triboelectric powder coaitng should give you a thick coating. up to 8 times thicker then normal powder coat. also you can coat over coat. unlike normal powder coat. a gun is like 250 dollaars. get some air and it should work. i still want to 🙂 but dont have 250 around

Hello everyone, long time lurker here to this great site.

As the title suggests I want a pair of large, curved ESLs, but of the only two people that I know that will build ESLs to order, I am not finding exactly what I am looking for...

Russ Knotts of justrealmusic builds them, but he only curves them to 22 degrees, and I am looking for more like 30, and the largest panels he makes are 16"x 60", and I want one a full 18" wide. Plus I don't think there is a return policy as this would be considered a custom build.

Buen (username) of Crescendo makes panels that wide, but there are a few things he does witch go against my desired outcome. Firstly, he constructs his ESLs using vertical spacers, and I want to use horizontal ones, preferably using double sided tape. Secondly, he uses aluminum coated diaphragms instead of clear, and to me it makes them appear as a wall instead of a window, if you know what I mean.

A little background: I own flat ESLs that are 14.5 inches by 42 inches that sit atop my (10 inch Peerless) 8 foot long tapered DIY transmission line. Now I love my t-lines, but my ESL stators are getting rusty, and most importantly, I am looking to get away from having my head in a vice just to enjoy the listening position. Plus I have just finished a home theater with a projector, and when I have people over, I'd like them to be able to enjoy the sound too, not just me.

Attached picture for reference:View attachment 374480

I'm sort of using Charlie's (Jazzman's) blog as a general guide, as it is very thorough and includes a supply list and links, but I have a few questions, (actually quite a few, lol).

- The ESLs I want to build will be 18 inches by 60 inches, with a frequency response that goes relatively flat to around 200Hz (x-over around 150-180), that's quite a bit larger than Charlie's 12”x48” (I believe), and a lower crossover point. Will the same step-up transformers and bias supply work for a design that much different, or do I need to completely rethink this?

- He uses spacers that are 3/8 of an inch wide, I found some double sided tape of the same thickness that is ¼ inch wide, does anyone see potential problems using this width?

- Doing a curved design, do the spacers between the diaphragm and the rear stator need to be a different thickness than the front as to avoid it hitting the rear stator?

- I noticed that quite a few ESL builders don't have their stators perforated all the way to the edge, they have a perimeter of around one inch from the edge that is not perforated, is this necessary, or do I need to just make sure the edges are wrapped with insulator tape of some sort?

- I plan on building a jig curved to 30 degrees for an 18 inch panel, but the jig needs to be around 22 inches wide (so I have room to tape horizontally), does anyone know an easy way to calculate this?

Well that's more than enough questions for now, but I'm really determined to fabricate these, not only to save a few dollars, but more importantly to have that satisfaction that comes from the accomplishment.

So to all you stat guys, please leave your answers/comments/further questions for me if you'd be so kind, if all goes well, and I get this ball rolling, I'd like to document any and all progress.

cheers

-wreck

Sound-Lab A-1 electrostatic loudspeaker | Stereophile.com

This is the ideal solution if u can pull it off...

Sound-Lab A-1 electrostatic loudspeaker | Stereophile.com

This is the ideal solution if u can pull it off...

wel its not a real curved panel 🙂 i wonder how they tune alll those panels. 🙂

wel its not a real curved panel 🙂 i wonder how they tune alll those panels. 🙂

Yep, not a true curved panel for sure, although a fraction of an inch 'dead spot' isn't all that big, it's still there. I too wonder how they tune all of those panels..

Hey WrineX, thanks for the post about the tribo, that's information that I did not have before.

I spent a little time perusing articles comparing that vs the C-gun.

Where are you seeing the triboelectric gun available for 250 though? Do you have a link?

cheers..🙂

Hi,

If only it were that easy 🙄

Rather than 250€ think of >>1.000€ for a complete spray system.

A oven is of course not included.

Mass flow, Airflow, constancy of Airpressure, etc. all play a role in the charging of the powder particles and as such on the quality of the coating.

One reason for thicker coating layers with tribo guns is the lower amount of charge, rep. lower amount of ions, that tend to ´push´ the powder particles away from each other.

I don´t know where the figure 8 times thicker stems from, but I seriously doubt it.

The typical layer thickness for corona guns is ~100µm.

You may achieve 150-200µm with tribo on a punched metal sheet but probabely not more.

Fluidized bed application has the potential for thicker layers, if You are able to melt the powder layer in fullness.

It may also be not so easy to source a useable powder in such small amounts.

Pure PA (Nylon, PA11, PA12) fore example, while beeing one of the best materials for ESL stators, becomes lower in impedance in a temperature range of 40°C to 70°C. Due to this effect it tends to loose charge (it dischrages into the metallic stator material) and simply falls off of the stator.

It needs additives like Polyolefines, PP or PB to hold the charge.

Having a powder gun system still requires equipment to melt the powder into a homogenous laquer.

I seriously doubt that even if one manages to melt one layer, a second coating layer is far beyond simple DIYing.

Leave powder coating to professionals if You require a professional and safe coating.

For all else one may still coat wet.

jauu

Calvin

..triboelectric powder coaitng should give you a thick coating. up to 8 times thicker then normal powder coat. also you can coat over coat..

If only it were that easy 🙄

Rather than 250€ think of >>1.000€ for a complete spray system.

A oven is of course not included.

Mass flow, Airflow, constancy of Airpressure, etc. all play a role in the charging of the powder particles and as such on the quality of the coating.

One reason for thicker coating layers with tribo guns is the lower amount of charge, rep. lower amount of ions, that tend to ´push´ the powder particles away from each other.

I don´t know where the figure 8 times thicker stems from, but I seriously doubt it.

The typical layer thickness for corona guns is ~100µm.

You may achieve 150-200µm with tribo on a punched metal sheet but probabely not more.

Fluidized bed application has the potential for thicker layers, if You are able to melt the powder layer in fullness.

It may also be not so easy to source a useable powder in such small amounts.

Pure PA (Nylon, PA11, PA12) fore example, while beeing one of the best materials for ESL stators, becomes lower in impedance in a temperature range of 40°C to 70°C. Due to this effect it tends to loose charge (it dischrages into the metallic stator material) and simply falls off of the stator.

It needs additives like Polyolefines, PP or PB to hold the charge.

Having a powder gun system still requires equipment to melt the powder into a homogenous laquer.

I seriously doubt that even if one manages to melt one layer, a second coating layer is far beyond simple DIYing.

Leave powder coating to professionals if You require a professional and safe coating.

For all else one may still coat wet.

jauu

Calvin

Sorry it à bit over 250 dollar

Easy Coat Powder Coating System and Powder | diy powder coating system

And some info

http://www.nordson.com/en-us/divisions/industrial-coating/Literature/Powder%20Documentation/White%20Papers/PWR0688.pdf

It states tribo layer thickness of several 100 micron !! In one pass. I am wel aware of the easy cost not bring an industrial gun, but really this is a DIY forum! If it does not have powder flow of an peof gun , you can do a. Second coat.

Also tribo like you mentioned Calvin does not repel as much powder as corona, even beter it does not suver from the faraday effect which is in my honest opinion, one of the mOst imported things since you want that powder in all perforations! It also has a beter finish the corona.

Next oven. Depending on the size of ur panel , everyone can buy a cheap second hand oven for about 50.

Hard to get powder.. Well the site above supply it , in fact almost al sites selling powder coats supply powder for tribo. And always in small quantity (250 gram to several kilo)

One thing I want to make clear I am in no way connected to any of the companies neither did I try it myself. I just looked for this option myself and these are my conclusions. Depending on how wel the easy coat coats it is a very nice way to give those panels a thick coat with far more benefits then corona coated panels. I would love to give it a try some day.

Easy Coat Powder Coating System and Powder | diy powder coating system

And some info

http://www.nordson.com/en-us/divisions/industrial-coating/Literature/Powder%20Documentation/White%20Papers/PWR0688.pdf

It states tribo layer thickness of several 100 micron !! In one pass. I am wel aware of the easy cost not bring an industrial gun, but really this is a DIY forum! If it does not have powder flow of an peof gun , you can do a. Second coat.

Also tribo like you mentioned Calvin does not repel as much powder as corona, even beter it does not suver from the faraday effect which is in my honest opinion, one of the mOst imported things since you want that powder in all perforations! It also has a beter finish the corona.

Next oven. Depending on the size of ur panel , everyone can buy a cheap second hand oven for about 50.

Hard to get powder.. Well the site above supply it , in fact almost al sites selling powder coats supply powder for tribo. And always in small quantity (250 gram to several kilo)

One thing I want to make clear I am in no way connected to any of the companies neither did I try it myself. I just looked for this option myself and these are my conclusions. Depending on how wel the easy coat coats it is a very nice way to give those panels a thick coat with far more benefits then corona coated panels. I would love to give it a try some day.

Last edited:

Hi,

no doubt that tribo has certain advantages over electrostatic, like layer thickness and reduced Faraday cage effect.

But the claims of the manufacturers typically regard other than our application.

For example, there are claims that Rilsan may be coated up to 3500µm in thickness in one layer(!!) using fluidized bed application.

Well that may be true for massive Offshore Oil rigg parts weighing several tons.

With punched metal sheets with a high degree of openness most coaters won´t even try, let alone succeed in applying a homogenous coating.

For parameters influencing tribo coating see this excerpt:

Fundamentals of Powder Coating, Chapter 5, p87ff.

If one still thinks that buying a tribo gun, ordering some powder, connecting a air pressure hose, and salvaging Mom´s kitchen oven will result in a smooth homogenous and safe functioning coating .... well, I´d be the last to stop You, as I like young enterprising men 😀

jauu

Calvin

no doubt that tribo has certain advantages over electrostatic, like layer thickness and reduced Faraday cage effect.

But the claims of the manufacturers typically regard other than our application.

For example, there are claims that Rilsan may be coated up to 3500µm in thickness in one layer(!!) using fluidized bed application.

Well that may be true for massive Offshore Oil rigg parts weighing several tons.

With punched metal sheets with a high degree of openness most coaters won´t even try, let alone succeed in applying a homogenous coating.

For parameters influencing tribo coating see this excerpt:

Fundamentals of Powder Coating, Chapter 5, p87ff.

If one still thinks that buying a tribo gun, ordering some powder, connecting a air pressure hose, and salvaging Mom´s kitchen oven will result in a smooth homogenous and safe functioning coating .... well, I´d be the last to stop You, as I like young enterprising men 😀

jauu

Calvin

Wreck, my man: when are you going to get your panels built? I've been waitin' for awhile here...you got the Xfmrs, the stators coated, when are you going to put everything together? Inquiring minds want to know! Good luck, and have a few beers...

Soon... in the mean time...

😛

But seriously, all the panels are ready, just gotta get busy lining up the DS tape to parallel, and stretching the Mylar..

Stay tuned...😉

😛

But seriously, all the panels are ready, just gotta get busy lining up the DS tape to parallel, and stretching the Mylar..

Stay tuned...😉

Last edited:

you got some patience😉 or indeed verry little time. pitfall for me i got loads of time 😉 but no patience

Very little time is about it, WrineX, working 60 hours this week alone. Patience? Not so much..haha 😀

*edit* ..plus spring cleaning after this very bad winter etc.etc.etc. ..and although this probably doesn't belong in the 'Building a large curved ESL' thread, I thought I'd vent a little.. 😛

I'll post some more soon..

*edit* ..plus spring cleaning after this very bad winter etc.etc.etc. ..and although this probably doesn't belong in the 'Building a large curved ESL' thread, I thought I'd vent a little.. 😛

I'll post some more soon..

Last edited:

Very little time is about it, WrineX, working 60 hours this week alone. Patience? Not so much..haha 😀

*edit* ..plus spring cleaning after this very bad winter etc.etc.etc. ..and although this probably doesn't belong in the 'Building a large curved ESL' thread, I thought I'd vent a little.. 😛

I'll post some more soon..

Hi Wreck,

Just wondering how it's going with your speakers. Please let us know!

Charlie

Hi Charlie

Truth be told, I'm having a helluva time juggling spring cleaning and now on my forth week of 60+ hours.. Then next week I have to cover another guy's territory, which is 75 minute commute there and another 75 back, on top of the hours..🙁

Then next week I have to cover another guy's territory, which is 75 minute commute there and another 75 back, on top of the hours..🙁

I did get the frames roughed in, but I'm setting my sights on next weekend for any real progress, sorry guys..😱

Truth be told, I'm having a helluva time juggling spring cleaning and now on my forth week of 60+ hours..

Then next week I have to cover another guy's territory, which is 75 minute commute there and another 75 back, on top of the hours..🙁

Then next week I have to cover another guy's territory, which is 75 minute commute there and another 75 back, on top of the hours..🙁I did get the frames roughed in, but I'm setting my sights on next weekend for any real progress, sorry guys..😱

Making some real progress now, despite the Mother's Day I forgot all about...Oops! Sorry Mom!

Pics this week..

Pics this week..

Sad tales update...

The 3m double sided tape I used shrunk, I mean, shrunk by a quarter inch or so... unusable!

Ordered some more that should be here by Wed. Quality stuff.

The 3m double sided tape I used shrunk, I mean, shrunk by a quarter inch or so... unusable!

Ordered some more that should be here by Wed. Quality stuff.

Hi Jer,

Just to clarify, it wasn't the VHB tape that shrunk, that's still adhered around the perimeter and ready to go...🙂

The tape that shrunk or crept (not sure which) is the 'regular' 3m DST that I used for the cross-spacing that did that, that tape felt a little stretchy while I was applying it, and when I inspected the next day it had resumed it's original size I guess.

I had to break down and order more VHB (expensive), and that should be here soon..

cheers

-wreck

Just to clarify, it wasn't the VHB tape that shrunk, that's still adhered around the perimeter and ready to go...🙂

The tape that shrunk or crept (not sure which) is the 'regular' 3m DST that I used for the cross-spacing that did that, that tape felt a little stretchy while I was applying it, and when I inspected the next day it had resumed it's original size I guess.

I had to break down and order more VHB (expensive), and that should be here soon..

cheers

-wreck

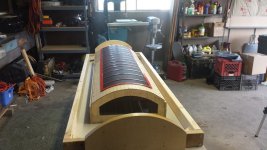

Well, a little progress here..

It turned out that the additional VHB tape that I ordered is not suitable for my project because of miscalculated thickness issues. I had to devise a way to cut down my existing tape to match width-wise, so I built a little tool to accomplish just that. (see attach #1)

The stretching jig is ready to go, and the DS tape is in it's final resting place. 🙂

(see rest of pics).

It turned out that the additional VHB tape that I ordered is not suitable for my project because of miscalculated thickness issues. I had to devise a way to cut down my existing tape to match width-wise, so I built a little tool to accomplish just that. (see attach #1)

The stretching jig is ready to go, and the DS tape is in it's final resting place. 🙂

(see rest of pics).

Attachments

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Planars & Exotics

- Building a large curved ESL