It's less than you think as these go in a letter envelope. But the Maxim chip has direct outputs to speakers. No filters or anything as far as I can tell. How do they do that? Is it not class D? Where's the inductor or the cap and snubber?

They run filterless in spread spectrum mode with "Maxim Modulation", like 1SPW. Measured them for radiation into RF band, not much to see there. Of course you don't want to have long speaker wires, but up to 150cm (that's what I'd tested) they are fine. Measurements are available on my website.

http://www.360customs.de/en/2015/02/tpa3132d2-vs-max9709-messungen-emiemv/

Pretty neat stuff.

Without filters there no "filter-sound". TI says, filterless gives better audio quality than half or full filter. (Of course the speakers itself acts as the reconstruction filter, so they need some minimal inductance to make the magic work)

http://www.360customs.de/en/2015/02/tpa3132d2-vs-max9709-messungen-emiemv/

Pretty neat stuff.

Without filters there no "filter-sound". TI says, filterless gives better audio quality than half or full filter. (Of course the speakers itself acts as the reconstruction filter, so they need some minimal inductance to make the magic work)

Last edited:

Incidentally, the 3118 Sanwu board is pretty tough. I accidentally hooked 12 V bat power to speaker outputs on one board. Red LED lit up so it took a few mins to figure it out. Switched to correct wiring and had no sound. Thought I tried the board but I tried again after some time and presto! The magic smoke is back in the dam board! Am I lucky or what? Oh, the boat/beach boogie speakers are half done. That is one is constructed of wood and wired up, the other is in foam board. Wow, does the wood speaker crank with only 12V bat power. No need to go24V and use the dc-dc converter. I might need it for the two 12 woofers though? Hey, how do you attach the boards to heatsinks? They were getting pretty hot cranked so I tried setting on a fined heatsink and the leads were shorting! Must have to use standoffs and build up the rtv sealnt/adhesive to get the connects away from the sink?

I use Kapton tape insulator to prevent shorting the board when attached to heat sink. I used thin layer of RTV silicone. What could also work is the silicone insulator sheets used in power transistors. The drill and tap 4 holes to match the board and clamp board to heat sink with silicone sheet in between.

Thanks x but what is kapton tape insulator? (Thanks for the foam board thread) great way to try out a new project quick and cheap!(oh, also for cornucopya! Done that one too!)

Never mind googled it! Dam that kapton is expensive! Won't be going that route! Just lost my job today!

You can get some from aliexpress if you do not mind the wait.

100Pcs TO 220 Insulation Pads Silicone Heatsink Shim for Laptop GPU CPU-in Fans & Cooling from Computer & Office on Aliexpress.com | Alibaba Group

100Pcs TO 220 Insulation Pads Silicone Heatsink Shim for Laptop GPU CPU-in Fans & Cooling from Computer & Office on Aliexpress.com | Alibaba Group

That's a good price in those. They are quite pricey if bought from Digikey or Mouser. There is a larger size for TO-3P transistors that may work better.

I agree Kapton tape is very specialized stuff. It's used a lot in electronics for its heat resistance and excellent electrical insulation properties. You can solder on it and it won't melt. The glue leaves no residue. So for about twice the price of a roll of duct tape it's not a bad deal considering.

I agree Kapton tape is very specialized stuff. It's used a lot in electronics for its heat resistance and excellent electrical insulation properties. You can solder on it and it won't melt. The glue leaves no residue. So for about twice the price of a roll of duct tape it's not a bad deal considering.

Yes maybe so, and normally I would go that route but now have to watch my few pennies! Thanks

Here is the cheapskate way to do it. Find some thin 2mil thick (or whatever needed to prevent contact of back of circuit to heat sink surface) sheets of plastic (for example, packaging from clear blister packs etc). Cut little shim strips with them and use that as a spacer around periphery of PCB to avoid direct contact with heat sink when applying RTV silicone caulking as heat sink compound and adhesive. The shims set the precise thickness to prevent the solder bump to heat sink contact. Once the RTV cures, you can pull the shims out (or leave in).

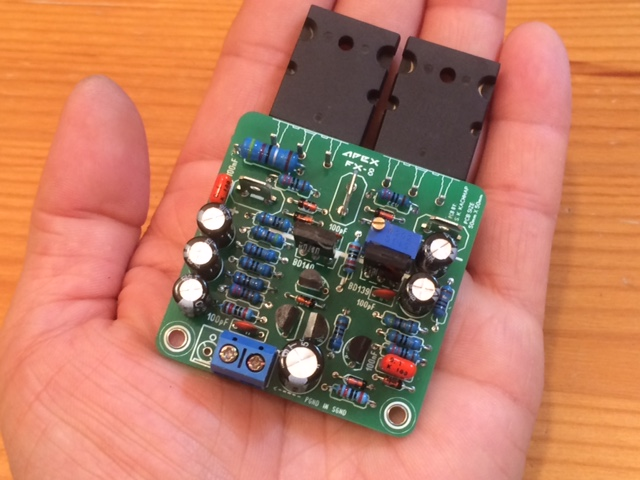

I just built the Apex FX8 amp - it is very small (50mmx50mm board) for a fully discrete thru hole component 100w class AB amp. I am still waiting for the MOSFET output stages to arrive so the ones shown are mockups to get the scale of the device.

My recent experience is that these discrete class AB's sound better than the TPA31xx amps.

Do you have a link to those 'pcb mount spade-connectors'?

I would like to buy them from aliexpress, but i don't know the correct english term...

What is the efficiency of your a/b build? The nice thing about 31xx is the sip electrons. Been running my pair of 3118's for about a week for a few hours a day without a charge on 12V 8AH SLA. It's still at 12.71 V!!

Look at prices at a distributor near you, I buy 500 or 1000 for 10 euro, not worth looking for prices at Ali.

Do you have a link to those 'pcb mount spade-connectors'?

I would like to buy them from aliexpress, but i don't know the correct english term...

PCB male soldering tabs

Online Shop 80pcs Board Mount PCB Solder Tab Male Terminals Uninsulated 6.3mm x 0.8mm|Aliexpress Mobile

There are two sizes 4.8mm and 6.3mm wide. I like the wider ones.

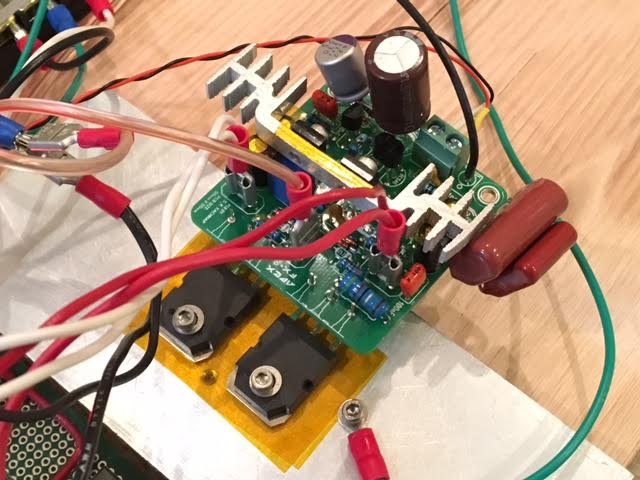

Here is the latest incarnation of that little MOSFET amp.

Last edited:

- Home

- Amplifiers

- Class D

- Cheap TPA3118D2 boards, modding them and everything that comes with it