Soldering questions

OK, the case and parts have been delivered and I'm looking forward to the build.

The amp boards are quite small. They seem to look larger in all the pictures that are on this thread. It means the old soldering iron is just too large and clunky for doing a good job on the aca boards.

The build guide, which is a wonderful document btw, lists a Hakko soldering station as a recommended tool. So here's a couple of soldering questions ...

The aca board has some pretty tiny places to solder (like around the small resistors). Is the tip that comes with the Hakko sufficient for the tiny connectons or should you get additional tips? And if so, which tips?

Also, I've never had anything but a cheap pencil type soldering iron that is either on or off. How do you know what temperature to use on the different sized components? Do the small resistor leads need less heat than the chunkier leads or do you just apply heat for a longer amount of time? Do the power and speaker wires soak up more heat?

Appreciate the help and guidance.

OK, the case and parts have been delivered and I'm looking forward to the build.

The amp boards are quite small. They seem to look larger in all the pictures that are on this thread. It means the old soldering iron is just too large and clunky for doing a good job on the aca boards.

The build guide, which is a wonderful document btw, lists a Hakko soldering station as a recommended tool. So here's a couple of soldering questions ...

The aca board has some pretty tiny places to solder (like around the small resistors). Is the tip that comes with the Hakko sufficient for the tiny connectons or should you get additional tips? And if so, which tips?

Also, I've never had anything but a cheap pencil type soldering iron that is either on or off. How do you know what temperature to use on the different sized components? Do the small resistor leads need less heat than the chunkier leads or do you just apply heat for a longer amount of time? Do the power and speaker wires soak up more heat?

Appreciate the help and guidance.

Barryso,

Form your questions, I would say you already know more than what I did when I started.

So yes, probably you would benefit from specific temps for each element and appropriate soldering tips depending on the component.

I had only a single 20W generic soldering iron with a fine pencil tip and used that for the entire job. I had no problems whatsoever! I did buy he recommended Kester rosin core solder to make things easier and allow better flow and freezing / melting points to avoid mushy solders.

Nothing got too hot. I even had to un solder a JFET and no problems there.

So I think you should be OK if you buy a good low power iron for this one.

Others will have better in-depth comments, I'm sure.

Rafa.

Form your questions, I would say you already know more than what I did when I started.

So yes, probably you would benefit from specific temps for each element and appropriate soldering tips depending on the component.

I had only a single 20W generic soldering iron with a fine pencil tip and used that for the entire job. I had no problems whatsoever! I did buy he recommended Kester rosin core solder to make things easier and allow better flow and freezing / melting points to avoid mushy solders.

Nothing got too hot. I even had to un solder a JFET and no problems there.

So I think you should be OK if you buy a good low power iron for this one.

Others will have better in-depth comments, I'm sure.

Rafa.

Soldering video, Watch Mr. Carlson labs on YouTube audio restoration

Watch this video on YouTube by Mr. Carlson labs he has several videos on soldering so search through his playlist to watch the other ones on selection of solder and flux different types of rosin core Sauter and the ue.

YouTube

He also has a video on desoldering. In many videos on the restoration of old tube and solid-state amplifiers and radios and other lab test gear for audio . There’s many old videos directly from solder manufacturers many of The videos were produced in the 70s 80s or 90s some good Sauter solder videos were produced for the military back in the 40s and they’re still pretty excellent videos.

OK, the case and parts have been delivered and I'm looking forward to the build.

The amp boards are quite small. They seem to look larger in all the pictures that are on this thread. It means the old soldering iron is just too large and clunky for doing a good job on the aca boards.

The build guide, which is a wonderful document btw, lists a Hakko soldering station as a recommended tool. So here's a couple of soldering questions ...

The aca board has some pretty tiny places to solder (like around the small resistors). Is the tip that comes with the Hakko sufficient for the tiny connectons or should you get additional tips? And if so, which tips?

Also, I've never had anything but a cheap pencil type soldering iron that is either on or off. How do you know what temperature to use on the different sized components? Do the small resistor leads need less heat than the chunkier leads or do you just apply heat for a longer amount of time? Do the power and speaker wires soak up more heat?

Appreciate the help and guidance.

Watch this video on YouTube by Mr. Carlson labs he has several videos on soldering so search through his playlist to watch the other ones on selection of solder and flux different types of rosin core Sauter and the ue.

YouTube

He also has a video on desoldering. In many videos on the restoration of old tube and solid-state amplifiers and radios and other lab test gear for audio . There’s many old videos directly from solder manufacturers many of The videos were produced in the 70s 80s or 90s some good Sauter solder videos were produced for the military back in the 40s and they’re still pretty excellent videos.

I would quite happily use a 1/4" chisel tip (on a Philips soldering station) for the ACA. Large parts and particularly cables and sockets can really soak up the heat. If the solder goes 'pasty' and flaky as you apply the iron to such parts then you haven't enough thermal capacity in the tip.

OK, the case and parts have been delivered and I'm looking forward to the build.

The amp boards are quite small. They seem to look larger in all the pictures that are on this thread. It means the old soldering iron is just too large and clunky for doing a good job on the aca boards.

The build guide, which is a wonderful document btw, lists a Hakko soldering station as a recommended tool. So here's a couple of soldering questions ...

The aca board has some pretty tiny places to solder (like around the small resistors). Is the tip that comes with the Hakko sufficient for the tiny connectons or should you get additional tips? And if so, which tips?

Also, I've never had anything but a cheap pencil type soldering iron that is either on or off. How do you know what temperature to use on the different sized components? Do the small resistor leads need less heat than the chunkier leads or do you just apply heat for a longer amount of time? Do the power and speaker wires soak up more heat?

Appreciate the help and guidance.

Here is a very inexpensive one where you can adjust temperature and it will have tips small enough, hope this helps

Stahl Tools STSSVT Variable Temperature Soldering Iron Station

Also, I've never had anything but a cheap pencil type soldering iron that is either on or off. How do you know what temperature to use on the different sized components? Do the small resistor leads need less heat than the chunkier leads or do you just apply heat for a longer amount of time? Do the power and speaker wires soak up more heat?

Appreciate the help and guidance.

Barry,

I got a Weller WLC100 while back (after my Heathkit iron failed -- 45 years).

While it is adjustable, it is dumb temperature-wise. It has a small enough tip for smaller through-hole stuff, but I'd look elsewhere if surface mount is in your future. I haven't needed more heat for large-mass items yet

Skip

Last edited:

To Barryso , inexpensive soldering station multipurpose

Barryso

My son and I have use this cheap Amazon or eBay purchased Sauter station for nearly 2 years now . My son uses it to repair laptops and computers and I use it for building amplifiers and headphone amplifiers and also stripping down all components for reuse from radios, amplifiers, microwaves, power supplies,TVs at the price for all the features it’s been a great starter entry into adjustable soldering iron‘s and getting into SMD (surface mount device) components.

Barryso

My son and I have use this cheap Amazon or eBay purchased Sauter station for nearly 2 years now . My son uses it to repair laptops and computers and I use it for building amplifiers and headphone amplifiers and also stripping down all components for reuse from radios, amplifiers, microwaves, power supplies,TVs at the price for all the features it’s been a great starter entry into adjustable soldering iron‘s and getting into SMD (surface mount device) components.

As an initial response, I'd offer the old saying, "If it ain't broke don't fix it."

The amp has been designed to work just fine if you build it to spec. I don't think using a PC and their heat management is a valid comparison. I've got 24V power feeding mine and the heat sinks measure around 50°C with ambient air at around 25°C. Seems reasonable. Yes, 50°C is warm but it won't immediately burn the skin. You'd have to leave a body part parked against the heat sink for a while to cook it. So, as long as you've got a well aired place to house the amp, on its own shelf, you should not have a problem.

If you're planning to put the amp in a closed cabinet, then I'd think about ventilating the cabinet but leave the amp stock. But for a thing of beauty, why hide your own handiwork?

I’ve build mine in the mini dissipate case and it runs 20-22 degree above room temperature. No problem at all. There is a Sugden A21 next to it, getting 10 degree C hotter and that amp is almost everlasting. That said, 50 degree C (for the heatsink, the fets are even higher in temp) is pretty hot for us humans but not for mosfets.

... So here's a couple of soldering questions ...

The aca board has some pretty tiny places to solder (like around the small resistors). Is the tip that comes with the Hakko sufficient for the tiny connectons or should you get additional tips? And if so, which tips?

Also, I've never had anything but a cheap pencil type soldering iron that is either on or off. How do you know what temperature to use on the different sized components? Do the small resistor leads need less heat than the chunkier leads or do you just apply heat for a longer amount of time? Do the power and speaker wires soak up more heat?

Appreciate the help and guidance.

I'm with Rafa, because this is the first time I'd done any serious soldering. I hunted down the recommended Kester 63/37 solder, same diameter. Bought a fume fan for the lead side of things, just in case. Years ago I bought a 60W station with temp control. Not wanting to cook any components, I ended up setting it to 210°C. I read recommendations that chisel tips help with heat conduction. I used a 2mm chisel tip because it looked like it would be fine enough to work with the small components.

Worked fine.

There were times with the massive components that conduct heat well that I just needed to be patient. Worked in the end and the ACAs I've got sound great. Powered up without a hitch first time .. gotta be happy with that.

Last edited:

210 C is not much…...around 360 to 400 C is more normal to use. It is better to have a very fast soldering and important the solder flows good. A fast solder with high temperature does that the heat will transfer less to the component itself rather than slow soldering with lower temperature.

Thanks for all the feedback and input on soldering. I've watched a few soldering videos today and have learned how to improve my technique. It's pretty obvious I'm over thinking this as there have been many kits built over the past few decades and they've worked just fine. It's just been a while.

There are a few builds to do after the ACA so soldering right is the skill that will carry through all the projects.

It looks like it'll be an interesting and entertaining fall/winter.

Thank you.

There are a few builds to do after the ACA so soldering right is the skill that will carry through all the projects.

It looks like it'll be an interesting and entertaining fall/winter.

Thank you.

210 C is not much…...around 360 to 400 C is more normal to use. It is better to have a very fast soldering and important the solder flows good. A fast solder with high temperature does that the heat will transfer less to the component itself rather than slow soldering with lower temperature.

Ohhh, cr@p. That's a pants down moment. Thanks for the advice. Filed for next time. Hopefully, I haven't stuffed it. Working fine now. Time will tell.

I use only Weller 430 deg C tips. I find 370 deg C too low... it takes much longer to heat up the soldering bits; 430 tip does much quicker and better job

For those who have built a lot... What to build next?

I've been listening to ACA 1.6 monos with the 24 volt supply for a while now. I have to say that I love the sound. I don't love the sound for the price, I love the sound compared to a lot of expensive stuff. I have an issue with the amps and my speakers though.

I measured the impedance of my most efficient speakers and they dip down to about three ohms in the mid-bass and again higher up. The ACAs sound amazing in the upper bass, mids and high frequencies with these speakers, but the lower bass gets a little muffled.

I am wondering if there is an amp build that has the delicious overall sound of the ACA but with a little more low bass control? Or do you give up the luscious mids and highs when you look for more bass control? I could also build a better matching pair of speakers instead of an amp, but I don't know what designs to look into.

Thanks for any suggestions.

I've been listening to ACA 1.6 monos with the 24 volt supply for a while now. I have to say that I love the sound. I don't love the sound for the price, I love the sound compared to a lot of expensive stuff. I have an issue with the amps and my speakers though.

I measured the impedance of my most efficient speakers and they dip down to about three ohms in the mid-bass and again higher up. The ACAs sound amazing in the upper bass, mids and high frequencies with these speakers, but the lower bass gets a little muffled.

I am wondering if there is an amp build that has the delicious overall sound of the ACA but with a little more low bass control? Or do you give up the luscious mids and highs when you look for more bass control? I could also build a better matching pair of speakers instead of an amp, but I don't know what designs to look into.

Thanks for any suggestions.

I also built an f4, this also has the liquid and lush midrange but everything is tighter and more so. It doesn't lose it on the bass. Taught as "insert tight analogy here".

I'm going to build a ba3 soon as well. Very similar output stage as f4 (complimentary op board) but doesn't require a special preamp.

I'm going to build a ba3 soon as well. Very similar output stage as f4 (complimentary op board) but doesn't require a special preamp.

I am wondering if there is an amp build that has the delicious overall sound of the ACA but with a little more low bass control? Or do you give up the luscious mids and highs when you look for more bass control? I could also build a better matching pair of speakers instead of an amp, but I don't know what designs to look into.

Thanks for any suggestions.[/QUOTE]

Have not driven an 8 ohm woofer with an ACA.

DAC > Active Crossover ACA AMPS (Balanced Mono Blocks) >Heil AMT

V -----Emotiva XPA 200 (Variable L Pad)---> Woofer

Crossover is set at 1.2 kHz (Off the shelf behringer)

Balanced inputs on the ACA's.

Sounds really nice to our ears!

Point of all of this babbling is you can get really good control of the bass by dedicating independent amps to the drivers. When you do that you are driving the speaker directly. Not with intervening passive networks that add to the confusion of what an audio amp has to deal with for a load.

Hope that helps!

Thanks for any suggestions.[/QUOTE]

Have not driven an 8 ohm woofer with an ACA.

DAC > Active Crossover ACA AMPS (Balanced Mono Blocks) >Heil AMT

V -----Emotiva XPA 200 (Variable L Pad)---> Woofer

Crossover is set at 1.2 kHz (Off the shelf behringer)

Balanced inputs on the ACA's.

Sounds really nice to our ears!

Point of all of this babbling is you can get really good control of the bass by dedicating independent amps to the drivers. When you do that you are driving the speaker directly. Not with intervening passive networks that add to the confusion of what an audio amp has to deal with for a load.

Hope that helps!

I use only Weller 430 deg C tips. I find 370 deg C too low... it takes much longer to heat up the soldering bits; 430 tip does much quicker and better job

It also depends of which solder you use. I use 60/40 (Tin/Lead) which has a melting point around 185 C. If you use lead free which has melting point above 200 C it makes sense to go past 400 C. Using the long slim Weller tips I use no. 8 which I think a 400 C tip. For the larger tips no. 7 usually works fine depending of the solder job. For large solder jobs I have old fashioned iron (100 W) which is heavy and has a large heat storage capacity in the tip. This can be more important that the temperature itself as a small Weller tip can be cooled down by the item you solder.

It also depends of which solder you use.

Definitely. I used solder with silver and copper that was okay to work with. It sounded really good. Lately, I use 10% silver-loaded Mundorf solder which is surprisingly easy to melt. It also sounds great. The typical 60/40 solder melts like butter...

Definitely. I used solder with silver and copper that was okay to work with. It sounded really good. Lately, I use 10% silver-loaded Mundorf solder which is surprisingly easy to melt. It also sounds great.

What does solder sound like? I guess a bit snake oil? 😀

I've been listening to ACA 1.6 monos with the 24 volt supply for a while now. I have to say that I love the sound. I don't love the sound for the price, I love the sound compared to a lot of expensive stuff. I have an issue with the amps and my speakers though.

I measured the impedance of my most efficient speakers and they dip down to about three ohms in the mid-bass and again higher up. The ACAs sound amazing in the upper bass, mids and high frequencies with these speakers, but the lower bass gets a little muffled.

I am wondering if there is an amp build that has the delicious overall sound of the ACA but with a little more low bass control? Or do you give up the luscious mids and highs when you look for more bass control? I could also build a better matching pair of speakers instead of an amp, but I don't know what designs to look into.

Thanks for any suggestions.

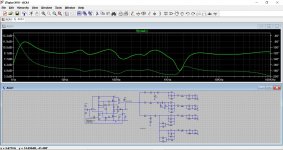

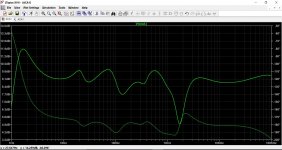

Interesting question. My B&W 703's also dip to around 3 ohm. This shows the output of the ACA into a such a speaker model.

Attachments

- Home

- Amplifiers

- Pass Labs

- Amp Camp Amp - ACA