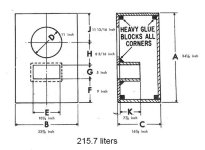

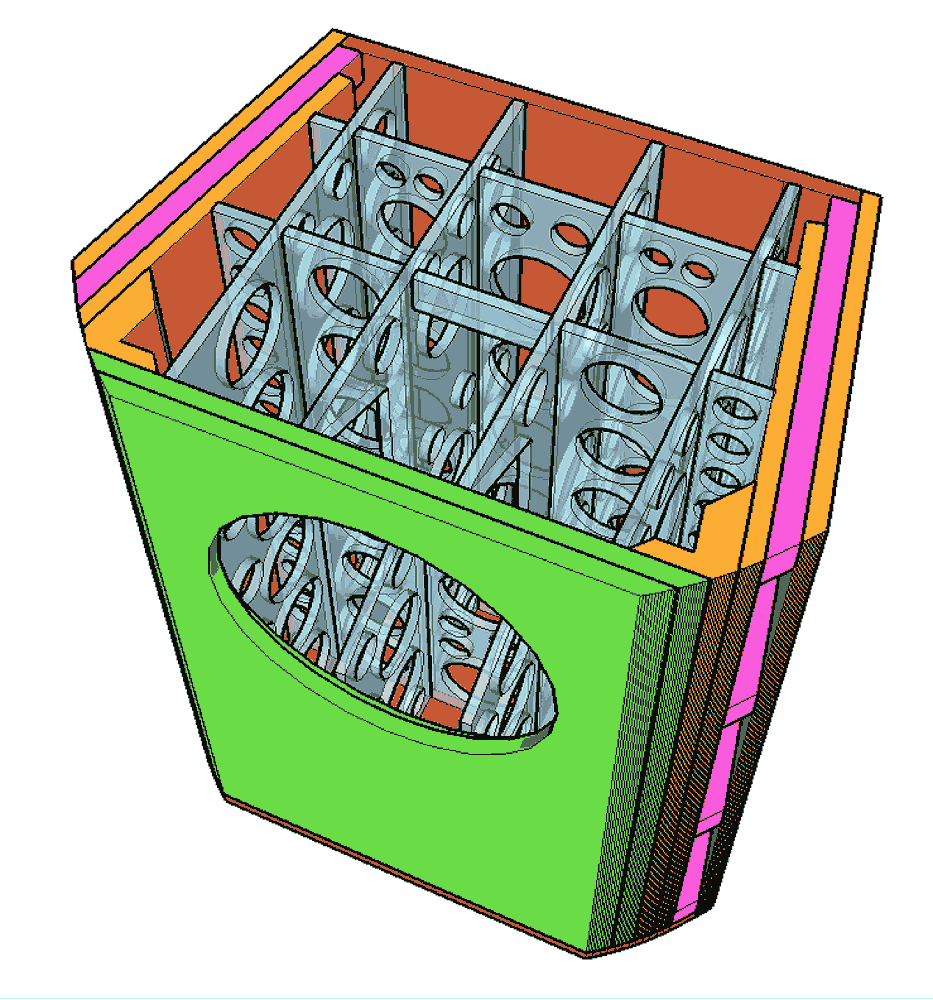

I'm currently building these for my Philips AD1256. The backs will be glued and nailed shut while the front will screwed down and able to be swapped out. Currently my built feels really strong and sturdy. I will add 2 cross beams to the middle and glue some butyl pads for dampening. Is a vertical brace necessary? I don't want to add too many braces that will affect the overall volume. Too bad I didn't consider bracing in the beginning. Any recommendations will be greatly appreciated.

Attachments

Cross braces are good. If you want another opportunity that doesn't use much internal space, you might think about external constrained layers. The back is a larger panel and can be CLD and attached to the front since the front has big holes cut into it.

Ideally braces shoud connect 4 sides and fill the corners. In a cabinet that aspect, braces are best placed vertically.

dave

dave

Hi! Could you clarify why vertical?In a cabinet that aspect, braces are best placed vertically

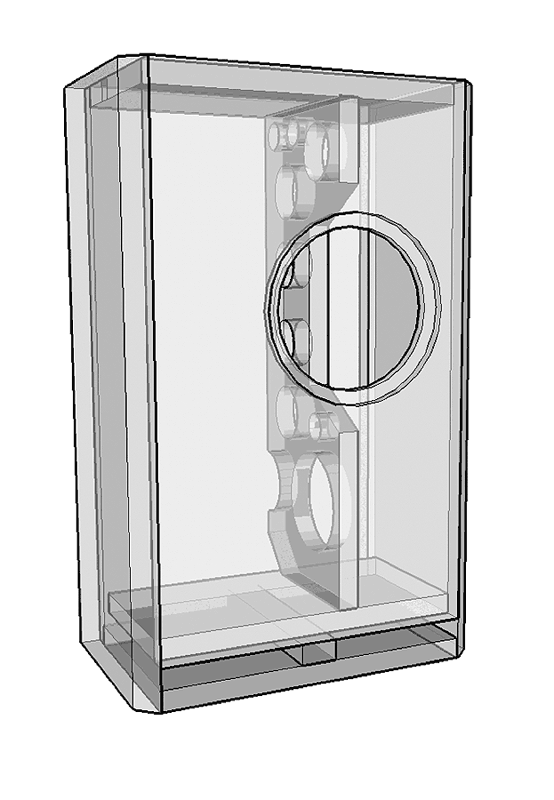

I'm currently resolving some resonances and I've created horizontal braces using that popular "window" and a U shape right behind the woofer to connect all the 4 sides.

This is a 10" loudspeaker for using as a monitor in a studio.

Back panel is screwed and glued to the bracing.

Could you comment?

Thank you!

Could you clarify why vertical?

Bigger number is better.

In words: The aspect-ratio of the subpanels should be greater tghan that of the panel being braced. SubPanela ≠ SubPanelb

Could you comment?

It could be done better.

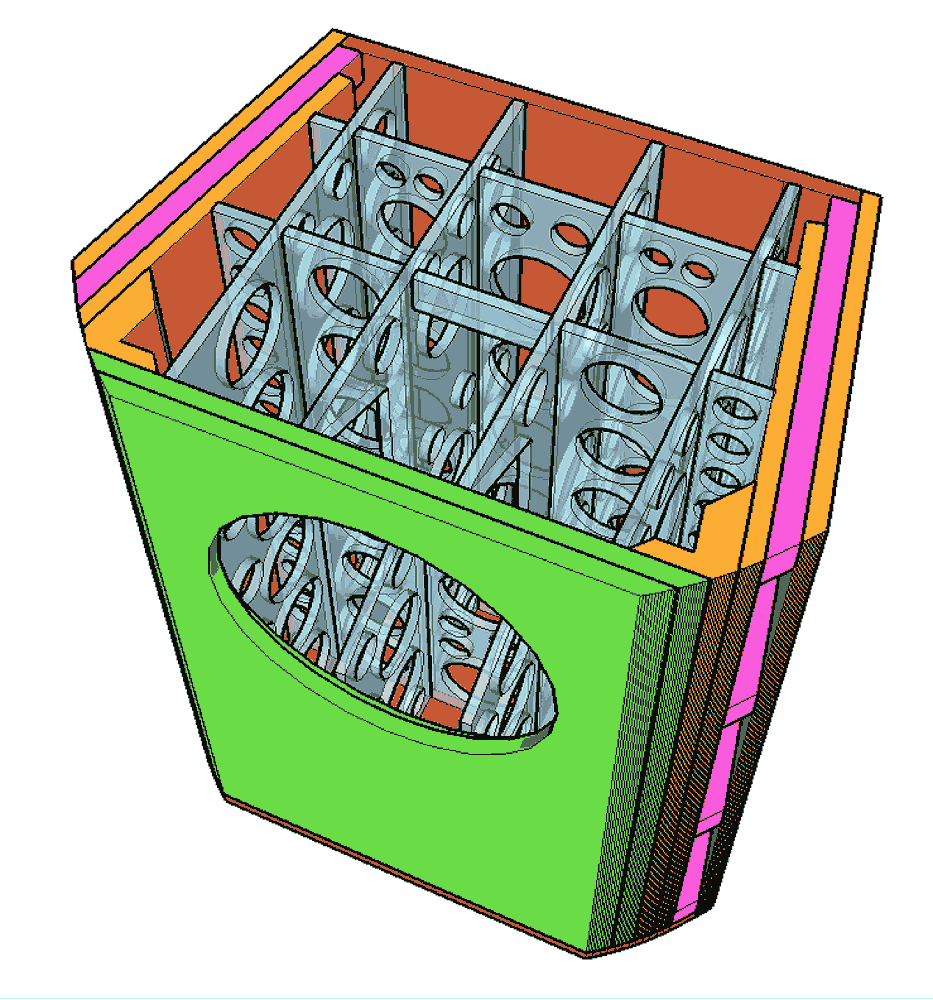

This is a biggish box (135 litre) but is well braced.

I also like to brace the driver across 3 more panels than just the baffle. Smaller box needs fewer braces.

dave

Last edited:

Dave, how do you apply that brace with bass reflex box, lets say Scott's double chamber or any box with back reflex tube?

Ok! Got it. In my box shape example, although horizontal bracing is effective (it dows bump the resonance to a higher frequency), the resonance frequency would go even higher with vertical bracing due to the final aspect ratio of the sub parts.In words: The aspect-ratio of the subpanels should be greater tghan that of the panel being braced. SubPanela ≠ SubPanelb

Thank you!

It's not the aspect ratio per se, but the smaller dimension.due to the final aspect ratio of the sub parts

Last edited:

Dave, how do you apply that brace with bass reflex box, lets say Scott's double chamber or any box with back reflex tube?

Both the boxes i posted are vented.

Here is a big one with basic bracing (GPA/Altec 604), Vent out the bottom. Paid plan so small pics w/o dimensions

Notice the lack of a brace parallel to the baffle right behind the driver.

dave

It's not the aspect ratio per se, but the smaller dimension.

Yes, the smaller dimesion is the primary mode and smaller = higher frequency = good.

Take a rectanular pane (taller than wide)l, divide it in half horizontally you get 2 more similar dimensions, not nearly as effecive.

dave

Dave don't take this the wrong way...

dave

I think that design is fantastic and probably sounds great, but I don't think that is how bracing should be done. There is a lot of damping being done, which is different than bracing. To brace the cabinet I would strengthen the empty surface areas of the large panels, not the corners, the corners are already strong, and not the middle of the enclosure, that needs no bracing running through it at all. The panels need to be made stiffer. The weak places need to be braced like on an aircraft or rocket or a sea fairing ship. Making an egg crate is good for egg transportation but it doesn't necessarily make a non-resonant egg crate. Honeycomb panels were used to great effect on aircraft wings in the 50's and 60's, constrained layer decades ago on helicopters. I think we should be taking these technologies and using them to our ends -- a non resonant enclosure.

What would Dave's enclosure sound like with an infinitely stiff material? Would it sound better because it had no resonances? Or would it sound worse because it has no plywood holey matrix damping? I think this needs more study and probably it's own thread

I would love to test this, send money to me. Thanks and have nice day.🙂

@Arthur Jackson

If I remember rightly, the matrix bracing scheme was made on the premise that it would control movement up to a certain frequency. For this reason it needed "cells" no larger than was portional to that wavelength.

If I remember rightly, the matrix bracing scheme was made on the premise that it would control movement up to a certain frequency. For this reason it needed "cells" no larger than was portional to that wavelength.

Not sure your point Arthur, there is no bracing at the corners, and no significantly large spans of wall panel. Braces are 18mm quality plywood. Outside is stranded bamboo plywood (a bit >18mm). Any potential rrsonaces are out of the bandwidth of the woofer.

My take on the B&W matrix, although mine evolved separatly (mostly).

dave

My take on the B&W matrix, although mine evolved separatly (mostly).

dave

There are big fat braces on the front corners, maybe they are required structurally for your design? OK so we agree on not having big fat braces in the strongest part of the box. And, yes you do brace the wall panels.👍 What I was getting at, one thing I often see in DIY speakers is a square board with a round hole in it used as bracing, this doesn't help much in my opinion because the strength is all in the corners and the speaker side panel will vibrate in the middle where it's braced lightly.

Most of what I was getting at is the bracing in the inside of your enclosure. I don't think that's necessary at all, unless it is part of the damping design. Which I guess it is. Bracing and damping got added together in one clever solution.

Bracing should look more like a bridge where the load is in the middle of the roadway. The speaker panels should be as stiff as possible. I have no way to make this nor can I test it, but I would make a grid or pattern of concrete strips over the panel. It should be spider-webbed with more stiffness imparted to the center of the board. Maybe it can be printed? Another idea is to use corrugated panels glued in layers with different orientations. Or use the corrugated board oriented in one direction like a honeycomb, but used on end like the bamboo in your panels. I need to do some more research and thinking.

Most of what I was getting at is the bracing in the inside of your enclosure. I don't think that's necessary at all, unless it is part of the damping design. Which I guess it is. Bracing and damping got added together in one clever solution.

Bracing should look more like a bridge where the load is in the middle of the roadway. The speaker panels should be as stiff as possible. I have no way to make this nor can I test it, but I would make a grid or pattern of concrete strips over the panel. It should be spider-webbed with more stiffness imparted to the center of the board. Maybe it can be printed? Another idea is to use corrugated panels glued in layers with different orientations. Or use the corrugated board oriented in one direction like a honeycomb, but used on end like the bamboo in your panels. I need to do some more research and thinking.

There are big fat braces on the front corners, maybe they are required structurally for your design?

They connect the baffle to the sides, while keeping the big chamfer.

Not sure how it was implemented in the build. This is how it was drawn.

dave

Finally done with these. At first, I was not thrilled with the sound after hooking it up. They sounded much better after I placed rubber isolation feet on. Thanks for everyone's help!! I'm getting an earlier version of the Philips 12 inch, 9762M. Do you think it would be a good idea to make another opening in the back for the 9762M's as a separate speaker within the same cabinet?

Attachments

- Home

- Loudspeakers

- Full Range

- Bracing Help