They look great, congratulations Jesper!

I also was positively surprised when I first listened to my own PA woofer + waveguided compression driver combination, that they sound so awesome at low volumes. Before, I had read they were hungry for high levels to really shine, but I don't think so. I really like to play them louder to enjoy the bass in full scale, but it is enjoyable to listen to them at lower levels in the night, too.

I also was positively surprised when I first listened to my own PA woofer + waveguided compression driver combination, that they sound so awesome at low volumes. Before, I had read they were hungry for high levels to really shine, but I don't think so. I really like to play them louder to enjoy the bass in full scale, but it is enjoyable to listen to them at lower levels in the night, too.

@ Jesper the man of action strikes again. Hats off to your progress and the wife with good taste.

I should really be clearer regarding the use of the bitumen or in general. The way you lined the horn chamber is good. Bitumen doesn't damp, its highly reflective and gives additional weight that helps with vibrations, so good to prevent vibration from the woofer chamber entering the horn chamber, for others building this it is slightly more effective to line the top and front of the woofer chamber before gluing the felt and acustilux and also in the center of large unbraced surfaces, but this will also work.

When Rese and I spoke about damping the horn you want to glue the bitumen strips to the actual plastic horn to reduce the vibrations there and give it more weight and "stability". Its one of the cheap but very effective ways to iprove the sound of the horn. This video shows you how it's done How to Modify Klipsch speaker horns for better sound. - YouTube

The other place the bitumen can help is around the woofer basket. It prevents it from ringing, especially if the basket has a tendency to ring or is flimsy and also soundwaves reflects off ofbitumen. Test this as often its great, sometimes little happens and rarely it can be weird/nothing/slighly negative e.g. some Altecs . A bit of bitumen around the hole of the woofer also helps calm vibrations and reflects sound off the front baffle coming from inside wall reflections, if you have left over pieces. The most important thing will be using bitumen on the plastic horn though, followed by the woofer basket and then the front baffle around the woofer hole and any big open surfaces that could vibrate.

Another thing you can do is fixate the compression driver and hold it in place either attached from the ceiling or floor of the horn chamber. There was a picture of the mods used for horns in this thread if you want to check it out.

Great work and enjoy the speaker that beer is well deserved.

Cheers

w

I should really be clearer regarding the use of the bitumen or in general. The way you lined the horn chamber is good. Bitumen doesn't damp, its highly reflective and gives additional weight that helps with vibrations, so good to prevent vibration from the woofer chamber entering the horn chamber, for others building this it is slightly more effective to line the top and front of the woofer chamber before gluing the felt and acustilux and also in the center of large unbraced surfaces, but this will also work.

When Rese and I spoke about damping the horn you want to glue the bitumen strips to the actual plastic horn to reduce the vibrations there and give it more weight and "stability". Its one of the cheap but very effective ways to iprove the sound of the horn. This video shows you how it's done How to Modify Klipsch speaker horns for better sound. - YouTube

The other place the bitumen can help is around the woofer basket. It prevents it from ringing, especially if the basket has a tendency to ring or is flimsy and also soundwaves reflects off ofbitumen. Test this as often its great, sometimes little happens and rarely it can be weird/nothing/slighly negative e.g. some Altecs . A bit of bitumen around the hole of the woofer also helps calm vibrations and reflects sound off the front baffle coming from inside wall reflections, if you have left over pieces. The most important thing will be using bitumen on the plastic horn though, followed by the woofer basket and then the front baffle around the woofer hole and any big open surfaces that could vibrate.

Another thing you can do is fixate the compression driver and hold it in place either attached from the ceiling or floor of the horn chamber. There was a picture of the mods used for horns in this thread if you want to check it out.

Great work and enjoy the speaker that beer is well deserved.

Cheers

w

Thank's for the nice words 🙂

It's not a problem, adding bitumen to the horn as instructed in the youtube video... I will take out the horn again when making finish to the baffle anyway

For what it's worth, i tried the "knocking" method before/after i glued in the bitumen pads in the hornchamper, and it for sure do make a difference.

The frontbaffle have a little space inside for a pad of bitumen also, which i will glue in doing the finish of the front baffle.

Btw. : Do any of you have some recommondations for howto threat the black hdf front baffle (Oil ???)

Jesper.

It's not a problem, adding bitumen to the horn as instructed in the youtube video... I will take out the horn again when making finish to the baffle anyway

For what it's worth, i tried the "knocking" method before/after i glued in the bitumen pads in the hornchamper, and it for sure do make a difference.

The frontbaffle have a little space inside for a pad of bitumen also, which i will glue in doing the finish of the front baffle.

Btw. : Do any of you have some recommondations for howto threat the black hdf front baffle (Oil ???)

Jesper.

The Asathor was inaugurated with Bavarian Weissbier - it couldn't be better.

They already look great Jesper and I'm very happy that the first sound impression is also positive.

Bitumen on the plastic horn and the woofer basket is definitely recommended.

I sealed black MDF / HDF with Clou hard wax oil:

CLOU(R) – aus Liebe zum Holz. | Clou DIY | Produkte DIY

This makes the black a lot more intense and gives it a matte sheen. If you wipe the surface with a wet sponge or cloth, it will look very similar. You can test that.

What finish do you have planned for the rest of it?

They already look great Jesper and I'm very happy that the first sound impression is also positive.

Bitumen on the plastic horn and the woofer basket is definitely recommended.

I sealed black MDF / HDF with Clou hard wax oil:

CLOU(R) – aus Liebe zum Holz. | Clou DIY | Produkte DIY

This makes the black a lot more intense and gives it a matte sheen. If you wipe the surface with a wet sponge or cloth, it will look very similar. You can test that.

What finish do you have planned for the rest of it?

Hey here !

- I miss visiting Germany 😡

Well...

Just to be sure, is it the black reinforcements that should be with bitumen on the woofer basket's? (I suppose so)

I will try to find some simullair oil here in DK, otherwise when i can get the chance driving to Flensburg again i can pick one up there 😀 (I live ~100km. from the border)

Jesper.

Ofcause it was... i kindoff knew that, that's why i enjoyed it so much also Rese.The Asathor was inaugurated with Bavarian Weissbier - it couldn't be better.

- I miss visiting Germany 😡

Well...

Just to be sure, is it the black reinforcements that should be with bitumen on the woofer basket's? (I suppose so)

I will try to find some simullair oil here in DK, otherwise when i can get the chance driving to Flensburg again i can pick one up there 😀 (I live ~100km. from the border)

Jesper.

Attachments

Exactly the black, relatively thin metal always resonates a little. It is better with a few strips of bitumen.

The hard wax oil is also available from other manufacturers. Osmo, for example.

Hartwachs-Ol Original - Osmo Holz und Color GmbH & Co. KG

Maybe this is also available in Denmark.

Peter, wheat beer is not for everyone. Only for the real beer connoisseurs ...😀

The hard wax oil is also available from other manufacturers. Osmo, for example.

Hartwachs-Ol Original - Osmo Holz und Color GmbH & Co. KG

Maybe this is also available in Denmark.

Peter, wheat beer is not for everyone. Only for the real beer connoisseurs ...😀

I eat wheat bread in the morning and drink Pilsner Urquell in the evening, too much of bread is not healthy😀😀

@Peterbrorson The Weissbier is exactly the oposite of the Pilsner, almost sweet. Not a big beer person but when it is warm or you are warm there is something to it😉 There is a German preference for Pils bitter type beers in general towards the north and a preference for Weisbier especially in Bavaria and reflects the traditional rivalries between the freestate and the rest. Some mean people say it also is a reflection of the general mood😉 Well at least until you meet a grumpy Bavarian😉

@Jesper Tips and ideas Copyright 2012-14

Oil in Denmark Troels uses

Give the woofer basket "legs" a flick with your fingers or hit with a piece of wood. It rings since they save money here and with a few strips of pitumen you "dampen" that easily by giving the basket more weight and reflect waves off of it. Make sure not to impede the airflow. Back of the driver moves the same air as the fornt. Glue onto outside only. Don't impede flow and increase reflection into the membrane😉

Next thing is the feet. Either get little wheels or you can experiment with spikes or vibram half spheres or whatever support you prefer. What will you be placing the speakers on?

Be carefulwith the oiling of the HDF and try to not get any oil on the MDF this can make the veneering more difficult/uneven. A bit of tape is helpful. I would veneer first and then apply the oil everywhere, not sure if you want that.

I have never done this with the baffles already glued on. Maybe Rese can give you some advice. Make sure to use good spatcheling copound. The ones for cars bodywork or similar. Search online to prep the MDF. Then still wait a few days, best a week or two for the mdf and glues to settle. (Keep speakers in a dry place. Sand again. The surface should be the same as for spraying paint. Really smooth that way you get veneer that will look great for a long time. Any shrinking or joints will be visible under the veneer. Those baffled edges are going to be a bit trickytoo if you want to continue the grain. Watch a lot of videos and read while you wait for everything to calm down in the speaker and that there is no more shrinkage/ change. Also make sure there is no more stink of glue inside and let it air out without woofers and drivers if there still is.

Great work for a first speaker build very impressive and especially lightning fast. Keep us posted

@Jesper Tips and ideas Copyright 2012-14

Oil in Denmark Troels uses

Give the woofer basket "legs" a flick with your fingers or hit with a piece of wood. It rings since they save money here and with a few strips of pitumen you "dampen" that easily by giving the basket more weight and reflect waves off of it. Make sure not to impede the airflow. Back of the driver moves the same air as the fornt. Glue onto outside only. Don't impede flow and increase reflection into the membrane😉

Next thing is the feet. Either get little wheels or you can experiment with spikes or vibram half spheres or whatever support you prefer. What will you be placing the speakers on?

Be carefulwith the oiling of the HDF and try to not get any oil on the MDF this can make the veneering more difficult/uneven. A bit of tape is helpful. I would veneer first and then apply the oil everywhere, not sure if you want that.

I have never done this with the baffles already glued on. Maybe Rese can give you some advice. Make sure to use good spatcheling copound. The ones for cars bodywork or similar. Search online to prep the MDF. Then still wait a few days, best a week or two for the mdf and glues to settle. (Keep speakers in a dry place. Sand again. The surface should be the same as for spraying paint. Really smooth that way you get veneer that will look great for a long time. Any shrinking or joints will be visible under the veneer. Those baffled edges are going to be a bit trickytoo if you want to continue the grain. Watch a lot of videos and read while you wait for everything to calm down in the speaker and that there is no more shrinkage/ change. Also make sure there is no more stink of glue inside and let it air out without woofers and drivers if there still is.

Great work for a first speaker build very impressive and especially lightning fast. Keep us posted

@tubeglow @Rese

Hey, it's cool with all the help... 🙂

If i start with the finish of the speaker's, i plan to (evt. look at page #6 of this thread) veneer them orriginally with black veneer, but having doubt if i should choose another style of veneer now, maybe somthing matching our floor? - Not sure now, but i plan to do the finish doing the summertime / late summertime, when i'am done with the "raw" speaker's they will stay in livingroom until i will veneer them.

I still miss adding bitumen to horn & basket's, also i have to make the impedance "add-on" filter and try that out also (wait and see, got boutique 😀 cap's for this one)

@Rese66 i found the OSMO hardwax oil here in DK, will order one and try it out on some scrape HDF.

Jesper.

Hey, it's cool with all the help... 🙂

If i start with the finish of the speaker's, i plan to (evt. look at page #6 of this thread) veneer them orriginally with black veneer, but having doubt if i should choose another style of veneer now, maybe somthing matching our floor? - Not sure now, but i plan to do the finish doing the summertime / late summertime, when i'am done with the "raw" speaker's they will stay in livingroom until i will veneer them.

Excatly what i intend to do.I would veneer first and then apply the oil everywhere, not sure if you want that.

I know this oil, (i use it for some tables we have in our house), it's not good in my opinion,.. Actually i hate this oil 😱 i'am searching for something else for thoose tables also.@Jesper Tips and ideas Copyright 2012-14

Oil in Denmark Troels uses

I still miss adding bitumen to horn & basket's, also i have to make the impedance "add-on" filter and try that out also (wait and see, got boutique 😀 cap's for this one)

@Rese66 i found the OSMO hardwax oil here in DK, will order one and try it out on some scrape HDF.

Jesper.

Attachments

Ahh... forgot picture's of livingroom floor & hornchamper "backplate's"

Good day out there guy's 🙂

EDIT :: Verneer here (sheet's @ 250cm. x 64cm. with fleece only)

Furnier, Massivholz & Edelholz online kaufen - designholz.com

Jesper.

Good day out there guy's 🙂

EDIT :: Verneer here (sheet's @ 250cm. x 64cm. with fleece only)

Furnier, Massivholz & Edelholz online kaufen - designholz.com

Jesper.

Attachments

Last edited:

Regarding veneer. I wood go with something lighter than that black. The contrast between black hdf and light is what looks so good. The speaker looks good even with the exposed mdf because of the contrast. Black on Black will maybe ruin that IMO, its definitely nice enough for real veneer.

Designholz are good but pricey. E-Bay auction seller in Germany for veneers is les expensive.

Careful completely matching room floor and speakers, unless you also have other funiture. Involve the wife in this decision. She will like to be involved at that stage😉 You can also order a sample pack of different pieces of veneer and see what best fits you guy's tastes.

Cheers

Designholz are good but pricey. E-Bay auction seller in Germany for veneers is les expensive.

Careful completely matching room floor and speakers, unless you also have other funiture. Involve the wife in this decision. She will like to be involved at that stage😉 You can also order a sample pack of different pieces of veneer and see what best fits you guy's tastes.

Cheers

I'm all about tubeglow - black veneer wouldn't work so well here.

I'm a big fan of the SaRaiFo from designholz. It is significantly (!) Easier to work with than normal veneer and is available in large widths. I even think the price is cheap. And you protect nature.

I'm a big fan of the SaRaiFo from designholz. It is significantly (!) Easier to work with than normal veneer and is available in large widths. I even think the price is cheap. And you protect nature.

Getting closer.

Baltic birch arrives Wednesday and the wife takes the kids out of town the following weekend.

Hoping the weather plays along. After an unseasonally warm and dry spell for the last 10 or days, the rain has returned.

I have some small projects I can do in the meantime. Crossover assembly and applying damping to the horn and woofer baskets.

Reese66, regarding the denim insulation I was planning to use, it's sized to fit 3.5" wall cavities so perhaps not as dense as the felt Troels seems to use and thicker than your "at least 2-3cm" recommendation. Should I use as is, attempt to split it in half, or simply compress against the walls with battens?

Baltic birch arrives Wednesday and the wife takes the kids out of town the following weekend.

Hoping the weather plays along. After an unseasonally warm and dry spell for the last 10 or days, the rain has returned.

I have some small projects I can do in the meantime. Crossover assembly and applying damping to the horn and woofer baskets.

Reese66, regarding the denim insulation I was planning to use, it's sized to fit 3.5" wall cavities so perhaps not as dense as the felt Troels seems to use and thicker than your "at least 2-3cm" recommendation. Should I use as is, attempt to split it in half, or simply compress against the walls with battens?

It's not a problem when the material is that thick. Jesper's material is also significantly thicker than mine. It probably makes it even better.

Closed loudspeakers are very insensitive to this. Like Jesper, you should then only reduce the amount of MDM-3 (or IKEA pillows). There should be some space around the woofer with no material.

Closed loudspeakers are very insensitive to this. Like Jesper, you should then only reduce the amount of MDM-3 (or IKEA pillows). There should be some space around the woofer with no material.

Do not use bipolar electrolytics in the crossover! Inexpensive polypropylenes are available. For all your hard work on the cabinet don’t skimp on the crossover. A film and foil polypropelene is recommended for the cap(s) in series with HF driver.

Evening here 🙂

@ticknpop, Rese suggest only to use bipolar's on the woofer section. He suggest using filmcap's on tweeter section.

@ultrachrome, i'am looking forward to see your'e build in the birch (Baltic birch is btw. VERY expensive here in DK, donno why but it is)

@tubeglow,

@Rese,

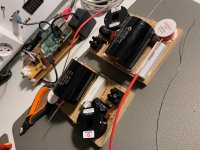

I'am doing my butique cap impedance "addon" 😉 today, also i'am done lining up my horn's (sure it was hard for the thumb's to press the bitumen into place on them)

After i was done i tried the knocking method on them, and they for sure are "dead" now compared to when raw!, i just don't understand why they don't sell them dampned, but again we all know it's because of the ++$$$ they have to cost then 😀

Jesper.

@ticknpop, Rese suggest only to use bipolar's on the woofer section. He suggest using filmcap's on tweeter section.

@ultrachrome, i'am looking forward to see your'e build in the birch (Baltic birch is btw. VERY expensive here in DK, donno why but it is)

@tubeglow,

Regarding veneer. I wood go with something lighter than that black. The contrast between black hdf and light is what looks so good. The speaker looks good even with the exposed mdf because of the contrast. Black on Black will maybe ruin that IMO, its definitely nice enough for real veneer.

@Rese,

It's true that you can get it cheaper on Ebay, but shipping cost vs. Designholz's shippingcost for it makes it easy to choose Designholz 🙂I'm a big fan of the SaRaiFo from designholz. It is significantly (!) Easier to work with than normal veneer and is available in large widths. I even think the price is cheap

I'am doing my butique cap impedance "addon" 😉 today, also i'am done lining up my horn's (sure it was hard for the thumb's to press the bitumen into place on them)

After i was done i tried the knocking method on them, and they for sure are "dead" now compared to when raw!, i just don't understand why they don't sell them dampned, but again we all know it's because of the ++$$$ they have to cost then 😀

Jesper.

Attachments

Last edited:

Woofer lining...

Btw. :: Could someone kind explain how they would line the woofer's basket with 4mm. bitumen pads? - I know Rese told me that i should lineup the small black reinforcements, but does it mean the hole widtht, or just the middle of them ???

Thank's guy's

Jesper.

Btw. :: Could someone kind explain how they would line the woofer's basket with 4mm. bitumen pads? - I know Rese told me that i should lineup the small black reinforcements, but does it mean the hole widtht, or just the middle of them ???

Thank's guy's

Jesper.

Attachments

Last edited:

I usually put felt on the inside of spokes if they are wide, it dampens also reflections, but never heard any improvements🙄

However, after mounting the driver on a baffle and tapping the basket without any treatment/damping, I stopped bothering about it. When driver is attached to baffle, any ringing is virtually gone. Easy to test, but it doesn't cure ones OCD😉

However, after mounting the driver on a baffle and tapping the basket without any treatment/damping, I stopped bothering about it. When driver is attached to baffle, any ringing is virtually gone. Easy to test, but it doesn't cure ones OCD😉

- Home

- Loudspeakers

- Multi-Way

- Asathor - a JBL 4367 Clone