In the hot desert Burning Man festival conditions, running highly compressed electronic dance music for extended periods, an "improperly" vented compression chamber may offer distinct thermal advantage over a tiny, sealed "reactance annulled" chamber that cooks the driver to death.

With a sealed rear-chamber design, would there be a thermal advantage in flipping the driver and mounting it with the voice coil on the throat-side of the box? This way the driver's motor-heat "could" make its way out of the horn - and not be literally trapped inside a sealed box. The driver's basket & magnet should not interfere much acoustically, as these are bass notes.

Hi Entropy455,

Post #301: "...would there be a thermal advantage in flipping the driver and mounting it with the voice coil on the throat-side of the box?"

Probably not for a front-loaded horn (FLH), but, it seems to make a difference in a tapped horn (TH). To evaluate this would require attaching some form of thermal sensor to the magnet structure, and measuring in place. Then you could embark on calculating the thermal circuit to arrive @ the coil temperature... 🙂 Wayne Parham from Pi-Speakers did a lot of work on that subject:

PiSpeakers Forum - Re: Woofer cooling device - Test Cycle with Heat Exchanger Installed - Wayne Parham, October 06, 2005 at 05:07:26

But, this shouldn't be a problem for your build, as you are not forced into building a minimally sized rear chamber for the driver(s), and you have a lot of freedom in driver choices, etc... I tried to indicate the relative minor importance of the size of the rear chamber for a full size very low frequency bass horn in Post #264; just get the rear chamber big enough, so that it does not create ripple in your simulation.

Regards,

Post #301: "...would there be a thermal advantage in flipping the driver and mounting it with the voice coil on the throat-side of the box?"

Probably not for a front-loaded horn (FLH), but, it seems to make a difference in a tapped horn (TH). To evaluate this would require attaching some form of thermal sensor to the magnet structure, and measuring in place. Then you could embark on calculating the thermal circuit to arrive @ the coil temperature... 🙂 Wayne Parham from Pi-Speakers did a lot of work on that subject:

PiSpeakers Forum - Re: Woofer cooling device - Test Cycle with Heat Exchanger Installed - Wayne Parham, October 06, 2005 at 05:07:26

But, this shouldn't be a problem for your build, as you are not forced into building a minimally sized rear chamber for the driver(s), and you have a lot of freedom in driver choices, etc... I tried to indicate the relative minor importance of the size of the rear chamber for a full size very low frequency bass horn in Post #264; just get the rear chamber big enough, so that it does not create ripple in your simulation.

Regards,

I am still here, and my project is still a go! I have two significant unresolved design issues:

(1) I am still on the hook as to whether or not to build one mono horn, or a pair of stereo horns. . . .

(2) I'm trying to finalize the horn shape. I.E. square/rectangle mouth, octagon mouth, hexagon mouth, etc. I'll have no problem in smoothly transitioning the round throat shape, into whichever final mouth shape I choose. Initially I was leaning towards making an octagon horn (assuming it would sound better than a square horn). So which shape sounds best??? Is this an opinion, or is there actual science behind it?

I keep reading parallel walls are bad. What??? There are no parallel walls in a horn. Example: assume a square-mouth horn. The horn walls can be approximated by an infinite series of tangential planes - where none of these planes are parallel - - - not a single one. . . .?

My concrete options are Shotcrete (a wet sprayed on concrete - like the type used to make curved swimming pools), and plain cast concrete. Shotcrete is pretty cool, however you cant really spray it overhead. . . I'd have to form the lower half of the horn from the inside, then the upper half of the horn from the outside - if I use Shotcrete. The issue I'm having with casting traditional concrete, is in trying to get the lower portions of the forms to completely fill (without voids), in a single pour. I can use super-plasticizers, which will certainly help, however the forms would need to be that much stronger.

I will be using individual sealed rear chambers for each driver. I had not originally considered cone sag, however I am considering it now. . . . I also have an idea to seal the horn mouth from the environment (when not in use) to keep out animals & moisture - which I'll post about this evening. . . .

With a sealed rear-chamber design, would there be a thermal advantage in flipping the driver and mounting it with the voice coil on the throat-side of the box? This way the driver's motor-heat "could" make its way out of the horn - and not be literally trapped inside a sealed box. The driver's basket & magnet should not interfere much acoustically, as these are bass notes.

Since it's already been discussed I can tell you that there isn't going to be any driver motor heat in your design as shown because each of the drivers are only consuming a small fraction of their rated power handling. I also told you round hemispherical shape is best theoretically (and would probably look best) because sound is round but it probably doesn't matter that much as long as it's reasonably close to a half horn, the mirror image boundary reflection makes the other half.

With respect to the rest of the questions, I can answer them all except specifics about concrete but I'm certainly not going to do it here. These guys seem to be more than happy to be hand fed information but also seem to insist on biting the hand that's feeding them. (No offense meant to tb46 or Zero D of course.)

I'd be happy to discuss the details at length with you but you'll have to PM me if you want further input from me since this discussion no longer has anything to with logic or common sense and has deteriorated into an insultingly petty personality conflict. I don't even mind personal attacks, even from people that don't see the irony of accusing me of exactly what they are doing, but I can't defend myself against a constant barrage of nonsense about a badly designed undocumented horn in the desert from people that would normally agree with what I'm saying but now need to take the opposite position out of spite no matter how ridiculous or indefensible it happens to be.

Last edited:

I’m not necessarily worried about overheating drivers in my particular application. My question was intended to be more of a conceptual one.

A sealed speaker box has always seemed to me like an easy-bake oven. I.E. feeding a steady 250 to 500 watts of input power to a driver - most of that energy will be converted to heat. In a sealed box, this becomes a heat trap. The only way to get the heat out is via conduction through the box walls, and via conduction through the driver cone itself. Should the rate of heat generation exceed the rate of heat conduction (for a given deta-T), then temperature inside the box will rise – possibly rise quite dramatically. Note that an easy-bake oven will cook food, using only a 100 watt lightbulb. . . .

For the rear chambers (separate volume for each driver), I was planning on making them a little oversize (in volume), each with a removable access panel (for accessing the driver). With this design, I could theoretically adjust (aka reduce) the rear chamber volume as desired, by adding an incompressible volume (blocks, filler, etc –something that won’t rattle). I suppose I could even add volume, by installing a pocket/void into the access panels.

I’m still trying to digest the idea of a half-circle horn. Of all the pictures of bass horns I’ve seen in existence (which is not many), I don’t believe I’ve ever seen a half-circle horn, mated directly to the half-space planar surface. The half-circle exponential shape will be very difficult for me to cast in concrete (requiring me to bend plywood about both the x and y axis). This is why I’m attracted to the square mouth design (or hexagon, or even octagon mouth) – as I only need to bend the wood about one axis to achieve the exponential expansion profile – which is doable in plywood. The other axial expansion dimensions are achieved by physically trimming the width of the forms.

Getting back to the half-circle design. My gut tells me that incorporating a flat surface along the entire length of the horn, is somehow not good. It is the exponential flair that builds the wave, and matches impedances. That being said, my gut has been wrong before. . . .

And do not get discouraged about internet disagreements. It’s just the internet. Besides, there are not many people on Earth who know enough about bass horn design, to even argue about it.

I find myself in a very unique position - in that I have the land, the equipment, the funds, and more importantly, the Wife’s permission, to build a set of no-compromise full-size outdoor bass horns out of reinforced concrete. I really don’t want to screw this up. . . . If I cast a mistake into my horns, there probably won’t be a second attempt. .. .

A sealed speaker box has always seemed to me like an easy-bake oven. I.E. feeding a steady 250 to 500 watts of input power to a driver - most of that energy will be converted to heat. In a sealed box, this becomes a heat trap. The only way to get the heat out is via conduction through the box walls, and via conduction through the driver cone itself. Should the rate of heat generation exceed the rate of heat conduction (for a given deta-T), then temperature inside the box will rise – possibly rise quite dramatically. Note that an easy-bake oven will cook food, using only a 100 watt lightbulb. . . .

For the rear chambers (separate volume for each driver), I was planning on making them a little oversize (in volume), each with a removable access panel (for accessing the driver). With this design, I could theoretically adjust (aka reduce) the rear chamber volume as desired, by adding an incompressible volume (blocks, filler, etc –something that won’t rattle). I suppose I could even add volume, by installing a pocket/void into the access panels.

I’m still trying to digest the idea of a half-circle horn. Of all the pictures of bass horns I’ve seen in existence (which is not many), I don’t believe I’ve ever seen a half-circle horn, mated directly to the half-space planar surface. The half-circle exponential shape will be very difficult for me to cast in concrete (requiring me to bend plywood about both the x and y axis). This is why I’m attracted to the square mouth design (or hexagon, or even octagon mouth) – as I only need to bend the wood about one axis to achieve the exponential expansion profile – which is doable in plywood. The other axial expansion dimensions are achieved by physically trimming the width of the forms.

Getting back to the half-circle design. My gut tells me that incorporating a flat surface along the entire length of the horn, is somehow not good. It is the exponential flair that builds the wave, and matches impedances. That being said, my gut has been wrong before. . . .

And do not get discouraged about internet disagreements. It’s just the internet. Besides, there are not many people on Earth who know enough about bass horn design, to even argue about it.

I find myself in a very unique position - in that I have the land, the equipment, the funds, and more importantly, the Wife’s permission, to build a set of no-compromise full-size outdoor bass horns out of reinforced concrete. I really don’t want to screw this up. . . . If I cast a mistake into my horns, there probably won’t be a second attempt. .. .

Last edited:

Here’s something to lighten the mood –

This is a Continental W-670 radial engine from WWII. My wife and I are going to restore this engine, put a nice wooden prop on it, and mount it up on the wall of our receiving room – as engineering “art”. . . . Now how cool is that???

This engine is 668 cubic inches of love, and still has the US Army property tag on it! They used these engines in Navy fixed-wing aircraft, Navy G-Class blimps, amphibious landing vehicles, and Sherman Tanks. This particular engine has the tank-spline crankshaft, which means it was used in either an amphibious lander, or a tank. . . .

So back to Bass Horns. . . . . Square mouth, vs octagon mouth? Does it really matter?

Puzzling to hear about multiple drivers and heat. True horns are greatly more efficient at putting out the sound than cones flapping in the air and make engineering sense in a way that all non-horn cone drivers do not*.A sealed speaker box has always seemed to me like an easy-bake oven. I.E. feeding a steady 250 to 500 watts of input power to a driver.

Where have you (and your long-winded but mostly horn-virginal advisors) gone astray in the thinking?

B.

*just as a radial engine makes a lot of sense for a prop airplane

Last edited:

Again, I’m not worried about driver heat in my horns. It was simply a conceptual question, based on something weltersys had posted.

It is my understanding that if you reduce the throat of a full-size exponential bass horn to something very small – say about a square inch – then mount a true “compression” driver to it – the horn will load the driver, and you’ll get bass. The problem is that assuming the compression cone were very strong, and capable of a somewhat decent stroke, and also capable of generating fierce hydraulic-like forces - the non-linearity of compressed air would introduce very audible distortion (at anything other than low listening levels). So where is the happy medium? Based on what I’ve read, it’s somewhere in the 12” paper-cone, high BL, low Qts driver region, with a 3:1 compression ratio - - - well, that’s where I’m going to start anyway. … .

I have plans to construct some "large" homemade bass-horn compression drivers. But that’s a down-the-road project. First, I need to build some bass horns. . . . .

It is my understanding that if you reduce the throat of a full-size exponential bass horn to something very small – say about a square inch – then mount a true “compression” driver to it – the horn will load the driver, and you’ll get bass. The problem is that assuming the compression cone were very strong, and capable of a somewhat decent stroke, and also capable of generating fierce hydraulic-like forces - the non-linearity of compressed air would introduce very audible distortion (at anything other than low listening levels). So where is the happy medium? Based on what I’ve read, it’s somewhere in the 12” paper-cone, high BL, low Qts driver region, with a 3:1 compression ratio - - - well, that’s where I’m going to start anyway. … .

I have plans to construct some "large" homemade bass-horn compression drivers. But that’s a down-the-road project. First, I need to build some bass horns. . . . .

Last edited:

It's obvious you are a person with sophisticated intuition. Yes, now you are re-inventing how horns like to operate, rather than a lot of wordy (and for some people, very self-aggrandizing) run-around. The trick is to find the right balance of available gear and compression. Sorry, don't know enough to offer smart words about drivers or compression.It is my understanding that if you reduce the throat of a full-size exponential bass horn to something very small – say about a square inch – then mount a true “compression” driver to it – the horn will load the driver, and you’ll get bass...

Just to offer a benchmark, a Klipschorn uses a 15-inch driver (of a fairly conventional sort) playing into a slot about 3 x 12 inches (been decades since I last saw it). It shakes a living room like nothing else can at 10 watts.... but they gotta be clean watts. I'd guess the sealed box behind the driver is less than a half cubic foot... which says something about how much loading the horn must be doing to the front of the cone (a good sign, eh).

BTW, I think a single horn is the inevitable choice from your final system design exercise, esp when you start to figure out where to place the chairs.

Ben

Last edited:

1) Yes, the hook in the "horns" of dilemma.1) I am still on the hook as to whether or not to build one mono horn, or a pair of stereo horns. . . .

2) I'm trying to finalize the horn shape. I.E. square/rectangle mouth, octagon mouth, hexagon mouth, etc. I'll have no problem in smoothly transitioning the round throat shape, into whichever final mouth shape I choose. Initially I was leaning towards making an octagon horn (assuming it would sound better than a square horn). So which shape sounds best??? Is this an opinion, or is there actual science behind it?

3) I keep reading parallel walls are bad. What???

4)There are no parallel walls in a horn. Example: assume a square-mouth horn. The horn walls can be approximated by an infinite series of tangential planes - where none of these planes are parallel - - - not a single one. . . .?

5)My concrete options are Shotcrete (a wet sprayed on concrete - like the type used to make curved swimming pools), and plain cast concrete. Shotcrete is pretty cool, however you cant really spray it overhead. . . I'd have to form the lower half of the horn from the inside, then the upper half of the horn from the outside - if I use Shotcrete. The issue I'm having with casting traditional concrete, is in trying to get the lower portions of the forms to completely fill (without voids), in a single pour. I can use super-plasticizers, which will certainly help, however the forms would need to be that much stronger.

6) I will be using individual sealed rear chambers for each driver. I had not originally considered cone sag, however I am considering it now. . . .

7)I also have an idea to seal the horn mouth from the environment (when not in use) to keep out animals & moisture - which I'll post about this evening. . . .

2) For low frequency horns, the shape makes little difference, though square or rectangular shapes maximize frontal area, which increases forward gain, and reduces rear radiation. Boundary reinforcement is established science, and in my opinion, results in "better sound", as well as measurably more SPL for a given voltage applied.

3) Yes, they are, they result in standing waves, which can be nasty if within the pass-band of the enclosure or room, though outdoors you don't have to fret about the "room", other than your shop reflections in the listening position.

4) There are parallel walls in a horn with parallel walls, but you are planning to build a horn with an approximated infinite series of tangential planes, which is a much more difficult construction than the usual "horn in a box" that has parallel walls of a dimension that are acoustically benign in the low frequency pass band.

5) Yeah, you have chosen a son-of-a-bitch material to build your bass horns from. My condolences

6) Cone sag is a real deal, but is less of a concern with tight suspension "pro" drivers than "floppy" foam surround drivers. That said, I would not mount "long term" drivers of any type horizontal unless an easy rotation plan could be employed to reverse the inevitable toll of gravity on the suspension.

7) Grill cloth works fine for that.

Your comments of heat generated in the compression chamber are not academic considering the outdoor distance you have decided upon will require 10 or more times more power and heat generated than what would be used if the system was located near the listening position.

Reversing the drivers so their magnetic structure is "outside the box" will make a large difference in voice coil heat reduction and it's resultant reduction of "power compression" when running near the thermal limits of a driver. High power drivers now all use back venting to air pump heat from the voice coil, some designs like the LAB 12" make a lot of air noise, which will be amplified by a large straight horn. Other designs, like those of B&C, pump a lot of heat from the voice coil with almost no audible air noise.

Happy hunting,

Art

Last edited:

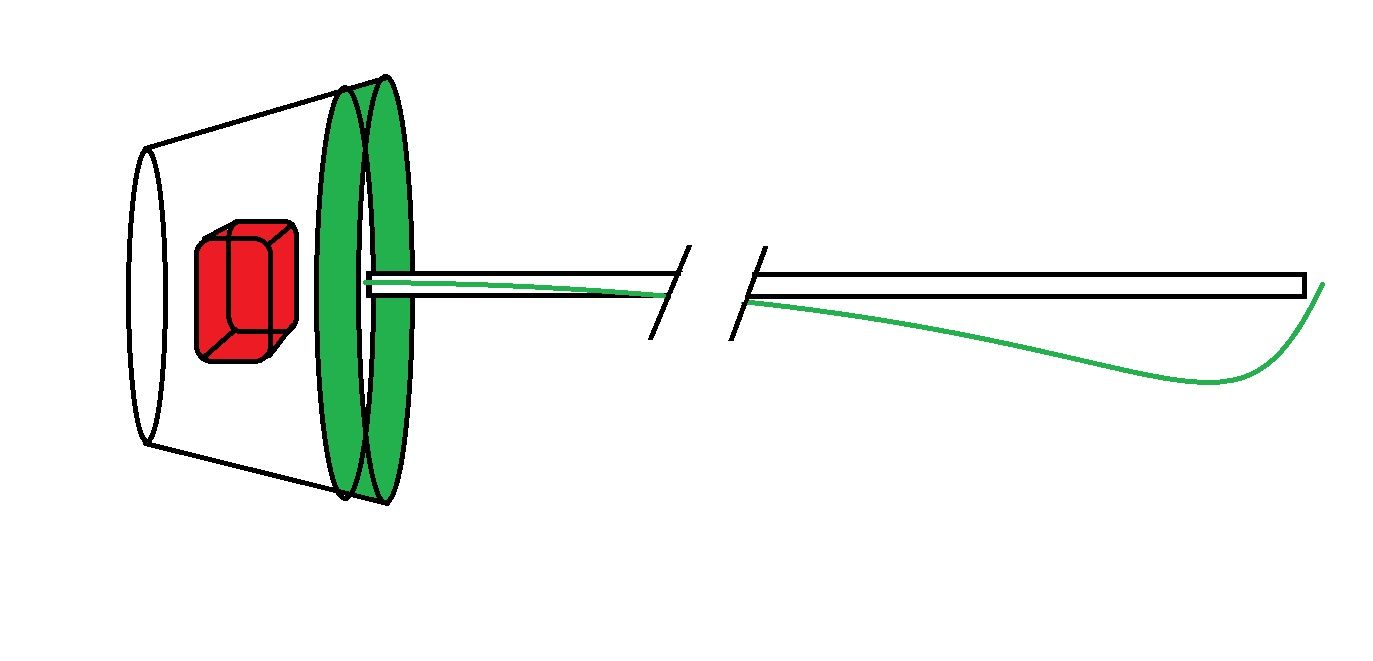

Here’s my idea for the horn plug (conceptual drawing).

This thing would be constructed out of 5052-H32 aluminum, or 304L stainless sheet. It’s basically a cone that I’d feed into the horn (deep towards the throat), using the reach-rod (aka 1” Schedule 40 steel pipe). Then using a hand air-pump, I’d inflate the "properly sized" tire tube (shown in green), via 1/4" air hose. This would “seal” the horn against the elements. The package in red would be desiccant – to adsorb any residual moisture in the throat – protecting the paper drivers from our obscenely wet western Washington State winters. I’d probably put some mini casters on the plug – so that I may roll it in easy.

In my backyard I’ve got birds, mice, rats (big rats thanks to people in my neighborhood not locking up their stupid animal feed. . . .) squirrels, raccoons, bobcat, cougar, deer, and black bear – and those are just the ones I’ve seen. (the bear I actually caught on my security camera. . . .)

My biggest fear (in addition to moisture damage) are animals nesting in my horns and chewing on my drivers - which I’m absolutely confident will happen if I don’t properly seal them off with a non-chewable metallic FME (Foreign Material Exclusion) plug. . . ..

Thoughts???

Last edited:

Yea. If it was my project, heat wouldn't concern me.I’m not necessarily worried about overheating drivers in my particular application. My question was intended to be more of a conceptual one.

As a welder, you could over-engineer the boxes by borrowing ideas from computer cooling - heat pipes connecting the drivers to massive finned heatsinks in the cabinets. Complete overkill, and probably 99% cosmetic, but since you enjoy engineering “art”*, it may appeal for visual reasons alone.

I’m still trying to digest the idea of a half-circle horn. Of all the pictures of bass horns I’ve seen in existence (which is not many), I don’t believe I’ve ever seen a half-circle horn, mated directly to the half-space planar surface. The half-circle exponential shape will be very difficult for me to cast in concrete (requiring me to bend plywood about both the x and y axis). This is why I’m attracted to the square mouth design (or hexagon, or even octagon mouth) – as I only need to bend the wood about one axis to achieve the exponential expansion profile – which is doable in plywood. The other axial expansion dimensions are achieved by physically trimming the width of the forms.

What Art said. Also, note that lots of mid and HF horns transition from a round to rectangular section. You could build a relatively easy square profile horn, then fill in the corners, to achieve exactly the same thing.

Casting is not the only option. I used to work on large concrete water tanks, building them on-site (regional Australia). We'd:

1) pour the bases (a disc of rebar + a truckload of concrete)

2) set up a temporary form for the walls

3) corset the form with rebar

4) plaster the outside

5) remove and clean the form

6) plaster the inside

...thus creating walls only a few cm thick that would hold many tons of water. All the strength was in the steel. The concrete just filled in the gaps. I couldn't find a photo that matches exactly this method, but have attached one that is similar.

Doing it this way would be a trade-off, turning form-building labour into plastering labour. Costs and planning would be easier: you could make a relatively small amount of formwork, then move it from place to place.

For tight curves at the throat, you wouldn't need any formwork: you could cover the rebar frame with something finer (e.g. a roll of vermin mesh), and plaster directly onto it. You'd need a small mixer and hand tools rather than a truck, and you could make any shape that you can bend the rebar into.

I really don’t want to screw this up. . . . If I cast a mistake into my horns, there probably won’t be a second attempt. .. .

The full-sized thing is more important that the exact shape. Within reason, different profiles are pretty close in performance, if the size is right. Most design wrangling, most of the time, is to maximise performance from a particular size and weight.

*Regarding radial engines: the FW190 also had a big radial engine, which saved a few of it's pilots: "[Soviet pilot] Goldonikov noted that German pilots appreciated the Fw 190 radial engine as a shield, and frequently made head-on attacks in air-to-air combat."

Attachments

some designs like the LAB 12" make a lot of air noise, which will be amplified by a large straight horn. Other designs, like those of B&C, pump a lot of heat from the voice coil with almost no audible air noise.

When I first got into audio, I used to break-in drivers (free-air), using a 10 Hz sinewave - then measure the individual Thiele parameters. That is, until I got lazy and started using the OEM's advertised parameters (which seems to work pretty well in most applications). But I digress. . . .

I know exactly what you are talking about, as some of the vented voice-coil drivers out there are real noisemakers on the backside. Some drivers will actually whistle!

On a somewhat related note - I've found that achieving a "rigid" speaker enclosure is of extreme importance to fidelity. If you can feel the sound by placing your hand on the speaker box, in my opinion, the box is not nearly stiff enough. This is in part what's attracting me to using concrete for my horns. . . .

Here’s my idea for the horn plug (conceptual drawing).

That seems like over-thinking, way more trouble than I'd go to 🙂

My biggest fear (in addition to moisture damage) are animals nesting in my horns and chewing on my drivers - which I’m absolutely confident will happen if I don’t properly seal them off with a non-chewable metallic FME (Foreign Material Exclusion) plug. . . ..

Thoughts???

If it was me, I'd opt for a fixed solution - I get annoyed when it takes time to power up my music.

Moisture:

1) some good pro drivers (e.g. Faital, see link) are advertised as water proof.

2) a mild slope would keep wind-driven rain from pooling in the throat (e.g. as shown for horn 3 from your post 149)

Mice etc:

a 'bug screen', a permanent fine wire barrier in the throat (e.g. vermin mesh).

Bears etc:

same thing, but bigger, such as a rebar grid halfway up the horn.

Beyma - Faital Pro Speakers, Faital Pro Speaker Parts, Faital Pro bass speakers, Faital Pro speaker upgrades. Faital Pro woofers, crossovers, horns, drivers, etc. Faital Pro has some of the finest speaker parts.

...other than your shop reflections in the listening position...

I thought my shop would be out-of-range - or at least at a sufficient off-angle, as to not interfere with the horns. Now I'm worried that I'm underestimating the potential acoustic impact of my garage. . . .

I'll have my wife stand where the horn's mouth would be (assuming a single bass horn) with her handgun. I'll stand in the listening area, and have her pop off a few rounds into the ground. If there's going to be an echo problem from my garage, it should present itself pretty clearly. . . .

If the garage does end up being an acoustic problem, I'll have to extend my clearing to the East, and move the horns to the East also. I suppose I could simply point my horns to the South. This would however defeat the whole purpose of pointing my horns to the North - as there are several hundred acres of vacant land to the North of my property. . . . And there are about 30 homes within a mile of my house to the South.

Last edited:

On a somewhat related note - I've found that achieving a "rigid" speaker enclosure is of extreme importance to fidelity. If you can feel the sound by placing your hand on the speaker box, in my opinion, the box is not nearly stiff enough. This is in part what's attracting me to using concrete for my horns. . . .

10 years ago I had this system (pix are now broken links, sorry)

system pics - hollowboy - High Efficiency Speaker Asylum

The 'enclosure" was also my bed. Most of the enclosure was cinderblock & concrete, but the "lid" was relatively frail: 2x4 timber bracing, topped with a thick sheet of MDF, topped with an additional sheet of fibreboard, topped with a futon. With music at 'normal' levels (less than a watt! I had forgotten that), I could lie on the futon and clearly feel the bass vibrations.

I piled on additional layers: more bracing, edge-on, with a 10cm layer of concrete between the beams, topped with another sheet of MDF. Victory! No more vibration. Huge masses of concrete = win.

1) My deck speakers are covered with two layers of Acoustone P450 grill cloth. Acoustone is a division of Newcastle Fabrics Corporation, Brooklyn New York. I have used their grill cloth for around 40 years, and it has lasted that long still looking new.1)Here’s my idea for the horn plug (conceptual drawing)...

In my backyard I’ve got birds, mice, rats (big rats thanks to people in my neighborhood not locking up their stupid animal feed. . . .) squirrels, raccoons, bobcat, cougar, deer, and black bear – and those are just the ones I’ve seen. (the bear I actually caught on my security camera. . . .)

My biggest fear (in addition to moisture damage) are animals nesting in my horns and chewing on my drivers - which I’m absolutely confident will happen if I don’t properly seal them off with a non-chewable metallic FME (Foreign Material Exclusion) plug. . . ..

Thoughts???

2)When I first got into audio, I used to break-in drivers (free-air), using a 10 Hz sinewave - then measure the individual Thiele parameters. That is, until I got lazy and started using the OEM's advertised parameters (which seems to work pretty well in most applications). But I digress. . . .

3)I know exactly what you are talking about, as some of the vented voice-coil drivers out there are real noisemakers on the backside. Some drivers will actually whistle!

4)On a somewhat related note - I've found that achieving a "rigid" speaker enclosure is of extreme importance to fidelity. If you can feel the sound by placing your hand on the speaker box, in my opinion, the box is not nearly stiff enough. This is in part what's attracting me to using concrete for my horns. . . .

As I mentioned previously, (good) grill cloth will not only protect the drivers from all the stuff you have crawling around, but won't require all the expense and time your plan would, and will allow you to listen year round. I have listened to mine while shoveling snow from the deck, and in the rain.

2) After a few minutes of breaking in a pair of B&C 18SW115-4 with an 11Hz sine wave, I felt ill for 15 minutes.

3) B&C's woofers don't whistle, get rid of heat like an air conditioner, and many are are moisture-proof, you can literally leave the cone filled with water and it won't soak through.

4) Sorry to burst your bubble, but using my Keystone subs outdoors I can feel the vibrations in 4" re-bar reinforced concrete slabs laying flat on the ground. The vibrations can be easily felt through my feet, and picked up a lot easier with fingertips.

The plywood cabinet walls also vibrate a bit, as expected with peaks of several horsepower of electromotive force being dissipated. Only a small fraction of the power used in even the most efficient horn actually is converted to acoustical energy, the difference in efficiency between a floppy, un-braced, 1/2" particle board cabinet and a 10" thick re-bar reinforced casting would be only a small fraction of the energy wasted.

This in no way implies heavy inert cabinet walls are not an excellent sonic choice, but a constrained layer damped sandwich construction using well braced LP SmartSide panel would actually be sonically superior to concrete, and would hold up to your Seattle weather with no fear of cracking from seismic or audio activity.

While flying an ultralight hang-glider trike, the (presumably) aircraft aluminum reduction drive mount on the Radial (brand, not design) engine broke off, the propeller winging it's way into a remote part of the same field I had to land in, thinking I had lost the drive belt, not the whole pusher prop assembly.

The Radial engine owner's manual clearly stated head bolt torque and tightening intervals, but mentioned nothing about the re-drive bolts, which was not subject to much thermal stress. The crappy Radial company owner would not give me a free replacement, even though the problem was caused by their failure to use thread lock on the one bolt (of three) that could not be accessed without removing the propeller, which used around eight fasteners. I verified those facts after recovering the propeller and broken re-drive, the wood propeller was undamaged by the 500 foot "free flight".

My point is simply that vibrations are transmitted through strong stiff materials, and that often ain't a good thing in aircraft, foundations, or speaker enclosures.

Cheers,

Art "Four Nasty Crashes & I'm Done Piloting Weight Transfer Controlled Aircraft" Welter

Last edited:

Heat build up etc

You could port the back chambers @ either a Very low f well under f3 LOW, or well above f3 HIGH. This would allow heat out, but won't affect the f response. The port/s could be at the back out of the way, mounted above the drivers to more easily allow heat out.

With regard to mounting the drivers inside out, take look at Volts Radial chassis drivers which offer an alternative to doing that - Volt Loudspeakers | Radial Technology & Volt Loudspeakers | PA Speakers & Volt Loudspeakers | Studio Speakers

Also i would seriously consider removing all the drivers as soon as the bad weather season begins, & store them in the boxes they came in, inside a dry non cold place. It's not just the cones you need to think about !

As for neighbors a mile away. Low f's are omni directional, so large SPL's from behind the horn's & sides, "might" still be heard/observed by them via the ground and/or air, although muffled !

You could port the back chambers @ either a Very low f well under f3 LOW, or well above f3 HIGH. This would allow heat out, but won't affect the f response. The port/s could be at the back out of the way, mounted above the drivers to more easily allow heat out.

With regard to mounting the drivers inside out, take look at Volts Radial chassis drivers which offer an alternative to doing that - Volt Loudspeakers | Radial Technology & Volt Loudspeakers | PA Speakers & Volt Loudspeakers | Studio Speakers

Also i would seriously consider removing all the drivers as soon as the bad weather season begins, & store them in the boxes they came in, inside a dry non cold place. It's not just the cones you need to think about !

As for neighbors a mile away. Low f's are omni directional, so large SPL's from behind the horn's & sides, "might" still be heard/observed by them via the ground and/or air, although muffled !

Zero D,Also i would seriously consider removing all the drivers as soon as the bad weather season begins, & store them in the boxes they came in, inside a dry non cold place. It's not just the cones you need to think about !

As for neighbors a mile away. Low f's are omni directional, so large SPL's from behind the horn's & sides, "might" still be heard/observed by them via the ground and/or air, although muffled !

Professional speakers are stored, transported and used in sub zero temperatures every winter by hundreds of sound companies with less ill effects than summertime use. I did exactly that with over a million dollars of sound and lighting gear for twenty years prior to moving from Minneapolis, Minnesota (not far from Frostbite Falls...) to more temperate zones. Without a doubt, hot wet conditions are worse for gear than cold wet conditions.

If waterproof drivers are used, removing the drivers out of weather concerns is a complete waste of time and effort, would use up indoor space, and eliminates outdoor listening for a good portion of the year in a place like Seattle, which is wet most all the time.

That said, my lady's daughter has brought us good luck, it has only rained a few times during our several visits to her over the years she has lived there.

If Eric were to consider multiple smaller subs, he could use beam steering techniques to direct the sub-woofer output in a cardioid (heart-shaped) pattern away from the neighbors. Low frequency noise complaints are a definite concern considering his plans to locate the sub(s) quite a distance away from the listening position, for some undisclosed reason.

Art

Last edited:

B&C's woofers don't whistle, get rid of heat like an air conditioner, and many are are moisture-proof, you can literally leave the cone filled with water and it won't soak through.

Sorry to burst your bubble, but using my Keystone subs outdoors I can feel the vibrations in 4" re-bar reinforced concrete slabs laying flat on the ground. The vibrations can be easily felt through my feet, and picked up a lot easier with fingertips.

My first horn driver choice, based on comparing BL, Qts, Xmax, and MMD parameters only, was B&C drivers. They are a bit more expensive (comparably), but apparently well worth it. . . .

Don't get me wrong. I'm not saying that concrete structures cannot ring like a bell, but rather I'm saying that concrete is not typically used to make bells. . . . How much a concrete structure vibrates is dependent on the design. Lots of bending inertia (aka stiffeners) will shift resonant frequency up, and significantly limit deflections with a given applied force. However the added mass will also work to shift the resonant frequency back down. Thus the goal is to increase bending inertia at a greater rate than you're increasing mass. This is pretty easy to do (with the correct design approach), as bending inertia is a function of distance-from-the-centroid raised to the third power. I intend to cast reinforced stiffeners into the horn walls (obviously on the outside walls - so as not to interfere with the interior contour of the horn). It's no different than gluing stiffeners inside wooden speaker boxes - to appreciably deaden the panels. Goal: if I stiffen the horn walls enough, I should be able to shift the structure's resonant frequency up to a point where the concrete will virtually deaden it - and simply not respond to forcing functions (aka minimally respond - particularly between 10 Hz and 160 Hz)

Last edited:

Hi Art,

Post #316: "...Only a small fraction of the power used in even the most efficient horn actually is converted to acoustical energy..."

I was under the impression that properly designed full size (for their frequency range) horns can approach 50% efficiency (electrical input power v. acoustical output power).

Either way, maybe it's time for the OP to define the desired SPL @ the listening level, and back-calculate to the necessary power level?

Regards,

Post #316: "...Only a small fraction of the power used in even the most efficient horn actually is converted to acoustical energy..."

I was under the impression that properly designed full size (for their frequency range) horns can approach 50% efficiency (electrical input power v. acoustical output power).

Either way, maybe it's time for the OP to define the desired SPL @ the listening level, and back-calculate to the necessary power level?

Regards,

- Home

- Loudspeakers

- Subwoofers

- Concrete Bass Horn Design Question