????? Implies that it takes more force to keep the body moving that it does to start it moving. I.E. as soon as there was any micro movement the force would have to jump instantaneously or the motion would stop.

John

Think of crossover distortion. It can be of two types, a vertical jump at the zero crossing or a horizontal jump at the zero crossing, basically a dead zone. This is exactly an analogous situation and I am not sure that you analogy is right.

But yes, it is possible for an object to take more force to move than to start it moving. There is nothing unrealistic about that. It simply means that motional friction is greater than static friction. It kind of like a needle standing on its tip in a very viscous liquid. It is conditionally stable, but nearly any force will make it move. Its not a typical condition but its perfectly possible.

Can probably rule a lot of this out for spiders exhibiting great linearity and restoring behavior that consistently returns cone to desired rest position.

Anybody heard a barking spider?

Barkhausen noise with ferrite magnet drivers likely bigger noise than barking from spider stiction.

Anybody heard a barking spider?

Barkhausen noise with ferrite magnet drivers likely bigger noise than barking from spider stiction.

Anybody heard a barking spider?

Do you mean like one of these?

Barking Spider - Invertebrates - Nature Notes - Alice Springs Desert Park

🙂.

I saw them live on stage in '83.Anybody heard a barking spider?.

Radian 745NEO with beryllium is outstanding! 🙂 Replaced the regular 745's I had been using, and planned to run some measurements. Instead, I have been listening to music ever since…just can't seem to stop.

Still have some further things to try in the coming months, including crossover revisions recommended by Lynn, and comparing my TD15M's with the alnico GPA 416B's, which should arrive in a couple of weeks.

Even if these speakers don't improve much beyond this, I am very, very pleased. Beyond the Ariel, indeed!

Still have some further things to try in the coming months, including crossover revisions recommended by Lynn, and comparing my TD15M's with the alnico GPA 416B's, which should arrive in a couple of weeks.

Even if these speakers don't improve much beyond this, I am very, very pleased. Beyond the Ariel, indeed!

????? Implies that it takes more force to keep the body moving that it does to start it moving. I.E. as soon as there was any micro movement the force would have to jump instantaneously or the motion would stop.

I don't know if it can actually occur in a typical speaker suspension (vicious losses in spider doping maybe?) but dynamic friction being greater than static friction is a common place phenomenon.

A typical example is hydraulic shock absorbers in a car. Damping is provided by vicious losses from oil being forced through small orifices at high velocities.

Static friction is zero, dynamic friction is non zero and increases with velocity. Unlike your suggestion there is no discontinuity about zero though, it increases in a smooth, continuous but definitely nonlinear fashion. (Friction increases at a greater rate than velocity due to the effects of turbulence)

Contrast this with typical sliding friction between two metal surfaces where static friction is almost always greater than dynamic friction, with a discontinuity at the force where it "lets go" and starts sliding. Once sliding there is less friction than there was just before it started sliding.

Most real world damping systems that use hydraulic damping such as a shock absorber also have some inevitable sliding friction, so the net result is a complex combination of the two contradictory systems, so whether friction increases with force/velocity or decreases or decreases then later increases again depends on the relative combinations. It's all nonlinear though.

In car suspension design sliding friction is to be minimised and avoided as much as possible as the stiction effect of the sliding surfaces leads to a harsh fidgety ride. If you can minimise sliding friction as much as possible and get as much of your required damping as possible from progressive hydraulic damping the ride is a lot smoother without any loss of body control at higher excursions, because the hydraulic damping doesn't suffer from stiction, nor does it suffer from any points where friction reduces as force increases.

How this all relates to friction and damping in speaker suspension I'm not sure though, except that we know that speaker suspension is both non linear in restoring force, and non linear in resistive losses...

Edit: on further thinking it would seem that most of the resistance in speaker suspension would be from sliding friction in the fibres of the spider, thus would include at least some stiction, while electrical damping would not suffer from stiction and would be more analogous to the hydraulic damping as described above. (Back EMF only resists motion and has no effect when the driver is stationary, and also no low level threshold effects)

The implication then is that achieving the target Qts using a high Qms, low Qes approach is the best way to minimise any potential effects of stiction at low SPL...

Last edited:

At low flow rates laminar flows and friction is proportional to velocity in a linear fashion

At high rate turbulenf flows friction is proportional to the square of velocity.

This is for Newtonian fluids, not all are that.

When heat comes into play it becomes more complicated...

At high rate turbulenf flows friction is proportional to the square of velocity.

This is for Newtonian fluids, not all are that.

When heat comes into play it becomes more complicated...

Last edited:

Lots of drivers shoot for highly linear spider, and design for damping with properties of rubber surround as it transitions from rolling/unfolding behavior to stretching where viscous behavior comes into play.

Gary - Thank you for sharing this. It is very good news.Radian 745NEO with beryllium is outstanding! 🙂 Replaced the regular 745's I had been using, and planned to run some measurements. Instead, I have been listening to music ever since…just can't seem to stop.

Edit: on further thinking it would seem that most of the resistance in speaker suspension would be from sliding friction in the fibres of the spider, thus would include at least some stiction

At the micro-level this may be true, but at the bulk level this would all likely average out to yield a negligible effect. It remains to be seen if any data will show this to be significant.

There are many considerings in how the motor, suspension, and mass come into play. Not really a simple task. The little J6rX did not have a spider, just the surround was very linear in comparison.Lots of drivers shoot for highly linear spider, and design for damping with properties of rubber surround as it transitions from rolling/unfolding behavior to stretching where viscous behavior comes into play.

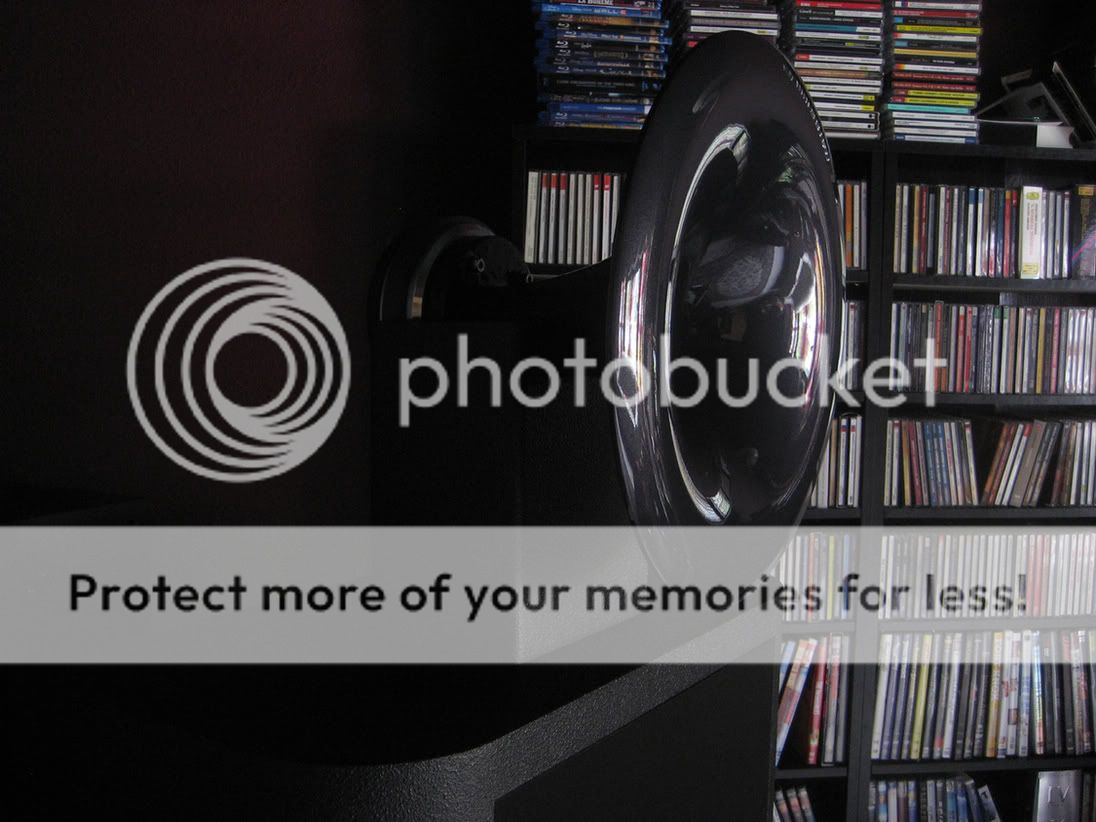

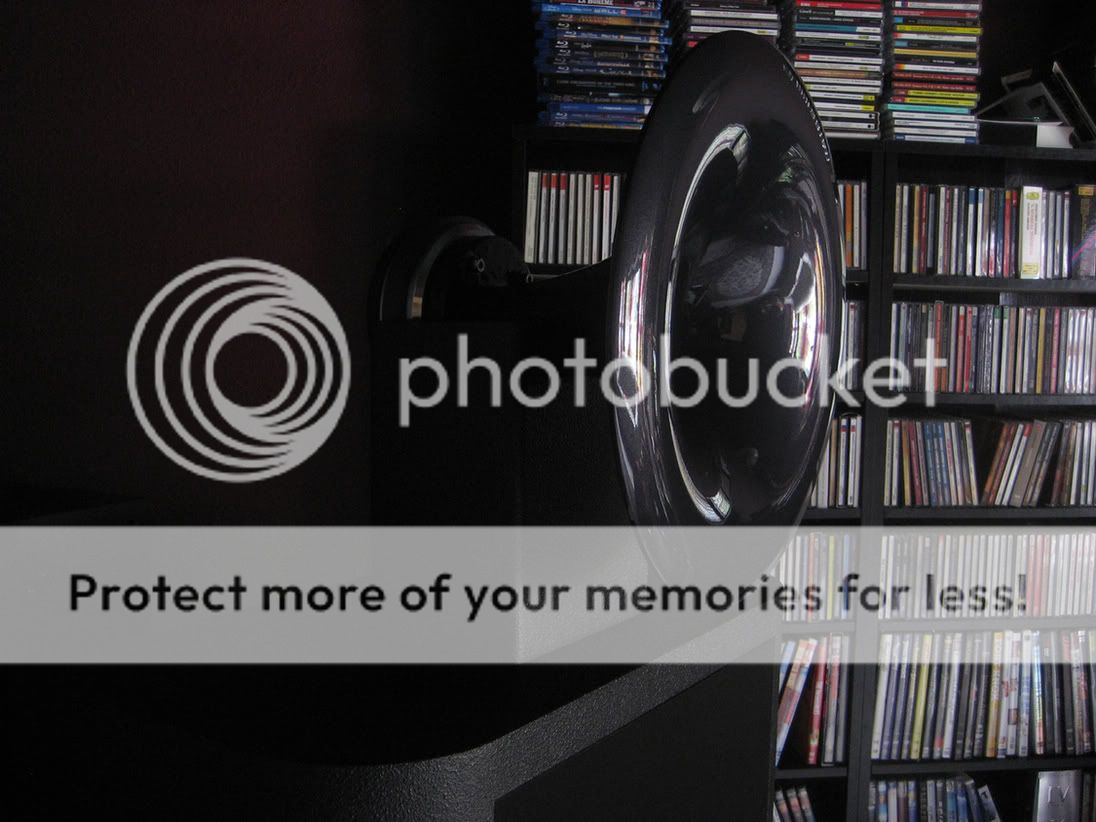

In case anyone hasn't seen (or doesn't remember) the context for my comments about the Radian 745NEO beryllium driver, here is a brief description of the speaker system.

Each channel:

Azurahorn AH-425 with Radian 745NeoBPB-16. Third-order high pass at 800 Hz, auto former attenuator by Dave Slagle.

Acoustic Elegance TD15-M in 3 cu ft sealed enclosure. Second-order low pass at 800 Hz. Minus 3 dB at 74 Hz.

Acoustic Elegance TD15-H in 5 cu ft enclosure with two Acoustic Elegance PR-700 passive radiators tuned to 23 Hz. Minus 3 dB at 43 Hz. Separately powered by plate amp.

These pictures were taken when I was still using the regular 745's (ferrite magnets, aluminum diaphragms). For some reason the last two pictures look "squished" in their preview mode (on my computer), but look fine when clicked on and enlarged.

Each channel:

Azurahorn AH-425 with Radian 745NeoBPB-16. Third-order high pass at 800 Hz, auto former attenuator by Dave Slagle.

Acoustic Elegance TD15-M in 3 cu ft sealed enclosure. Second-order low pass at 800 Hz. Minus 3 dB at 74 Hz.

Acoustic Elegance TD15-H in 5 cu ft enclosure with two Acoustic Elegance PR-700 passive radiators tuned to 23 Hz. Minus 3 dB at 43 Hz. Separately powered by plate amp.

These pictures were taken when I was still using the regular 745's (ferrite magnets, aluminum diaphragms). For some reason the last two pictures look "squished" in their preview mode (on my computer), but look fine when clicked on and enlarged.

Thanks, Gary and Martin, for the most recent posts. Sounds like Gary is enjoying the step-up from the Radian 745 (ceramic) to the 745 Neo/Be version. He mentioned on the phone that the string sound was particularly improved, not just in the HF, but in the lower midrange between cello and violin, which is significant. (Same passive crossover, same transistor amplifier, same source, which is mostly classical music.)

He's more keenly attuned to classical music than I am, since he's a choirmaster, plays tympani in the local orchestra, and his wife is a violinist. His remarks about the sound of the lower and upper strings are interesting, since this was an area that I really wanted to focus on ... getting massed-string sound correctly balanced, with no added edge of HF grit and harshness.

We were both a bit concerned that the beryllium Radians would sound like the TAD drivers, but to Gary's credit, he took the plunge, bought a pair of the new drivers, and told me that the slightly soft TAD sound is not there. Instead, the HF fizz is gone, the upper mids have better tone, and clarity and depth are improved. The improvement at HF was expected, but I didn't expect it would be better in the lower midrange, but apparently it is.

He's more keenly attuned to classical music than I am, since he's a choirmaster, plays tympani in the local orchestra, and his wife is a violinist. His remarks about the sound of the lower and upper strings are interesting, since this was an area that I really wanted to focus on ... getting massed-string sound correctly balanced, with no added edge of HF grit and harshness.

We were both a bit concerned that the beryllium Radians would sound like the TAD drivers, but to Gary's credit, he took the plunge, bought a pair of the new drivers, and told me that the slightly soft TAD sound is not there. Instead, the HF fizz is gone, the upper mids have better tone, and clarity and depth are improved. The improvement at HF was expected, but I didn't expect it would be better in the lower midrange, but apparently it is.

Last edited:

That is also the kind of improvement I got through when going from Ti to Truextent Be (ie not just HF, but midrange also, which seemed more "vivid" and realistic sound).

That said great care must be taken to re EQ the driver, as the Be will typically be more efficient in the midrange (higher mass break point).

The difference with the 4" diaphragm was as much as +3dB in the midrange, which would of course make any comparison meaningless without EQ.

That said great care must be taken to re EQ the driver, as the Be will typically be more efficient in the midrange (higher mass break point).

The difference with the 4" diaphragm was as much as +3dB in the midrange, which would of course make any comparison meaningless without EQ.

Interesting. Curious how the 3" beryllium diaphragm used in the 745NeoBe turns out in terms of measurements. The AH425 is flat as it can be, so the difference between the older 745 (ceramic, aluminum) and the 745NeoBe will come down to possible changes in the phase plug and the diaphragm.

Last edited:

Yes, tonality and resolution are both improved in an obvious way, and the sound has a beautifully liquid quality. I realize now that I was blaming the TD15m for some of the compression driver's sins. If the alnico GPA 416 is better still, that will be icing in the cake.

One change I didn't mention. Since the purpose of the phase plugs in the AE drivers is HF extension (I don't need the cooling), I removed them. In this application, it seems to help.

Lynn's experiments with his prototype indicated further improvements with higher-order crossovers (3rd order LP and 4th order HP), so I will definitely try that as well.

One change I didn't mention. Since the purpose of the phase plugs in the AE drivers is HF extension (I don't need the cooling), I removed them. In this application, it seems to help.

Lynn's experiments with his prototype indicated further improvements with higher-order crossovers (3rd order LP and 4th order HP), so I will definitely try that as well.

That said great care must be taken to re EQ the driver, as the Be will typically be more efficient in the midrange (higher mass break point).

Hello Pos

I had the same issue with the 435 Al vs 435 Be, there was a shift in both amplitude and frequency response that required the network be changed to get the same original frequency response. You should re-measure to see what the changes are.

Rob🙂

This is an area of sound which is an excellent marker ... however, I exercise full control over the qualities here by tweaking the electronics behaviour, earlier in the chain - the speaker attributes are quite irrelevant, apart from any suspension issues, 😀, 'solved' by heavily conditioning with high level driving ... 🙂His remarks about the sound of the lower and upper strings are interesting, since this was an area that I really wanted to focus on ... getting massed-string sound correctly balanced, with no added edge of HF grit and harshness.

Great to see someone appreciates removing things in front of the diaphragm......

One change I didn't mention. Since the purpose of the phase plugs in the AE drivers is HF extension (I don't need the cooling), I removed them. In this application, it seems to help.

...

- Home

- Loudspeakers

- Multi-Way

- Beyond the Ariel