Vil said:Very interesting and thanks for your work Nanook . I found one item on ebay , maybe it can be option for us too ? look to No 260197098215 .

Vil

It really depends on the level of quality you're looking for. If you want a well made platter that will rotate without runout or wobble it must be machined on all surfaces. Looking at that photo I can't tell if it has been polished after machining of just left uncut. If it is indeed uncut, it will definitely wobble on every rotation.

It doesn't make sense having to modify it because you risk damaging it during the modification process and the chances of getting perfect concentricity are pretty slim (result means excessive runout with balancing issues), unless you have machining skills and a lathe or mill to do the job correctly. You can't just drill the hole to a larger size for the bearing if you want a good fit.

thanks for the clarification vinyl-addict.

I will stick with Nanook and what ever he comes up with

I will stick with Nanook and what ever he comes up with

diy hifi parts...

I can say that if the motor pod that I purchased via the Maxon motor group buy is an indication of the Bix products, I'm not sure I'd go with any of it Apparently diy hifi supplied the motor pods and covers.

I have perhaps the most expensive, terrible looking ashtray in the history of the world (and I don't even smoke). I know I won't be using it. It is missing some set screws as well. And they wanted another $50 or so for the top plate. Please this is not a dig at Algar_emi and the Maxon motor Group Buy. I must say that I am a little disappointed in what I ended up with for $286 landed. The pulley, and motor are very good. The motor pod is the problem. I'll most likely keep the motor pod as an "experimenters' motor enclosure", spend some more money, have a top plate made for it, and find some set screws. And then get my own motor pod made.

I know the Bix table has received some good reviews and I cannot argue against it, if that is what you want. Hey, the whole table can be had for around $1000 landed in North America (without tonearm). The strobe marks are good to have , but are a little on the fugly side. Again perhaps my taste in cleaner looking designs is overtaking me, but I like the sleeker concept of "form follows function" as illustrated by Shaker, Craftsman and mid-century modern (Eames etc) designs. As indicated earlier, I love the way the Roksan Xerkses table looks. Plain. Simple. Straightforward.

just click on turntables and have a look at it.Roksan's home page

The bearing topology is perhaps the biggest variance. To my knowledge, the Bix bearing is a typical well type bearing. My design is an inverted design using the balanced mass approach as per Verdier, and of similar quality to Teres. The use of a Teflon /ceramic, or ceramic/ceramic ball and wearplate are a couple of others. It is being over-built in the event some may want to mass load their platters.

a note about platters: The platters need to be milled on both sides, prior to machining. That way we end up with a "trued" plate to start with (as Vinyl-Addict points out correctly). I can tell you that if I get the wordthat the existing high-end maker agrees to provide us with the bearings and platters, you will be getting a platter and bearing that is part of a $5000 turntable in your diy project. Until finalized, I simply cannot say much more.

I do have a sketch of the bearing design, and how the platter fits, as well as a few photos of the platter from the first prototype commercial turntable using a modified direct drive well type bearing. I just need to find out where to post them or shrink them small enough to attach to my posts.

newsflash:

it appears that diy hifi is getting out of the turntable business, and Triode Systems indicates that it is no longer available. For those that are interested.

stew

I can say that if the motor pod that I purchased via the Maxon motor group buy is an indication of the Bix products, I'm not sure I'd go with any of it Apparently diy hifi supplied the motor pods and covers.

I have perhaps the most expensive, terrible looking ashtray in the history of the world (and I don't even smoke). I know I won't be using it. It is missing some set screws as well. And they wanted another $50 or so for the top plate. Please this is not a dig at Algar_emi and the Maxon motor Group Buy. I must say that I am a little disappointed in what I ended up with for $286 landed. The pulley, and motor are very good. The motor pod is the problem. I'll most likely keep the motor pod as an "experimenters' motor enclosure", spend some more money, have a top plate made for it, and find some set screws. And then get my own motor pod made.

I know the Bix table has received some good reviews and I cannot argue against it, if that is what you want. Hey, the whole table can be had for around $1000 landed in North America (without tonearm). The strobe marks are good to have , but are a little on the fugly side. Again perhaps my taste in cleaner looking designs is overtaking me, but I like the sleeker concept of "form follows function" as illustrated by Shaker, Craftsman and mid-century modern (Eames etc) designs. As indicated earlier, I love the way the Roksan Xerkses table looks. Plain. Simple. Straightforward.

just click on turntables and have a look at it.Roksan's home page

The bearing topology is perhaps the biggest variance. To my knowledge, the Bix bearing is a typical well type bearing. My design is an inverted design using the balanced mass approach as per Verdier, and of similar quality to Teres. The use of a Teflon /ceramic, or ceramic/ceramic ball and wearplate are a couple of others. It is being over-built in the event some may want to mass load their platters.

a note about platters: The platters need to be milled on both sides, prior to machining. That way we end up with a "trued" plate to start with (as Vinyl-Addict points out correctly). I can tell you that if I get the wordthat the existing high-end maker agrees to provide us with the bearings and platters, you will be getting a platter and bearing that is part of a $5000 turntable in your diy project. Until finalized, I simply cannot say much more.

I do have a sketch of the bearing design, and how the platter fits, as well as a few photos of the platter from the first prototype commercial turntable using a modified direct drive well type bearing. I just need to find out where to post them or shrink them small enough to attach to my posts.

newsflash:

it appears that diy hifi is getting out of the turntable business, and Triode Systems indicates that it is no longer available. For those that are interested.

stew

another great post Nanook ,

I never had any intend to dimish your endeavour (well I hope my english is Ok) . Now its pretty clear what is our target . I really wanna spend more but wanna get GOOD PRODUCT . Life is too short for sh...t .

Vil

I never had any intend to dimish your endeavour (well I hope my english is Ok) . Now its pretty clear what is our target . I really wanna spend more but wanna get GOOD PRODUCT . Life is too short for sh...t .

Vil

Vil...

I just edited my last post. Appears that diy hifi is getting out of the turntable business.

I just edited my last post. Appears that diy hifi is getting out of the turntable business.

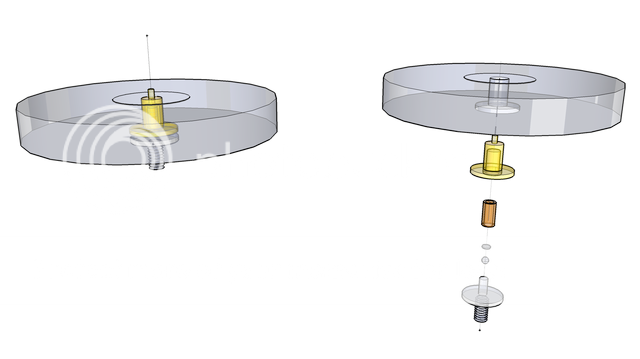

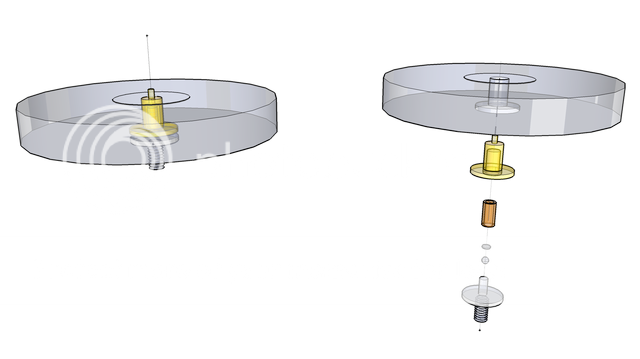

some pictures via photobucket

please have a look.

The platter is similar to what we most likely end up with. The bearing will be completely different (see the Teflon tape needed to take up the machined "slop"?).

The sketch is of the assembled inverted bearing and platter, and an exploded view showing parts,

any comments are welcome.

stew

please have a look.

The platter is similar to what we most likely end up with. The bearing will be completely different (see the Teflon tape needed to take up the machined "slop"?).

The sketch is of the assembled inverted bearing and platter, and an exploded view showing parts,

any comments are welcome.

stew

can the spindle be extended and threaded in the final version so that "clamps" can be used to hold the vinyl to the platter?

Neil, that depends...

on everyone else here. I like the idea of a reflex style clamp that can grab hold of a smooth spindle. But that's only my opinion. If a threaded type, whose standard do we use? English or metric threads? Or do we use the magic "310 gram" mass type clamp? (someone pointed this out to me, it seems most mass style "clamps" are 310 grams, who'd a figured....).

Neil, for now we'll leave it pretty much alone until we verify which company will be making the platters and the bearings. Then ask them for options if possible. It is important to stay focussed on the big picture, I view clamp style as an afterthought to platter and bearing design (but an important afterthought).

Any comments on the drawing?

stew

on everyone else here. I like the idea of a reflex style clamp that can grab hold of a smooth spindle. But that's only my opinion. If a threaded type, whose standard do we use? English or metric threads? Or do we use the magic "310 gram" mass type clamp? (someone pointed this out to me, it seems most mass style "clamps" are 310 grams, who'd a figured....).

Neil, for now we'll leave it pretty much alone until we verify which company will be making the platters and the bearings. Then ask them for options if possible. It is important to stay focussed on the big picture, I view clamp style as an afterthought to platter and bearing design (but an important afterthought).

Any comments on the drawing?

stew

In the photo showing the platter, is there a sleeve installed into the acrylic into which the brass is inserted?

Looks good.

Looks good.

Brass inserted....

Ed,

the brass is inserted into the platter. In this case it wa to modify the bearing and to allow us to salvage the platter. The original bearing was made of aluminum, and loose balls. It was terrible. I think I threw it away.

Hopefully bty Tuesday I'll have a response from the "high end" manufacturer and will make a determination on which direction to go based on cost, and turnar=oubd time. If this is the option, there is no need to wait and see---we should just all "buck up" and get it all coming. There may be a reduction to 40 mm thickness on the platter, to allow milling of the platter faces. Still crossing my fingers on this one as I think the best possible scenario for the diy GB and the commercial venture.

High quality=no headaches 🙂

stew

Ed,

the brass is inserted into the platter. In this case it wa to modify the bearing and to allow us to salvage the platter. The original bearing was made of aluminum, and loose balls. It was terrible. I think I threw it away.

Hopefully bty Tuesday I'll have a response from the "high end" manufacturer and will make a determination on which direction to go based on cost, and turnar=oubd time. If this is the option, there is no need to wait and see---we should just all "buck up" and get it all coming. There may be a reduction to 40 mm thickness on the platter, to allow milling of the platter faces. Still crossing my fingers on this one as I think the best possible scenario for the diy GB and the commercial venture.

High quality=no headaches 🙂

stew

Update: platters and bearings and HQ= no problems

so we did get some information back from the "high end" manufacturer. They will gladly sell to us. Great. Now all I have to do is get 80 more folks to take the rest of the lot that they want to sell to us for their minimum order. If it can be worked out, it may still happen , but it is looking a little disheartening. The price is increased too, about 25% over the original quote from the original maker, it's just having to take 100 platter/bearing assemblies is on the long side for me, and even the commercial project to deal with.

so still plodding along.

stew

so we did get some information back from the "high end" manufacturer. They will gladly sell to us. Great. Now all I have to do is get 80 more folks to take the rest of the lot that they want to sell to us for their minimum order. If it can be worked out, it may still happen , but it is looking a little disheartening. The price is increased too, about 25% over the original quote from the original maker, it's just having to take 100 platter/bearing assemblies is on the long side for me, and even the commercial project to deal with.

so still plodding along.

stew

an edit....

so we did get some information back from the "high end" manufacturer. They will gladly sell to us platters and bearings. I think we should go for this. The cost is slightly increased to $500. We will order once we get 20 interested GB parties. 30 would be preferred.Pretty much the same as the original idea but with a known high quality platter and bearing, needing no prototypes for approval.

About 4-6 weeks out from the time of order. So all interested parties should get their Paypal accounts lined up.

No split on the bearing /platter split cost, and generally I wouldn't want to split the pairs, but I think those that were interested in the separates were pretty much similarly numbered.I'm "guessing 45% for platter, 55% for the bearing. I should find out within a day

Ideas about how long to leave the GB open? A week?

I'll also post my Paypal account information later tonight. Remember, shipping is the end user's responsibility and shipped from T1H 4V7, Lethbridge, Alberta, Canada. Approximately 13-15 pounds packaged. Approximately 16" X 16" X 6" to be on the safe side for shipping estimates.

stew

so we did get some information back from the "high end" manufacturer. They will gladly sell to us platters and bearings. I think we should go for this. The cost is slightly increased to $500. We will order once we get 20 interested GB parties. 30 would be preferred.Pretty much the same as the original idea but with a known high quality platter and bearing, needing no prototypes for approval.

About 4-6 weeks out from the time of order. So all interested parties should get their Paypal accounts lined up.

No split on the bearing /platter split cost, and generally I wouldn't want to split the pairs, but I think those that were interested in the separates were pretty much similarly numbered.I'm "guessing 45% for platter, 55% for the bearing. I should find out within a day

Ideas about how long to leave the GB open? A week?

I'll also post my Paypal account information later tonight. Remember, shipping is the end user's responsibility and shipped from T1H 4V7, Lethbridge, Alberta, Canada. Approximately 13-15 pounds packaged. Approximately 16" X 16" X 6" to be on the safe side for shipping estimates.

stew

Since this is from a high end manufacturer is there an option to purchase the platter with a polished finish?

finishes on the platter

As far as I understand there is only one option, the way they make em. I'll double check, but that generally is the labour intensive (expensive) part of acrylic platters. They will supply as they make. So if polished is what you want , you may end up polishing it yourself (I have never seen a polished platter from this maker on even their most expensive table).

Thankfully polishing is time consuming but not difficult.

Just a reminder , payment is required prior to being ordered, so please advance payment as soon as you make your decision. Regardless of decision, please let me know. Thanks

I'll check with Paypal to see if the allow temporary accounts for things like this group buy.

stew

As far as I understand there is only one option, the way they make em. I'll double check, but that generally is the labour intensive (expensive) part of acrylic platters. They will supply as they make. So if polished is what you want , you may end up polishing it yourself (I have never seen a polished platter from this maker on even their most expensive table).

Thankfully polishing is time consuming but not difficult.

Just a reminder , payment is required prior to being ordered, so please advance payment as soon as you make your decision. Regardless of decision, please let me know. Thanks

I'll check with Paypal to see if the allow temporary accounts for things like this group buy.

stew

A question about the bearing. Is there a max suggested platter weight for this bearing? I was just pondering a 310 gram weight in combination with my intended mass loaded 6" delrin platter.

Dave

Dave

exact details

Nanook,

What is the exact details of the platter(dimension, thickness, etc) and the bearing(what kind? inverted bearing, standard bearing, etc? and the spindle details?)

I'm interested in both but w/o details, it is very hard to decide.

Nanook,

What is the exact details of the platter(dimension, thickness, etc) and the bearing(what kind? inverted bearing, standard bearing, etc? and the spindle details?)

I'm interested in both but w/o details, it is very hard to decide.

prototype

Hi Nanook,

I agree with the previous post by nameci, a few more details on the dimensions of the platter etc. would be good and if possible pictures of the prototype?

thanks anyway for your efforts!

Hi Nanook,

I agree with the previous post by nameci, a few more details on the dimensions of the platter etc. would be good and if possible pictures of the prototype?

thanks anyway for your efforts!

Nanook,

As you are counting those interested, please remove my name from consideration. I must do this for financial reasons. I wish you the best! There are going to be many fine tables that result from your efforts. I'll continue watching...

As you are counting those interested, please remove my name from consideration. I must do this for financial reasons. I wish you the best! There are going to be many fine tables that result from your efforts. I'll continue watching...

some answers..

ok here goes:

Most of these details were earlier in the thread.

As far as a 6" (152 mm)Delrin platter goes, DaveM you are on your own in making this bearing fit and work with a platter that thick. This bearing has been used with platters up to 80 mm. But as far as modifying it to work with something 110mm thicker, you will need to do some rework on the platter to make it work, I am sure. And I'm not sure that it will support a 24 pound platter. I know it will support a 16 pound platter though.

I hope that helps.

At this time I simply cannot tell you who the maker is, but I can tell you they also make bearings and platters (and even complete high end turntables for other brands that are very well-known in the audiophile community, including their own). I guarantee that you will not be disappointed in the platter or the bearing.

Ed, thanks for the update. Sorry that you won't be able to participate in this.

stew

ok here goes:

- the platter is 40 mm thick, unpolished acrylic, clear with label recess

- the bearing is essentially the same as my previously posted rendering: an inverted bearing, ceramic ball and ceramic wear plate, sintered bronze bushing, lubricant free

- plus 310 grams will have little to no effect on the bearing

- the total mass of a platter will have an effect on all bearings, so I guess will it support a mass loaded platter? Depends on the total mass of the platter. Thankfully in this case, the wear plate and ceramic ball are replaceable, but the limiting factor is the ceramic ball and the thrust plate itself. I've never looked into the load capabilities of ceramic balls and thrust plates

- the spindle is as per current RIAA standards, 7.24 mm

- the bearing is machined within .1mm (approximately .004")

Most of these details were earlier in the thread.

As far as a 6" (152 mm)Delrin platter goes, DaveM you are on your own in making this bearing fit and work with a platter that thick. This bearing has been used with platters up to 80 mm. But as far as modifying it to work with something 110mm thicker, you will need to do some rework on the platter to make it work, I am sure. And I'm not sure that it will support a 24 pound platter. I know it will support a 16 pound platter though.

I hope that helps.

At this time I simply cannot tell you who the maker is, but I can tell you they also make bearings and platters (and even complete high end turntables for other brands that are very well-known in the audiophile community, including their own). I guarantee that you will not be disappointed in the platter or the bearing.

Ed, thanks for the update. Sorry that you won't be able to participate in this.

stew

- Status

- Not open for further replies.

- Home

- Group Buys

- Any interest in an acrylic platter group buy, and a bearing?