Could you recommend someone in Europe who could CNC all the pieces of my own subwoofer design (Solidworks) without it costing an arm and a leg? It's a one-off custom project for my own HT.

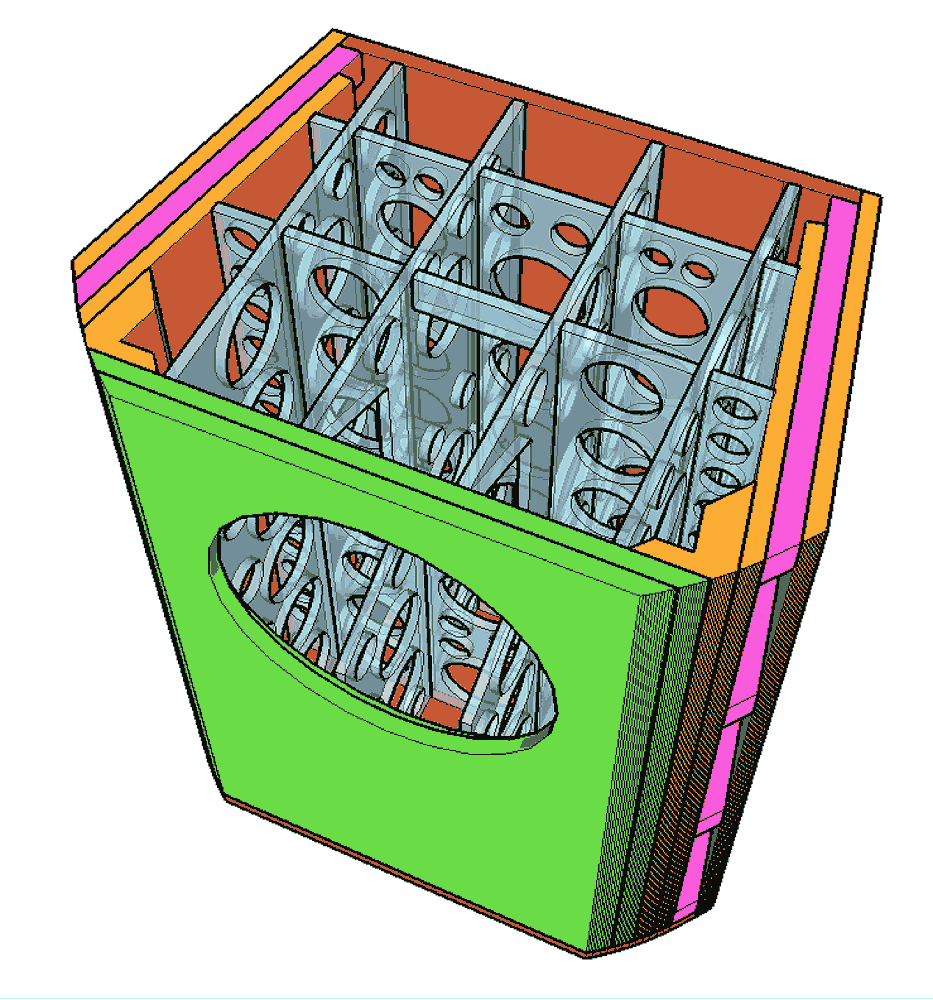

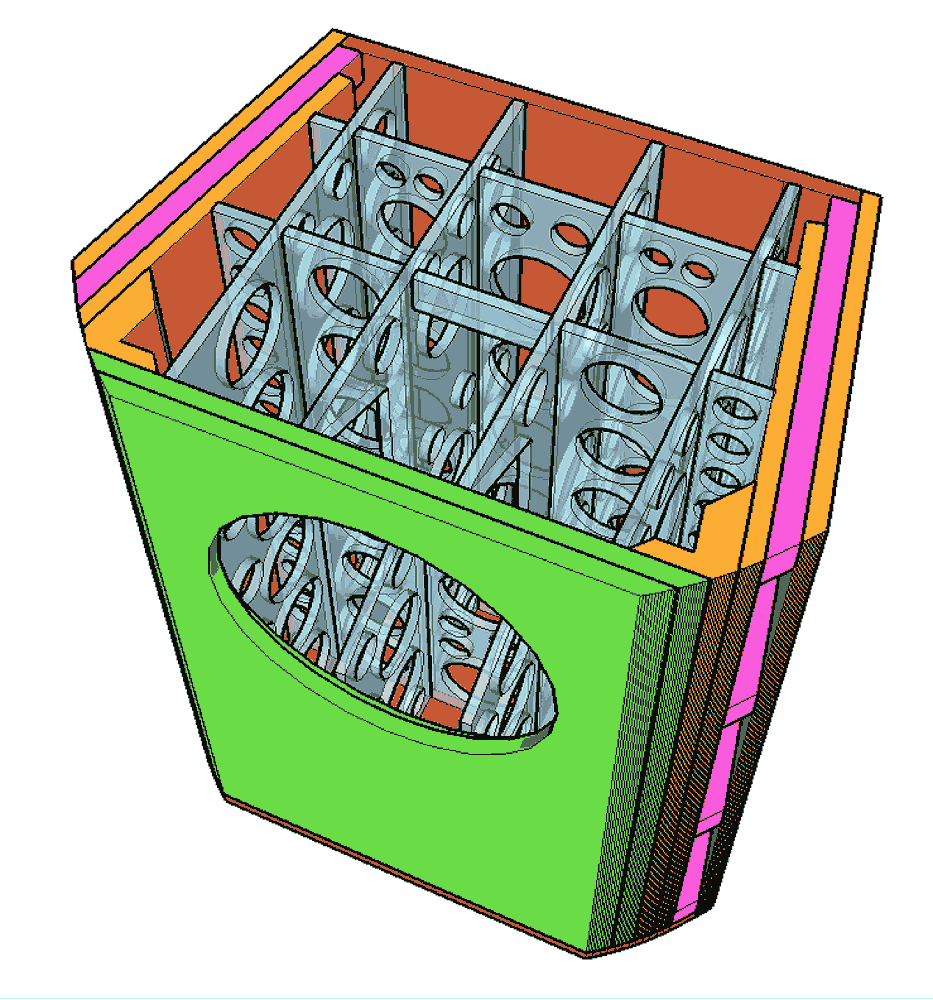

It’s a pretty serious piece requiring a few advanced cuts, going by what a few friends ‘in-the-know’ have told me, so I don’t know what kind of machine is required - although in my world, it’s basically just a “simple box” with no rocket science involved. But OK, the bracing is pretty brutal, so if Apollo 13 had been as structurally sound they would probably never have had their “Houston, we have a problem” moment… 😉

Here’s a link to the design (HTML eDrawings). Use right-click for options like removing or isolating pieces:

Subwoofer_assSplit_200617.html

I’m open to suggestions from anywhere in EU or the UK as long as the cost is competitive to justify the shipping cost.

It’s a pretty serious piece requiring a few advanced cuts, going by what a few friends ‘in-the-know’ have told me, so I don’t know what kind of machine is required - although in my world, it’s basically just a “simple box” with no rocket science involved. But OK, the bracing is pretty brutal, so if Apollo 13 had been as structurally sound they would probably never have had their “Houston, we have a problem” moment… 😉

Here’s a link to the design (HTML eDrawings). Use right-click for options like removing or isolating pieces:

Subwoofer_assSplit_200617.html

I’m open to suggestions from anywhere in EU or the UK as long as the cost is competitive to justify the shipping cost.

i could do it for you

you could make the cam yourself in sw.

saves some time .

btw i,m located in amsterdam

you could make the cam yourself in sw.

saves some time .

btw i,m located in amsterdam

Hey, that´s some seriously stiff/rigid structure!!! 🙂

Thanks. Hopefully it will pay off.

Thanks. Have sent them an email but a bit confusing when there is no option to view their website in English. Would be a natural fit though since the enclosure will be hosting Italian drivers 😉

I don't think the design is particularly complex. If you cut the 'triangular' braces the same size as the front and back panels you end up with mostly squarish brace panels with 4 windows cut in each. It would be fairly easy to design this to make the square brace panels the same size and make a template to route them from. (I'd probably rough cut with a jigsaw and finish with router)

Don't know if you have a tablesaw but if yes that would make it even easier.

Cheers,

Rob.

Way back when I had access to a laser cutter I built these midbass boxes. I think I could do them by hand now, just takes more time..

Don't know if you have a tablesaw but if yes that would make it even easier.

Cheers,

Rob.

Way back when I had access to a laser cutter I built these midbass boxes. I think I could do them by hand now, just takes more time..

Attachments

3-axis CNC router probably enough if you make angled vertical cuts and chamfers manually out of a flat surface. 5-axis router services are horribly expensive.

I don't think the design is particularly complex. If you cut the 'triangular' braces the same size as the front and back panels you end up with mostly squarish brace panels with 4 windows cut in each. It would be fairly easy to design this to make the square brace panels the same size and make a template to route them from. (I'd probably rough cut with a jigsaw and finish with router)

Don't know if you have a tablesaw but if yes that would make it even easier.

Cheers,

Rob.

Way back when I had access to a laser cutter I built these midbass boxes. I think I could do them by hand now, just takes more time..

Thanks, Rob. Those boxes are beauties

I've had help doing the 3D CAD and there's not really any flexibility in changing the design from this point onwards tbh. Sure, the roundovers on the bracing windows aren't necessary, acoustically or optically, but were more an OCD thing (of the variety we all suffer...) and I guess there might be some other features that could be left out if just a PITA.

3-axis CNC router probably enough if you make angled vertical cuts and chamfers manually out of a flat surface. 5-axis router services are horribly expensive.

Thanks, this is my understanding as well, that a 3-axis CNC is enough, although the two-sided features will require flipping over the pieces and realigning them.

Seems there's more to CNC than first meet the (naive) eye. Ironically, it wouldn't be too difficult for a carpenter to make this enclosure the old-fashioned way with standard tools. Assembled, the matrix structure makes it look a lot more complex than it really is when the individual pieces are laid out. Just that building it will be a flashback to the Mekano and Lego days.... 😛

Why? The design while truly beautiful seems mechanically unsophisticated for the purposes of a speaker cabinet. Are you just trying to be able to use just 3 mm styrofoam panels for the walls with that much bracing?

Thin-wall tubing (or used hockey sticks) can be epoxied in place at opposite sides to achieve the same rigidity.

Super-rigidity seems to be a current fad of dubious proven value.

B.

Thin-wall tubing (or used hockey sticks) can be epoxied in place at opposite sides to achieve the same rigidity.

Super-rigidity seems to be a current fad of dubious proven value.

B.

Last edited:

^ With these kinds of broad, strong worded statements, surely you have all the structural analysis to share and back up your assertions?

OP: Good idea to have the dados in there to self-align all the bracing. Might actually be stronger (in ensemble) to use thicker bracing elements at lower density because you'll have greater glue surface at each junction.

OP: Good idea to have the dados in there to self-align all the bracing. Might actually be stronger (in ensemble) to use thicker bracing elements at lower density because you'll have greater glue surface at each junction.

Last edited:

KJF Audio in Kent does a lot of speaker CNC work.

With regards to your holey braces, i would personally leave a bit more meat on the braces to minimize their deflection. I like circles.

Are you uplanning on quality plywood, or MDF (a waste for a sub IMO)?

dave

With regards to your holey braces, i would personally leave a bit more meat on the braces to minimize their deflection. I like circles.

Are you uplanning on quality plywood, or MDF (a waste for a sub IMO)?

dave

A sub needs to be rigid enuff that any potential resonances are well above the bandwidth it will be playing.

dave

dave

Since you are using two drivers, have you considered "Push-Push"? Is it possible that the bracing could affect the functioning of the port in a similar way that stuffing isn't generally used in a bass reflex enclosure?

Last edited:

"Push-Push"

If 2 drivers are the case, then not using push-push to actively canceling a huge amount (90%) of the load into the box, greatly reducing the need for over-the-top bracing.

dave

^ With these kinds of broad, strong worded statements, surely you have all the structural analysis to share and back up your assertions?...

Uniformity is always a tip-off that a design is short on deep thought.

Immediately obvious that there is bracing near to points that need no bracing (like edges which are inherently strong and don't vibrate).

Lots of bracing in places that are already OK and equally that long concatenations of bracing is no better than the weakest point of the long brace.

Clear that square and uniformly divided structure isn't as efficient as triangular and smart-spaced structure.

And so on. And can you imagine what somebody who knew what they were talking about would say (and that's not me, of course).

About the need for bracing and where it needs no more, I have yet to see any hearing evidence ever - and I've asked many times. Sure, with a sensitive sensor you can detect vibration. But that's analogous to sensing covid-19 on a piece of cardboard days later if you use highly sensitive lab tools that can detect a molecule of the virus.

B.

Last edited:

Are you just trying to be able to use just 3 mm styrofoam panels for the walls with that much bracing?

Thin-wall tubing (or used hockey sticks) can be epoxied in place at opposite sides to achieve the same rigidity.

Super-rigidity seems to be a current fad of dubious proven value.

No 3mm styrofoam, only 18mm birch plywood throughout, except baffle 30mm.

Braces spaced 20-30cm apart (i.e. no unsupported outside area larger than 30 x 30 cm) to keep panel resonances above the passband. Cannot see how that could be achieved more elegantly with hockey sticks.

Do not agree that rigidity is a fad with dubious value. On the contrary, I could probably point you to quite a few studies/examples proving otherwise (if I was so inclined).

- Home

- Loudspeakers

- Subwoofers

- CNC services