John brings up an interesting bit of history. During the brief heyday of analog computers a huge amount of work was done investigating cap behavior, particularly DA because it fouled the calculation results from integrators and differentiators. No idea where that info can be had today. I have a couple old books on analog computers, but they only mention it in passing.

I'm a measurement freak and bridge collector. Not the Golden Gate type, but the General Radio type. Since the topic comes up so often, I put a short "build a bridge" write up-on my web site. It won't answer the subtle questions here, but might be useful to somebody-

bridge project

FWIW, DA is tough to measure because it's so condition dependent. Silver-mica is great in all respects except that one. I'm pretty sure the multi-layer C0G types are far better. I'm not sure how they compare to polystyrene, nor if all polystyrenes are created equal. IMHO, you have to measure because all generalization on caps are risky at best.

I'm a measurement freak and bridge collector. Not the Golden Gate type, but the General Radio type. Since the topic comes up so often, I put a short "build a bridge" write up-on my web site. It won't answer the subtle questions here, but might be useful to somebody-

bridge project

FWIW, DA is tough to measure because it's so condition dependent. Silver-mica is great in all respects except that one. I'm pretty sure the multi-layer C0G types are far better. I'm not sure how they compare to polystyrene, nor if all polystyrenes are created equal. IMHO, you have to measure because all generalization on caps are risky at best.

Re: that is a very nice argument

I think probably most would agree that if you are going to use a ceramic, use a good quality Class 1 NP0/CG0. As to what is a good quality one, from what I have read, I would avoid Xicon brand. Murata and TDK are readiliy available brands, but I haven't heard positive or negative about their quality/reliability. TDK has some values with non-magnetic leads, if that is important to you. However, not in all values.

sakis said:thanks everybody for the input

can somebody place a conclusion of all this ????

thanks

the OP

I think probably most would agree that if you are going to use a ceramic, use a good quality Class 1 NP0/CG0. As to what is a good quality one, from what I have read, I would avoid Xicon brand. Murata and TDK are readiliy available brands, but I haven't heard positive or negative about their quality/reliability. TDK has some values with non-magnetic leads, if that is important to you. However, not in all values.

John, here's a link to the Mouser catalog page for Kemet C0G caps. These only go up to 200V. For 200V, they go up to 0.047uF, and for 100V they go up to 0.1uF. Those higher values are expensive though! But the ones in the range for Miller comp, input LPF etc. are very reasonably priced.

The Vishay/Sprague 1kV 561R series C0G only go up to 270pF.

The Vishay/Sprague 1kV 561R series C0G only go up to 270pF.

john curl said:OK, use them at your own risk. They still have 10 times the DA as polypropylene.

You are amazing, John 🙂 Who in hell said it will use ceramics instead of polypropilene, polystyrene, etc...?

This is for the 4th time I'm repeating this, here are my rules of thumb:

- Silver mica has larger DA than NP0 and C0G. In the same 0-100pF range, in the signal path (frequency compensation), NP0 and C0G ceramics are superior from all perspectives, in particular high voltage models.

- In the 100pF to 10nF range in the signal path (RIAA, etc...), the best option seems to be polystyrene.

- 10nF and up in the uF range, in the signal path (RIAA, interstage coupling, etc...), polypropilene rules.

- For supply decoupling, ceramics (even the X7R) are good enough; foil caps are inferior due to larger ESL, potentially leading to parasitic resonances.

- Teflon caps do not bring any significant improvements in audio.

Values ranges can be, of course, subject to debates and are somehow arbitrary.

pooge said:Come on, guys. Let's stop this needless, endless goating.

Impossible.

We must wait till sin08 publishes his complete encyclopedia of No-BS definitions...

I am thinking usually of using mica vs ceramic caps up to 1000pf as the same basic size mica fits the whole range. Mica is not perfect, but it seems to work OK, and I KNOW what it is. With ceramic, I can't be as sure without second checking the codes on the case.

To be more clear and to teach many here something more useful. It can be shown that many ceramic caps transition to inferior dielectrics as the cap value is increased.

This is unusual, because you don't see this with mica, polystyrene, etc.

This is because SIZE can be all important in a design, and once the SIZE of the cap is specified, you have to take what you can get, as far as dielectric is concerned. This can be problematic, and something that I usually want to avoid in my own designs.

This is unusual, because you don't see this with mica, polystyrene, etc.

This is because SIZE can be all important in a design, and once the SIZE of the cap is specified, you have to take what you can get, as far as dielectric is concerned. This can be problematic, and something that I usually want to avoid in my own designs.

That's why you need to look at the datasheet. Always know the properties of the components you are using, and if the manufacturer doesn't make the required information available then don't use them.john curl said:...It can be shown that many ceramic caps transition to inferior dielectrics as the cap value is increased...

This seems like an interesting phenomenon that is worthy of further investigation, but leads to a great many questions.

First of all, is this phenomenon evident in Class 1 caps, limited to Class 2 and/or Class 3 caps, or differences in construction, etc.?

If it is only evident in the very large sizes out of the Class 1 cap range, is the "transistion in dielectrics" an actual blend in dielectrics? In other words, to get a really high value in a manageable size, are there changes in the dielectric between layers of ceramics of higher K? That would seem doubtful due to cost. Or, in the again used generic term "ceramic", is this issue then limited to values for which only class 3 is available?

First of all, is this phenomenon evident in Class 1 caps, limited to Class 2 and/or Class 3 caps, or differences in construction, etc.?

If it is only evident in the very large sizes out of the Class 1 cap range, is the "transistion in dielectrics" an actual blend in dielectrics? In other words, to get a really high value in a manageable size, are there changes in the dielectric between layers of ceramics of higher K? That would seem doubtful due to cost. Or, in the again used generic term "ceramic", is this issue then limited to values for which only class 3 is available?

Ceramic caps actually are made of very different materials with different properties, so the simple question is not valid. Also, they have different constructions. First types were produced of ceramic tubes. They had different tangents of loss angles, different temperature coefficients specified for the working temperature (20 degrees C), and different capacitances due to sizes and dielectric properties. Capacitors that have zero thermal coefficient on 20 degrees C are called NP0 (Negative/Positive Zero). Later another types were produced, like multilayer capacitors, of smaller sizes per capacitances. So called segneto-ceramics were used for largest values of capacitances, the latter had highest piezo effects and highest temperature coefficients on 20 degrees C. Far the more, on different temperatures thermal coefficients are different, even go through zero. Are they good or bad? They are good when size matters.

Different capacitors of different constructions and made of different dielectrics are very different. And they are good for different purposes.

Different capacitors of different constructions and made of different dielectrics are very different. And they are good for different purposes.

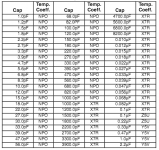

Mr Evil said:I expect John is referring to the way a single range of capacitors changes dielectric as in the attached table.

yes, I suspect the same. A transistion from a Class 2 to a Class 3 type as the value range of Class 2 is exceeded. But that is not a mystery phenom.

- Status

- Not open for further replies.

- Home

- Amplifiers

- Solid State

- ceramic capacitors ....