check out for this procedure the images in post #1+12.Ah many thanks tiefbassübertr, I'll look into the links you have submitted. Anyway, I think I'll reuse the switch, this amp is very dear to me and I'd like to have it in it's original state as much as possible.

Some years ago I have made this on same devices from Onkyo and Creek.

Choosing this switch from ALPS for such amplifiers wasn't a good decision - some other rotary switches in open version - go to

https://www.ebay.com/itm/124912532841

(10-20 years older than this ALPS model) haven't any contact problems after cleaning with contact spray like tuner 600 (in opposite to this ALPS model).

The main reason for the extensive oxidation seems to be the the used contact grease (also a great issue on plastic rotary switches from LORLIN - go to

https://www.diyaudio.com/community/...rlin-rotary-switch-replace-by-elma-04.308235/)

Last edited:

another issue occurs over the years - go to the images under

http://audiopub.co.kr/2020/05/25/인켈-ax-7r-인티앰프-4-알프스-전동-셀렉터-살려내기/

this rotary switch is in use on Sherwood's AX-7r :

https://www.hifihouse.de/hifi-gebraucht/sherwood-ax-7r/

http://www.hifi-forum.de/viewthread-185-8902.html#1

http://audiopub.co.kr/2020/05/25/인켈-ax-7r-인티앰프-4-알프스-전동-셀렉터-살려내기/

this rotary switch is in use on Sherwood's AX-7r :

https://www.hifihouse.de/hifi-gebraucht/sherwood-ax-7r/

http://www.hifi-forum.de/viewthread-185-8902.html#1

Hi tiefbassuebertr.

Happy new year.

I'm doing the same cleanup on my Arcam Delta 290 rotary switch. I've found Alps to use grease too on the contacts. What did you use in place of the grease?

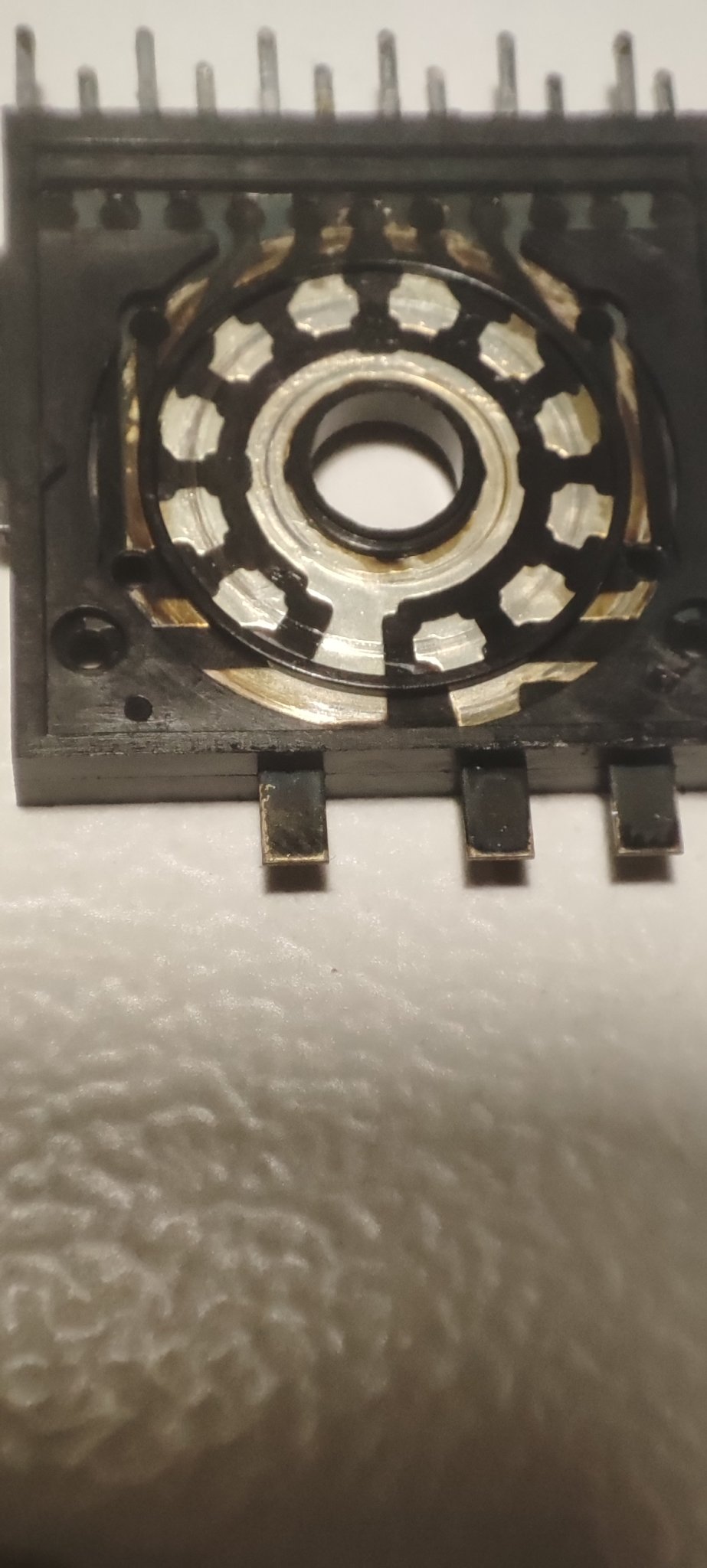

The photo was taken before cleaning it

Happy new year.

I'm doing the same cleanup on my Arcam Delta 290 rotary switch. I've found Alps to use grease too on the contacts. What did you use in place of the grease?

The photo was taken before cleaning it

happy new year also for you

I removed the grease completely and polished it with cotton buds soaked in Kontakt 60

https://www.kontaktchemie.com/KOC/KOCproductdetailV2.csp?product=KONTAKT

https://www.amazon.de/-/en/Cotton-cotton-cleaner-cleaning-sticks/dp/B09Y541KM1?th=1

After this and assembling there wasn't observed any crackling over the years.

I removed the grease completely and polished it with cotton buds soaked in Kontakt 60

https://www.kontaktchemie.com/KOC/KOCproductdetailV2.csp?product=KONTAKT

https://www.amazon.de/-/en/Cotton-cotton-cleaner-cleaning-sticks/dp/B09Y541KM1?th=1

After this and assembling there wasn't observed any crackling over the years.

Then I won't grease it again!

For what I read, this Kontakt 60 is not oily, right? Wouldn't it be better to use an oily one? I really don't want to solder 38 joints one more time, neither in 10 years 😀

Thank you very much!

For what I read, this Kontakt 60 is not oily, right? Wouldn't it be better to use an oily one? I really don't want to solder 38 joints one more time, neither in 10 years 😀

Thank you very much!

you cannot make a better resp. long life rotary switch from this original part from alps by use of a certainly grease.

check out my post #19 and the attached pdf file (5. Replace the Source Selector Switch)

check out my post #19 and the attached pdf file (5. Replace the Source Selector Switch)

Attachments

Last edited:

I also own a Yamaha RX-750 and it suffered from the same problem. I disassembled the switch. The switch was full of contact spray on the inside and outside and yet the contacts on certain parts did not make contact and that could be heard in the sound. So with or without contact spray the switch crackles. The switch is cleaned with acetone and alcohol and allowed to dry. That got me thinking. In fact, such a switch is used so little that the parts that are not in contact can oxidize. I cleaned the contacts and also increased the spring tension of the contact fingers. The switch was then reassembled without contact spray. And even though the switch was clean, the switch still cracked. So it must be something different. My theory is that even though they are gold contacts, an insulating layer remains on the contacts despite cleaning with acetone and alcohol. How do you get this layer removed?

I was able to clean sealed relays by connecting them behind an astable multi-vibrator and letting it chatter with a 2 Hz signal for a few hours at a slightly higher voltage than specified. Success assured.

Now back to the ALP. The problem turned out to be just at the beginning and end of the switching point. So there was a spot with pretty good contact and then an area on either side with the insulation layer. The solution was to manually rotate the switch through all positions with a large number of turns at 1 Hz. You essentially sand away the insulation layer by repeatedly turning. So far the cracking has not returned. The same technique can also be applied to potentiometers to a certain extent. I often add some silver graphite for locks into the potentiometer and turn them around. That's better than injecting greasy gunk into the potentiometers.

The pictures are in the dirty state of the contacts.

I was able to clean sealed relays by connecting them behind an astable multi-vibrator and letting it chatter with a 2 Hz signal for a few hours at a slightly higher voltage than specified. Success assured.

Now back to the ALP. The problem turned out to be just at the beginning and end of the switching point. So there was a spot with pretty good contact and then an area on either side with the insulation layer. The solution was to manually rotate the switch through all positions with a large number of turns at 1 Hz. You essentially sand away the insulation layer by repeatedly turning. So far the cracking has not returned. The same technique can also be applied to potentiometers to a certain extent. I often add some silver graphite for locks into the potentiometer and turn them around. That's better than injecting greasy gunk into the potentiometers.

The pictures are in the dirty state of the contacts.

Attachments

I have repaired one of these in a musical fidelity nu-vista amp - it was a laborious job to disassemble enough to desolder the switch, take it apart, clean the contacts and reassemble. Luckily the board was decent and traces were not damaged. That was 2 years ago and it is still OK now.

I also bought a grayhill switch as I don't think another cleaning in some years will be successful.

I also bought a grayhill switch as I don't think another cleaning in some years will be successful.

for me the best solution for integrated amps with this kind of rotary switch is a bypass for the internal input selector unit and the replace by an outdoor unit as to find in post #22 under

My favorite rotary switch is the ELMA 04. In the unit under

https://web.archive.org/web/20070206191733/http://www.redwineaudio.com:80/Signature_3S.html

this rotary switch is in use.

Who know currently available input selector units, where this ELMA 04 is inside ?

Thank you very much for an advice.

Hi,

I'm building a gainclone amp, and I need a rotary selector to switch between sources. I have three inputs to the amp, and I bought one of these:

Rotary Switches : Rotary Switches : Maplin Electronics

I got the 4-pole 3-way one and that's fine, but will this switch do for audio?

Can you recommend something else I can use for this purpose? This is my first attempt at something like this and I'm not sure if this switch will work or not, I'd like to be sure before I solder everything up.

Thanks,

I'm building a gainclone amp, and I need a rotary selector to switch between sources. I have three inputs to the amp, and I bought one of these:

Rotary Switches : Rotary Switches : Maplin Electronics

I got the 4-pole 3-way one and that's fine, but will this switch do for audio?

Can you recommend something else I can use for this purpose? This is my first attempt at something like this and I'm not sure if this switch will work or not, I'd like to be sure before I solder everything up.

Thanks,

https://web.archive.org/web/20070206191733/http://www.redwineaudio.com:80/Signature_3S.html

this rotary switch is in use.

Who know currently available input selector units, where this ELMA 04 is inside ?

Thank you very much for an advice.

Last edited:

- Home

- Amplifiers

- Solid State

- Alps Rotary Switch Dropout Issues for Input Select (e.g. Onkyo, Yamaha, Creek)