looking at building some pensil type speakers, and at the moment don't have the drivers called for in any of the designs. Is there some rule of thumb that I can use to modify the box dimensions to get close enough to re-size the box to drivers I do have?

Drivers I want to try currently are Mark Audio CHN-70. There will be others soon enough, I'm sure.

I have modeled a few of the various published boxes in CAD (I use fusion 360), so that I could figure out the net volume (not including the driver), and have not really figured out what speaker parameters are the cause for a bigger or smaller box. I'm guessing the Fo, and the Qts are the more important numbers, but also the Vas?

pensil R70.3 has a volume of 2124 in3, pensil p70.2 has 2098 in3 - Not a huge difference. The original pensil R70 had 1792 in3 and the p70 had 2303 in3 volumes. I have not found the specs on those drivers yet to compare. of the currently available drivers with parameters listed online, the CHN-70 look closest in t/s parameters to the CHP-70 gen 2, though they have slightly lower Qts, larger Vas, smaller magnet, and lighter cone. I could try a box built to the same size as called for in the P70.2, but if I knew how to adjust these properly, it might save a bunch of trouble.

I'm also curious about bracing on these boxes. They don't seem really big enough to need it, but the plans say to refer to how the super pensil is braced, which is easy enough to follow. What I'm not sure about it whether I should keep the overall volume inside the same with the bracing, or increase it based on how much space the bracing takes up.

I have hornresp on my computer, but haven't quite figured out the ins and outs of getting useful information from it yet. I'll mess around with it some more and see if I can figure out how to input models of this kind of speaker (this is a mass loaded transmission line?).

Drivers I want to try currently are Mark Audio CHN-70. There will be others soon enough, I'm sure.

I have modeled a few of the various published boxes in CAD (I use fusion 360), so that I could figure out the net volume (not including the driver), and have not really figured out what speaker parameters are the cause for a bigger or smaller box. I'm guessing the Fo, and the Qts are the more important numbers, but also the Vas?

pensil R70.3 has a volume of 2124 in3, pensil p70.2 has 2098 in3 - Not a huge difference. The original pensil R70 had 1792 in3 and the p70 had 2303 in3 volumes. I have not found the specs on those drivers yet to compare. of the currently available drivers with parameters listed online, the CHN-70 look closest in t/s parameters to the CHP-70 gen 2, though they have slightly lower Qts, larger Vas, smaller magnet, and lighter cone. I could try a box built to the same size as called for in the P70.2, but if I knew how to adjust these properly, it might save a bunch of trouble.

I'm also curious about bracing on these boxes. They don't seem really big enough to need it, but the plans say to refer to how the super pensil is braced, which is easy enough to follow. What I'm not sure about it whether I should keep the overall volume inside the same with the bracing, or increase it based on how much space the bracing takes up.

I have hornresp on my computer, but haven't quite figured out the ins and outs of getting useful information from it yet. I'll mess around with it some more and see if I can figure out how to input models of this kind of speaker (this is a mass loaded transmission line?).

Per above, Pensil N70 I did for it back in 2014 & linked to via the Markaudo site:

https://frugal-phile.com/boxlib/pensils/Pensil-N70-plan-100914.pdf

The pensils are a custom hybrid alignment I came up with many years ago; the calculations are not published because with a few custom exceptions they're reserved for Markaudio. Regarding bracing, whenever it's recommended in any of my designs, it's actually the default i.e. it's assumed to be present.

Hope that helps!

https://frugal-phile.com/boxlib/pensils/Pensil-N70-plan-100914.pdf

The pensils are a custom hybrid alignment I came up with many years ago; the calculations are not published because with a few custom exceptions they're reserved for Markaudio. Regarding bracing, whenever it's recommended in any of my designs, it's actually the default i.e. it's assumed to be present.

Hope that helps!

I have hornresp on my computer, but haven't quite figured out the ins and outs of getting useful information from it yet. I'll mess around with it some more and see if I can figure out how to input models of this kind of speaker (this is a mass loaded transmission line?).

Yes, you'd model this as an MLTL. To get started, the easiest way is probably to use the Input Wizard (found on the Help menu), and then, when you've entered the required info, click the "Edit" button on the main screen and use the Loudspeaker Wizard (accessed from the Tools menu). One tip I found useful when I started with it was to remember to set a path length (i.e. the distance between the driver and the vent), which you can do from the Chamber sub-menu.

Of course you may not need to bother now that you've got the official Pensil design. 🙂

Not sure how I missed that! I dug through all of the designs, or so I thought! 😅

Thanks!

Per above, Pensil N70 I did for it back in 2014 & linked to via the Markaudo site:

https://frugal-phile.com/boxlib/pensils/Pensil-N70-plan-100914.pdf

The pensils are a custom hybrid alignment I came up with many years ago; the calculations are not published because with a few custom exceptions they're reserved for Markaudio. Regarding bracing, whenever it's recommended in any of my designs, it's actually the default i.e. it's assumed to be present.

Hope that helps!

Hi Scott,

Just to be clear, it says in the plans for the N70 that “bracing is optional” does that mean that the additional interior volume for bracing is included in the design? The statement is a little unclear to me whether it is recommended or not.

I was also wondering if there is any benefit to making these slightly taller, maybe 47-48”? If so, is it as easy changing the port height to adjust the tuning, or would I want to keep the overall interior volume close to the same as the original design? Easiest method would be to add height using a foot or plinth, but I was curious if extra length on the enclosure would be beneficial?

Yes, you'd model this as an MLTL. To get started, the easiest way is probably to use the Input Wizard (found on the Help menu), and then, when you've entered the required info, click the "Edit" button on the main screen and use the Loudspeaker Wizard (accessed from the Tools menu). One tip I found useful when I started with it was to remember to set a path length (i.e. the distance between the driver and the vent), which you can do from the Chamber sub-menu.

Of course you may not need to bother now that you've got the official Pensil design. 🙂

I think I will still try to model it, just for the education… I was unsure of a few settings, and will check back here once I get a chance to start inputting numbers. The main question for now, is whether I select point source or half space or quarter space? My first inclination would be that half space would be selected if the speaker boxes were meant to be placed against a wall?

Just to be clear, it says in the plans for the N70 that “bracing is optional” does that mean that the additional interior volume for bracing is included in the design?

While I'm not Scott, he did comment on this above - you maybe missed it? -

Regarding bracing, whenever it's recommended in any of my designs, it's actually the default i.e. it's assumed to be present.

Regarding your question about altering the height, you probably don't want to do that. A TL is different from a reflex or sealed box, where it's generally OK to alter one dimension so long as you preserve the volume. In a TL, you have a quarter-wave resonance established by the longest dimension, which is the height, here. Altering that would alter the tuning.

In Hornresp, I often chose half-space, but actually it doesn't matter all that much, because it just shifts the curve up or down, at low and mid frequencies anyway. Also you can change your selection later, from inside the Loudspeaker Wizard.

=Just to be clear, it says in the plans for the N70 that “bracing is optional” does that mean that the additional interior volume for bracing is included in the design? The statement is a little unclear to me whether it is recommended or not.

Regarding bracing, whenever it's recommended in any of my designs, it's actually the default i.e. it's assumed to be present.

=I was also wondering if there is any benefit to making these slightly taller, maybe 47-48”?

The pensils are a custom hybrid alignment

They are the dimensions they are to achieve the target alignment. But you can certainly create an MLTL of different proportions if you have a different alignment in mind, no worries on that front. That's why I often show three or four variations for different drivers on the Markaudio site; they all have different load behaviour & alignments to suit different preferences, so like anything else, a case of 'name your poison'. 😉

As has been explained above, but giving a bit more detail, an MLTL is different to a Helmholtz vented box in that there are several different contributing loading characteristics that determine tuning & alignment; the physical length & when relevant taper ratio in quarter-wave enclosures is a functional part of the tuning, as is the driver & when relevant the vent offsets -that apart from Vb and damping. As noted, the pensils are a slightly unusual [at least, for this century...] hybrid on a quarterwave with traditional pre T/S vented boxes & TLs so they're a little odd in some of their operating character, as they're by design an acoustically efficient, moderately broadband, high-gain alignment with no load-forcing where TL levels of damping are used to control the response and also provide a well-damped impedance, which is valuable for those who have amplifiers with relatively little electrical damping. But that's just the pensil alignment & the objects I had for it -per the above, there's plenty of alternative types of alignment if you prefer something else.

Hope that's of some help!

Last edited:

It was worded unclearly to me, as to whether the bracing was figured in already on the designs where it is "optional". If yes, lack of bracing makes the box marginally too big, and if no, adding bracing makes it marginally too small. I imagine the box is forgiving enough that it doesn't matter that much, but wanted to confirm. I could always build both ways (adjusting the volume to compensate for addition of bracing and see what happens, but there are so many variables at play, I wouldn't necessarily know which was "correct". I don't have a lot of practical experience with speaker design, so I figured I'd build these as close as possible to how they were designed as a point of reference for other experiments, unless I'm so pleased with what I make that I don't feel the need to. I'm drawing up CAD files that are parameter based, so it is relatively trivial to add or subtract a bit from the depth or width of the box in order to try variations. My model calculates the actual interior volume for me, even for complex shapes.While I'm not Scott, he did comment on this above - you maybe missed it? -

Regarding your question about altering the height, you probably don't want to do that. A TL is different from a reflex or sealed box, where it's generally OK to alter one dimension so long as you preserve the volume. In a TL, you have a quarter-wave resonance established by the longest dimension, which is the height, here. Altering that would alter the tuning.

In Hornresp, I often chose half-space, but actually it doesn't matter all that much, because it just shifts the curve up or down, at low and mid frequencies anyway. Also you can change your selection later, from inside the Loudspeaker Wizard.

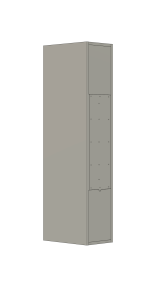

The only change I'm making for now, is to make the removable section of the back shorter. I'm cutting on a CNC router, so drew it up with rabbet joints to make it easier to glue together. I still need to make a spot for a board to mount binding posts in the back, and then ready to cut. 3/4" MDF for now, with 1/2" interior baffle. If I like what I end up with, I can make again from nicer looking wood.

Attachments

Got my terminal cutout worked out, and the internal baffle still has about the same total surface area, around 45% of the full baffle is cut out. Hopefully my hands can fit into this tiny space! The speakers seem much bigger on screen, until I look at the little 4" drivers. By tomorrow evening I'll know whether this will all work or not 🙂

Attachments

It’s only 7” wide… the plans didn’t call for one, though thinking about it, the longer sides are not stiffened by the brace. I guess if I were to make it with thinner material, a side brace could be beneficial, but this will be 3/4” (19mm) thick panels.

My understanding was that the front to back bracing was to help somehow to keep front panel from resonating because the driver is attached to it? The back of the driver is supposed to touch the wood behind it, and transfer energy to the back of the case. Not sure how much that really matters… the driver frame and magnet has significantly more mass than the moving parts.

My understanding was that the front to back bracing was to help somehow to keep front panel from resonating because the driver is attached to it? The back of the driver is supposed to touch the wood behind it, and transfer energy to the back of the case. Not sure how much that really matters… the driver frame and magnet has significantly more mass than the moving parts.

Yes, the front to back brace will stiffen the baffle (and enable you to brace the back of the driver). The Pensil planset does say that the side to side brace can be omitted on the smaller ones, I see. At 292mm deep, the N70 is kind of in the middle, depth-wise. Personally I'd have a brace on a panel that size, but I guess it's a matter of personal preference. Maybe @Scottmoose has advice?

=It’s only 7” wide… the plans didn’t call for one,

On Pensil N70 planset pdf:

Point 3/ bracing is optional. For bracing ideas plase see the bracing sheet in the superPensil12 plan

SuperPensil 12 pdf [which does need a little searching as it was for the original Alpair 12]:

https://www.frugal-phile.com/boxlib/pensils/superPensil12-map.pdf

p.2 shows the longitudinal bracing both axis, which is unless stated otherwise is always assumed to be present in the pensils & the default setting. The lateral can be omitted, but on a box as substantial as Pensil N70 [and it's a big enclosure for a 4in driver] that's almost 300mm / 12in deep, I'd always use it. As far as bass enclosures go, you can't have too rigid a structure -there are no acoustic disadvantages & it does reap dividends. They're a pain to make unless you have automated cutting, I admit, but if you can -do so, is my advice. Oh, and when you're finished -if you can, stick a large Boston fern / choice of pot-plant on the top. If you're not a fan of plants, a piece of marble, slate, granite or similar is no bad thing. People get the wrong idea about mass -they think it's best low down. Which it is -for stability. For acoustics, if you put something nice & heavy on the top, you mass-load all the structure straight into the floor. Again, no bad thing.

Hope that helps!

I ended up adding bracing side to side. I only put in two, 3" tall, since I was worried it would be hard to get the stuffing up front, since the cabinet is so narrow (only 5.5" side to side).

I almost went to 1/2" wall thickness, due to not having enough 3/4" MDF on hand, but I finally found a big enough piece to make two cabinets behind a pile of stuff. My boss wants me to toss a bunch of the random materials we have laying around left over from student projects, so it's a win-win. 🙂,

I almost went to 1/2" wall thickness, due to not having enough 3/4" MDF on hand, but I finally found a big enough piece to make two cabinets behind a pile of stuff. My boss wants me to toss a bunch of the random materials we have laying around left over from student projects, so it's a win-win. 🙂,

Attachments

The smaller and thinner pieces, you need to add tabs, so that they can still hold down to the table with the vacuum blower. Thankfully, they are easy to cut off with a flush trim bit and a hand held router (or router table). I had the machine chamfer the driver openings, because I wanted to leave some full thickness posts for the screws. It looks nasty at first, but rubbing/burnishing with a metal edge, like the side of a chisel cleans it right up, with almost no need to sand (especially since it's hidden inside the cabinet. I usually apply either water-thin super glue or some polyurethane finish to surfaces like this to prevent them from so readily absorbing moisture from the air.

Attachments

It takes 21 minutes to cut what is shown here, mostly due to the time it takes to make steps down 0.01" at a time over the sloped surface. I also have it pre-drill holes for me with an 1/8" bit to help line up for screws. Usually screw holes in MDF will get some water-thin super glue on them to help the screw have more to grab onto. The super glue also works wonders on raw cabinet edges to keep them from getting dented. On a nice cabinet made with plywood, I prefer to put edge banding using 1/4-3/4" of solid wood to cover and protect raw edges from damage.

- Home

- Loudspeakers

- Full Range

- calculating Pensil speaker dimensions for arbitrary drivers