Thanks. So, in some circuits, and to some ears...

C0G = clear and bright

PMMA = smoother and more organic/meatier

PPS = neutral, without a special signature

Few folks opine romantically about SMT caps. Maybe they aren't as sensual without the legs?

C0G = clear and bright

PMMA = smoother and more organic/meatier

PPS = neutral, without a special signature

Few folks opine romantically about SMT caps. Maybe they aren't as sensual without the legs?

Last edited:

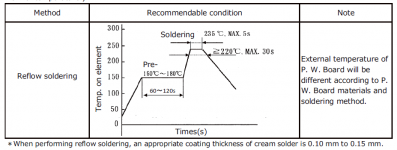

Read the datasheets carefully. Aside from the difficulty of DIY soldering of SMT film caps, many of them show a permanent shift in value after going through a reflow oven. It seems predictable that it will happen, but the amount of change is not likely deterministic. That's not particularly useful if you care about the exact value -- i.e., RIAA EQ network.

Thanks. So, in some circuits, and to some ears...

C0G = clear and bright

PMMA = smoother and more organic/meatier

PPS = neutral, without a special signature

Few folks opine romantically about SMT caps. Maybe they aren't as sensual without the legs?

I will not say it like that, i.e. equal. People could undeterstand it as they are always giving this behavior. Change ears, certainly by : "depend of the sum of the device when you check with a listening session.

C0G gives often a clearer rendering in the sum of my devices I listened (in a DAC circuitry), not always bright but can be. (clear in my language = a lot of information, no veiled if you prefer, sometimes I found it can be fatiguing; I have three loudspeakers to compare...)

FCA cap from Cornel Dublier are the most evident to identify

PPS can be quite neutral I found in the sense they are very near from a ceramic class I, although without all those light sometimes you can have in some circuitry with ceramic class I (decoupling to ground with some clocks and DAC chip).

Hope it's clearer, it's just what I have noticed. Alas I can not extract an "always" works like this. This is more what I tried to explain (sorry my bad english) from what I experienced.

Last edited:

Read the datasheets carefully. Aside from the difficulty of DIY soldering of SMT film caps, many of them show a permanent shift in value after going through a reflow oven. It seems predictable that it will happen, but the amount of change is not likely deterministic. That's not particularly useful if you care about the exact value -- i.e., RIAA EQ network.

Yes, difficult to extract a rule from these experiments, it could be a capacitance drift due to the soldering. However when you experienced many times close behavior, the temptation is to write something like I did, just because this is what your ears checked many times.

Diyiggy, please pardon me if I misrepresented your experience. I agree that is unwise to generalize too broadly; I am grasping at simplistic generalizations only because there is a dearth of information like this, as far as I can tell. I invited subjective impressions along with measured performance conparisons, and I value your input.

Thanks. So, in some circuits, and to some ears...

C0G = clear and bright

PMMA = smoother and more organic/meatier

PPS = neutral, without a special signature

Few folks opine romantically about SMT caps. Maybe they aren't as sensual without the legs?

What makes you think capacitors can impart such variations.

Capacitors are selected on the basis for a specific purpose. The reason for the popularity of smd capacitors has more to do with the automation of electronic assembly than any mythological sonic nuances.

Linear Audio Volume 12: Samuel Groner + Scott Wurcer --- Quadrature Bridge Measures Harmonic Distortion in Capacitors to measure capacitor distortion down to −150 dB.

What makes you think capacitors can impart such variations.

Capacitors are selected on the basis for a specific purpose. The reason for the popularity of smd capacitors has more to do with the automation of electronic assembly than any mythological sonic nuances.

My ears tell me! Of course we choose the parts for a specific purpose. In this hobby, that purpose is good sound. Since I believe the electrical performance of a capacitor can affect its subjective performance, I want to learn more, so I can choose more wisely. That's why I started this thread.

I agree that SMT caps were not created for audio nuts to drool over. They simply jive with the push for automated assembly and product miniaturization, and in some ways handicap DIYers. I do think they offer some benefits in terms of minimizing parasitics and noise. For better or worse, my audio gear is full of SMT, so that's why I'm interested.

Thanks for the link, Jackinnj! I think I actually have that article somewhere...

My ears tell me!

Its impossible for any human to hear distortion at -150dB when the distortion added by the loudspeaker is 1000's of times higher in magnitude.

What your are purporting is based upon a audiophile belief system. Electronic engineering is not wine tasting.Of course we choose the parts for a specific purpose. In this hobby, that purpose is good sound. Since I believe the electrical performance of a capacitor can affect its subjective performance.

Get used to smd, its been around for 30years, engineering progress doesn't care about the ability for diy'ers to needlessly cap swap.I agree that SMT caps were not created for audio nuts to drool over. They simply jive with the push for automated assembly and product miniaturization, and in some ways handicap DIYers.

It is not the right question to ask which caps are better. You can only ask which caps are better for this specific application.

Are you AC coupling a signal with a nominal 0V DC?

Are you compensating the VAS of an amplifier?

Are you bypassing IC's? Power output transistors?

Are you suppressing RF or doing snubbing on a rectifier?

Are you doing RIAA or other active filtering?

Are you doing a passive crossovers in a loudspeaker?

Are you creating a negative rail with a charge pump to power an op amp?

Each of these applications has a different set of requirements, and a different type of capacitor meets those requirements best. A better question is "What type of SMT cap is best for an RIAA filter?"

It certainly is valid to say that, in general, I try to avoid SMT film caps because they often do not survive soldering. Or, I have not found any SMT caps that work well in that position. SMT caps are not going away, but neither are thru-hole. If it's experimenting with different values that you want, I find ceramic chip caps much easier to swap than thru-hole.

For DC-blocking, I generally just bite the bullet and use a thru-hole film cap.

Are you AC coupling a signal with a nominal 0V DC?

Are you compensating the VAS of an amplifier?

Are you bypassing IC's? Power output transistors?

Are you suppressing RF or doing snubbing on a rectifier?

Are you doing RIAA or other active filtering?

Are you doing a passive crossovers in a loudspeaker?

Are you creating a negative rail with a charge pump to power an op amp?

Each of these applications has a different set of requirements, and a different type of capacitor meets those requirements best. A better question is "What type of SMT cap is best for an RIAA filter?"

It certainly is valid to say that, in general, I try to avoid SMT film caps because they often do not survive soldering. Or, I have not found any SMT caps that work well in that position. SMT caps are not going away, but neither are thru-hole. If it's experimenting with different values that you want, I find ceramic chip caps much easier to swap than thru-hole.

For DC-blocking, I generally just bite the bullet and use a thru-hole film cap.

Yes, off course Russell. I can't agree more, you're right.

Now, sometimes, into the right choice of parts needed for the same task, you have choice enough as the three caps the op asks in the thread subject.

Let's just talk about decoupling with them here - cause as coupling 99% of the time we know there are better choice as silver-mica that also exists with smd casing - have also some in glass with legs for spatial applications that sounds also different at iso pF value than their smd counterpart-, or styren cap, or polypro caps - then you can experiment when the smallest inductance is not needed* than those acrylic or PPS can be usefull in your audio toolbox.

An other illustration could be about RIAA filter : very precise styren are often most welcome for the sound (we know the quality of this dielectric) but some gives better subjective tasting than many european diyer experienced just cause they have the choice between many manufacterers : the old enthusiasts are knowing than the tin foilded little axial caps from Philips or Roe were sounding very good instead the cheap styrenes you can find today (really night and day differences) and they really are not angry to the young engineers not knowing it btw. Knowledge is needed but experience matters.

Because at the end tasting is exactly what matters. Let say engineering law made you wine and of course we stay inside, it's not about magic, you will have at the end different tastings that make some wine rubish and some diamond... though both are still wine. So it's clearly not about going against electrical laws.

Why for instance just to talk about distortion ??? It's very limited when talking about audio and sounding feeling. If you hear a difference and it sounds better with worse distortion for illustration, then it's just this is not the distortion that is involved here in the result.

I'm like you and prefer through holes, but sometimes smt is just what you have on hands - not saying sometimes you have already a good circuitry layout all made of smd you want to enhance or adapt in the sum of your devices- or can be useful like for instance 0405 smt casing where ceramic class 2 is mandatory cause you need very low inductance (so yes engineering laws matter and no one is saying the opposite).

If you have the possibility one day to try those FCA caps from Cornell Dublier in some clock or DAC circuitry, try if very precise capacitance number is not mandatory: at the right area it sometimes improves the things a lot... while being just a cap in a sum of devices that sounds, you can hear a difference. Sometimes this good result in the sum you check with ears can be a default you introduced locally in the specific area you tweaked... but at the end it's the sum you taste and enjoy : coocking is a good analogy... just respect the engineering laws (nature) and don't coock with poison for the circuitry to work.

If laws of nature made the water, human-being forced a little the thing to make wines, and there are clearly some betters than others, like a basic Pioneer amp or a Kondo amp...both respect the enginnering laws but the last had more optimisation and the designers went into the last details as the synergy of the parts chosen !

Nothing bad to talk about parts in that context !

Now, sometimes, into the right choice of parts needed for the same task, you have choice enough as the three caps the op asks in the thread subject.

Let's just talk about decoupling with them here - cause as coupling 99% of the time we know there are better choice as silver-mica that also exists with smd casing - have also some in glass with legs for spatial applications that sounds also different at iso pF value than their smd counterpart-, or styren cap, or polypro caps - then you can experiment when the smallest inductance is not needed* than those acrylic or PPS can be usefull in your audio toolbox.

An other illustration could be about RIAA filter : very precise styren are often most welcome for the sound (we know the quality of this dielectric) but some gives better subjective tasting than many european diyer experienced just cause they have the choice between many manufacterers : the old enthusiasts are knowing than the tin foilded little axial caps from Philips or Roe were sounding very good instead the cheap styrenes you can find today (really night and day differences) and they really are not angry to the young engineers not knowing it btw. Knowledge is needed but experience matters.

Because at the end tasting is exactly what matters. Let say engineering law made you wine and of course we stay inside, it's not about magic, you will have at the end different tastings that make some wine rubish and some diamond... though both are still wine. So it's clearly not about going against electrical laws.

Why for instance just to talk about distortion ??? It's very limited when talking about audio and sounding feeling. If you hear a difference and it sounds better with worse distortion for illustration, then it's just this is not the distortion that is involved here in the result.

I'm like you and prefer through holes, but sometimes smt is just what you have on hands - not saying sometimes you have already a good circuitry layout all made of smd you want to enhance or adapt in the sum of your devices- or can be useful like for instance 0405 smt casing where ceramic class 2 is mandatory cause you need very low inductance (so yes engineering laws matter and no one is saying the opposite).

If you have the possibility one day to try those FCA caps from Cornell Dublier in some clock or DAC circuitry, try if very precise capacitance number is not mandatory: at the right area it sometimes improves the things a lot... while being just a cap in a sum of devices that sounds, you can hear a difference. Sometimes this good result in the sum you check with ears can be a default you introduced locally in the specific area you tweaked... but at the end it's the sum you taste and enjoy : coocking is a good analogy... just respect the engineering laws (nature) and don't coock with poison for the circuitry to work.

If laws of nature made the water, human-being forced a little the thing to make wines, and there are clearly some betters than others, like a basic Pioneer amp or a Kondo amp...both respect the enginnering laws but the last had more optimisation and the designers went into the last details as the synergy of the parts chosen !

Nothing bad to talk about parts in that context !

Last edited:

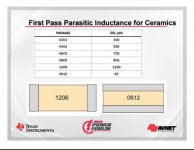

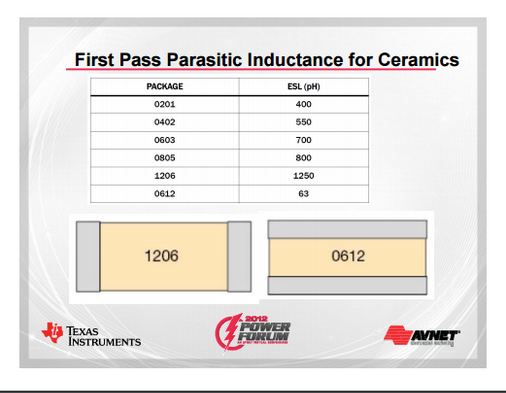

The reverse package sizes look handy for staying with C0G caps when inductance matters.

Attachments

Last edited:

I have a "Toaster Reflow Oven" with the Controleo3 MCU. Whizoo.com Works great for SMT film capacitors most of the time, but I have found that the devices oftentimes don't like to remain seated.

You can design your own reflow profile to fit the datasheet of your solder paste and film capacitor with the Controleo3.

I recommend getting a stencil -- those from JLCPCB are stainless steel and very good.

You can design your own reflow profile to fit the datasheet of your solder paste and film capacitor with the Controleo3.

I recommend getting a stencil -- those from JLCPCB are stainless steel and very good.

Attachments

The reverse package sizes look handy for staying with C0G caps when inductance matters.

C0G of course are very usefull when needed, precise capacitance values, better size as you say, maybe better at coupling cap in the signal path at very high frequency than PPS/acrylic (not sure though for audio) if needed.

iirc, the lowest size of FCA cap serie are not better than 0805 smt sizing ?! But their capacitance value are going till 47 uF with the Rubycon PPS, a little bulky while style smt devices.

Iancanada edited a nice little how to on soldering smt at low temperature" in a family oven with the grey soldering paste if you just need soldering from times to times.

Last edited:

I have not seen those before. ESL is an important spec for decoupling/bypass caps. Sometimes ESL is extremely critical.The reverse package sizes look handy for staying with C0G caps when inductance matters.

I have not investigated its importance in compensation caps. My intuition says it's not that important there. The ESL of either 1206 or 0612 is going to be quite a lot better than thru-hole ESL.

I don't know how is the measurment in esl spec but radial lytics with 2.5 mm leads spacinf still exists.

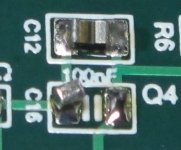

Looks like the capacitors for C16 & C12 are too small for the pad size. The causation is typically the thermal mass interactions by the component pads and track geometry pulling the capacitor to one end as the solder paste starts to flow. It can be fixed by either using the correct size capacitors or by changing the pad sizes. You can get the same effect with inadequate thermal reliefs for components that connect to a ground plane (aka Tombstoning). You can see Q11 is also slightly off centre due to dissimilar connecting track sizes.I have a "Toaster Reflow Oven" with the Controleo3 MCU. Whizoo.com Works great for SMT film capacitors most of the time, but I have found that the devices oftentimes don't like to remain seated.

Last edited:

Great info in the article recommended by Jackinnj:

Quadrature Bridge Measures Harmonic Distortion in Capacitors

"The 2nd harmonic distortion of ceramic C0G capacitors is proportional to the fundamental level, and the 3rd harmonic distortion proportional to the square of fundamental level."

(Groner and Wurcer)

This could explain some subjective differences between ceramic and film caps. All of the film types--even polyester (which is higher THD than C0G) have a dominant second harmonic. C0G has a dominant third harmonic signature, which gets further emphasized as signal level increases.

Quadrature Bridge Measures Harmonic Distortion in Capacitors

"The 2nd harmonic distortion of ceramic C0G capacitors is proportional to the fundamental level, and the 3rd harmonic distortion proportional to the square of fundamental level."

(Groner and Wurcer)

This could explain some subjective differences between ceramic and film caps. All of the film types--even polyester (which is higher THD than C0G) have a dominant second harmonic. C0G has a dominant third harmonic signature, which gets further emphasized as signal level increases.

... not sure it suffices to explain it all, cause sometimes, some like a little of third harmonic in the sound. Although it could be a beginning toreduce the uncertainty.

It's certainly harder to discover the rule that apply with the ones already known that sometimes experiments. although in science, experients are here to test a theory. Sometimes, it can be faster to just try if you have a short term subjective goal focused on one device only . And that's why I would not talk about universal behavior or equal sign as we talk before. Just what I often noticed with those caps you are talking about.

Problemwith audio as usual is to abstract from a local scientific rule in an area of the device what it will give in a sum of subjectivity : the sum of the different devices, listerners, rooms...

Sometimes you just have to try and hopes it is fr a better result. But yea engineering rules of course matters first... we are talking about the last percents of optimization with passive parts game (however it's all about what our hobby is)

It's certainly harder to discover the rule that apply with the ones already known that sometimes experiments. although in science, experients are here to test a theory. Sometimes, it can be faster to just try if you have a short term subjective goal focused on one device only . And that's why I would not talk about universal behavior or equal sign as we talk before. Just what I often noticed with those caps you are talking about.

Problemwith audio as usual is to abstract from a local scientific rule in an area of the device what it will give in a sum of subjectivity : the sum of the different devices, listerners, rooms...

Sometimes you just have to try and hopes it is fr a better result. But yea engineering rules of course matters first... we are talking about the last percents of optimization with passive parts game (however it's all about what our hobby is)

Member

Joined 2009

Paid Member

Indeed, for low values of capacitance c0g has been my go to choice too. I use them in typical frequency compensation spots like Cdom.

- Home

- Design & Build

- Parts

- Comparing "Good" SMT Capacitors - C0G vs. PMMA (Acrylic) vs. PPS