if I see correctly, your frame has rounded edges where the mylar adheres well when air is sucked in and remains taut.

I ask - is it better to take the measurements by removing the black acoustic sheet?

I ask - is it better to take the measurements by removing the black acoustic sheet?

Yes, edges and corners are all rounded. The black stuff around the opening in the stretcher is neoprene foam that allows the diaphragm to be pressed into intimate contact with the sometimes concave frame of the driver grid.

I am not familiar with the construction of the ES300, so I don't know what the acoustic sheet is, but if you're measuring diaphragm resonance using the technique I used, you'll want just the diaphragm (with or without whatever conductive coating is on it).

I am not familiar with the construction of the ES300, so I don't know what the acoustic sheet is, but if you're measuring diaphragm resonance using the technique I used, you'll want just the diaphragm (with or without whatever conductive coating is on it).

If you're referring to the neoprene on my stretcher, not using the neoprene might give a final resonance on the driver that more closely matches the resonance on the stretcher, but as it is, there's a known 9 Hz offset that works reliably. If I want 86 Hz resonance in the driver to match the factory resonance, I set resonance on the stretcher to 77 Hz.if I see correctly, your frame has rounded edges where the mylar adheres well when air is sucked in and remains taut.

I ask - is it better to take the measurements by removing the black acoustic sheet?

I'll load them onto the van by this evening, then I'll remove the black acoustic canvas and take some initial photographs. Then I'll do a low-volume test and take a closer look to see how it's assembled.

as I was saying... maybe they are the first models and the frame is made of raw wood with black canvas covering it. three power supplies embedded, it is not clear how and some resistors in series outside the power supply area, placed in the lower area of the frame where there is the mylar.

completely oxidized:

completely oxidized:

also on one there are the aluminum strips that hold the copper/wire loop, in the lower part that have detached from the milar frame - 3 completely and 2 others only on one side. this however does not seem to have any effect on the sound which remains very, very low.

Oh now I see where the black stuff is. I remember a similar one offered second hand. This is a very old one!

These are indeed very early ones, I think these models were still sold under the Megalith name, late 1980's. I own a pair of very early ES200's of identical construction, see https://www.diyaudio.com/community/threads/anyone-knows-this-unknown-audiostatic-es200-model.408281/. Interface looks identical too, with the mirror drive transformer.

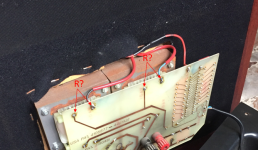

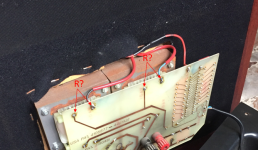

Looks like they were not always stored in a dry location. But nothing terrible. Do you have a multimeter? If not, you should get one. Try measuring the resistance between the points indicated in the picture. And measure the resistance of the four 47k resistors that are connected to on each stator, they look a bit crusty.

It all looks factory built to me, no signs of a later rebuild. So my bet is still on the coating. They must be at least 35 years old by now. You'll need to take of the cloth completely first and desolder the wires to the ESL element. The element is glued to the MDF frame in these, it easily pushed out breaking the glue bond. White or black stator wires?

Looks like they were not always stored in a dry location. But nothing terrible. Do you have a multimeter? If not, you should get one. Try measuring the resistance between the points indicated in the picture. And measure the resistance of the four 47k resistors that are connected to on each stator, they look a bit crusty.

It all looks factory built to me, no signs of a later rebuild. So my bet is still on the coating. They must be at least 35 years old by now. You'll need to take of the cloth completely first and desolder the wires to the ESL element. The element is glued to the MDF frame in these, it easily pushed out breaking the glue bond. White or black stator wires?

yes, they are old and yes, they have taken humidity, you can see it. I will proceed with the measurement of the resistance on the 4 points indicated.

I also have to figure out how the three transformers are locked into the box - maybe glued, it's not clear.

I also have to figure out how the three transformers are locked into the box - maybe glued, it's not clear.

🙂Oh now I see where the black stuff is. I remember a similar one offered second hand. This is a very old one!

I know this person who had them well and they took them used many years ago and are in excellent working condition.

Do not try to take the transformers out! They are glued in the wooden frame. It takes a lot of force to remove them, with a high risk of damaging them. So leave them there.

There is no need to take them out at this point anyway. If you later need to remove the pcb (to rebuild the HV supply for instance), unsolder the connections of all three transfomers. That allows you to remove the pcb leaving the transformers in place.

There is no need to take them out at this point anyway. If you later need to remove the pcb (to rebuild the HV supply for instance), unsolder the connections of all three transfomers. That allows you to remove the pcb leaving the transformers in place.

Btw I aquired my old pair of ES200 about a year and a half ago, they too were still factory original. And they too still played albeit very soft. So the coating Audiostatic used back then must have been quite stable. But after almost 30 years, it's time for a rebuild...

The worst thing of these is separating the wooden panels from the esl element. Originally they are glued. It takes quite some force and there is a risk of splitting the wood. When unlucky some of the metal bars may get loose. I fixed them with super glue.

- Home

- Loudspeakers

- Planars & Exotics

- Audiostatic ES300