I repeat my method of restoring any relays.

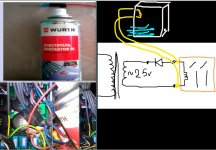

Liquid German -wurth contact cleaneris needed .

We solder the relay. we make a hole in the relay. through the needle, we inject the liquid into the relay.

We include the relay in such a scheme. Several times a minute.

It is important that the position of the relay is as in the picture, so that the moving contacts are in the liquid!

This will completely restore the relay contacts for at least a year

Liquid German -wurth contact cleaneris needed .

We solder the relay. we make a hole in the relay. through the needle, we inject the liquid into the relay.

We include the relay in such a scheme. Several times a minute.

It is important that the position of the relay is as in the picture, so that the moving contacts are in the liquid!

This will completely restore the relay contacts for at least a year

Attachments

I don't have a problem. Arcam buyers and Chinese components have problems. it is very interesting what was stolen in Chinese relays for a mass of 1 gram.

PS at the moment, the AVR600 has been repaired.

PS at the moment, the AVR600 has been repaired.

Have you ever dismantled the relays to see what physical damage there is? Nowadays, the relays are sealed and filled with an inert gas, evidenced by a one-piece plastic case with a thermosetting resin compound poured around the connecting leads - as your pic at #41 shows. Copies of old style speaker relays with removable, clear plastic covers are available to the DIY market but audio manufacturers ceased using them 20 years ago.

If you puncture the casing of a sealed relay and allow air to enter, the relay life will be shortened if it isn't already but owners probably wouldn't notice any immediate problem. You have to ask yourself though; what caused the contacts to stop working? Sealing means there should be little or no chance of contamination so is it arcing residue? If so, there will be arcing damage or pitting of the contacts. That's a more serious problem and the relay should be replaced regardless of what has been achieved in a temporary fix. Of course, you won't be able to visually inspect this damage until the relays are opened up but the solution should be self-evident.

I've seen many unsealed speaker relays from the old days; all of them giving some degree of trouble but most could be restored with careful burnishing of the contacts with a small strip of card (thick paper). Done properly, this could restore relays like Omron's quality products, for a further number of years use but we can't be certain if we don't keep detailed records or see the unit again.

If you puncture the casing of a sealed relay and allow air to enter, the relay life will be shortened if it isn't already but owners probably wouldn't notice any immediate problem. You have to ask yourself though; what caused the contacts to stop working? Sealing means there should be little or no chance of contamination so is it arcing residue? If so, there will be arcing damage or pitting of the contacts. That's a more serious problem and the relay should be replaced regardless of what has been achieved in a temporary fix. Of course, you won't be able to visually inspect this damage until the relays are opened up but the solution should be self-evident.

I've seen many unsealed speaker relays from the old days; all of them giving some degree of trouble but most could be restored with careful burnishing of the contacts with a small strip of card (thick paper). Done properly, this could restore relays like Omron's quality products, for a further number of years use but we can't be certain if we don't keep detailed records or see the unit again.

Inert gas relays are the hermetically sealed metal can units in military or space equipment.

Unlikely in stereos.

Some waterproof or weatherproof ones are used in cars.

But I have not seen a reference for inert gas filling, plastics would be permeable to that.

Best way is to use over size relays from a good maker, and add an arc quencher across the contacts.

Overkill?

Add one at the mains, between live and neutral, works on mains side.

Speaker relays are going to see comparatively few amps, but a quencher might affect sound quality.

Food for thought.

Unlikely in stereos.

Some waterproof or weatherproof ones are used in cars.

But I have not seen a reference for inert gas filling, plastics would be permeable to that.

Best way is to use over size relays from a good maker, and add an arc quencher across the contacts.

Overkill?

Add one at the mains, between live and neutral, works on mains side.

Speaker relays are going to see comparatively few amps, but a quencher might affect sound quality.

Food for thought.

Thermoset is Bakelite or rubber...cannot pour it after heating.

The word means heat to set. It becomes rigid or stiff at least once heated

Thermoplastics can be poured after heating.

The relay sealant is usually a flow able (thin) epoxy, or similar. Rarely hot glue, or sometimes a RTV silicon type material may be used.

The word means heat to set. It becomes rigid or stiff at least once heated

Thermoplastics can be poured after heating.

The relay sealant is usually a flow able (thin) epoxy, or similar. Rarely hot glue, or sometimes a RTV silicon type material may be used.

Last edited:

Naresh, no need to fly into a wiki search mode. I'm an industrial chemist of sorts; trained in the manufacture, R&D and QC of thermoset type plastics. I'm therefore aware of their chemistry and what actually defines them as thermosetting as opposed to thermoplastic. Epoxies are classified as thermosetting, whether they are cold curing adhesive pastes, fluids or pulverised solid, hot moulding compounds. However, there's no need for either of us to lecture on the topic here, it's for just for you to think on.

Signal relays and other small, sealed types of relays used for compact, low cost and above all, high reliability, are generally sealed at the point of nitrogen filling, to eliminate aerobic contamination i.e. oxidants, airborne sulphur compounds, moisture and many other trace gases compounds that may enter the contact atmosphere area. Other, larger relay types are often treated similarly in manufacture without it being specifically detailed in electronic parts supplier's catalogs.

Sealed relays have been used in high reliability applications like aerospace, military, telecommunications and life support systems for many years now and the benefits of an inert gas atmosphere at the final stage assembly stage assists in a long service life. Many sealed types are indeed nitrogen for example, rather than local environmental air filled but first the casing design has to be suitable for sealing - I'd think it rather easy to spot that a simple open-top box was the natural choice, with a layer of fluid epoxy or similar, poured on top, just as we can see in the illustration.

Signal relays and other small, sealed types of relays used for compact, low cost and above all, high reliability, are generally sealed at the point of nitrogen filling, to eliminate aerobic contamination i.e. oxidants, airborne sulphur compounds, moisture and many other trace gases compounds that may enter the contact atmosphere area. Other, larger relay types are often treated similarly in manufacture without it being specifically detailed in electronic parts supplier's catalogs.

Sealed relays have been used in high reliability applications like aerospace, military, telecommunications and life support systems for many years now and the benefits of an inert gas atmosphere at the final stage assembly stage assists in a long service life. Many sealed types are indeed nitrogen for example, rather than local environmental air filled but first the casing design has to be suitable for sealing - I'd think it rather easy to spot that a simple open-top box was the natural choice, with a layer of fluid epoxy or similar, poured on top, just as we can see in the illustration.

Last edited:

I am a plastic molder since 1993...injection, thermoplastic.

Basically a Graduate Mechanical Engineer.

Plastics are a lot more permeable than metal I think.

And here we get mostly Chinese relays, even a batch of Omron tiny relays was fake.

So my view is different from yours in this regard, based on my personal experience here..

Basically a Graduate Mechanical Engineer.

Plastics are a lot more permeable than metal I think.

And here we get mostly Chinese relays, even a batch of Omron tiny relays was fake.

So my view is different from yours in this regard, based on my personal experience here..

Last edited:

Have you ever dismantled the relays to see what physical damage there is?....

I'll photograph the old relays tomorrow.

my relay recovery method (german liquid Wurth) described for cases when it is not possible to buy new ones. And my method helps.

Regarding the Gas/tightness in the relay - I described earlier the USSR relay with gold contacts that work outdoors for 50 years. The main thing in the relay is the quality of the contacts.

That is why sometimes it is better to repair an old relay than to buy a Chinese one, which (as I showed above) is why about 1 gram lighter than the original one.

relay contacts

Ag,

AgSnIn,

AgSnO,

AgCdO,

AgNi,

AgPd,

AgCe,

And sometimes Gold.

unfortunately, gold is not the best conductor. Silver is much better. But the silver contacts oxidize quite quickly and stop conducting current.

I will take a picture of the relay from the amplifier tomorrow, and you will cry when you see the primitive OMRON contacts in such expensive equipment

In the USSR there were interesting relays -

8Э14 (6A 27V)) the relay on the contacts is 3 grams of silver. No sealing and even more so. inert gas inside.

these relays work to this day without problems. Probably there is silver of the highest grade (99,99), as in the batteries of submarines.

PS And I again express dissatisfaction with the quality of the radio components used by ARCAM.

the relay must be put on a more powerful current (5 Amper), It is the relays that are to blame for the defects of the amplifiers.

For such expensive Arcam equipment (price in 2010 AVR600 = 4000$ !!!) it would be ideal to use a relay with gold contacts (as in the USSR) and then no neutral gas is needed at all for OMRON penny relays.

in the photo, radio components of the USSR - gold 99.9

here are the contacts you need to put in high-quality equipment

Attachments

Last edited:

3 grams of gold in a relay would make it costly, so would silver.

Ordinary consumer grade audio or auto relays would have contacts made of mostly a hard copper alloy, with Tungsten, Beryllium, Cadmium, and Silver as possible additives.

Ordinary consumer grade audio or auto relays would have contacts made of mostly a hard copper alloy, with Tungsten, Beryllium, Cadmium, and Silver as possible additives.

Thanks for the pics and details. Those multi-leaf relays remind me of the types once used in telephone systems. We called them Telecom relays and they were produced by the 100s of thousands here and elsewhere, no doubt. My company produced the material for injection moulding the insulation between the contact arms and I spent a lot of hours observing and monitoring the processes.

I agree that there has been a decline in Arcam's component quality, no doubt started by a push for higher profit margins by owner JAM industries (2012) and continued by Harman, the US corporate giant who is the current owner of Arcam since 2017.

Relays ratings are critical to reliable operation. Speaker relays come under the highest stress in DC fault conditions when they have to break an arc which is in the process of welding the contacts together. AC arcs are no problem - DC arcs are a big problem because they require a lot of spring force to open the contacts and hence, a larger solenoid to close. That means a more expensive relay than you find in a lot of AV products. Cheap out on the relays and it does seem that get trouble like we see here.

Typically, a 60WPC amplifier would need a minimum 30V/5A DC rating for the speaker relay contacts and this would have meant an Omron G2R type relay or better. The product is still out there but the last one I replaced failed after 3 cycles. It was a Malaysian assembled version that sells for about $7 US from the major distributors.

I agree that there has been a decline in Arcam's component quality, no doubt started by a push for higher profit margins by owner JAM industries (2012) and continued by Harman, the US corporate giant who is the current owner of Arcam since 2017.

Relays ratings are critical to reliable operation. Speaker relays come under the highest stress in DC fault conditions when they have to break an arc which is in the process of welding the contacts together. AC arcs are no problem - DC arcs are a big problem because they require a lot of spring force to open the contacts and hence, a larger solenoid to close. That means a more expensive relay than you find in a lot of AV products. Cheap out on the relays and it does seem that get trouble like we see here.

Typically, a 60WPC amplifier would need a minimum 30V/5A DC rating for the speaker relay contacts and this would have meant an Omron G2R type relay or better. The product is still out there but the last one I replaced failed after 3 cycles. It was a Malaysian assembled version that sells for about $7 US from the major distributors.

Last edited:

3 grams of gold in a relay would make it costly, so would silver.

Ordinary consumer grade audio or auto relays would have contacts made of mostly a hard copper alloy, with Tungsten, Beryllium, Cadmium, and Silver as possible additives.

even if 3 grams of gold x 4 relays = 12 grams, which is $500 in prices. But at the price of an amplifier of $ 5000 , gold will be unnoticeable ! I'm not saying that you need to put 3 grams of gold in each relay, I'm talking about the fact that when selling products worth thousands of dollars, it makes sense to put high-quality radio components in important nodes if they cost this + 10% of the total price.

here are photos of the relays that are used in Arcam 2xx-3xx .

Black is the power relay, blue is the sound In black shows a large contact. And I note that it has turned black.

And in the blue relays , the contact is very small ! And you can also see that they have turned black.

Now think about why such weak relays are put into the sound circuit of the device at a price of thousands of dollars.

I can't say about the need for a budget amplifier of 12 grams of gold, but if I were a developer, I would give up blue relays in favor of black ones.

The last photo is the golden relay contacts from the USSR

Attachments

Last edited:

for the future - if your arcam (7, 600, 777, 300 ) are older than 5-7 years and there are clicks, or sound loss when turned on, then first of all replace the relay!

Try to buy only original relays - you can see from my photos that even the original relays have very weak contacts!

I hope my advice will be useful to many

Try to buy only original relays - you can see from my photos that even the original relays have very weak contacts!

I hope my advice will be useful to many

If needed, I get O/E/N relays, they are locally made, better than their competitors.

If they are not in stock, or not the right replacement, I use PLA or Paramount, both are also Indian.

But Omron and Panasonic should be available in your country..

Arcam is part of Samsung through Harman, did not expect this poor quality and shoddy treatment of buyers it implies.

If they are not in stock, or not the right replacement, I use PLA or Paramount, both are also Indian.

But Omron and Panasonic should be available in your country..

Arcam is part of Samsung through Harman, did not expect this poor quality and shoddy treatment of buyers it implies.

probably the company is satisfied with the operation of the device for 5-7 years. And they rely on service centers. The only problem is the cost of the service center, which costs 300-500-700 dollars..

It is much cheaper to repair yourself if.

Still, I would recommend installing more expensive relays in such expensive amplifiers. At least relays, I'm not even talking about capacitors...

It is much cheaper to repair yourself if.

Still, I would recommend installing more expensive relays in such expensive amplifiers. At least relays, I'm not even talking about capacitors...

I get Keltron, or whatever Japanese capacitors are available.

Or sometimes known Chinese good quality if it is an odd voltage (6.3, 10)

We still have parts shops and repairmen, none below 40 in audio.

Or sometimes known Chinese good quality if it is an odd voltage (6.3, 10)

We still have parts shops and repairmen, none below 40 in audio.

Last edited:

but still - more and more fakes. Even buying in well-known online stores there is a chance to buy a fake.

the very quality of the manufactured equipment also suffers. For example, take a scandal with the same (not cheap!) with a B&W Zeppelin Air column (the power supply always breaks, repair is impossible. board replacement only)

the very quality of the manufactured equipment also suffers. For example, take a scandal with the same (not cheap!) with a B&W Zeppelin Air column (the power supply always breaks, repair is impossible. board replacement only)

Attachments

hello everyone.

brought for repair - Technics SE-A900S

1. an interesting point - the relays are exactly the same as in the Arcam 300

2. if the fan is not spinning, then check and clean the contacts. they are oxidized.

brought for repair - Technics SE-A900S

1. an interesting point - the relays are exactly the same as in the Arcam 300

2. if the fan is not spinning, then check and clean the contacts. they are oxidized.

Attachments

- Home

- Amplifiers

- Solid State

- Arcam is being disabled (resolved)