Yes, so the working area of a 15" driver.ultrachrome said:If I understand correctly Sd 855cm2 is about 330mm diameter.

@Tubeglow, I see your points and tend mostly to agree.. except with some of the conclusions.

Eg time aligning. It's been shown through testing what timing differences we can mostly be expected to hear. Have you tested to see whether it is something else? Varying the timing and doing nothing else is likely to change the response, not only on-axis, or off-axis, but relatively between them. This could be a plausible conclusion for differences heard.

It's a hypothesis I have. Dipoles tend to present a rich mix of reflections, into which baffle diffraction may contribute to the variety, and perhaps be a preference of designers of dipoles.What do you mean with practical monopoles? Time aligned, fullrange, or coax? Or something else? and tend to have differences which weigh into how acceptable this is??? Could you phrase that differently.

However as you noted it isn't necessarily like that with a monopole.

best practices

Should I be concerned about the lip where the corners meet in the throat?

What about cabinet treatments? I was going to use 19mm MDF with the prescribed braces. Would any wall treatments like dynamat be advisable? How about for the waveguide

Should I be concerned about the lip where the corners meet in the throat?

What about cabinet treatments? I was going to use 19mm MDF with the prescribed braces. Would any wall treatments like dynamat be advisable? How about for the waveguide

Attachments

The lip can be an issue. It may sound OK as it is but I would fill it, or file it. There is already a shape compromise there with the corner filling, but there isn't a lot that you can do to make that kind of transition other than like that.

Geddes on Waveguides

Plastic waveguides are quite thin. Concerns are that the throat might flex under pressure, walls may resonate and the whole waveguide might move. Hard to say in general.

You mean like this?How about for the waveguide

Geddes on Waveguides

Plastic waveguides are quite thin. Concerns are that the throat might flex under pressure, walls may resonate and the whole waveguide might move. Hard to say in general.

You mean like this?

Geddes on Waveguides

Plastic waveguides are quite thin. Concerns are that the throat might flex under pressure, walls may resonate and the whole waveguide might move. Hard to say in general.

Yes, that.

I found an old post by Moray James on the Klipsch forum when I was playing with a pair of Klipsch KG4s a neighbor gifted me. Among the suggestions were:

- "Dynamat the back of the horns"

- "Damp the baskets with dynamat on the struts and inside with 1/4" S.A.E. rated F-11 acoustical felt."

- "make three 1/8" thick doughnuts and install then over the spider of the woofers"

- 'place a layer of 1/8" F-11 over your woofers"

Not sure they all apply to this case. Also perused the augerpro monster thread looking for anything I might want to incorporate if not too complex but was quickly overwhelmed.

Finding other areas to fret about like screw head shape. And of course grills.

Absolutely, I have not tested this experimentally. Just some blind testing of Vandersteen vs the B&W 801s, etc., for a musician client. (Much better ears than me! and my boss back then agreed although he made less of a sale😉 Two of the best ears I know) Both stated that the 802s were technically clearly better and cleaner but there was something unnatural with them.Eg time aligning. It's been shown through testing what timing differences we can mostly be expected to hear. Have you tested to see whether it is something else? Varying the timing and doing nothing else is likely to change the response, not only on-axis, or off-axis, but relatively between them. This could be a plausible conclusion for differences heard.

We did once measure a Focal Maestro Utopia time aligned adjusted and not time aligned for the sweatspot. Although we did not measure off axis response the measured differences were negligible, but when it was right it was Right. We did end up moving the sitting location because we had to battle some nasty room modes but the measurements were very similar in the mids and highs aligned and not, which was suprising and could have cut setup time.

Didn't like dealing with the company at all, hope you never have to return anything... but they do make some good speakers.

Anyway anecdotal at best. And different people are bothered by different things and need different things. I am usually OK with speakers where a Telecaster sounds like a Telecaster and not a Stadocaster, has a sweet midrange, good bass and high dynamics but can appreciate when they sound Right.

It's a hypothesis I have. Dipoles tend to present a rich mix of reflections, into which baffle diffraction may contribute to the variety, and perhaps be a preference of designers of dipoles.

However as you noted it isn't necessarily like that with a monopole.

Interesting, I could see that, have way too little experience with Dipoles to judge that. Not often/once or twice??? installed due to room positioning, low WAF and type of bass with clients I had. Also somehow not what I look for at shows or visiting people. Could be the right type of "distortion" for some though, never thought of it that way. Basically a board or single plane that diffracts alterntively into "opposite directions" instead of a box speaker where the inside diffractions are mostly absorbed by the damping inside. Next time I hear one I will try to pay attention. Wonder what happens when you use felt on the back side?

Cheers

Should I be concerned about the lip where the corners meet in the throat?

What about cabinet treatments? I was going to use 19mm MDF with the prescribed braces. Would any wall treatments like dynamat be advisable? How about for the waveguide

Dynamat, both on the walls and on the back of the horn, is recommended.

I would grind off sharp edges on the throat. You can also fill in the corners, but that is very laborious and does not help much. We compared the Monacor MRH-200 with the Celestion Horn. Both are almost identical, only the Monacor has completely filled corners on the throat. It measures a little better, but makes no difference in practice.

Some build progress

Nothing special, just some pic's.. I allway's like pic's... so cozy 😀

Jesper..

Nothing special, just some pic's.. I allway's like pic's... so cozy 😀

Jesper..

Attachments

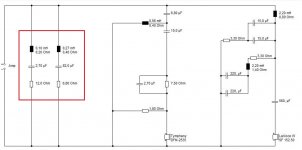

For tube amps I have now made an impedance linearization, marked in red in the picture.

Unfortunately, two RCLs are necessary for this, but except for the 82µF cap, all components are very small and inexpensive. For the Cs, electrolytic caps can be used without any problems. The resistors should be 20 watt types.

Unfortunately, two RCLs are necessary for this, but except for the 82µF cap, all components are very small and inexpensive. For the Cs, electrolytic caps can be used without any problems. The resistors should be 20 watt types.

Attachments

Great Rese66 🙂

Am i right that the 2,2mH (1,4ohm) + 440uF (2x220uF) + 3,3ohm is upside down on your'e new schematic, compared to the first one you posted (also i'am pretty sure that it dosent matter at all when it's crossover's)

Jesper.

Am i right that the 2,2mH (1,4ohm) + 440uF (2x220uF) + 3,3ohm is upside down on your'e new schematic, compared to the first one you posted (also i'am pretty sure that it dosent matter at all when it's crossover's)

Jesper.

Yes, the order does not matter in this case. I changed that because it was easier to read in the plan.

@ lykkedk

very nice progress. Looking forward to your impressions.

Just one question regarding your 2 pieces of bracing for the woofer. Why did you cut out the area close to the center of the speaker walls and keep the corners braced?

Usually you brace the center of the walls, because this is where there is the most movement occurs (=vibration of panels) and to reduce the length of the vibrating wave.

Maybe there is something I am not understanding, but I would glue those circle pieces back in and to give it strength add a little strips of wood to connect the circle slices and the bracing and wall you have, either vertically or horizontally or both.

Reese's bracing seen inpost #34 has the bracing cover the center of the panels as well.

If you think your corner joint is not strong enough getting 45 degree strips into the corners can help but the main reason for pracing is to reduce the length of panel sections that can vibrate, else you will have more of a secondary membrane effect. This can be interesting if this is what the designer wants, but here being a closed box I am not sure it would be beneficial.

If you have some acoustic damping left you can use it in the horn chamber, but it is not needed. More important will be adding some alubutyl to the horn and other factors. If you want to brace further you could add a north south brace, a (or better two) simple piece(s) of MDF into the horn chamber connecting the top of the speaker to the top of the woofer chamber. All nice touches but not necessary.

Cheers

very nice progress. Looking forward to your impressions.

Just one question regarding your 2 pieces of bracing for the woofer. Why did you cut out the area close to the center of the speaker walls and keep the corners braced?

Usually you brace the center of the walls, because this is where there is the most movement occurs (=vibration of panels) and to reduce the length of the vibrating wave.

Maybe there is something I am not understanding, but I would glue those circle pieces back in and to give it strength add a little strips of wood to connect the circle slices and the bracing and wall you have, either vertically or horizontally or both.

Reese's bracing seen inpost #34 has the bracing cover the center of the panels as well.

If you think your corner joint is not strong enough getting 45 degree strips into the corners can help but the main reason for pracing is to reduce the length of panel sections that can vibrate, else you will have more of a secondary membrane effect. This can be interesting if this is what the designer wants, but here being a closed box I am not sure it would be beneficial.

If you have some acoustic damping left you can use it in the horn chamber, but it is not needed. More important will be adding some alubutyl to the horn and other factors. If you want to brace further you could add a north south brace, a (or better two) simple piece(s) of MDF into the horn chamber connecting the top of the speaker to the top of the woofer chamber. All nice touches but not necessary.

Cheers

Last edited:

tubeglow49...

Thank's for the advises.

While i allready glued in the daemping material now 😱 - I guess i'll leave it for now through.

I simply didn't know this, and i thought that making the brace's like this was best, also to hold it on the corner's as you also describe.

Not that easy to redo now, but let's see?

Btw. :: I still have to goto IKEA and grab them "Inner" pillows, ripping them apart and fill it in, but i guess i can do that even if i do the front baffle.

Jesper.

Thank's for the advises.

While i allready glued in the daemping material now 😱 - I guess i'll leave it for now through.

I simply didn't know this, and i thought that making the brace's like this was best, also to hold it on the corner's as you also describe.

Not that easy to redo now, but let's see?

Btw. :: I still have to goto IKEA and grab them "Inner" pillows, ripping them apart and fill it in, but i guess i can do that even if i do the front baffle.

Jesper.

Attachments

@lykkedk

Wow you are making some good progress there.

You can test if you hear any difference between the top two braces and the bottom one by knocking it with your knuckles and thumping strongly with your palm. See if you hear a big difference in the area around the top braces and the area around the bottom brace. If you do then you can still add cross bracing, or incresed bracing with some pieces of wood. You can get the insulation off with a spatula and then reapply it the inside of a speaker. Don't worry too much not the end of the world.

For additional bracing in some speakers e.g. some Klipsches, you take a knife cut a rectangle and remove a strip. If you used tile cement ala Troels this might reguire a wood chisel or screwdriver.

In your case you can use the circular cut outs by the walls and push a piece of wood towards the walls with an F clamp. One end in the circle hole the other pressing the wood towards the speaker wall.

The issue is that in a closed box speaker the pressure inside the chamber is larger than with a BR or Passive radiator. And you don't want the walls to act like Passive Radiators. But if you chose thick MDF this all might not be a big deal.

Hope this helps and looking forward to your progress.

Cheers

W

Wow you are making some good progress there.

You can test if you hear any difference between the top two braces and the bottom one by knocking it with your knuckles and thumping strongly with your palm. See if you hear a big difference in the area around the top braces and the area around the bottom brace. If you do then you can still add cross bracing, or incresed bracing with some pieces of wood. You can get the insulation off with a spatula and then reapply it the inside of a speaker. Don't worry too much not the end of the world.

For additional bracing in some speakers e.g. some Klipsches, you take a knife cut a rectangle and remove a strip. If you used tile cement ala Troels this might reguire a wood chisel or screwdriver.

In your case you can use the circular cut outs by the walls and push a piece of wood towards the walls with an F clamp. One end in the circle hole the other pressing the wood towards the speaker wall.

The issue is that in a closed box speaker the pressure inside the chamber is larger than with a BR or Passive radiator. And you don't want the walls to act like Passive Radiators. But if you chose thick MDF this all might not be a big deal.

Hope this helps and looking forward to your progress.

Cheers

W

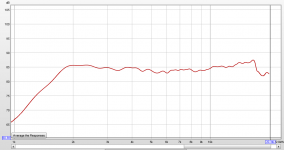

I wired up the tweeter crossovers and did a quick measurement.

My response seems to be rising at 10k compared to Reese66's. I see this with both drivers.

Specified XO values compared to my components measured with DATS v3 that produced the attached response:

6.8 uF -> 7.346 uF

10 uF -> 10.68 uF

2.7 uF -> 2.886 uF

.55 mH -> .5284 mH (.4748 ohms)

7.5 ohms -> 6.966 ohms

2 ohms -> 1.868 ohms

The second tweeter has nearly identical response and the component values are very close to the above measured values.

Any idea which components I should look at?

My response seems to be rising at 10k compared to Reese66's. I see this with both drivers.

Specified XO values compared to my components measured with DATS v3 that produced the attached response:

6.8 uF -> 7.346 uF

10 uF -> 10.68 uF

2.7 uF -> 2.886 uF

.55 mH -> .5284 mH (.4748 ohms)

7.5 ohms -> 6.966 ohms

2 ohms -> 1.868 ohms

The second tweeter has nearly identical response and the component values are very close to the above measured values.

Any idea which components I should look at?

Attachments

- Home

- Loudspeakers

- Multi-Way

- Asathor - a JBL 4367 Clone