vinylkid58 said:

I've seen Helicoils used in engineering plastics many times. You don't need to use glue with this type of insert, would get kind of messy anyway. There are other types of threaded inserts used for jigs and fixtures, but Helicoils are the most common and easiest to get, and available in metric too.

Jeff

Jeff, bless you for "helicoils". I've been away from motorcycles for too long 🙁 don't get old it's a stupid thing to do.

but I thought the whole point of glue was to make things messy!!!!

The armboard is not overly thick, about what, 1cm? it would be neat to have some acrylic extensions, kind of like washers, to give the helicoils more depth. Then you would need washers around the acrylic extensions to provide standoffs against which the bolts could be snugged. hmm perhaps this is the direction in which insanity lies.

AndrewT said:Hi,

The "problem" with the helicoil system is the special tap required to match the original thread pitch but to the larger diameter of the insert. A full set are required if you work with many standard threads.

Hey AndrewT!!!

This is ONLY a problem for people who don't like spending hundreds of dollars / euros / pounds acquiring obscure items to add to their toolboxes. I can't imagine that there is anyone on this forum with an aversion to this practice. he he.

I can hear the discussion now:

sweetie: "and WHAT exactly is THIS?"

me: "well, I needed this special tap for inserting these three helicoils into my new turntable armboard, and the tap cost $37.50, but I was able to acquire a whole set of these taps for only $247.95 on eBay"

sweetie: "oh so you can use them for other things around the house then"

me: "well of course, I can think of a lot of things around here that need helicoils of varying sizes installed to make them work properly".

(with apologies to my dear wife who puts up with this kind of thing).

Helicoil kits for a specific size (metric or imperial) have been available for a long time. I bought my first 6mm kit back in the 70's when my Honda 500-Four started to leak oil from the top end. You can also order extra inserts, when you've used up the ones from the kit, which happens very quickly when working on an old Honda.😡

Jeff

Jeff

rd-11

I'm way over my head here, but I've been thinking of breaking into the Hi-Fi world, and someone is selling an Ariston RD-11s with a SME tonearm for $500, and I was wondering if this was a good price.

I probably would've bought it already, except I noticed a few issues:

1. It has a slight buzz, as if something weren't grounded properly. Yes the ground wire is attached. I'm wondering if perhaps the aftermarket tonearm wasn't setup properly? Is this something that would be easy to fix?

2. When I put the belt on the lower pulley for 45 rpm, the belt flies off because the pulley is in no way aligned with the height of the platter. The pulley is way too low, and the platter too high. Is something setup incorrectly? The shaft seemed to fit properly into the bearing.

Thanks 🙂

I'm way over my head here, but I've been thinking of breaking into the Hi-Fi world, and someone is selling an Ariston RD-11s with a SME tonearm for $500, and I was wondering if this was a good price.

I probably would've bought it already, except I noticed a few issues:

1. It has a slight buzz, as if something weren't grounded properly. Yes the ground wire is attached. I'm wondering if perhaps the aftermarket tonearm wasn't setup properly? Is this something that would be easy to fix?

2. When I put the belt on the lower pulley for 45 rpm, the belt flies off because the pulley is in no way aligned with the height of the platter. The pulley is way too low, and the platter too high. Is something setup incorrectly? The shaft seemed to fit properly into the bearing.

Thanks 🙂

Re: rd-11

My Ariston buzzed slightly whilst switched off. This was because the basic motor supply board still allows some components to be in circuit even when the switch is off. You can feel the vibration in the motor if you lightly move the platter at the edge with your finger ( with the switch off ). If this bothers you switch off at the plug/socket.

If the lower pulley does not align with the hub then I think the subchassis must be too high and all the nuts under the suspension springs will need turning down. This will lower the subchassis accordingly. The motor won't move as it's fixed to the top plate.

Hope this helps, Si.

ardarvin said:1. It has a slight buzz, as if something weren't grounded properly. Yes the ground wire is attached. I'm wondering if perhaps the aftermarket tonearm wasn't setup properly? Is this something that would be easy to fix?

2. When I put the belt on the lower pulley for 45 rpm, the belt flies off because the pulley is in no way aligned with the height of the platter. The pulley is way too low, and the platter too high. Is something setup incorrectly? The shaft seemed to fit properly into the bearing.

Thanks 🙂 [/B]

My Ariston buzzed slightly whilst switched off. This was because the basic motor supply board still allows some components to be in circuit even when the switch is off. You can feel the vibration in the motor if you lightly move the platter at the edge with your finger ( with the switch off ). If this bothers you switch off at the plug/socket.

If the lower pulley does not align with the hub then I think the subchassis must be too high and all the nuts under the suspension springs will need turning down. This will lower the subchassis accordingly. The motor won't move as it's fixed to the top plate.

Hope this helps, Si.

Re: rd-11

ardarvin, my $0.02 worth.

the price seems high to me, but I don't know what I would expect it to be!

you can get your SME - it's a 3009? - serviced by AudioOrigami.

not sure about the buzz, how do you hear it? just when you put your ear close to the table? my RD11 motor is very noisy and I can hear it running with my ear close by - and it's a buzz.

with respect to the 45rpm groove being too low for the platter, it could be that you have too much oil in the bearing, which will make the subplatter ride high. it could also be, as harwoodspark says, that your motor is too low. finally, check to make sure that there is a little nylon cup pressed against the bottom of the motor shaft by a helical spring. if this is missing it could be the cause of the buzz too.

ardarvin said:I'm way over my head here, but I've been thinking of breaking into the Hi-Fi world, and someone is selling an Ariston RD-11s with a SME tonearm for $500, and I was wondering if this was a good price.

I probably would've bought it already, except I noticed a few issues:

1. It has a slight buzz, as if something weren't grounded properly. Yes the ground wire is attached. I'm wondering if perhaps the aftermarket tonearm wasn't setup properly? Is this something that would be easy to fix?

2. When I put the belt on the lower pulley for 45 rpm, the belt flies off because the pulley is in no way aligned with the height of the platter. The pulley is way too low, and the platter too high. Is something setup incorrectly? The shaft seemed to fit properly into the bearing.

Thanks 🙂

ardarvin, my $0.02 worth.

the price seems high to me, but I don't know what I would expect it to be!

you can get your SME - it's a 3009? - serviced by AudioOrigami.

not sure about the buzz, how do you hear it? just when you put your ear close to the table? my RD11 motor is very noisy and I can hear it running with my ear close by - and it's a buzz.

with respect to the 45rpm groove being too low for the platter, it could be that you have too much oil in the bearing, which will make the subplatter ride high. it could also be, as harwoodspark says, that your motor is too low. finally, check to make sure that there is a little nylon cup pressed against the bottom of the motor shaft by a helical spring. if this is missing it could be the cause of the buzz too.

No, it's not a physical/mechanical buzz, it's a static/electrical buzz heard through the headphones, similar to what you'd hear if the ground wire wasn't attached.

It's quite faint, but as I move my hand closer to the tonearm it gets louder.

I offered him $400, as is...but if I don't think I can fix the buzz, I definitely will pass on it.

It's quite faint, but as I move my hand closer to the tonearm it gets louder.

I offered him $400, as is...but if I don't think I can fix the buzz, I definitely will pass on it.

Hum gets worse as you get closer to the cartridge - sounds like a bad connection or missing shielding or a bad ground somewhere.

Here are a random collection of things to try.

You might want to rotate the electrical plug (I know that sounds weird but try it if you can, mine has the usual two-prong north american plug and there are two ways of putting it in the socket).

If that doesn't work, try with and without the ground line hooked up to the phono pre-amp.

If you have no cartridge in the arm, that's probably the source of the buzz. If you have a cartridge in and it's an MM, it might be sensitive to the motor - try with and without the motor turned on. MCs are usually less sensitive to this kind of thing.

Check the hookups of the wires at the cartridge end. I don't know how the ground wire works on the SME. On the Grace it is soldered to a copper plate that sits between the cartridge and the headshell.

Put some contact cleaner on the cartridge connections and reseat them. Put some cleaner on the headshell connections and reseat them.

Is the hum in both channels or just one?

What is the cartridge, some (like Grados) are often said to be hum-sensitive?

Is the hum louder when the cartridge is closer to the motor and quieter when further away?

Is the tonearm cable well-separated from the power wire?

Does the tonearm cable pass near the capacitors, motor, etc etc under the turntable?

Is the tonearm cable properly connected at the base of the tonearm? Clean these connectors too.

Can you try another tonearm cable?

Experiment with re-orienting the cables (electrical and signal) that pass between the turntable and the pre-amplifier. Does anything change?

Here are a random collection of things to try.

You might want to rotate the electrical plug (I know that sounds weird but try it if you can, mine has the usual two-prong north american plug and there are two ways of putting it in the socket).

If that doesn't work, try with and without the ground line hooked up to the phono pre-amp.

If you have no cartridge in the arm, that's probably the source of the buzz. If you have a cartridge in and it's an MM, it might be sensitive to the motor - try with and without the motor turned on. MCs are usually less sensitive to this kind of thing.

Check the hookups of the wires at the cartridge end. I don't know how the ground wire works on the SME. On the Grace it is soldered to a copper plate that sits between the cartridge and the headshell.

Put some contact cleaner on the cartridge connections and reseat them. Put some cleaner on the headshell connections and reseat them.

Is the hum in both channels or just one?

What is the cartridge, some (like Grados) are often said to be hum-sensitive?

Is the hum louder when the cartridge is closer to the motor and quieter when further away?

Is the tonearm cable well-separated from the power wire?

Does the tonearm cable pass near the capacitors, motor, etc etc under the turntable?

Is the tonearm cable properly connected at the base of the tonearm? Clean these connectors too.

Can you try another tonearm cable?

Experiment with re-orienting the cables (electrical and signal) that pass between the turntable and the pre-amplifier. Does anything change?

Thanks! That gives me a lot of stuff to try.

The cartridge that he had on it was some garbage thing, and when you touched it, it would give off a MASSIVE buzz in the right channel.

I took it off, played with the cartridge wires, etc, and finally just tried a completely different cartridge, a standard Shure MM with a technics headshell, which fixed the large buzz.

I'm assuming the minor buzz that is still present is something else. I'll have a closer look at it and get back to you.

The cartridge that he had on it was some garbage thing, and when you touched it, it would give off a MASSIVE buzz in the right channel.

I took it off, played with the cartridge wires, etc, and finally just tried a completely different cartridge, a standard Shure MM with a technics headshell, which fixed the large buzz.

I'm assuming the minor buzz that is still present is something else. I'll have a closer look at it and get back to you.

This minor buzz can still be a grounding issue. There are a number of connections to chassis ground from the subchassis, the motor, tonearm, etc which are not making ideal contact You may still have minor ground loop hum. Also if the turntable is not plugged into the same set of sockets or power bar as the amplifier you can also have minor ground loop problem even more so if the the two sockets are on different circuits.

Anyways while I was waiting I decided to see if the Axis supply would work on my Linn LP-12. I thought that it would work because I have placed a LP-12 platter on an Axis table before and it played just fine. To my disappointment I was wrong. The LP-12 must use a different motor which is more difficult to drive.

Is yours perhaps an early Linn LP12 perhas with the motor that can apparently not be used with a valhalla? (nothing to do with pulley btw, something to do with the motor design)

I believe Axis PSU on LP12 has been done and I have run one on a Rega 3 without problems for years. Also uses an Airpax motor that seems more like the LP12 one then the Axis motor. IE Axis has solder tags, not fly leads.

No my Linn is a Valhalla. I'm not sure what the issue is with the Axis supply and the LP-12 motor. If I run the Axis motor in its place I have no problems with the speed consistency. Unfortunately the pulley on the Axis motor is different so the motor can't simply be fitted without an adaptive spacer.

OK I should be packing, but I had to pose this one last question before the big move.

I was looking around on Google today, seeing what (if anything) people had done with their Grace 707 tonearms, and I had this idea.

First, my impression of the Grace is that it is thought to be not a bad old tonearm, and that the most commonly pointed-out shortfall is the plastic headshell.

As I was looking at a picture of someone else's Grace, I thought to myself:

"what if I were to disassemble the bearing assembly - which probably needs it by now anyway - and build a new arm / cartridge mount / counterweight that used the old bearing assembly"?

I'm still on my 30cm arm craze, still thinking of carbon fibre.

Anyone heard of such a thing before? Contemplated it? Done it?

I was looking around on Google today, seeing what (if anything) people had done with their Grace 707 tonearms, and I had this idea.

First, my impression of the Grace is that it is thought to be not a bad old tonearm, and that the most commonly pointed-out shortfall is the plastic headshell.

As I was looking at a picture of someone else's Grace, I thought to myself:

"what if I were to disassemble the bearing assembly - which probably needs it by now anyway - and build a new arm / cartridge mount / counterweight that used the old bearing assembly"?

I'm still on my 30cm arm craze, still thinking of carbon fibre.

Anyone heard of such a thing before? Contemplated it? Done it?

Sounds like a real challenge to me. I'm not familar with the Grace G707 but know that it was a well rated tonearm in its day. From some old reviews I found it was given a "very good" rating for sound which is the same rating given to Linn Ittok, Mission 774, and Syrinx PU2. I would have to assume it's a pretty decent arm to be in that group of company. There was a lot of engineering that went into those arms. I don't know how easy it would be to re-engineer your arm from scratch and have it sound better. Not without a lot of trial and error which usually equates to a lot of time and $$$.

Well I made my armboard. I used a piece of 10mm black acryllic and I drilled 3 holes and tapped them to accept 10-24 thread. Then I used 3 x 10-24 x 1" bolts and cut them down to 3/4 "threaded rod. Then I secured them with Loctite red. I had to drill out the existing holes in the subchassis to accept this larger threaded rod. I thought about using a helicoil or time-sert but they are generally longer then 10mm and I didn't want the bolts protruding through the top of the arm board. I have secured the board on with locknuts and just have to be careful with how tight I torque them up. I can get it atleast as tight if not tighter than the original wood screws. When I'm setting it up for good I may consider a layer of silicone caulking between the two surfaces.

Well I made my armboard. I used a piece of 10mm black acryllic and I drilled 3 holes and tapped them to accept 10-24 thread. Then I used 3 x 10-24 x 1" bolts and cut them down to 3/4 "threaded rod. Then I secured them with Loctite red. I had to drill out the existing holes in the subchassis to accept this larger threaded rod. I thought about using a helicoil or time-sert but they are generally longer then 10mm and I didn't want the bolts protruding through the top of the arm board. I have secured the board on with locknuts and just have to be careful with how tight I torque them up. I can get it atleast as tight if not tighter than the original wood screws. When I'm setting it up for good I may consider a layer of silicone caulking between the two surfaces.

Hi tkwou;

Your armboard solution sounds good. I can't recall ever trying to put screws into acrylic, the thing I wondered was whether it was more brittle than MDF and pieces might flake off. Sounds like not - super! I bet it looks very good.

On the Grace, I wouldn't want to modify the whole arm assembly. That way would definitely be WTMFM (way too much for me).

What I was thinking of, is the arm tube itself - which is quite small diameter, perhaps 6-7mm going from memory here - sits inside a larger diameter solid aluminum cylindrical mounting block to which the bearings fit. Then the mounting block protudes out the rear of the bearing assembly and the counterweight assembly mounts to that.

You can see all of this quite clearly on the image at

http://www.zenn.com.sg/grace_707_silver.htm

So, it seems to me that the entire arm tube / mounting block / counterweight assembly could be fairly simply uninstalled and replaced with "something else". That would leave behind the arm post, bearing assembly, cueing assembly, and anti-skating assembly for re-use.

Also, if I did this carefully, it would allow me to re-assemble the Grace at a later time.

My theory - inside the short, skinny Grace is a longer, fatter Grace trying to get out 😀

Anyway, it's just an idea right now, perhaps a stupid one. I see also that AudioOrigami has done some Grace work; I might try dropping them a line as John seems like a wonderfully helpful sort.

Your armboard solution sounds good. I can't recall ever trying to put screws into acrylic, the thing I wondered was whether it was more brittle than MDF and pieces might flake off. Sounds like not - super! I bet it looks very good.

On the Grace, I wouldn't want to modify the whole arm assembly. That way would definitely be WTMFM (way too much for me).

What I was thinking of, is the arm tube itself - which is quite small diameter, perhaps 6-7mm going from memory here - sits inside a larger diameter solid aluminum cylindrical mounting block to which the bearings fit. Then the mounting block protudes out the rear of the bearing assembly and the counterweight assembly mounts to that.

You can see all of this quite clearly on the image at

http://www.zenn.com.sg/grace_707_silver.htm

So, it seems to me that the entire arm tube / mounting block / counterweight assembly could be fairly simply uninstalled and replaced with "something else". That would leave behind the arm post, bearing assembly, cueing assembly, and anti-skating assembly for re-use.

Also, if I did this carefully, it would allow me to re-assemble the Grace at a later time.

My theory - inside the short, skinny Grace is a longer, fatter Grace trying to get out 😀

Anyway, it's just an idea right now, perhaps a stupid one. I see also that AudioOrigami has done some Grace work; I might try dropping them a line as John seems like a wonderfully helpful sort.

Well, it looks great, I must say. Sad to hear you're having problems with those studs; I'm surprised that the loctite didn't hold them in - it sure used to hold my motorcycle together! Maybe it doesn't work so well on acrylic. Or is there a chance there is some oil or other dirt on the acrylic or on the studs?

Got to pack now, talk to you in September I hope!

Got to pack now, talk to you in September I hope!

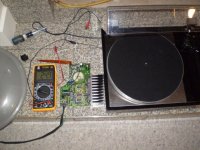

Here is the first test run. Axis motor removed from ps and installed on Ariston. Speed control is steady with ps in quiet mode running at 24.9 VAC. If you purposely slow the platter down it quickly jumps up to almost 80 VAC and then slowly settles back to 24.9 VAC. I tried this same power supply on my LP-12 but it wouldn't maintain speed. Everytime it switched to quiet mode the speed slowed just enough to cause the servo to fire back up to high voltage. Possibly the windings on the LP-12 motor draw too much current for the Axis power supply or possibly the Axis motor is designed to maintain higher torque at the lower voltage. Either way it means my LP-12 stays with its Valhalla or else I build a "Lingo" type supply and project Ariston is one step closer to completion.

Attachments

The Ariston is now functional. I have the power supply jury rigged to the motor and I have a Rega RB250 arm with OL1 counterweight and VTA adjuster attached to the acryllic armboard. The cartridge is an AudioTechnica ATF3/OCC moving coil. I have been listening through a modified Musical Fidelity XPLS which is a good MMpreamp and a decent MC preamp. So far things sound pretty good. Presentation is quite a bit different than my LP-12/Ittok/AT-160ML MM cartidge. Bit brighter and more air and space.

I have new development which has caught me right off guard. An all original Mission 776 preamp(not working) came up on Ebay and I scooped it up for $250. For those of you who are not familar with this product, it is a high end battery powered discrete preamp from from the early 80's, back before opamps got to be acceptable for quality sound. Back then discrete transistor preamps were the only way to go. The case is chiseled out of a block of aluminum with the name carved into the face plate and is used as the heatsink. There was has a matching high speed MOSFET amp using the same type of case. I last saw one at the Mission dealership in the early 80's when I was a struggling student. I still have all the original brochures. I have always been a big Mission fan having owned just about everything they have ever made. Anyway I got the preamp and quickly fixed the power supply issues and the preamp fired up fine. The high level input sounded fine but when I plugged my LP-12 into the phono I was extremely disappointed. There was a gain problem and the high frequencies were very rolled off. This occurred in both channels so I suspected an impedance problem or something screwy in the RIAA. Well the 776 is a modular design with each channel of the preamp plugging into the main board so I pulled off one of the boards last night and got busy tracing out the circuit. There is a phono preamp circuit on one side of the board and a high level preamp circuit on the other side of the board. After drawing out the phono preamp circuit I realized the problem, the phono input was loaded with about 100 ohms. No wonder the MM was sounding so strange. This circuit also had four stages of gain. Finally it hit me that this circuit was a moving coil preamp, something that I never knew existed with this preamp. So this morning I plugged the Ariston into the 776 and "magic". I'm in heaven. Phonoclone has just been scratched off my "to do" list. I have sent an email off to Mission/Cyrus. I was totally unaware that they made MC specific versions of this preamp.

I have new development which has caught me right off guard. An all original Mission 776 preamp(not working) came up on Ebay and I scooped it up for $250. For those of you who are not familar with this product, it is a high end battery powered discrete preamp from from the early 80's, back before opamps got to be acceptable for quality sound. Back then discrete transistor preamps were the only way to go. The case is chiseled out of a block of aluminum with the name carved into the face plate and is used as the heatsink. There was has a matching high speed MOSFET amp using the same type of case. I last saw one at the Mission dealership in the early 80's when I was a struggling student. I still have all the original brochures. I have always been a big Mission fan having owned just about everything they have ever made. Anyway I got the preamp and quickly fixed the power supply issues and the preamp fired up fine. The high level input sounded fine but when I plugged my LP-12 into the phono I was extremely disappointed. There was a gain problem and the high frequencies were very rolled off. This occurred in both channels so I suspected an impedance problem or something screwy in the RIAA. Well the 776 is a modular design with each channel of the preamp plugging into the main board so I pulled off one of the boards last night and got busy tracing out the circuit. There is a phono preamp circuit on one side of the board and a high level preamp circuit on the other side of the board. After drawing out the phono preamp circuit I realized the problem, the phono input was loaded with about 100 ohms. No wonder the MM was sounding so strange. This circuit also had four stages of gain. Finally it hit me that this circuit was a moving coil preamp, something that I never knew existed with this preamp. So this morning I plugged the Ariston into the 776 and "magic". I'm in heaven. Phonoclone has just been scratched off my "to do" list. I have sent an email off to Mission/Cyrus. I was totally unaware that they made MC specific versions of this preamp.

Wow, spend several months away and a thread pops up near and dear to my heart. I have a RD11Superieur thats due for some upgrading. At the moment it has a Signet TK50 Arm (AT1100 relabel, IIRC) and a Monster Cable alpha 2 cart. Been a few years since I fired it up, and need to replace the DIN plug at the base of the arm, though I'm leaning towards discrete wires and using some Amp sockets wired to some RCA's at the rear. What mods give the biggest bang for the buck/effort?

erie patsellis

erie patsellis

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- ariston RD11, Linn Vector-like DIY