how thick is the aluminum. i have some 0.5mm stuff that is preanodised and coloured black. unfortunately i have only 1 sheet of 1200x600 mm.

I will soon be building a pair of Line Array's that house 12 7"

Kevlar Mids and 12 Ribbons per cabinet. They will be sealed and

there will be a pair of stereo 12" sealed subs used with these.

The cabinets are made of 3/4" MDF 88" tall and braced with 3/4"

MDF every 12" The corners will be MDF Roundovers (2 or 3") on

all 4 corners.

I know the cabinet will be very strong. Do you think adding 30

ounce Carbon Fiber on all of the cabinet (except the baffel) would

add much more rigidity? I was thinking about doing the CF For

Asthetic reasons and finishing the baffel in WilsonArt Satin

Aluminum Metalaminate.

Kevlar Mids and 12 Ribbons per cabinet. They will be sealed and

there will be a pair of stereo 12" sealed subs used with these.

The cabinets are made of 3/4" MDF 88" tall and braced with 3/4"

MDF every 12" The corners will be MDF Roundovers (2 or 3") on

all 4 corners.

I know the cabinet will be very strong. Do you think adding 30

ounce Carbon Fiber on all of the cabinet (except the baffel) would

add much more rigidity? I was thinking about doing the CF For

Asthetic reasons and finishing the baffel in WilsonArt Satin

Aluminum Metalaminate.

Brett D. said:Line Array's that house 12 7"

Kevlar Mids and 12 Ribbons per cabinet.

What drivers?

dave

The Stryke Audio SA071 Mid and RTW2 Ribbon

John Janowitz had been playing around with some DiPole LA's

using these drivers a while ago. I wanted a pair of LA's but I do

not have the knowledge to design the XO so I asked him if he

could do a design using a sealed LA since I will be running a sub

on the bottom end and I didn't want DiPoles because I really

do not have enough room to let them breath.

He decided to do a sealed and vented design. I plan on making

a post in a day or so showing the progress that John has made

so far. I will be ordering all the drivers plus another AV-12 sub

next week. I am going to run dual sealed AV-12's with a .5 Q

and run these LA's off my Tube Amps or a pair of Aragon Paladium

1K's (depending on my mood).

I realise that these aren't Scan-Speak or Seas etc... I simply could

not afford to do an LA with such pricey drivers and since each

driver is doing 1/12th the amount of work and I won't expect

them to reach much lower than 70Hz or so, I think they should

sound fantastic and the price when completed will be less than

$2K I figure.

John Janowitz had been playing around with some DiPole LA's

using these drivers a while ago. I wanted a pair of LA's but I do

not have the knowledge to design the XO so I asked him if he

could do a design using a sealed LA since I will be running a sub

on the bottom end and I didn't want DiPoles because I really

do not have enough room to let them breath.

He decided to do a sealed and vented design. I plan on making

a post in a day or so showing the progress that John has made

so far. I will be ordering all the drivers plus another AV-12 sub

next week. I am going to run dual sealed AV-12's with a .5 Q

and run these LA's off my Tube Amps or a pair of Aragon Paladium

1K's (depending on my mood).

I realise that these aren't Scan-Speak or Seas etc... I simply could

not afford to do an LA with such pricey drivers and since each

driver is doing 1/12th the amount of work and I won't expect

them to reach much lower than 70Hz or so, I think they should

sound fantastic and the price when completed will be less than

$2K I figure.

Brett D. said:John Janowitz had been playing around with some DiPole LA's

I've seen a smaller line array design from John... i've always been interetsed in how that 7" sounds -- i have a single pr of the ribbons. And i have to admit line arrays are intrguing.

That's a lot of holes. Are you going to get him to CNC the baffles at least?

dave

Attachments

Dave,

The full size LA's will have a large roundover on every edge this

should certainly help with difraction issues. The small version

would make a great L/R Surround in an HT 🙂

Yeah that's going to be lots of holes... Too many! I talked to

John about having him possibly do the baffels on his CNC Router

(Ohh I would kill to have that beaut!) shipping will be the main

issue.. Just the drivers alone (24 Ribbons, 24 Mids and one AV-12)

will weigh nearly 200Lbs (He's going to ship palletized BAX) I

guess we could do the same with the baffels perhaps and just

make sure the edges are well protected.

I also have to order those premade MDF corners (x8 pcs) that's

$120.00 plus at least 3 sheets of 3/4 MDF and I need to pick up

a Kreig Pocket Hole jig (it's either spend $30.00 on that, or buy

60 clamps!)

Heh they certainly won't be cheap but it should be one heck of a

fun project and the end result will be efficient and clean sounding.

The full size LA's will have a large roundover on every edge this

should certainly help with difraction issues. The small version

would make a great L/R Surround in an HT 🙂

Yeah that's going to be lots of holes... Too many! I talked to

John about having him possibly do the baffels on his CNC Router

(Ohh I would kill to have that beaut!) shipping will be the main

issue.. Just the drivers alone (24 Ribbons, 24 Mids and one AV-12)

will weigh nearly 200Lbs (He's going to ship palletized BAX) I

guess we could do the same with the baffels perhaps and just

make sure the edges are well protected.

I also have to order those premade MDF corners (x8 pcs) that's

$120.00 plus at least 3 sheets of 3/4 MDF and I need to pick up

a Kreig Pocket Hole jig (it's either spend $30.00 on that, or buy

60 clamps!)

Heh they certainly won't be cheap but it should be one heck of a

fun project and the end result will be efficient and clean sounding.

navin said:How thick is the aluminium? I have some 0.5mm stuff that is preanodised and coloured black.

That should be fine. The strength comes from the core.

Brett D. said:at least 3 sheets of 3/4 MDF

MDF is easier to work with & too finish and cheaper, but i prefer plywood.

dave

MDF certainly cuts better (harder on blades) the cuts are so nice

and smooth right off the saw or router. It has more mass and

is more acousticaly dead. I have heard arguments both ways as

far as materials being acousticaly dead or somewhat adding

color. I have heard numerous people say plywoods work very

well and I do not doubt it at all. If I were doing folded horn loaded

widebands (Lowther, Moth Audio, Fostex, Tang Band etc.) I would

go ply without any hesitation.

But for this project I think the MDF will be a lot easier on me... I

have a lot of work ahead of me.. I still haven't ruled out having

John CNC route the baffels and ship them to me just for the

fact that they will be perfectly routed and doing all these holes

by hand, one screw up and a whole new baffel may hafe to be

constructed (boy that would seriously erk me!).

I still am unsure how I am going to finish them...

I got a material swatch at Lowes today for WilsonArt's granite

Laminate. I think I am going to do square bases out of MDF with

internal cavities filled with black beauty sand and then laminated

with the granite WilsonArt. I still have this idea in my head about

wrapping the back and sides of the enclosure with real Carbon

Fiber and doing the baffel in WilsonArt Brushed Aluminum.

I am not a big "wood" kinda guy.. Wood is nice and all, but I am

more of a techie freak (well ok, so the tube amps aren't exactly

technie...) 🙂

and smooth right off the saw or router. It has more mass and

is more acousticaly dead. I have heard arguments both ways as

far as materials being acousticaly dead or somewhat adding

color. I have heard numerous people say plywoods work very

well and I do not doubt it at all. If I were doing folded horn loaded

widebands (Lowther, Moth Audio, Fostex, Tang Band etc.) I would

go ply without any hesitation.

But for this project I think the MDF will be a lot easier on me... I

have a lot of work ahead of me.. I still haven't ruled out having

John CNC route the baffels and ship them to me just for the

fact that they will be perfectly routed and doing all these holes

by hand, one screw up and a whole new baffel may hafe to be

constructed (boy that would seriously erk me!).

I still am unsure how I am going to finish them...

I got a material swatch at Lowes today for WilsonArt's granite

Laminate. I think I am going to do square bases out of MDF with

internal cavities filled with black beauty sand and then laminated

with the granite WilsonArt. I still have this idea in my head about

wrapping the back and sides of the enclosure with real Carbon

Fiber and doing the baffel in WilsonArt Brushed Aluminum.

I am not a big "wood" kinda guy.. Wood is nice and all, but I am

more of a techie freak (well ok, so the tube amps aren't exactly

technie...) 🙂

Surfboards, carbon fibre, now you're talking my language

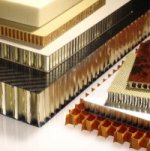

I've been designing and building windsurfers since the mid eighties, and my preferred method now is a vaccuum bagged sandwich construction of carbon/1/4" core-cell/carbon over a polystyrene core.

If I could put this expertise to good use building speaker cabinets I'd be thrilled. Does anyone have any design suggestions? I was about to start researching LA's (I know virtually nothing about speaker design) because of these little 3" tang bands I've been fiddling with. They're so cheap, and even in bad boxes they sound pretty good.

Chris

I've been designing and building windsurfers since the mid eighties, and my preferred method now is a vaccuum bagged sandwich construction of carbon/1/4" core-cell/carbon over a polystyrene core.

If I could put this expertise to good use building speaker cabinets I'd be thrilled. Does anyone have any design suggestions? I was about to start researching LA's (I know virtually nothing about speaker design) because of these little 3" tang bands I've been fiddling with. They're so cheap, and even in bad boxes they sound pretty good.

Chris

Re: Surfboards, carbon fibre, now you're talking my language

Would that method of construction work for the shape in Post #35?

Christopher said:I've been designing and building windsurfers since the mid eighties, and my preferred method now is a vacuum bagged sandwich construction of carbon/1/4" core-cell/carbon over a polystyrene core.

Would that method of construction work for the shape in Post #35?

Yes, that would not be too dificult, but obviously I couldn't use that cabinet as is for totally different drivers. I've also been toying with something like the B&W nautilus, but I have no idea what the theory behind the design is.

To sell more speakers?Christopher said:I've also been toying with something like the B&W nautilus, but I have no idea what the theory behind the design is.

_____________________________

Christopher - your idea of a curved cabinet for Tangbands could be a real winner but there's no reason why it should be a 'bad box'. Stick around and with help from these guys you could come up with a great box.

And to get you kick started on the theory, four reasons why curved can be a good idea:

1. Cleans up diffraction problems

2. Reduces or eliminates internal standing waves

3. Reduces cabinet vibration by eliminating flat panels

4. Looks sexier

Wonderbread sandwich...

This reminds me that up in the rafters of my dad's garage, I stored a 20 sq. ft sheet of carbon fibre-nomex honeycomb-carbon fibre sandwich. I got it at Boeing surplus in Kent, WA almost 13 years ago with the intent of building a recumbent bike out of it. Cheap in surplus but outrageous when new. As the baffle or box of a speaker, hmmm...

And, this stuff is strong.

http://www.dupont.com/nomex/

It can be had in many versions and in various thicknesses. The "cheap" ones of fibreglass are what you walk on inside the airliner. (I love the look on fellow passengers when I explain that the only thing separating them from their luggage is about 3/8" of "flexible material.") The most expensive stuff is the carbon fibre and there is a mid-range that uses aluminum skin. I saw a chunk at Boeing of the alum type that was over an inch thick and used aluminum sheet that was about 1/8" thick. My guess was for structural bulkheads.

🙂ensen.

Brett D. said:I still have this idea in my head about

wrapping the back and sides of the enclosure with real Carbon

Fiber and doing the baffel in WilsonArt Brushed Aluminum.

Christopher said:I've been designing and building windsurfers since the mid eighties, and my preferred method now is a vaccuum bagged sandwich construction of carbon/1/4" core-cell/carbon over a polystyrene core.

This reminds me that up in the rafters of my dad's garage, I stored a 20 sq. ft sheet of carbon fibre-nomex honeycomb-carbon fibre sandwich. I got it at Boeing surplus in Kent, WA almost 13 years ago with the intent of building a recumbent bike out of it. Cheap in surplus but outrageous when new. As the baffle or box of a speaker, hmmm...

And, this stuff is strong.

http://www.dupont.com/nomex/

It can be had in many versions and in various thicknesses. The "cheap" ones of fibreglass are what you walk on inside the airliner. (I love the look on fellow passengers when I explain that the only thing separating them from their luggage is about 3/8" of "flexible material.") The most expensive stuff is the carbon fibre and there is a mid-range that uses aluminum skin. I saw a chunk at Boeing of the alum type that was over an inch thick and used aluminum sheet that was about 1/8" thick. My guess was for structural bulkheads.

🙂ensen.

Attachments

WRT the curved ally boxes, why not fill with concrete, plaster or resin?

I know they'd be heavy but...

Cheers

Rob

I know they'd be heavy but...

Cheers

Rob

I think that blue jellyfish would make a great addition to a VW Beetle...

It got me thinking again...

What about an aluminum soda can with some stuffing inside as it is perfect for a pressurized fluid?

What about some of the really heavy stainless or iron pots? Could you imagine a sub made from a huge garage sale cauldron?

Or a bathtub sub? Just add a baffle, stuffing, maybe some interior volume changes and voila...

🙂ensen.

It got me thinking again...

What about an aluminum soda can with some stuffing inside as it is perfect for a pressurized fluid?

What about some of the really heavy stainless or iron pots? Could you imagine a sub made from a huge garage sale cauldron?

Or a bathtub sub? Just add a baffle, stuffing, maybe some interior volume changes and voila...

🙂ensen.

purplepeople said:What about an aluminum soda can with some stuffing inside as it is perfect for a pressurized fluid?

Stop it, stop it, stop it 🙂

I've got enough projects on the go as it is!

Attachments

RobWells said:WRT the curved ally boxes, why not fill with concrete, plaster or resin?

I know they'd be heavy but...

Exactly. But that's what I wanted to avoid. The lighter you can make the material, the higher in frequency you push the panel resonances. If you push them high enough, there's the possibility that fibre filling can sufficiently attenuate the rear radiation from the driver that it doesn't significantly excite them, giving you an inert box.

I originally wanted to make the (flat) baffle out of expanded polystyrene sheet laminated with 1mm (or less) aluminium, but it would have been difficult to mount the drivers. However, I think I now know how to crack that one, so I will use a composite baffle.

All I need to do now is to lose the MDF from the ends. Sigh...

You're spot on here EC8010 regarding panel resonances for rigid, lightweight panels.EC8010 said:Exactly. But that's what I wanted to avoid. The lighter you can make the material, the higher in frequency you push the panel resonances. If you push them high enough, there's the possibility that fibre filling can sufficiently attenuate the rear radiation from the driver that it doesn't significantly excite them, giving you an inert box.

However, I still have some concerns. We know that low frequencies are not so easily absorbed by material. Some will be reflected by the cabinet walls but some will pass straight through. Look how the bass frequencies can pass through lightweight room walls and be heard in the next room.

Some energy that isn't absorbed will come out through the cone. Perhaps this is unavoidable. However, is the bass passing through the cabinet walls a concern and is this effect worsened by lightweight material?

"Use it or lose it" is an old loudspeaker designer maxim and I think that we need to further our understanding of what happens to the energy emitting from the rear of the cone. Well, I do at least.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Cabinet materials - why not more diversity?