And this type of testing can fry a sound card if done incorrectly. So it might be better to get yourself familiar with the process using a lower priced unit before upgrading.

Howto - Distortion Measurements with REW

which you referenced in your post #2788 has good information.

Many have done it, including me who had no prior experience. Just be careful, read and understand the procedures, and double and triple check before proceeding.

Well, thought I was going to have a completed B1K today until I realized the frontplate of the Galaxy 2U black chassis has a 3/8" thick front plate. The threaded shaft of the ALPS Pot I bought won't clear it. I even had it wired and was ready to install. When I look online, none of the ones I see including the ALPS Black Beauty seem to have enough thread to get a nut on the outside. Any suggestions of an Attenuator that will work with this faceplate? Help!

The faceplate can be cut (machined) to fit the Alps. It wouldn't take much to cut a hole larger, than the through hole, and not very deep, to allow the nut to go on. If you're ever over San Antonio, way we should get together and talk audio.

By the way, I just finished a pair of Anaview D-class amps and the chassis' I got from Aliexpress were already machined to fit the Alps.

You know, if you buy a chassis designed to be used for audio projects, would it be too much to ask them to design them where components would work? Could they not imagine a need to mount a volume control through the front plate? I mean good grief...

Eric, that was a good idea and looks good. But I have all black brushed front components.

A while back I did something like this in pictures. Aluminum square rod drilled to couple front panel and pot. Pot extended with 6mm rod glued with epoxy and secured with flat metal in slot...

I guess pictures explain.

Attachments

Wardsweb I do find myself over there on business at times. we may have to try that.

Bassivus that looks crafty as heck but I hope to find something easier. I'll post my solution if it works. Thanks for the suggestions folks. Still disappointed to have these issues with a relatively expensive chassis. If I wanted to make a chassis work I'd have bought a Chinese one. Likely to do just that next time. Or just some heat sinks and build my own.

Bassivus that looks crafty as heck but I hope to find something easier. I'll post my solution if it works. Thanks for the suggestions folks. Still disappointed to have these issues with a relatively expensive chassis. If I wanted to make a chassis work I'd have bought a Chinese one. Likely to do just that next time. Or just some heat sinks and build my own.

Any thoughts on using socket strip for jfet installation ? It would make trouble shooting that involves moving, replacing jfets easier. But would it compromise performance or reliability ?

Works just fine IMHO.

I use this arrangement in my stripboard Pearl Phono for all the JFets and BP semis in it.

One has to remember that Revox had a similar approach in some of their decks.

Go ahead and don't worry too much.

Works just fine IMHO.

I use this arrangement in my stripboard Pearl Phono for all the JFets and BP semis in it.

I would like to build a phono preamp to put in front of the B1K. Or even inside the B1K. I searched the Pearl project you referenced and it looks interesting. Is that board still available anywhere? 2010 was a while ago but just thought I'd ask. Any other suggestions for a similar project would be appreciated too. https://www.passdiy.com/pdf/PEARL 2.pdf

I searched the Pearl project you referenced and it looks interesting. Is that board still available anywhere?

Yes in PassDiy store PassDiy

... until I realized the frontplate of the Galaxy 2U black chassis has a 3/8" thick front plate. The threaded shaft of the ALPS Pot I bought won't clear it. ... Any suggestions of an Attenuator that will work with this faceplate? Help!

You could get a forstner bit and hog out the back of the panel to make the mounting surface thinner.

That video shows a few things;

1) Steel bits cut soft aluminum quite nicely. Any cutting liquid is a necessity.

2) Clean the swarf out of the work more often!

3) That drill press (pillar drill) is junk. Look at all the wobble. Much (or all) of that would have been avoided had the user cleared the hole of the metal cuttings earlier in the process.

1) Steel bits cut soft aluminum quite nicely. Any cutting liquid is a necessity.

2) Clean the swarf out of the work more often!

3) That drill press (pillar drill) is junk. Look at all the wobble. Much (or all) of that would have been avoided had the user cleared the hole of the metal cuttings earlier in the process.

You could get a forstner bit and hog out the back of the panel to make the mounting surface thinner.

I have a set of those but never imagined using them on metal. I'll know tomorrow if my plan A will work or not. If push come to shove though... Thanks for the idea 6L6.

You could also drill and tap the plate for the thread of the Pot Shaft itself and just screw it in from the back using the nut as a stop to position it. I've discovered the thread is a 9 x .75 mm through some trial and error. That tap arrives tomorrow. That is probably the ONLY metric tap I don't own already.

I had same issue with BA-3 pre. I took the easy solution and ordered a thin (3mm) front panel.

News from diyaudiostore:

NO ITALIAN ORIGIN CHASSIS SHIPMENTS DURING AUGUST

Posted by diyAudio Store on Aug 01, 2019

Please note: Our Italian chassis partners Hifi2000 are closed for summer holidays between the 3rd to the 25th of August 2019. Chassis shipping will resume during the last week of of August, most likely towards the end of that week. We do apologize for any inconvenience this causes.

Question:

Is this news further delaying the chassis output for the B1, or is it from another provider?

NO ITALIAN ORIGIN CHASSIS SHIPMENTS DURING AUGUST

Posted by diyAudio Store on Aug 01, 2019

Please note: Our Italian chassis partners Hifi2000 are closed for summer holidays between the 3rd to the 25th of August 2019. Chassis shipping will resume during the last week of of August, most likely towards the end of that week. We do apologize for any inconvenience this causes.

Question:

Is this news further delaying the chassis output for the B1, or is it from another provider?

Didn't realize there was another Pass DIY store. Thanks! I was hoping for less than $200 for the board and FETs though. Adding the PS and other components will push this up into the range of some decent finished Phono-Pre components. But no challenge/fun there, right?Yes in PassDiy store PassDiy

It's with 2 x 6 = 12 matched genuine Toshiba jfet's and 2 pcb's.I was hoping for less than $200 for the board and FETs though.

Yes not cheap but stay affordable and no need care about counterfait semiconductors made in Ch**a 😉

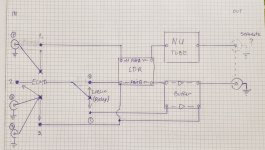

Dear audio frends, I’m planning on putting Nutube in box with my good old PSMLS with buffer. For those not familiar with it, it’s Poor Serbian Man Light Speed, aka LDR optocoupler based attenuator. I had it running in balance mod that I no longer need. That means I have 4 signal lines in both Elma selector, LDR and buffer. It gives me a ton possibilities to wire in normal RCA mode. I have done some drawings by hand since I’m on vacation and have no computer at hand. I came with pretty complicated wiring idea and would be delighted if someone knowledgeable had a look at it if there are some flaws and possibly problems.

1. Input> LDR pair a)> NUtube> RCA out (probably dedicated)

2. Input> Lolrlin a) >LDR pair b)> Buffer pair b)> RCA out // Lorlin b)> Buffer pair a)> LDR pair b)> Buffer pair b)> RCA out

3. Input >LDR pair b)> Buffer pair b)> RCA out

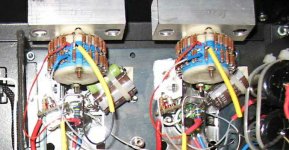

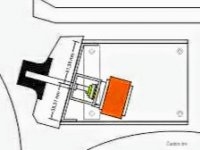

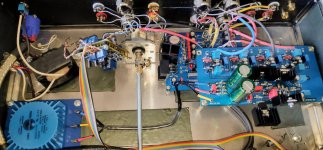

Here’s schematic and pic of current buffer and LDR attenuator that would be rearranged.

1. Input> LDR pair a)> NUtube> RCA out (probably dedicated)

2. Input> Lolrlin a) >LDR pair b)> Buffer pair b)> RCA out // Lorlin b)> Buffer pair a)> LDR pair b)> Buffer pair b)> RCA out

3. Input >LDR pair b)> Buffer pair b)> RCA out

Here’s schematic and pic of current buffer and LDR attenuator that would be rearranged.

Attachments

Question:

Is this news further delaying the chassis output for the B1, or is it from another provider?

The first batch is being shipped before they close. Which means the second batch will be available after they return and make them.

If you want one and they are available in the store, don’t delay, since there’s going to be a wait, and the first batch isn’t that big.

Dear audio frends, I’m planning on putting Nutube in box with my good old PSMLS with buffer. For those not familiar with it, it’s Poor Serbian Man Light Speed, aka LDR optocoupler based attenuator. I had it running in balance mod that I no longer need. That means I have 4 signal lines in both Elma selector, LDR and buffer. It gives me a ton possibilities to wire in normal RCA mode. I have done some drawings by hand since I’m on vacation and have no computer at hand. I came with pretty complicated wiring idea and would be delighted if someone knowledgeable had a look at it if there are some flaws and possibly problems.

1. Input> LDR pair a)> NUtube> RCA out (probably dedicated)

2. Input> Lolrlin a) >LDR pair b)> Buffer pair b)> RCA out // Lorlin b)> Buffer pair a)> LDR pair b)> Buffer pair b)> RCA out

3. Input >LDR pair b)> Buffer pair b)> RCA out

Here’s schematic and pic of current buffer and LDR attenuator that would be rearranged.

both NuTube and PSMLS Buffer are having high Rin , so you can use standard selector - attenuator (LDR) arrangement , then feeding both Nu and PSMLS Buffer (practically inputs in parallel ) , then taking each output separately , using whichever you want whenever you want

- Home

- Amplifiers

- Pass Labs

- B1 with Korg Triode