Ha ha I'm sure it will when the fan kicks in. Definitely need bolting down.

Ah I'll re check that. Can just fill in and re print.

That's Lot of work by hand ew. Steady hand otherwise start all over again.

Ah I'll re check that. Can just fill in and re print.

That's Lot of work by hand ew. Steady hand otherwise start all over again.

Ah of course yeah can imagine not as easy as it looks especially from a picture. Lucky got board so traced it out even that took a while but managed to make the tracks slightly thicker so you can drill along it without losing the track itself. The original was like modern boards ultra small traces. Still can’t beat point to point wiring.

You bring back fond memories. I started over 10 years ago drawing out

amps like the store's "Badger" with a Sharpie on copper board.

Then I got the simple CAD (sprint) made in germany. Made the official Store

AB amp. The store amp is mostly one sided. That was where I was 6 years ago.

Using both Sides is a current challenge. I got it.

I like fat traces , too.

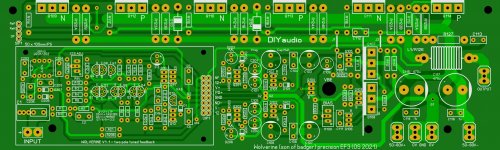

For real good amps , fat is good for current. The new amp (below) ....

6mm traces can do 15A.Both voltages are on one trace , one on top-

one on the bottom.

Big fat areas of copper where they are not needed might be bad. Picks up

current and stray fields. The amp might not work a good as it could.

Then there is toner transfer. Brother toner based printers are the best. Print out

either a paint shop program image or Sprint one sided reversed (on a glossy

magazine cover), Iron it on the board - wash - done ...etch.

Muriatic acid and peroxide can be an etchant. Water turns green,board is

etched. Hold yer breath - chlorine gas is emitted. But it etches in a minute.

PS - now I let the Chinese deal with all that BS !!

OS

Attachments

Ah learnt something there re bigger tracks better current handling. All new to me so used to valve gear completely different setup. Voltages not current so taken a while to switch me head round. Quite hard to be honest.

Funny you should say brings back memories last time I ever traced anything out was at 10 years old so thats 46 years ago cor. But very therapeutic.

I've used a Canon and the print is nice and thick on the paper.

I also noted that your supposed to seal the copper to stop oxidation but not sure which is best there. Some of the prices well 60 quid forgot that. Or tin plating solution.

One company gave me all this buff and said it would could cost me £1000 plus I wasn't polite. If it was pure gold fine ha.

I'll have a look at that package tried a few programs but you need a good couple weeks to get your head around it. One say wanted to place j50 on diagram it took you straight to different companies who sell parts but there obsolete so that was pointless. Just wanted a symbol.

Funny you should say brings back memories last time I ever traced anything out was at 10 years old so thats 46 years ago cor. But very therapeutic.

I've used a Canon and the print is nice and thick on the paper.

I also noted that your supposed to seal the copper to stop oxidation but not sure which is best there. Some of the prices well 60 quid forgot that. Or tin plating solution.

One company gave me all this buff and said it would could cost me £1000 plus I wasn't polite. If it was pure gold fine ha.

I'll have a look at that package tried a few programs but you need a good couple weeks to get your head around it. One say wanted to place j50 on diagram it took you straight to different companies who sell parts but there obsolete so that was pointless. Just wanted a symbol.

Also with Audio , pulses must negate each other , look at G1 and G2

on my pix. That is "star grounding".

Notice every thing is equal length and width going to the central points.

Another thing that will make everything work better.

Just coat your copper with solder to stop oxidation. paint flux

on it ,even use your waste solder blobs.

OS

on my pix. That is "star grounding".

Notice every thing is equal length and width going to the central points.

Another thing that will make everything work better.

Just coat your copper with solder to stop oxidation. paint flux

on it ,even use your waste solder blobs.

OS

Ah okay got plenty around. Cheers for that.

Yes I can it is much better layout I can see why you've done 2 layers just solder from top. Plus easier to get readings as well. Not sure in that league just yet ha ha.

Yes I can it is much better layout I can see why you've done 2 layers just solder from top. Plus easier to get readings as well. Not sure in that league just yet ha ha.

Ha ha I'm sure it will when the fan kicks in. Definitely need bolting down.

Fan speed will be temperature dependent (working on the controller)

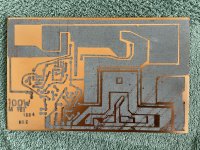

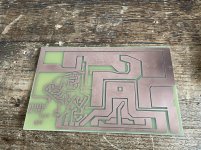

That’s okay then quite a bit the clad was pretty scored so ink did not fill in gaps or scratches otherwise that would have been spot on.

I always clean the clad with 000 steel wool and IPA after that to remove dirt and grease (finger prints) and it has worked out for me.

Good luck

Good luck

I gave it a really good clean with wire wool then rub down with alcohol. But did notice after cleaning had had been scratched and nicks in it so ink had nothing to adhere too. I’ll buy better quality board next time. Anyhow I went over it with a permanent marker and it worked well.

I’m quite happy with my first attempt. Just one spot well line that crosses over to the other track. So I’ll have to scrape that off otherwise all intact.

Pic attached.

I’m quite happy with my first attempt. Just one spot well line that crosses over to the other track. So I’ll have to scrape that off otherwise all intact.

Pic attached.

Attachments

I was gonna say forgot did you get this email from forum? The DIY Sony VFET Amplifier.

Any good lot of hype about it.

Any good lot of hype about it.

I get email notifications from the projects I follow.

Sony Vfet are very difficult to come by and very expensive.

Sony Vfet are very difficult to come by and very expensive.

Just wondered if any good never heard of it before. The kit seems pretty fair price wise if it’s that rare. Not interested in the chassis or cabinet. Thinking from sound point of view does not seem to be much comparison to valve amps. Sometimes this solid state gear can be sterile personnel opinion. No warmth and missing the detail in the highs and lows. When you put headphones on you go oh never heard that before but with say my gear it’s no different to listening with headphones on except it’s all coming through the speakers. Hence never use headphones don’t need too. Probably wrong place to throw opinions ask if any good. I’ll do a bit of research.

Maybe you should have a look at the Pass Labs forum very good reviews over there and simple builds and people say the sound is comparable/like valve sound.

I specially like the F4 ( my first Pass build)

I specially like the F4 ( my first Pass build)

- Home

- Amplifiers

- Solid State

- BK Electronics mosFET 100 watt modules