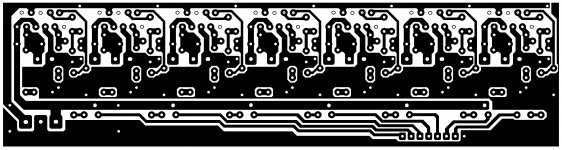

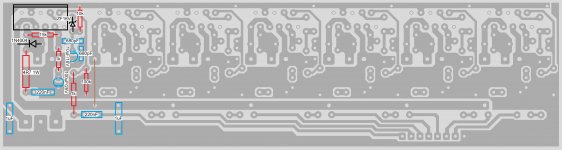

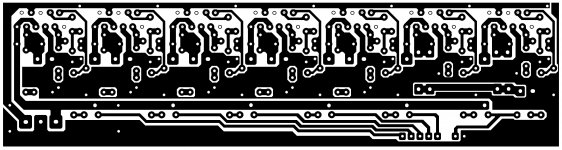

7 Channel Chip-amp TDA7294 based.

Working fine.

Working fine.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Dear rakesh_sharma23 how does that heat sink configuration works?

What about noise from those fans?

Great desing by the way!

What about noise from those fans?

Great desing by the way!

Heat sink are three stock AMD Cpu heatsink joint together, with stock fans.

Running fan with 9v using 7809-IC and no fan noise and decent cooling too.

Tested all amp running on some what 80% of volume for two hours of non stop music and heatsink were little more than warm..

Running fan with 9v using 7809-IC and no fan noise and decent cooling too.

Tested all amp running on some what 80% of volume for two hours of non stop music and heatsink were little more than warm..

5.1 PCB

last two Lm3886 chips are bridged together to drive subwoofer.

last two Lm3886 chips are bridged together to drive subwoofer.

Attachments

Last edited:

@rakesh_sharma23

Thanks for the layout. what about the top layout for the 2 lm3886 bridge?

God bless!

Thanks for the layout. what about the top layout for the 2 lm3886 bridge?

God bless!

5.1 PCB

last two Lm3886 chips are bridged together to drive subwoofer.

One can parallel connect last two chips with two 0.3 Ohms Resistance in parallel, to drive subwoofer.

Tropical fish

What's with the striped cap? Does add tone? I have seen these in instrument amps.

What's with the striped cap? Does add tone? I have seen these in instrument amps.

What's with the striped cap? Does add tone? I have seen these in instrument amps.

It's a Mullard C280 Polyester film cap.

Capacitors don't "add" anything they are passive.

Frank

Thanks Frank for explaining, I am using it on Power supply section just to filter supply voltage.

It's a Mullard C280 Polyester film cap.

Capacitors don't "add" anything they are passive.

Frank

If the cap and circuit trace has a resonance in the audible band it can "add" a coloration to the signal. More often a passive cap would be used to "remove" a portion of the signal however a poorly designed circuit will create a tank and appear to "add" something.

I don't think that was his intent with the striped cap but a blanket statement could confuse the less experienced.

Finally built it up -- took me half passed forever to build the enclosure, but my audiosector.com kit is finally up and making noise. Here's the imgur gallery.

The transformer is an Antek 200VA transformer (AS-2224) and the kit is the LM3875 'Classic Kit' from Peter Daniels.

I used wood for the side rails and L-shaped aluminum brackets mounted on there. The chips are mounted to a U-shaped bracket; that bracket is mounted to the back and bottom (with silicone grease of course).

I'd never cut aluminum before and found it surprisingly easy to cut with a bi-metal blade in a jigsaw. In retrospect, I shouldn't have used wood for the rails as there's no room for expansion -- but I had absolute zero faith in my ability to machine, tap, and line up aluminum. Besides that, I'm quite happy with the results!

The switch in the back isn't working and a replacement is on the way. Now, off to build up my Mesmerized DCB1 buffer and a proper media console to sit it all on.

The transformer is an Antek 200VA transformer (AS-2224) and the kit is the LM3875 'Classic Kit' from Peter Daniels.

I used wood for the side rails and L-shaped aluminum brackets mounted on there. The chips are mounted to a U-shaped bracket; that bracket is mounted to the back and bottom (with silicone grease of course).

I'd never cut aluminum before and found it surprisingly easy to cut with a bi-metal blade in a jigsaw. In retrospect, I shouldn't have used wood for the rails as there's no room for expansion -- but I had absolute zero faith in my ability to machine, tap, and line up aluminum. Besides that, I'm quite happy with the results!

The switch in the back isn't working and a replacement is on the way. Now, off to build up my Mesmerized DCB1 buffer and a proper media console to sit it all on.

Last edited:

A tip:

With that thick front panel (>4mm) you do not need to drill the mounting holes through the plate. Drill carefully from back side of the plate with a 2.5mm drill and only to about 3mm depth, not completely through the plate.

Then use stainless steel M3 screws and screw them directly to the 2.5mm hole, use oil as lubricant when screwing (and there is nothing perverted in this as my late dance teacher would have said) and you have nice attachment for the panel from the back side invisible to the front - which is nice...

With that thick front panel (>4mm) you do not need to drill the mounting holes through the plate. Drill carefully from back side of the plate with a 2.5mm drill and only to about 3mm depth, not completely through the plate.

Then use stainless steel M3 screws and screw them directly to the 2.5mm hole, use oil as lubricant when screwing (and there is nothing perverted in this as my late dance teacher would have said) and you have nice attachment for the panel from the back side invisible to the front - which is nice...

A tip:

With that thick front panel (>4mm) you do not need to drill the mounting holes through the plate. Drill carefully from back side of the plate with a 2.5mm drill and only to about 3mm depth, not completely through the plate.

Then use stainless steel M3 screws and screw them directly to the 2.5mm hole, use oil as lubricant when screwing (and there is nothing perverted in this as my late dance teacher would have said) and you have nice attachment for the panel from the back side invisible to the front - which is nice...

Thanks, but I like the screws up front. Also far easier for me to drill and align 2 holes coming in from the front. I was having trouble drilling through two plates and having them both match enough for me to tap. This thread from Peter Daniel's was helping a great deal during the build.

- Home

- Amplifiers

- Chip Amps

- Chip Amp Photo Gallery