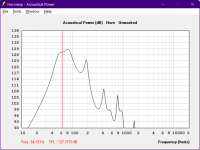

You could probably see what you are looking for in the Hornresp "Impulse Response" screen, and compare different cabinet designs.Does Hornresp do a simulation of step response - I'd be fascinated to see what such a long tract does to dynamics.

As far as the impulse response, a sealed cabinet will have the least "junk", followed by bass reflex, front loaded horns, and tapped horns.

Does Hornresp do a simulation of step response.

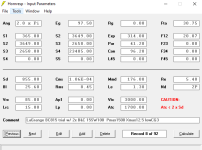

Yes. I model with the stepped feature (red S1 thru red S5) all the time. Dealing with angles $ucI<.

What other step response is there?

His enclosure and my enclosure are both BP4's.

He has flared segments.

I have stepped segments.

His enclosure and my enclosure are both BP4's.

He has flared segments.

I have stepped segments.

Step response is a common alternative term for impulse response. We can see the decay of energy in the system following a short pulse.What other step response is there?

@All_1, keep up the good work, and I would suggest the same as Weltersys, cut some holes in the bracings to reduce overall weight.

Bass strings and a foot on the speaker works for me very well too. Two parallel channels and plugging in a custom PJ with TRS taking P-neck to channel one and J-bridge to channel two and routing to parallel two more channels. This is using a Yamaha console. Simultaneous heavy attack on muted strings creating percussive sounds, clean and a deep low shadow activating the port. If the driver can produce these 4 channels back into the mix with clarity and stop when you stop the string, then it's a legendWe can see the decay of energy in the system following a short pulse

Currently, I have found two such drivers that eat up all the energetic thumb attack that I can muster and those found on recordings

When I was reading his link, that's exactly what I thinking. At the bottom of the page is a link to impulse response.Step response is a common alternative term for impulse response. We can see the decay of energy in the system following a short pulse.

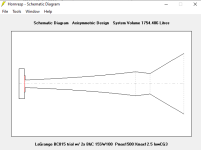

For the Hornresp simulations, I think you're missing the final expansion. And that's what makes a BC horn a BC horn instead of a normal FLH. Tom posted some hints to this, where he described it as a "bubble". If you picture a wavefront "bubbling" out from the exit of the speaker, that wavefront then keeps expanding. It's boundaries are the ground, and the front face of the speaker. So this is like an additional conical horn section. This is a bit easier to picture with the BC215, BC412 and BC415. With the BC218, I picture that wavefront spilling/diffracting off the narrow side a bit. So I'm not sure what you do for the bubble surface then. Perhaps take an average of the two distances along each perpendicular direction it would expand. I did some Hornresp guesses of the BC415 at some point and convinced myself adding this extra expansion was a good approach (and backed that up with some ABEC3 sims). That is a cool thing about a BC horn -- you don't have to carry around structure for that final expansion. Still, this is a heavy beast and a whole lot of wood. For a DIY approach, I like the BC215 sized/shaped things instead. And that makes for a more obvious "bubble".

Here's an example of a 215-like something. Red line is the path. Blue is the horn structure. White is the "bubble". I did this stuff back in 2016 and never built anything.

Attachments

Wow...EXP, PAR, & CON segments in the same model.Here's an example of a 215-like something. Red line is the path. Blue is the horn structure. White is the "bubble". I did this stuff back in 2016 and never built anything.

Interesting, could you share .stp file with me? I might be interested to build 2 or 4 of those in the future. Would it be possible to increase depth to use with 18 inch drivers? I can also go with something like 15SW115 but would prefer on staying on 18s. Bc215 seem quite popular and go low enough for 99% of applications. I started bc218 thread because I wanted something more extreme but something like BC215 definitely seem better for a lot of aplications.Here's an example of a 215-like something. Red line is the path. Blue is the horn structure. White is the "bubble". I did this stuff back in 2016 and never built anything.

It's DIY so you can use any size driver you want. What I did with 2x 15's was about 48" square and 24" deep externally. I was sizing things with 1.25" thick panels though. This was for 1/8" thick plywood skins on 1" thick cardboard honeycomb core with poplar edge closeouts for mass savings. You could certainly size something for a single or double 18 and normal plywood thickness construction. You pay a steep price in SPL for going lower and lower in frequency. Hoffman's Iron law is a nuisance like that. Making the front face bigger will get you more directivity lower in frequency, so I'd maximize the frontal area before doing deeper in size.

Project update

Recieved plywood, now waiting in CNC workshop for cutting. They are kinda busy right now so it might take a while.

Recieved 4 pieces of 6mm aluminium plates used for cooling back chamber, they look sturdy but i might have to add some additional bracing

Will keep you updated

Recieved plywood, now waiting in CNC workshop for cutting. They are kinda busy right now so it might take a while.

Recieved 4 pieces of 6mm aluminium plates used for cooling back chamber, they look sturdy but i might have to add some additional bracing

Will keep you updated

Now I am purchasing drivers new for them and since we decided to keep our tapped horns, I could go with something else than 18SW115. Is 18DS115 or 18IPAL maybe a better choice in horns where power is limited due to closed back chamber? Anyone has any experience with those drivers? Or is 18SW115 still one of the best drivers and I would not see any major improvement. Seems like on those 2 drivers motor is much stronger but at least DS might not be as linear as SW or IPAL.

Any feedback and info appreciated. For testing I could still use 18SW115 since I have them but really looking for maximum output.

Any feedback and info appreciated. For testing I could still use 18SW115 since I have them but really looking for maximum output.

Last edited:

- Home

- Loudspeakers

- Subwoofers

- Boundary control BC subwoofer BC218/2 Design