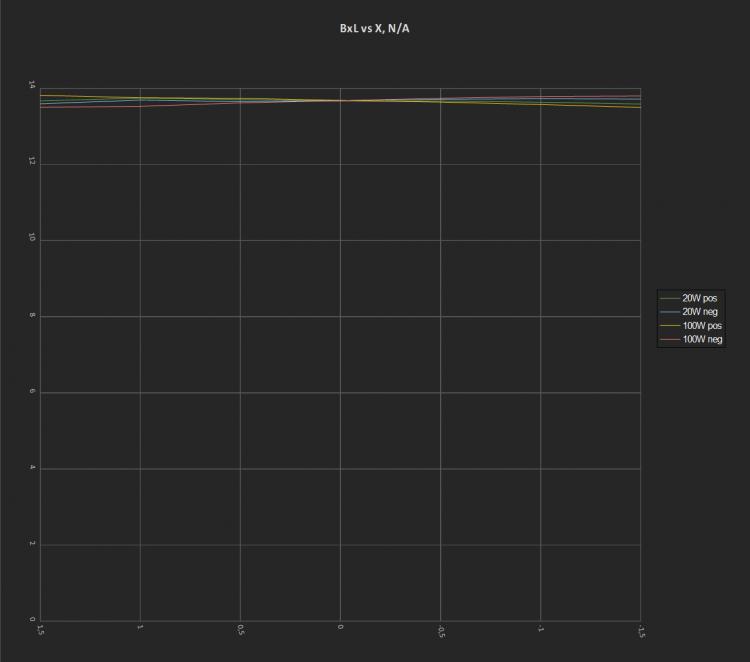

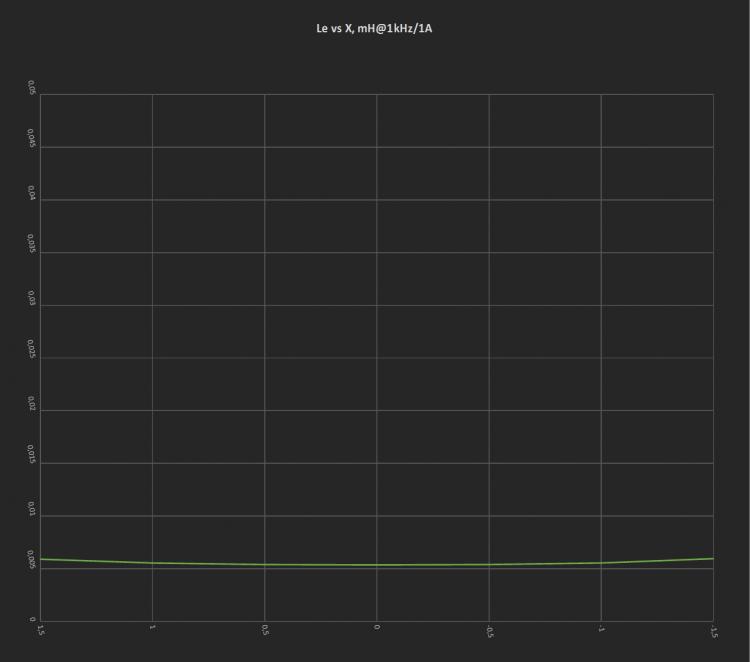

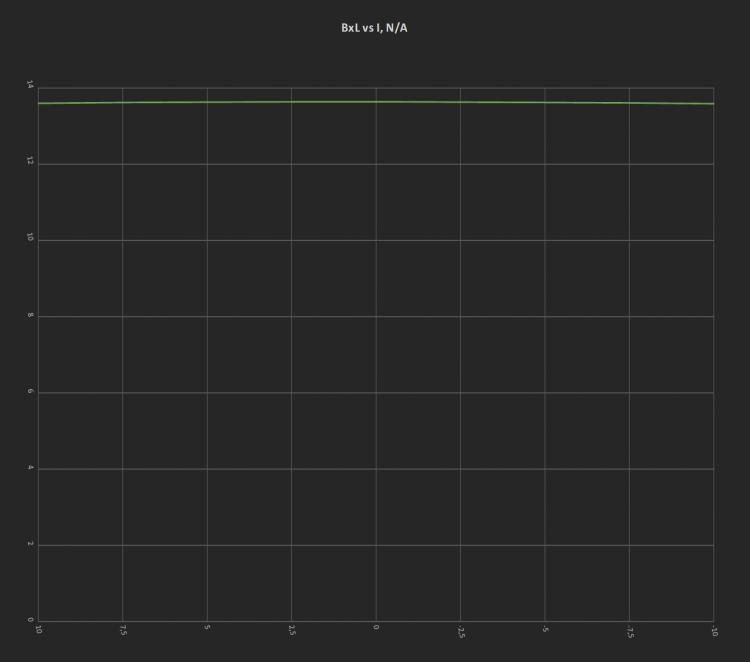

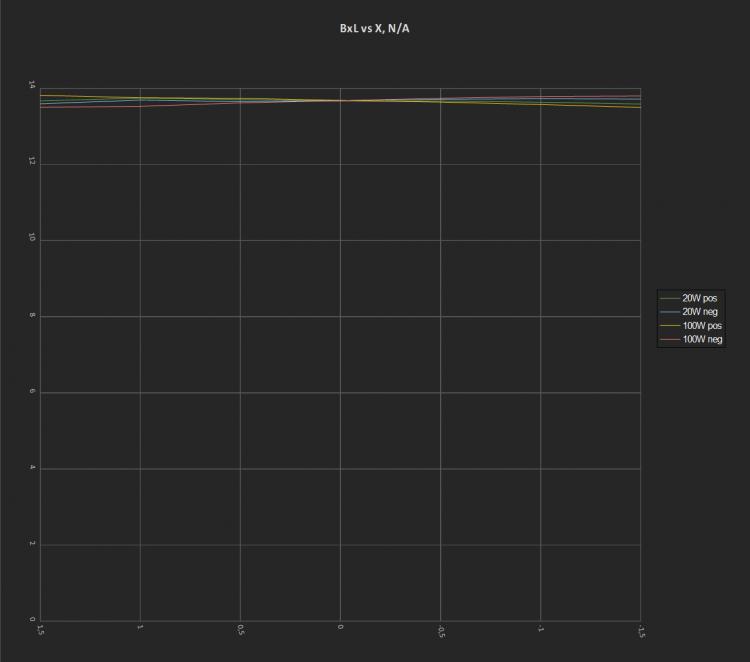

This method is also useful to plot BxL(i) and combined multi curve BxL(x) at different power levels and both polarities, as well as Le (x) (which I believe you would want to see on a FR driver). Here are some examples I have been working on a midrange driver, and I did these plots for it:

Notice the extremely low inductance. I can not wait to see how reliable FEMM is on this point.

I also ran some simulations on another driver with a more traditional topology. It had a 235% error at max current. This plot will reveal the DC-component of the motor.

And here you see the BxL curve at two given power levels and both positive and negative current direction. The 235% error got even worse in this test.

The curves are only simple excel/calc diagrams.

Sorry for OT, did not mean to hijack your thread.

I noticed your control edges to get the magnet positioned right. But if you have access to a 3D printer, why not print a non magnetic guide for it? You could also make them out of aluminium, and make negative groves in the steel parts to control the aluminium that in turn controls the magnet.

Do you know how you can plot the BxL (x)-curve in FEMM? If not, since you already have a coil in the simulation, just click the area-tool (next to the line tool) in the view-module and click the coil. Then select the integratl tool, and you can get the Lorentz force as absolute in R and Z-directions. So if you move the coil by moving the actual geometry in the drawing, you can run several simulations to get the force-plot.

This method is also useful to plot BxL(i) and combined multi curve BxL(x) at different power levels and both polarities, as well as Le (x) (which I believe you would want to see on a FR driver). Here are some examples I have been working on a midrange driver, and I did these plots for it:

Notice the extremely low inductance. I can not wait to see how reliable FEMM is on this point.

I also ran some simulations on another driver with a more traditional topology. It had a 235% error at max current. This plot will reveal the DC-component of the motor.

And here you see the BxL curve at two given power levels and both positive and negative current direction. The 235% error got even worse in this test.

The curves are only simple excel/calc diagrams.

Sorry for OT, did not mean to hijack your thread.

I noticed your control edges to get the magnet positioned right. But if you have access to a 3D printer, why not print a non magnetic guide for it? You could also make them out of aluminium, and make negative groves in the steel parts to control the aluminium that in turn controls the magnet.

@theaudiopath

No worries mate... I'm Chinese in Singapore but my chinese sucks. Matter of fact my conversation in chinese is quite poor, I still have trouble finding the correct words to describe an item. LOL

And of course native Chinese in Singapore is totally different from China, we are not the same. If you have a chance here in Singapore you can tell the difference apart by the mentally, behaviour is totally different, and most of the time we don't eat the same food.😀 BTW I speak a little bit of malay. I would say Singapore chinese is more closer to Hong Kong or Taiwan 😉

Back to the paper, it will be great to have someone making and manufacturing paper to know just bit more in the in(s) and out(s) on the solvent they use on their paper pulp.

Papyrus is also in the back of my mind, haven't found the suitable form of papyrus I find online yet. And Lokta, probably I be flying over to Nepal next year to find out more on their paper. 🙂

@Snickers-is

I did create a coil of X amount of turns in FEMM and get the result, also the script created for the FEMM to move the VC up and down and the results. I think I have the results but never save them down in my excel. I could run again tonight and use a finer incremental of 0.2mm for the VC linear movement. I really hate the scripting in FEMM.

No worries mate... I'm Chinese in Singapore but my chinese sucks. Matter of fact my conversation in chinese is quite poor, I still have trouble finding the correct words to describe an item. LOL

And of course native Chinese in Singapore is totally different from China, we are not the same. If you have a chance here in Singapore you can tell the difference apart by the mentally, behaviour is totally different, and most of the time we don't eat the same food.😀 BTW I speak a little bit of malay. I would say Singapore chinese is more closer to Hong Kong or Taiwan 😉

Back to the paper, it will be great to have someone making and manufacturing paper to know just bit more in the in(s) and out(s) on the solvent they use on their paper pulp.

Papyrus is also in the back of my mind, haven't found the suitable form of papyrus I find online yet. And Lokta, probably I be flying over to Nepal next year to find out more on their paper. 🙂

@Snickers-is

I did create a coil of X amount of turns in FEMM and get the result, also the script created for the FEMM to move the VC up and down and the results. I think I have the results but never save them down in my excel. I could run again tonight and use a finer incremental of 0.2mm for the VC linear movement. I really hate the scripting in FEMM.

I might order a 3D printer next year when the field coil goes into development. I could maybe find time to try out your method, at the same time I was wanting to plate my pole piece in copper to create a Faraday ring. But now is near impossible to remove the Neo Magnet out from the motor.I noticed your control edges to get the magnet positioned right. But if you have access to a 3D printer, why not print a non magnetic guide for it? You could also make them out of aluminium, and make negative groves in the steel parts to control the aluminium that in turn controls the magnet.

Last edited:

To be honest, I have spoken to a few manufacturer in China that produces fullrange.

All of them state that the paper is the most crucial part of the design everything else can be secondary.😀

All of them state that the paper is the most crucial part of the design everything else can be secondary.😀

Do you have a separate schript to do the motion automatically? Where did you get it? Would you please share?

Do you have a separate schript to do the motion automatically? Where did you get it? Would you please share?

I hijack this script from the offical FEMM tutotrial. You might need to create your grouping and change the variables or parameters your wanted in the script.

-- Introduction

--

-- The purpose of this script is to automate the analysis of a Motor motor.

-- The notebook produces the static performance curves that designers often

-- desire during the development of a new transducer: the actuator's "BL"

-- (the amount of force produced on the voice coil per amp of coil current);

-- the coil's self-inductance, and a plot of the magnetic field in which the

-- coil is immersed.

--

-- Because there are so many possible variations in speaker motor geometry,

-- the notebook does not create the speaker geometry within the notebook. Rather,

-- it reads an existing geometry info FEMM and analyses it at a number of different

-- coil locations. It is assumed that the speaker motor has been drawn with all

-- elements in the coil belonging to group number 1, so that the voice coil can

-- be easily selected and moved by the notebook. It is also assumed that the .fem

-- file describing the motor is located in the same directory as the notebook

-- (although the user could manually change the path to the .fem file).

--------------------------------------

-- Design - Specific Parameters

--------------------------------------

-- Model Name

ModelName = 'Motor.fem';

-- Maximum excursion + /- from the centered position:

Xlim = 5;

-- Movement increments used during the analysis

dX = 1;

--------------------------------------

-- Analysis Routines

--------------------------------------

-- Analyze BL and incremental inductance at 1 mm steps between - Xlim and + Xlim

open(ModelName);

mi_saveas('temp.fem');

mi_selectgroup(1);

mi_movetranslate(0, -Xlim);

mi_clearselected();

showconsole();

clearconsole();

print('Disp(mm)','BL(N/A)','Inductance(uH)');

for k=-Xlim,Xlim,dX do

mi_modifycircprop('icoil',1,1);

mi_analyze(1);

mi_loadsolution();

mo_groupselectblock(1);

fz = mo_blockintegral(12);

parm1,R,fl1 = mo_getcircuitproperties('icoil');

mo_close();

mi_modifycircprop('icoil', 1, 0);

mi_analyze(1);

mi_loadsolution();

parm1,parm2,fl0 = mo_getcircuitproperties('icoil');

L = (fl1 - fl0)*10^6;

print(k, fz, L);

mi_selectgroup(1);

mi_movetranslate(0, 1);

end

mi_close();

remove('temp.fem');

remove('temp.ans');

print('');

print('DC coil resistance = ',R);

There are few scripts from the official tutorial online, but have to modify them.

the one I posted is from

-- David Meeker --

-- dmeeker@ieee.org

the one I posted is from

-- David Meeker --

-- dmeeker@ieee.org

No problem, there is also another script that simulate using desire freq. But even using the default motor from the tutorial i still get odd results. I still trying to figure that out.

The problem with paper is the modern methods of production that rely heavily on solvents & acids & they tend to eat themselves slowly over time. That is why many pages on books a few decades old tend to yellow & disintegrate. Hemp fibre production tends to avoid those manufacturing techniques or not need them.

Traditional paper making methods tend to avod this but are labour intensive. Carbon fibre is excellent but the only one that seems to have mastered it's sonics is Audax. As I see from your loudspeaker taste for your multi way speakers you would tend to agree. The best sounding Scanspeaks are cabon/pulp hybrids.

Sourcing vintage wood for pulp is a finite dwindling resource.

Lokta is a renewable that might indeed supply you what you need.

Being highly regulated by the Nepalese Authorities supply in any quantity might still be an issue. Other possibilities are Papyrus, Banana fibre & don't laugh Nomex. I also see you are a Mundorf fan. Me too Lastly apologies for thinking you were Chinese when you are from Singapore.

https://www.youtube.com/watch?v=1ohZMEIleRY

The water they used, I wonder if they add any additives or bonding ingredients?

Past few days, i have been testing out paper hardening using 50/50 water with glue mixture. Then using a cloth ironing to heat press on it.

Will update on the result again.

Will update on the result again.

Sorry for the delay in responding Ghemmi. When we talked last I had no sleep for 24 hours. Working on tuning speakers by ear I get so wrapped up I forget essential elements requred by nature like sleep. Not in front of a PC @ the moment but when I am I will give you a more detailed response.

Cheers Mark

Cheers Mark

A more concise response

Hi again Ghemmi

Finally in front of a PC. No more irritating little phone screen text menus!

First up put it down to lack of sleep but there is one loudspeaker I do know of that pulls off the fullranger trick better than any other.

It is made of carbon fibre. It utilizes bending wave technology. It has omnidirectional response above 100 Hz and utilizes a front firing horn for the Bass response. They are hand assembled in Germany and yes they are expensive. Excluded Manger bending wave technology because it is still problematic. the link to that is under the first.

German Physiks - High End Technology Loudspeaker Manufactur - DDD Driver - THE UNICORN MK II

No free lunch though. They still tend to lack efficiency with 88 db @ 4 Ohms nominal

Manger MSW

Here is one of the drivers for sale on Geman eBay

www.ebay-kleinanzeigen.de/s-anzeige/german-physiks-2x-ddd-biegewellenwandler-carbon-fuer-selbstbau/522049234-172-8938

Secondly thanks for being so understanding of my stuff up. It was about an hour after I posted that I thought what if he is ex pat Chinese living in Singapore? It was then that I realised some sleep was essential.

Unfortunately I am not much help when it comes to paper formulation. My early interest stemmed from having calligraphy as a hobby. I was mainly interested in resistance to print through and how my pen would run on the paper and I was only interested in ready made product.

But we live in an exiting time where the possibilities are always expanding.

www.youtube.com/watch?v=eQr7XnJBbsY

Early days for this emerging technology but sounds promising.

Cheers and I hope this helps PS; I will add that the finest headphones I ever heard were the AKG K1000. The diaghragm of these were treated with a multi layer shellac like surface treatment. AKG remain tight lipped about exactly what that treatment was.

Hi again Ghemmi

Finally in front of a PC. No more irritating little phone screen text menus!

First up put it down to lack of sleep but there is one loudspeaker I do know of that pulls off the fullranger trick better than any other.

It is made of carbon fibre. It utilizes bending wave technology. It has omnidirectional response above 100 Hz and utilizes a front firing horn for the Bass response. They are hand assembled in Germany and yes they are expensive. Excluded Manger bending wave technology because it is still problematic. the link to that is under the first.

German Physiks - High End Technology Loudspeaker Manufactur - DDD Driver - THE UNICORN MK II

No free lunch though. They still tend to lack efficiency with 88 db @ 4 Ohms nominal

Manger MSW

Here is one of the drivers for sale on Geman eBay

www.ebay-kleinanzeigen.de/s-anzeige/german-physiks-2x-ddd-biegewellenwandler-carbon-fuer-selbstbau/522049234-172-8938

Secondly thanks for being so understanding of my stuff up. It was about an hour after I posted that I thought what if he is ex pat Chinese living in Singapore? It was then that I realised some sleep was essential.

Unfortunately I am not much help when it comes to paper formulation. My early interest stemmed from having calligraphy as a hobby. I was mainly interested in resistance to print through and how my pen would run on the paper and I was only interested in ready made product.

But we live in an exiting time where the possibilities are always expanding.

www.youtube.com/watch?v=eQr7XnJBbsY

Early days for this emerging technology but sounds promising.

Cheers and I hope this helps PS; I will add that the finest headphones I ever heard were the AKG K1000. The diaghragm of these were treated with a multi layer shellac like surface treatment. AKG remain tight lipped about exactly what that treatment was.

Last edited:

No worries, been trying out Elmer yellow wood glue mixture in water. Applying them on the paper using a brush, hang it up to let it dry followed by ironing them with a cotton cloth over it.

I think I need to repeat this process a few times to get the desired paper hardness.

I think I need to repeat this process a few times to get the desired paper hardness.

The Manger driver look very interesting, hope I could find some photo of the diaphragm.

German Physiks, I heard a few of them in China Audio Show a year back. To be honest, they need very good amplifier to push them to get the correct sound texture (Probably tube amps). When i heard them during the show, most are using solid state amp which I find the sound very dry and hard.

German Physiks, I heard a few of them in China Audio Show a year back. To be honest, they need very good amplifier to push them to get the correct sound texture (Probably tube amps). When i heard them during the show, most are using solid state amp which I find the sound very dry and hard.

- Home

- Loudspeakers

- Full Range

- Custom DIY 6.5" Fullrange Driver