just trying to test the waters concerning offering a 43 mm acrylic platter and bearing assembly. NO $$ value set yet, I'll have to get a quote based on number interested.

Machined acrylic plater, .005" label area recess, 315mm diameter. If bearing not purchased then drilled for .25" to allow for machining of bearing of your choice.

Bearing design to be conventional, non-inverted type (mainly to keep costs down). Robust housing, hardened shaft, bearing and bearing end plate.

I've got something like a week or maybe a week and one half to decide on this. Delivery to take something in the order of 8 weeks.

Again, to start, this is only to check interest. If high enough to justify the expense then will set an "official" group buy.

stew

Machined acrylic plater, .005" label area recess, 315mm diameter. If bearing not purchased then drilled for .25" to allow for machining of bearing of your choice.

Bearing design to be conventional, non-inverted type (mainly to keep costs down). Robust housing, hardened shaft, bearing and bearing end plate.

I've got something like a week or maybe a week and one half to decide on this. Delivery to take something in the order of 8 weeks.

Again, to start, this is only to check interest. If high enough to justify the expense then will set an "official" group buy.

stew

no ball park

I am really just checking the amount of interest. The amount of interest will dictate the price as all know quantities effect the quote.

I have a figure in my mind, that I think most would find suitable enough, but I am unsure if it's realistic enough (hence the inquiry). This may turn into an ongoing commercial concern, however any that commit (once the price is finalized) would be provided with the platter and bearing at the original quoted price.

There may also be a limited number of tonearms available as part of the group buy.

stew

I am really just checking the amount of interest. The amount of interest will dictate the price as all know quantities effect the quote.

I have a figure in my mind, that I think most would find suitable enough, but I am unsure if it's realistic enough (hence the inquiry). This may turn into an ongoing commercial concern, however any that commit (once the price is finalized) would be provided with the platter and bearing at the original quoted price.

There may also be a limited number of tonearms available as part of the group buy.

stew

what else would be required to get a fully operational turntable? I imagine one would need to buy a motor and controller and make a suitable base? Are motors/controllers easy to buy for diyers and how hard is it to get one up and running costs etc?

Would something like this outperforma good used turntable? So many questions🙂

Would something like this outperforma good used turntable? So many questions🙂

mainly a motor/electronics......

what else would be needed for a complete table?

this is an offshoot of a commercial product that I have been involved in the design with, but may never see the light of day.

All the above products would be available as part of a kit, or separately. For example, if a Rega owner wanted a new plinth, one could be made available, as long as the person could provide accurate measurements for the placement of the tonearm, bearing well and motor attachment. Same could be said of the platter, provide dimensions accurately, and it could be made available. Think of it as a DIY turntable project, custom made to your specifications. That way you could source exactly what you wanted, where you wanted.

For example, if you want to use an Origin Live motor, get the motor from them, the platter from me, etc. Again, this is mainly a "custom" approach. Materials would have to be limited to a few choices.

I too would limit tonearm mounting to a common one, say a Rega or Linn mounting distance, drilled for that particular tonearm base. SME type arm mounting may not be out of the question either.

And it all depends on the number of folks interested. (and as long as no one tries to infringe on someone else's ownership of designs, copyrights, etc)

As far as outperforming a good used table, I guess that would depend on the used turntable. I am not saying it wouldn't, but is it a used Goldmund? or a Teres? or a $10000 "super deck? I'm thinking that perhaps a complete table without a tonearm could be put together for something in the neighborhood of $1000-$1300 or less (if you build your own plinth for example, less). Most likely similar in performance to the original Teres (although not a copy, other than perhaps in concept). I've prototyped a turntable using an old bearing from a discarded direct drive turntable, bearing cost=$0.00. So a complete table will cost whatever one wants to purchase vs salvage for the construction of it.

I hope to have some pricing in the near future to post,. I'll announce it here, and in the analog and vendor's section as well when I confirm the pricing.

stew

what else would be needed for a complete table?

- motor

- pulley

- electronics to control the motor

- plinth(s)

- tonearm

- power supply for motor

- feet and some hardware

- wiring for the tonearm, and motor

this is an offshoot of a commercial product that I have been involved in the design with, but may never see the light of day.

All the above products would be available as part of a kit, or separately. For example, if a Rega owner wanted a new plinth, one could be made available, as long as the person could provide accurate measurements for the placement of the tonearm, bearing well and motor attachment. Same could be said of the platter, provide dimensions accurately, and it could be made available. Think of it as a DIY turntable project, custom made to your specifications. That way you could source exactly what you wanted, where you wanted.

For example, if you want to use an Origin Live motor, get the motor from them, the platter from me, etc. Again, this is mainly a "custom" approach. Materials would have to be limited to a few choices.

I too would limit tonearm mounting to a common one, say a Rega or Linn mounting distance, drilled for that particular tonearm base. SME type arm mounting may not be out of the question either.

And it all depends on the number of folks interested. (and as long as no one tries to infringe on someone else's ownership of designs, copyrights, etc)

As far as outperforming a good used table, I guess that would depend on the used turntable. I am not saying it wouldn't, but is it a used Goldmund? or a Teres? or a $10000 "super deck? I'm thinking that perhaps a complete table without a tonearm could be put together for something in the neighborhood of $1000-$1300 or less (if you build your own plinth for example, less). Most likely similar in performance to the original Teres (although not a copy, other than perhaps in concept). I've prototyped a turntable using an old bearing from a discarded direct drive turntable, bearing cost=$0.00. So a complete table will cost whatever one wants to purchase vs salvage for the construction of it.

I hope to have some pricing in the near future to post,. I'll announce it here, and in the analog and vendor's section as well when I confirm the pricing.

stew

Hi.

I would be interested, dependent on price of course. I have just conceived the idea of a diy turntable after i re-discovered a guitar template machined from solid mahogany, sitting unused in my garage. my pro-ject platter fits perfectly on the guitar body and the finished article will, i believe look fantastic. Quick question though, how do you determine how far away form the spindle (ie center of the platter) you place the arm mounting. Is there a formula. My Pro-ject is 20 cm (normal??????).

Regards

John

I would be interested, dependent on price of course. I have just conceived the idea of a diy turntable after i re-discovered a guitar template machined from solid mahogany, sitting unused in my garage. my pro-ject platter fits perfectly on the guitar body and the finished article will, i believe look fantastic. Quick question though, how do you determine how far away form the spindle (ie center of the platter) you place the arm mounting. Is there a formula. My Pro-ject is 20 cm (normal??????).

Regards

John

Hi John...

well mainly you need to know the arm length (effective) and the overhang, as well as the alignment "style" the manufacturer used, and the headshell "offset"(in degrees). This information may be available from your turntable manual or on the 'net. 20cm seems on the short side to me but I don't know the Pro-ject products.

well mainly you need to know the arm length (effective) and the overhang, as well as the alignment "style" the manufacturer used, and the headshell "offset"(in degrees). This information may be available from your turntable manual or on the 'net. 20cm seems on the short side to me but I don't know the Pro-ject products.

I would be interested in the platter, if the price is right. Not so much interest in the bearing.

Jeremy

Jeremy

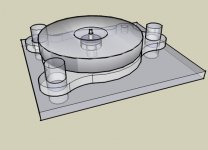

here's a sneak peak of the prototype

just a teaser of the prototype. pretty much all parts would be available, or as a complete piece if you would like.

The turntable with an arm and cartridge is aimed at $1500-$1700, so less than Teres, etc. Complete tables less arm and cart available and pretty much any permutation of parts .

stew

just a teaser of the prototype. pretty much all parts would be available, or as a complete piece if you would like.

The turntable with an arm and cartridge is aimed at $1500-$1700, so less than Teres, etc. Complete tables less arm and cart available and pretty much any permutation of parts .

stew

I'm interested. I have a motor and plans for drive electronics. I could upgrade my old VPI, but a new table is pretty appealing.

SY, maybe we should switch Avatars 🙂

seeing that my Avatar IS Richard Feynman....

ok, so it seems the interest is high enough to proceed. I'll get quotes in the next little while. I did try to post a picture of the protype (the arm in the photo is not the intended arm) and shrink it to fit, but somehow I can't....so I will post a pix if I can shrink it and post directly here.

The arm will either be a custom one or a Famous brand thats starts with R and ends with A, but reworked with a custom weight, VTA adjuster and finger nut adjustment. Re-wire kits can be had as well. This arm would be an upcharge of course. Like I said, pretty much everything will be available. Choose as much or as little as you want. One of the problems thusfar is the motor. The controller is done, and works but the motor is simply too small, need to source a Maxxon or Asian built unit to do the job.

stew

seeing that my Avatar IS Richard Feynman....

ok, so it seems the interest is high enough to proceed. I'll get quotes in the next little while. I did try to post a picture of the protype (the arm in the photo is not the intended arm) and shrink it to fit, but somehow I can't....so I will post a pix if I can shrink it and post directly here.

The arm will either be a custom one or a Famous brand thats starts with R and ends with A, but reworked with a custom weight, VTA adjuster and finger nut adjustment. Re-wire kits can be had as well. This arm would be an upcharge of course. Like I said, pretty much everything will be available. Choose as much or as little as you want. One of the problems thusfar is the motor. The controller is done, and works but the motor is simply too small, need to source a Maxxon or Asian built unit to do the job.

stew

Attachments

ok, folks. I guess I'll make the call tomorrow.

I don't think I'll get an answer tomorrow. The platter is 43 mm thick with a .005" deep label area (kinda odd to use metric and "English" units in a description). The cg of the platter is approximately 18mm down from the top of the platter , based on a 12 mm pilot near the top and a 60mm diameter bearing housing. The platter is currently designed as 315mm in diameter.

The belt is intended to ride at or slightly above that point, and the bearing "ball" is designed to sit below, some 30mm. the hardened steel shaft is expected to be 10mm in diameter and 35mm in length and to be replaceable (as well as the hardened steel ball, and hardened steel thrust plate).

The plinth may also be available. I'm getting quotes on all pieces before I post any. The only thing I would recommend against is perhaps the motor, until that is sorted.

Here's another sketchup sketch of the turntable to give you an idea.

I don't think I'll get an answer tomorrow. The platter is 43 mm thick with a .005" deep label area (kinda odd to use metric and "English" units in a description). The cg of the platter is approximately 18mm down from the top of the platter , based on a 12 mm pilot near the top and a 60mm diameter bearing housing. The platter is currently designed as 315mm in diameter.

The belt is intended to ride at or slightly above that point, and the bearing "ball" is designed to sit below, some 30mm. the hardened steel shaft is expected to be 10mm in diameter and 35mm in length and to be replaceable (as well as the hardened steel ball, and hardened steel thrust plate).

The plinth may also be available. I'm getting quotes on all pieces before I post any. The only thing I would recommend against is perhaps the motor, until that is sorted.

Here's another sketchup sketch of the turntable to give you an idea.

Attachments

- Status

- Not open for further replies.

- Home

- Group Buys

- Any interest in an acrylic platter group buy, and a bearing?