AR2,

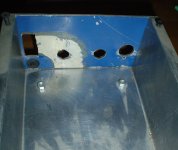

Gorgeous cases. Thanks for sharing with us.

I am sure they will undoubtedly qualify for having enough heat-sinking capability.

Everything comes at a price, don't they ?

😉

Best regards,

Patrick

Gorgeous cases. Thanks for sharing with us.

I am sure they will undoubtedly qualify for having enough heat-sinking capability.

Everything comes at a price, don't they ?

😉

Best regards,

Patrick

AR2,

Everything comes at a price, don't they ?

😉

Best regards,

Patrick

not if you out source to China😀

i agree.

i bought full alum chassis enough for the f5 about 120us$, weighs about 20kg.

cheers

henry

i bought full alum chassis enough for the f5 about 120us$, weighs about 20kg.

cheers

henry

Roughly, the cost of the raw material.i bought full alum chassis enough for the f5 about 120us$, weighs about 20kg.

Roughly, the cost of the raw material.

I guess that depends where in the world you live. Cost of raw materials has alot to do with infrasruture costs,ie transport, power, real estate, labour etc. Clearly this is cheaper in China than Germany.

since i bought them myself in guangzhou, so i can choose which one to buy.

the raw aluminum market price there between 15-20,000rmb or 2200-3000usd/ton depends on the time of the market.

china have many things to choose from, u can buy the cheapest available, but u can also buy things that really have good value.

cheers

henry

the raw aluminum market price there between 15-20,000rmb or 2200-3000usd/ton depends on the time of the market.

china have many things to choose from, u can buy the cheapest available, but u can also buy things that really have good value.

cheers

henry

I am sure within a month of us publishing our photos, you can buy a cheap copy on Ebay.

The question is whether you just want it cheap, or whether you want something decent, and support the forum at the same time.

Patrick

The question is whether you just want it cheap, or whether you want something decent, and support the forum at the same time.

Patrick

....you want something decent...

Decent said by Patrick means astonishing..... for sure! 😉

Can't wait.

Should one worry about thermal expansion problems?

What about differences in the coefficients of thermal expansion of the pc board vs. the heatsinks? Also, between the opposite sides (ie. the opposite polarity halves) of the amplifier? Could this pose problems of mechanical stress on the terminals of the output MOSFETs?

The idea is good, but if you would read posts #326, 327, (339) and 341, you might also agree that it brings very little.

At most 2~3°C, at the expense of larger PCB and long signal path for the X.

Patrick

What about differences in the coefficients of thermal expansion of the pc board vs. the heatsinks? Also, between the opposite sides (ie. the opposite polarity halves) of the amplifier? Could this pose problems of mechanical stress on the terminals of the output MOSFETs?

i dont like to buy copies also. i bought the boards from cviller and parts from tech diy.

just saying in general.

alot of agressiveness here

cheers

henry

just saying in general.

alot of agressiveness here

cheers

henry

The coefficient of thermal expansion for aluminum is 12.3 x 10^-6 inches per degree Fahrenheit. So if you have a difference of 20 to 65 Celsius, thats roughly a difference of 70 degrees Fahrenheit. Over a PCB that is say 6 inches long, that means the aluminum would expand roughly 0.005 inches (assuming I didn't mess up on the crappy windows calculator).

I wouldn't think that's going to pose any problems.

I wouldn't think that's going to pose any problems.

There is enough flexibility in the bended legs of the MOSFET to allow for such differential expansions, something that is more difficult with SMD components.

Patrick

Patrick

> alot of agressiveness here

Was not intending to be. My apologies.

If you know manufacturing in China, then you know that you can get from junk to top quality, with vastly different prices.

Just take the front panel. You can use US imported 6061, or Chinese 6061.

If you black anodise, then you would probably not notice any difference.

If you do matt silver anodise, you can tell which is which immediately.

And we have thrown away a thousand USD's worth of front panels (for our own use) just for that reason.

Patrick

Was not intending to be. My apologies.

If you know manufacturing in China, then you know that you can get from junk to top quality, with vastly different prices.

Just take the front panel. You can use US imported 6061, or Chinese 6061.

If you black anodise, then you would probably not notice any difference.

If you do matt silver anodise, you can tell which is which immediately.

And we have thrown away a thousand USD's worth of front panels (for our own use) just for that reason.

Patrick

> alot of agressiveness here

Was not intending to be. My apologies.

If you know manufacturing in China, then you know that you can get from junk to top quality, with vastly different prices.

Just take the front panel. You can use US imported 6061, or Chinese 6061.

If you black anodise, then you would probably not notice any difference.

If you do matt silver anodise, you can tell which is which immediately.

And we have thrown away a thousand USD's worth of front panels (for our own use) just for that reason.

Patrick

Perhaps next time you might consider offering them for sale here on DIYA.

hi patrick,

im kind of curious what would be the difference is? the chassis i bought wast machine milled from a alum profiles extrusions.

i dont know for sure the grades they are using, but it does look less pleasing as PASS XA AMPS.

cheers

henry

im kind of curious what would be the difference is? the chassis i bought wast machine milled from a alum profiles extrusions.

i dont know for sure the grades they are using, but it does look less pleasing as PASS XA AMPS.

cheers

henry

Another update :

Variac is now up to speed and we had our first team meeting by email.

I received the draft of 3 of the PCBs today and shall check them in the next day or so.

We agreed who would be doing the prototype builds, etc., and we also agreed that all PCBs will be prototyped and tested first before volume production.

We also had the first discussion with the case production people.

Apart from a few things that need finalising, we think we'll be able to keep to the promised production costs.

So things are moving at pace, at last.

😉

Patrick

Variac is now up to speed and we had our first team meeting by email.

I received the draft of 3 of the PCBs today and shall check them in the next day or so.

We agreed who would be doing the prototype builds, etc., and we also agreed that all PCBs will be prototyped and tested first before volume production.

We also had the first discussion with the case production people.

Apart from a few things that need finalising, we think we'll be able to keep to the promised production costs.

So things are moving at pace, at last.

😉

Patrick

The prototype team might be ordering transformers in the next couple of weeks.

Details see -- http://www.diyaudio.com/forums/pass-labs/172770-balanced-f5-question-9.html#post2351154

With electrostatic shield. No encapsulation in a can.

Anyone else interested ?

Patrick

Details see -- http://www.diyaudio.com/forums/pass-labs/172770-balanced-f5-question-9.html#post2351154

With electrostatic shield. No encapsulation in a can.

Anyone else interested ?

Patrick

- Status

- Not open for further replies.

- Home

- Amplifiers

- Pass Labs

- Balanced F5 question