By "top notch prices" I mean good prices. Realistic prices, not pie in the sky.

"This pair of immaculate Aleph 2 amplifiers are the best, because they are mine. I will allow you to give me $24,000, cash, and then you can drive by at my most convenient hour, you can pack them and take them with you". Guy in NYC on eBay.

"This Marantz 2235 is a rare piece of audio history. My expert master technician opened it up, counted the capacitors, put it new LED lights, buffed the cabinet and gave it an excellent rating. I shall entertain the first offer of $3600 that is presented my way, cash only!". All over the Internet.

"This Superscope receiver was conceived and built by the Master Crafstmen at Marantz in Reseda. Our elves sprinkled their dust on it, and now we are offering for sale for only $1200 to the first person who offers us the money, in cash, and we deem fit to purchase it from us...". eBay, of course.

I'm sure you've heard the type.

Anyhow, I think I've taken this pop corn way off the beginning.

We can hear the sound of capacitors, simple as that.

Likely you can measure them too.

I do wonder sometimes what kind of understanding and concomitant measurements are missing that we can hear differences in components that we don't know how to measure... but that's why the hobby is fun.

"This pair of immaculate Aleph 2 amplifiers are the best, because they are mine. I will allow you to give me $24,000, cash, and then you can drive by at my most convenient hour, you can pack them and take them with you". Guy in NYC on eBay.

"This Marantz 2235 is a rare piece of audio history. My expert master technician opened it up, counted the capacitors, put it new LED lights, buffed the cabinet and gave it an excellent rating. I shall entertain the first offer of $3600 that is presented my way, cash only!". All over the Internet.

"This Superscope receiver was conceived and built by the Master Crafstmen at Marantz in Reseda. Our elves sprinkled their dust on it, and now we are offering for sale for only $1200 to the first person who offers us the money, in cash, and we deem fit to purchase it from us...". eBay, of course.

I'm sure you've heard the type.

Anyhow, I think I've taken this pop corn way off the beginning.

We can hear the sound of capacitors, simple as that.

Likely you can measure them too.

I do wonder sometimes what kind of understanding and concomitant measurements are missing that we can hear differences in components that we don't know how to measure... but that's why the hobby is fun.

Last edited:

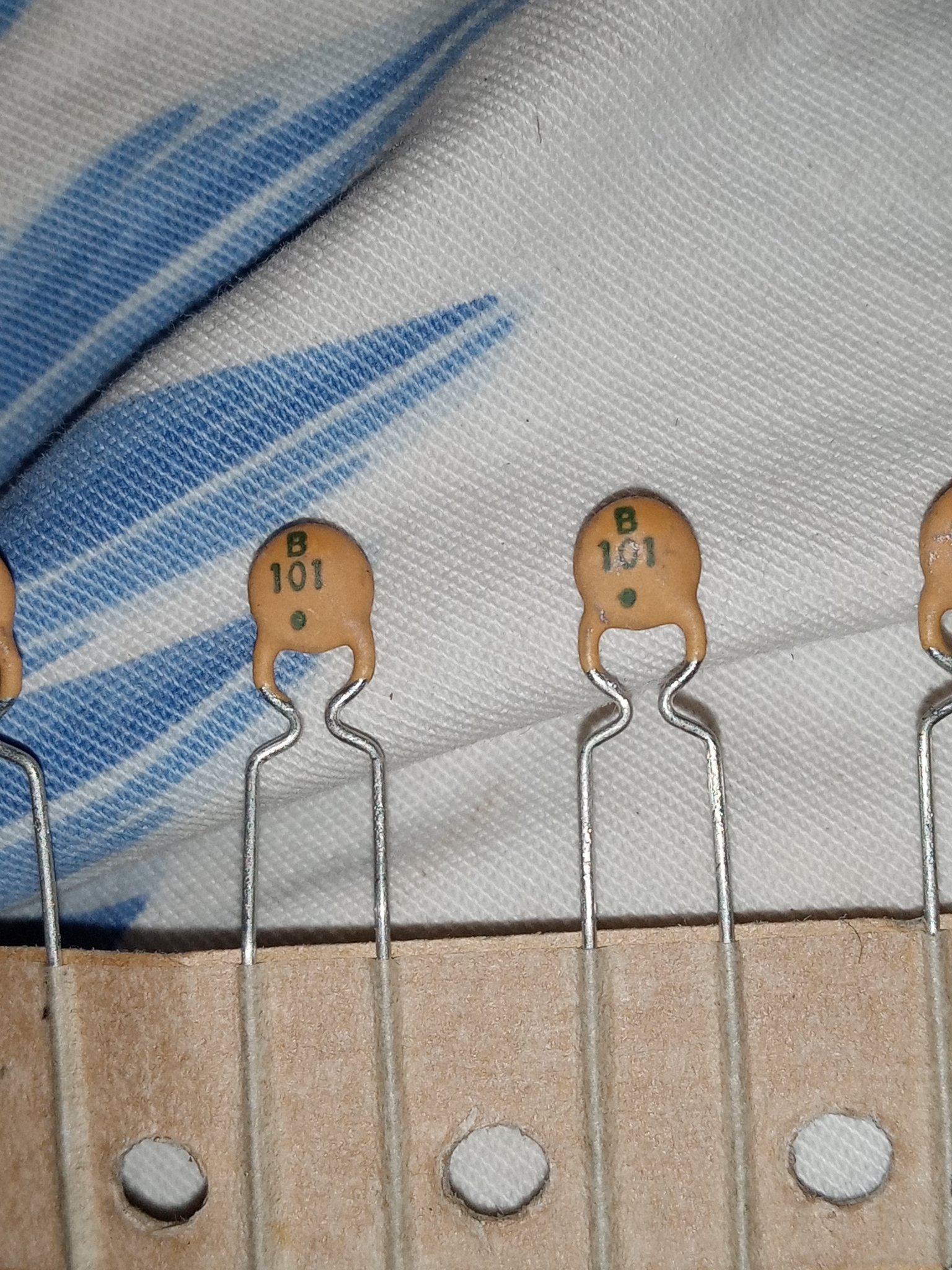

Need help. How many volts can take this ceramic?

Is it written on it? I see only capacity 100pF

Is it written on it? I see only capacity 100pF

Got to laugh, a question about a ceramic capacitor in a electrolytic cap thread, as off topic as the rest of those discussions 🙂

I’d have to say that the Sansui G- 7500 is a lousy design, I have one, the owner blew it up so many times it’s ridiculous. They used a single pair of ~100-125W bjts with a +/-70V supply, 90w/ch nonsense.

Teflon caps for audio is also nonsense. Same goes for Teflon dielectric for a pcb. John Curl comes to mind. Name one audio manufacturer that routinely uses those?

I’d have to say that the Sansui G- 7500 is a lousy design, I have one, the owner blew it up so many times it’s ridiculous. They used a single pair of ~100-125W bjts with a +/-70V supply, 90w/ch nonsense.

Teflon caps for audio is also nonsense. Same goes for Teflon dielectric for a pcb. John Curl comes to mind. Name one audio manufacturer that routinely uses those?

Hi Tony,

Well, the owner wants it fixed. It looks great and it is up to him whether to part it out or not. He chose not. So do I refuse the job and allow someone to hack the unit? To be honest, the design of the output stage is so terrible, I would upgrade (forklift it out entirely) if it where mine and I was somehow driven to own one. These things were garbage back then, and all Marantz 4 channel receivers were the worst performing units they ever produced. I have a 4300 I may restore, or part out. The reason? They are really difficult to work on, and the performance is in the basement.

Stereos are not cars Tony. A 2325 for example is not ever going to be worth more than $20K. So extreme efforts do not make sense one tiny bit. When I restore one, it is a 2325 with proper part values (capacitors are a higher voltage to allow them to fit properly). For mine, I will enhance it. It will still be a 2325 and will sound like a 2325 - just with lower distortion and noise. I recently restored a 2500 that 4 shops had hacked. Sorry, I designed a new capacitor PCB for it because someone decided to cut the perfectly good filter caps to attempt stuffing them with new capacitors. Gee whiz, you can't make up the original values doing that, and the replacement might overheat. The board looks like it could have been factory. I have saved three other 2385 and 2500 receivers this way. So should we have parted them out? Also, the hacked unit took me in excess of 70 hours to rebuild in order to restore it. I also have output bushings I designed to replace the mistake the factory made. Should we attempt to find the original melted ones (I got the last 38 washers way back in the 80's from Superscope in California)? Nope, I guess we shall pitch every 2600, 2500 and 510 amp that needs them. It cost me a fortune to do this by the way.

I don't buy and sell audio equipment Tony. I fix it, and improve it when the owner wishes. Units that have been enhanced are kept by their owners, they can't recoup the service costs, these are not cars. I do not "recap" units, just replace the capacitors that need it. I do keep things looking like original and perform tuner alignments when that section is part of the unit.

Honestly, I'd much rather own a set after I have enhanced it than something someone decided was "stock" the the way it should be by using silly parts. Because, you have zero idea what it did sound like new, none. Certainly not better than I do since I worked in the industry and sold / serviced them since the 70's. We are probably similar as far as memory is concerned, except I know I can't trust mine for an absolute idea of what they did sound like.

Coupling capacitors? No, you cannot hear them unless you compare a cap of poor quality or it is defective. That has been proved over decades by many. Can you imagine equipment in industry, aerospace or test and measurement if coupling caps made that much difference? Sorry, that is simply fanciful imagination.

Cars. I had a stock '67 Cutlass with a 330 CID engine, 43,000 original miles on it. It was a great car. Then I improved the suspension and driveline. It ran mid-12's in the quarter, and it was LOUD as you can imagine. It still handled amazingly well. Today, I would love to get another, restore it and improve the suspension. Except this time I would use a current Corvette driveline. That car was scary to drive, I think the newer driveline would be easier to handle on the road and get much better gas mileage. lol! Now if I ran across an Olds Starfire, that would be returned to stock. However, if I had trouble with the driveline - it gets a new one.

I guess I have offended you enough Tony. What I do with audio components is restore them to proper functioning and sound. If the client wants improved performance, they still sound like whatever they were but with lower distortion and noise. The MC60's I am working on now will be basically stock using today's improved resistors and capacitors. I even had to install similar wire since the idiot before me pulled everything. I even had to install terminals on the board they had removed to install adjustment pots. I'm sorry, but what you are sticking to doesn't make any sense at all. Modern parts do not change the sound unless it is a guitar amp (which I do also). For those I retain the distortion causing parts because we are creating a sound. With audio, we are reproducing sound. Totally different situation. To cap it off, design engineers have all said they intended to get the best performance they could, lowest distortion and noise. They would have used today's parts had they been available. So anyone who rebuilds / restores equipment using todays parts that fit are in fact following the spirit of the original design team. You are not. You are on your own little mission.

-Chris

Well, the owner wants it fixed. It looks great and it is up to him whether to part it out or not. He chose not. So do I refuse the job and allow someone to hack the unit? To be honest, the design of the output stage is so terrible, I would upgrade (forklift it out entirely) if it where mine and I was somehow driven to own one. These things were garbage back then, and all Marantz 4 channel receivers were the worst performing units they ever produced. I have a 4300 I may restore, or part out. The reason? They are really difficult to work on, and the performance is in the basement.

Stereos are not cars Tony. A 2325 for example is not ever going to be worth more than $20K. So extreme efforts do not make sense one tiny bit. When I restore one, it is a 2325 with proper part values (capacitors are a higher voltage to allow them to fit properly). For mine, I will enhance it. It will still be a 2325 and will sound like a 2325 - just with lower distortion and noise. I recently restored a 2500 that 4 shops had hacked. Sorry, I designed a new capacitor PCB for it because someone decided to cut the perfectly good filter caps to attempt stuffing them with new capacitors. Gee whiz, you can't make up the original values doing that, and the replacement might overheat. The board looks like it could have been factory. I have saved three other 2385 and 2500 receivers this way. So should we have parted them out? Also, the hacked unit took me in excess of 70 hours to rebuild in order to restore it. I also have output bushings I designed to replace the mistake the factory made. Should we attempt to find the original melted ones (I got the last 38 washers way back in the 80's from Superscope in California)? Nope, I guess we shall pitch every 2600, 2500 and 510 amp that needs them. It cost me a fortune to do this by the way.

I don't buy and sell audio equipment Tony. I fix it, and improve it when the owner wishes. Units that have been enhanced are kept by their owners, they can't recoup the service costs, these are not cars. I do not "recap" units, just replace the capacitors that need it. I do keep things looking like original and perform tuner alignments when that section is part of the unit.

Honestly, I'd much rather own a set after I have enhanced it than something someone decided was "stock" the the way it should be by using silly parts. Because, you have zero idea what it did sound like new, none. Certainly not better than I do since I worked in the industry and sold / serviced them since the 70's. We are probably similar as far as memory is concerned, except I know I can't trust mine for an absolute idea of what they did sound like.

Coupling capacitors? No, you cannot hear them unless you compare a cap of poor quality or it is defective. That has been proved over decades by many. Can you imagine equipment in industry, aerospace or test and measurement if coupling caps made that much difference? Sorry, that is simply fanciful imagination.

Cars. I had a stock '67 Cutlass with a 330 CID engine, 43,000 original miles on it. It was a great car. Then I improved the suspension and driveline. It ran mid-12's in the quarter, and it was LOUD as you can imagine. It still handled amazingly well. Today, I would love to get another, restore it and improve the suspension. Except this time I would use a current Corvette driveline. That car was scary to drive, I think the newer driveline would be easier to handle on the road and get much better gas mileage. lol! Now if I ran across an Olds Starfire, that would be returned to stock. However, if I had trouble with the driveline - it gets a new one.

I guess I have offended you enough Tony. What I do with audio components is restore them to proper functioning and sound. If the client wants improved performance, they still sound like whatever they were but with lower distortion and noise. The MC60's I am working on now will be basically stock using today's improved resistors and capacitors. I even had to install similar wire since the idiot before me pulled everything. I even had to install terminals on the board they had removed to install adjustment pots. I'm sorry, but what you are sticking to doesn't make any sense at all. Modern parts do not change the sound unless it is a guitar amp (which I do also). For those I retain the distortion causing parts because we are creating a sound. With audio, we are reproducing sound. Totally different situation. To cap it off, design engineers have all said they intended to get the best performance they could, lowest distortion and noise. They would have used today's parts had they been available. So anyone who rebuilds / restores equipment using todays parts that fit are in fact following the spirit of the original design team. You are not. You are on your own little mission.

-Chris

If you want authentic vintage units, then go thru the pains of making them authentic.

If you don't, then don't.

Too many people enjoying telling others what to do instead of just enjoying doing for themselves.

There's some irony in this post.

Good times.

If you don't, then don't.

Too many people enjoying telling others what to do instead of just enjoying doing for themselves.

There's some irony in this post.

Good times.

There is no need of "vintage " capacitors if the one you place has the same characteristics as the old one , it is a matter of effort and time not money 😉

.

.

Well i have a problem recapping Pioneer CS-801 loudspeakers - can't find 14 uF ( 100Vdc ? ) Bi-Polar caps.

These are 50 years old and working alright but i just can't convince myself these and other capacitors are good as when they where new ( 3 Uf + 1,5 uF ).

First i don't have a clue who made caps for Pioneer back then and second the closest thing to do is buying some F&T 12uF paralleld with 2u2 to get the value - the problem is small crossover pcb dimension so any paralleling will have a "flying" leads few cm long ie the parts would be in air above crossover pcb connected by leads only. 15uF is one other solution which i do not like at all since this is changing the value of the cap in the crossover.

The only 14 uF capacitors that i know of are motor run caps and they are too big ( or maybe some dc-link caps ), i could mount them beside the crossover pcb but the leads to pcb would be 50+mm long at least. Additionally i would not like to do a polypropilene cap modification at this time.

Anny recommendation ?

These are 50 years old and working alright but i just can't convince myself these and other capacitors are good as when they where new ( 3 Uf + 1,5 uF ).

First i don't have a clue who made caps for Pioneer back then and second the closest thing to do is buying some F&T 12uF paralleld with 2u2 to get the value - the problem is small crossover pcb dimension so any paralleling will have a "flying" leads few cm long ie the parts would be in air above crossover pcb connected by leads only. 15uF is one other solution which i do not like at all since this is changing the value of the cap in the crossover.

The only 14 uF capacitors that i know of are motor run caps and they are too big ( or maybe some dc-link caps ), i could mount them beside the crossover pcb but the leads to pcb would be 50+mm long at least. Additionally i would not like to do a polypropilene cap modification at this time.

Anny recommendation ?

In parallel with Bass unit. 14uF is on the right side of the picture, obscured by inductor at lower right side.you have all the place you want , is the caps in series with mid ?

Thanks

How about moving the Pioneer CS-801 loudspeakers discussion to it's own thread so others can later reference the solutions?

Something an administrator could possibly do and also the long discussion on a coupling cap selection process and servicing ... 🙂

Something an administrator could possibly do and also the long discussion on a coupling cap selection process and servicing ... 🙂

put mundorf 15u that are 5% ...In parallel with Bass unit. 14uF is on the right side of the picture, obscured by inductor at lower right side.

Thanks

Got to laugh, a question about a ceramic capacitor in a electrolytic cap thread, as off topic as the rest of those discussions 🙂

I’d have to say that the Sansui G- 7500 is a lousy design, I have one, the owner blew it up so many times it’s ridiculous. They used a single pair of ~100-125W bjts with a +/-70V supply, 90w/ch nonsense.

Teflon caps for audio is also nonsense. Same goes for Teflon dielectric for a pcb. John Curl comes to mind. Name one audio manufacturer that routinely uses those?

Audio Research, Conrad Johnson.

Hi Tony,

Well, the owner wants it fixed. ...

Stereos are not cars Tony. ...

I don't buy and sell audio equipment Tony. I fix it, and improve it when the owner wishes. ...

Coupling capacitors? No, you cannot hear them unless you compare a cap of poor quality or it is defective. That has been proved over decades by many....

Cars. I had a stock '67 Cutlass with a 330 CID engine, 43,000 original miles on it. It was a great car. Then I improved the suspension and driveline. ....

I guess I have offended you enough Tony. What I do with audio components is restore them to proper functioning and sound. If the client wants improved performance...

-Chris

No, you have not offended me. Don't worry about it.

I guess that fundamentally we're in different planets. When it comes to vintage, I stick right to as close to OEM or nothing. I only agree to parts replacement when replacements can not be found.... that's part of the fun... finding the replacements. Heck, just last night I found a picture of the wired remote for the Akai.... an Akai RC-4CX. Let me know if you find one... It might be years before I find it...

You, OTOH, are in the business of repairing so you don't have the luxury of choosing how to do it, or whether to do it. So you are dogmatic, simply exercising the wishes of the customer, within reason.

Cars.... yes, you can often "improve" a car, but usually at the expense of other parts of the car... given how such products are mostly balanced compromises. But you will note that a vintage car loses a lot of value when so "modified". If you find a stock, matching parts, Cutlass 330 it will be worth a lot more than something that was "improved". Many people would get the OEM car, as a reflection of what it was, than someone's idea of what it ought to be. And t he price will reflect that.

IMHO, if I want improved performance, I just listen to the modern systems in my house, but in my bedroom, I fire up the vintage units.

Oh, @rsavas - the G-7500 did have some issues with build design and circuit choices. The output transistors were stressed from day one and they sat in the worst part of the chassis, in what was described to me as a "Valley Of Heat"... so yeah, they need ventilation. When I ran it full time, eons ago, it worked quite well. Indeed I actually burned up a midrange in one of the ADS L810 speakers. Playing Eric Clapton and Freddie King Farther On Up The Road.. Live! Dueling guitars at 11..... the dealer and factory didn't believe it could be done, but they replaced the parts and paid for the repair on the sole condition they got the part to their R&D to examine the failure... If I ran it full time and loud, I'd put a fan on top of it.

But, those High Speed Sansuis sounded good. I guess, as a former owner of an Alfa Romeo, I understand the G-7500 as a product.

Okay, cool Tony.

I don't have my hands tied except by ethics and doing a proper job that was instilled in me during training. I just have trouble justifying using a lower quality component at usually higher cost than what we have access to these days. The original sound is an elusive, murky thing, not a defined target.

I make certain that parts fit properly and the unit looks like it should. Performance is often unavoidably improved. Brake linings for cars today are better than the original ones. What do you use? You are correct, improvements in a car are a carefully considered compromise sometimes. In audio gear, you are improving performance to begin with or you wouldn't be doing anything to it. So why would you go half way going through all the trouble to obtain (usually more expensive) parts and pay the additional shipping in order to get similar performance to when the unit was new (hopefully)? If what you end up with sounds the same, but performs a little better with regard to noise and performance, what have you harmed? If I were buying a restored car, would I demand the original crappy tires and brakes we suffered with? I'm sure you can get them and it may make sense for a 1930's or earlier car, but for anything you would actually drive on the road it seems silly. Same for air and oil filters, belts - you name it. How about the oil and lubricants?

Anyway, it is rare for a person to request an exact rebuild. Most would wish for a neat restoration using modern, good components with the unit aligned properly. That is most of what I do, aside from repairing "recap" damaged by idiots. I do not push upgrades at all. Most folks are overjoyed simply by having a neat, proper repair job done.

The high speed transistors are not in themselves the answer. A 4 MHz device is plenty quick enough and more robust. The higher speed parts are also good, but it is more important that the collector current vs beta curve is flat. No, that does not change the sound,. If you just swap outputs without redoing the high frequency compensation you run into other issues that may affect how it sounds. So comparing by simply swapping parts is not a valid way to compare some things. The other critical thing is a tightly matched differential pair, that can make a world of difference. No sound change beyond lower distortion. If you have multiple output devices, match the beta between them.

Anyway, happy fixing and enjoy your stuff. Better performance is anything but evil!

I don't have my hands tied except by ethics and doing a proper job that was instilled in me during training. I just have trouble justifying using a lower quality component at usually higher cost than what we have access to these days. The original sound is an elusive, murky thing, not a defined target.

I make certain that parts fit properly and the unit looks like it should. Performance is often unavoidably improved. Brake linings for cars today are better than the original ones. What do you use? You are correct, improvements in a car are a carefully considered compromise sometimes. In audio gear, you are improving performance to begin with or you wouldn't be doing anything to it. So why would you go half way going through all the trouble to obtain (usually more expensive) parts and pay the additional shipping in order to get similar performance to when the unit was new (hopefully)? If what you end up with sounds the same, but performs a little better with regard to noise and performance, what have you harmed? If I were buying a restored car, would I demand the original crappy tires and brakes we suffered with? I'm sure you can get them and it may make sense for a 1930's or earlier car, but for anything you would actually drive on the road it seems silly. Same for air and oil filters, belts - you name it. How about the oil and lubricants?

Anyway, it is rare for a person to request an exact rebuild. Most would wish for a neat restoration using modern, good components with the unit aligned properly. That is most of what I do, aside from repairing "recap" damaged by idiots. I do not push upgrades at all. Most folks are overjoyed simply by having a neat, proper repair job done.

The high speed transistors are not in themselves the answer. A 4 MHz device is plenty quick enough and more robust. The higher speed parts are also good, but it is more important that the collector current vs beta curve is flat. No, that does not change the sound,. If you just swap outputs without redoing the high frequency compensation you run into other issues that may affect how it sounds. So comparing by simply swapping parts is not a valid way to compare some things. The other critical thing is a tightly matched differential pair, that can make a world of difference. No sound change beyond lower distortion. If you have multiple output devices, match the beta between them.

Anyway, happy fixing and enjoy your stuff. Better performance is anything but evil!

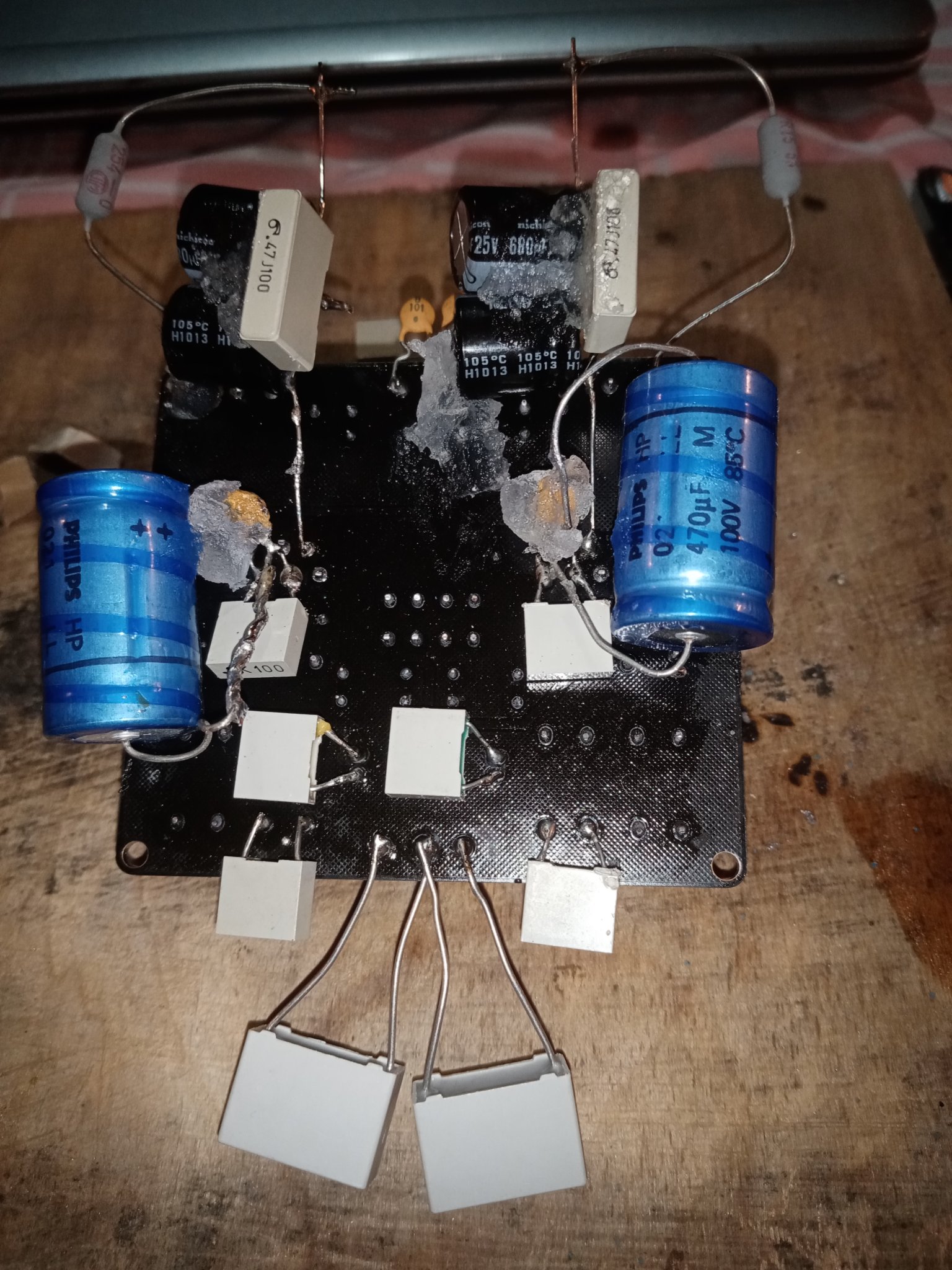

Is it a help to put to electrolytic in parallel a foil type condenser?

On ready made amp boards I omit desoldering and only put foils in parallel.

Sonically seems to work.

https://www.diyaudio.com/community/...fication-to-current-drive.389985/post-7543404

On ready made amp boards I omit desoldering and only put foils in parallel.

Sonically seems to work.

https://www.diyaudio.com/community/...fication-to-current-drive.389985/post-7543404

Nope. Sorry, no benefit at all except top those selling film caps. It also makes a mess of the circuit and you may end up picking up noise or radiating it.

The deal is, people think putting a 1uF cap or less in parallel with one with dielectric issues will somehow solve it. No, sorry. Damage (if any) has been done. Normally there is no damage. Let's imagine in a fairytale world that a film capacitor can reverse whatever you are trying to fix. Look at the differences ion capacitor size. That tiny thing, even if it could affect things isn't big enough to correct the "problem". Therefore, you'd just use a film cap alone (which would be far too large).

What isn't helpful is that some folks assume a bypass capacitor position is the same as a coupling capacitor. It isn't. With power supplies we try to keep a low AC impedance across a wide range of frequencies when in coupling applications our frequency range is extremely limited by comparison. With high AC impedance at high frequencies, a circuit or component may oscillate at 10 MHz (for example). The typical audio circuit simply doesn't respond above 1 MHz and usually much, much lower. Your audio frequencies of interest range up to 20 KHz by convention, most cannot hear past 15 KHz but we like to pass 100 KHz or above. Given this range of frequencies, why would you worry about 1 MHz or above???

This is an excellent example of some folks becoming worried about a textbook argument without any consideration to reality. Given the impedances we are talking about in coupling applications, even a "not great" electrolytic capacitor will pass very, very high frequencies with minimal loss. Again, consider the circuit and what signals you are interested in passing. Not even your dog will hear the effect of a film bypass on a coupling capacitor.

By the way, those Philips capacitors are cheap and nasty. I won't use them. Clean that poor circuit board up, don't block air flow and enjoy.

The deal is, people think putting a 1uF cap or less in parallel with one with dielectric issues will somehow solve it. No, sorry. Damage (if any) has been done. Normally there is no damage. Let's imagine in a fairytale world that a film capacitor can reverse whatever you are trying to fix. Look at the differences ion capacitor size. That tiny thing, even if it could affect things isn't big enough to correct the "problem". Therefore, you'd just use a film cap alone (which would be far too large).

What isn't helpful is that some folks assume a bypass capacitor position is the same as a coupling capacitor. It isn't. With power supplies we try to keep a low AC impedance across a wide range of frequencies when in coupling applications our frequency range is extremely limited by comparison. With high AC impedance at high frequencies, a circuit or component may oscillate at 10 MHz (for example). The typical audio circuit simply doesn't respond above 1 MHz and usually much, much lower. Your audio frequencies of interest range up to 20 KHz by convention, most cannot hear past 15 KHz but we like to pass 100 KHz or above. Given this range of frequencies, why would you worry about 1 MHz or above???

This is an excellent example of some folks becoming worried about a textbook argument without any consideration to reality. Given the impedances we are talking about in coupling applications, even a "not great" electrolytic capacitor will pass very, very high frequencies with minimal loss. Again, consider the circuit and what signals you are interested in passing. Not even your dog will hear the effect of a film bypass on a coupling capacitor.

By the way, those Philips capacitors are cheap and nasty. I won't use them. Clean that poor circuit board up, don't block air flow and enjoy.

Thanks for the reply.

The foils on the mentioned board are mainly in place for decoupling like mentioned in the data sheet or like often recommended to decouple power supply directly on the chip.

For the feedback capacitor I did not know if a nonpolar type can help the sound.

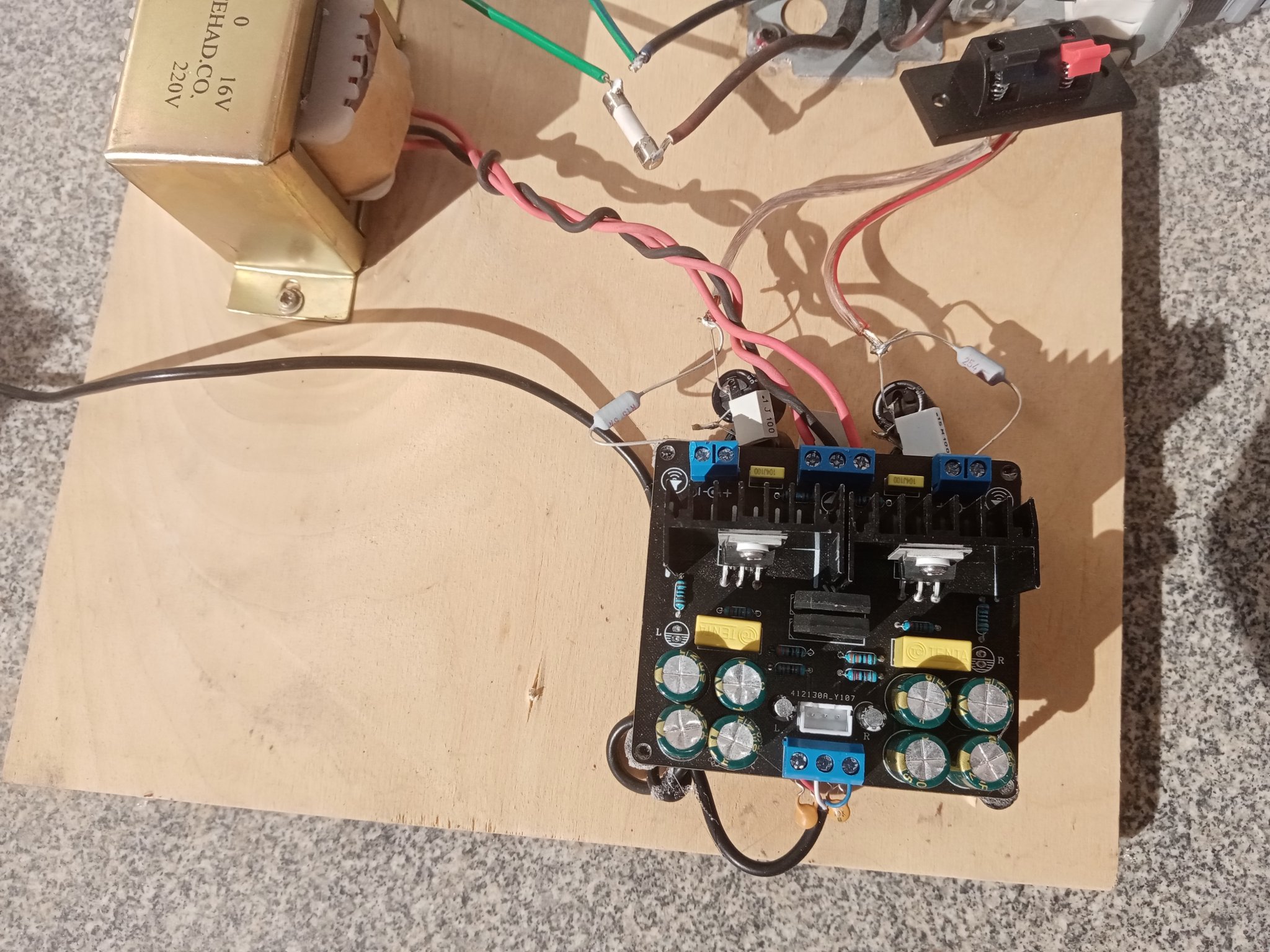

For the transformation of LM1875 from voltage to current drive I had to add it on the fly so no nice layout from the scratch was available.

Only the polar input electrolytics of 4.7 uF got 0.1uF MKT as bypass.

The foils on the mentioned board are mainly in place for decoupling like mentioned in the data sheet or like often recommended to decouple power supply directly on the chip.

For the feedback capacitor I did not know if a nonpolar type can help the sound.

For the transformation of LM1875 from voltage to current drive I had to add it on the fly so no nice layout from the scratch was available.

Only the polar input electrolytics of 4.7 uF got 0.1uF MKT as bypass.

We would have to be familiar with the schematic, board layout and parts you used to comment. In general, at audio frequencies the way they made the board would be sufficient. If you can find the right values, Poly-Aluminum capacitors would perform better as bypass capacitors. That is far better than a forest of stuff hanging around.

This is textbook thinking, now the practical. The bypass caps they included are more than good enough. Blocking air currents, gluing crap and flying components are almost never good. You have to consider the built circuit as a whole and not focus on things that "might be better". If you want to add something and it can't fit neatly - don't. Either that or design a PCB where it does, however PCB layout can make a bigger difference. You may have the optimal solution right there. Also, ceramic capacitors are better as bypass capacitors than foil types. Depends on value of course.

Most disasters I get to repair are based in textbook thinking without regard to the characteristics of the components they added. If something was designed by engineers, I would tread very, very carefully in attempting to improve a design if you aren't also an experienced, trained engineer. That and you absolutely do require the equipment needed to ensure the circuit is operating properly and that changes you made did in fact improve performance. I get stuff in that is oscillating for example. A simple oscilloscope will show that (analogue is best here). It's amazing how many people say it sounded fine, then when things are fixed they say "I can't believe I didn't notice that".

You tell me.

This is textbook thinking, now the practical. The bypass caps they included are more than good enough. Blocking air currents, gluing crap and flying components are almost never good. You have to consider the built circuit as a whole and not focus on things that "might be better". If you want to add something and it can't fit neatly - don't. Either that or design a PCB where it does, however PCB layout can make a bigger difference. You may have the optimal solution right there. Also, ceramic capacitors are better as bypass capacitors than foil types. Depends on value of course.

Most disasters I get to repair are based in textbook thinking without regard to the characteristics of the components they added. If something was designed by engineers, I would tread very, very carefully in attempting to improve a design if you aren't also an experienced, trained engineer. That and you absolutely do require the equipment needed to ensure the circuit is operating properly and that changes you made did in fact improve performance. I get stuff in that is oscillating for example. A simple oscilloscope will show that (analogue is best here). It's amazing how many people say it sounded fine, then when things are fixed they say "I can't believe I didn't notice that".

You tell me.

- Home

- Design & Build

- Parts

- Best electrolytic capacitors