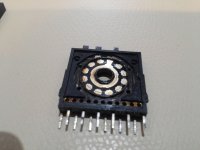

Alps Rotary Switch for Input Select for Onkyo (e. g. Integra A-9711/9911) and Creek (5350SE)

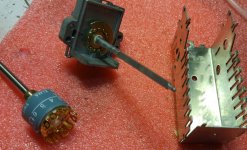

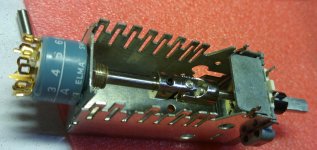

The main issue at this Alps input selector is the use of contact grease resp. contact liquid between the contact springs at the plastic device and the contact itself (see the images). For this reason it is impossible to remove the internal unwanted transition resistances with the help of any kind of contact cleaners e.g. like follow:

CRC WebSite: Maintenance and Repair products

KOC WebSite: Maintenance and Repair products

KOC WebSite: Maintenance and Repair products

If it had not provided this lubrication at the contacts, I would use tuner 600 etc and success is provided.

This means, all kind of switches like the follow URLs must be disassembled.

http://bilder.hifi-forum.de/max/599916/sam0273o_69807.jpg

Onkyo A-9711 - Welche Funktionen fernbedienbar?, Verstärker/Receiver - HIFI-FORUM

http://images.gutefrage.net/media/f...911-aus-eingangswahlschalter-defekt/0_big.jpg

Wer kennt sich mit ONKYO- integra Vollverstärker A-9911 aus? Eingangswahlschalter defekt! (onkyo-integra-a-9911)

Onkyo A-8051 und kranke Schalter von ALPS

View image: 20130429 151559

View image: 20130429 151526

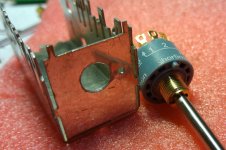

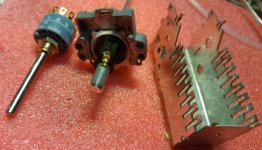

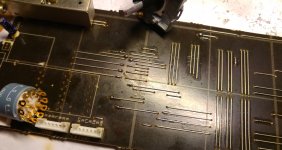

The attached images are from me.

Clearly to see are the contacts before and after cleaning. After assembly the rotary switch and resold on the PCB the user get a kind of operating while the input select like new condition, i. e. without any dropouts at one of the channels.

It is particularly difficult (very hard) to desolder the rotary switch in such cases, where the solder pins were bent before soldering.

In case of breaking the solder pins silver wires must be soldered. That means the risc of alter the correct installation position.

The main issue at this Alps input selector is the use of contact grease resp. contact liquid between the contact springs at the plastic device and the contact itself (see the images). For this reason it is impossible to remove the internal unwanted transition resistances with the help of any kind of contact cleaners e.g. like follow:

CRC WebSite: Maintenance and Repair products

KOC WebSite: Maintenance and Repair products

KOC WebSite: Maintenance and Repair products

If it had not provided this lubrication at the contacts, I would use tuner 600 etc and success is provided.

This means, all kind of switches like the follow URLs must be disassembled.

http://bilder.hifi-forum.de/max/599916/sam0273o_69807.jpg

Onkyo A-9711 - Welche Funktionen fernbedienbar?, Verstärker/Receiver - HIFI-FORUM

http://images.gutefrage.net/media/f...911-aus-eingangswahlschalter-defekt/0_big.jpg

Wer kennt sich mit ONKYO- integra Vollverstärker A-9911 aus? Eingangswahlschalter defekt! (onkyo-integra-a-9911)

Onkyo A-8051 und kranke Schalter von ALPS

View image: 20130429 151559

View image: 20130429 151526

The attached images are from me.

Clearly to see are the contacts before and after cleaning. After assembly the rotary switch and resold on the PCB the user get a kind of operating while the input select like new condition, i. e. without any dropouts at one of the channels.

It is particularly difficult (very hard) to desolder the rotary switch in such cases, where the solder pins were bent before soldering.

In case of breaking the solder pins silver wires must be soldered. That means the risc of alter the correct installation position.

Attachments

Last edited:

Nicely done! How did you remove the worn ridges in the contacts?

I do wonder though, just how long your patch will survive for.

Many have found such work as only delaying the inevitable.

Real issue is these are Low Quality switches.. Period.

The contacts are thin, soft and largely inadequate for significant ongevity.. at least much beyond the Unit's Mfg Warranty.

I do wonder though, just how long your patch will survive for.

Many have found such work as only delaying the inevitable.

Real issue is these are Low Quality switches.. Period.

The contacts are thin, soft and largely inadequate for significant ongevity.. at least much beyond the Unit's Mfg Warranty.

I don't understand the marked term.Nicely done! How did you remove the worn ridges in the contacts?

I do wonder though, just how long your patch will survive for.

Many have found such work as only delaying the inevitable.

Real issue is these are Low Quality switches.. Period.

The contacts are thin, soft and largely inadequate for significant ongevity.. at least much beyond the Unit's Mfg Warranty.

However - you are right with your estimate with bad reliability and short longevity in some cases. But most amps work since several years without trouble after doing this work.

In this case I have a question: In which other amp models this kind of Alps rotary switches are in use?

I know until now this models:

1) Creek 5350SE

2) Onkyo Integra 9911 and 9711

3) Onkyo A8051

4) Pioneer A501R

Because this switches at Alps no longer available such list of amp models are helpful to get parts for replace faulty parts like spring contacts.

Thanks for advices.

Last edited:

There is some Yamaha , a few Sansui AUX series , the Arcam delta 290 and also got to be a few Marantz also .

The switch has been an issue many years now and cleaning even if done your way ( we do it with other ways also ) so beyond cleaning always there will be an issue of how firm the contacts will be .

Been cleaning some with 100% success but some other i had to replace with relay boards ( lost the remote though ) to keep the amp running .

@ tiefbassuebertr Please check your PM list i ve send you a message but it was never replied

Kind regards

Sakis

The switch has been an issue many years now and cleaning even if done your way ( we do it with other ways also ) so beyond cleaning always there will be an issue of how firm the contacts will be .

Been cleaning some with 100% success but some other i had to replace with relay boards ( lost the remote though ) to keep the amp running .

@ tiefbassuebertr Please check your PM list i ve send you a message but it was never replied

Kind regards

Sakis

The rotary swich from this amp I have had shortly for disassembly and cleaning:

Minhembio.com - Hemma hos Buj - Under skalet på anläggningen

the closer inside look shows the same problems than the pics from post #1.

From Sansui I don't know models, where this switch or similar versions are in use.

Additional I want to know the exact order code resp. modell No from Alps.

The actually products are all other kinds of rotary switches:

http://www.alps.com/prod/info/E/HTML/Switch/Rotary/Rotary_list1.html

The most used kind of input selector switches in amps without remote control are follow:

http://forums.naimaudio.com/fileSen...nlineImage/true/nac62%20input%20selector..jpg

http://www.electronicsurplus.com/alps-160595-3-switch-rotary-contacts-4-pole-5-position

http://thumbs2.ebaystatic.com/d/l225/m/mIoatLtMtOguuLpoD9GIKTQ.jpg

The kind of rotary switch from post #1 seems to be relatively rare.

Where I can order this Alps rotary swich from post #1 ??

Thanks for advices.

Minhembio.com - Hemma hos Buj - Under skalet på anläggningen

the closer inside look shows the same problems than the pics from post #1.

From Sansui I don't know models, where this switch or similar versions are in use.

Additional I want to know the exact order code resp. modell No from Alps.

The actually products are all other kinds of rotary switches:

http://www.alps.com/prod/info/E/HTML/Switch/Rotary/Rotary_list1.html

The most used kind of input selector switches in amps without remote control are follow:

http://forums.naimaudio.com/fileSen...nlineImage/true/nac62%20input%20selector..jpg

http://www.electronicsurplus.com/alps-160595-3-switch-rotary-contacts-4-pole-5-position

http://thumbs2.ebaystatic.com/d/l225/m/mIoatLtMtOguuLpoD9GIKTQ.jpg

The kind of rotary switch from post #1 seems to be relatively rare.

Where I can order this Alps rotary swich from post #1 ??

Thanks for advices.

Last edited:

Look here: Condor Audio |

and download the Arcam upgrade pdf under the Projects tab

and download the Arcam upgrade pdf under the Projects tab

I have an Onkyo a-9711 and when i touch the selector it makes a buzzing sound in the speakers and sometimes one channel in not clear, and when i change the input from remote control sometimes skips and the knobs acts strange i mean it goes to another channel and sometimes do not react to the remote input. Is it possible to be the same problem bad contact and do not recognize position? The amplifier visually is in perfect condition i mean exactly like it came out from the factory i think it was used very little. Can i find this rotary switch at any other producer? And another thing there are 2 resistance near the speaker connections that tend to heat up but they are not broken and the pcb under them is a little bit dark brown what is the cause they heat up and what is their role in the amplifier?

Working on Onkyo a-9711 rotary switch cleaned with tooth paste and polished with tooth paste. And it works perfectly after.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Dear All,

I am presently trying to fix my Alp selector on a 9711.

I have dismounted, it, cleaned it,

but I did not precisely note the alignment of the wheels.

Can any of you tell me how to mount the selector back, by providing precise informatio on the alignment, Are all the wheels align in the same way ?

What about the first one which is different from the others ?

Thanks for all

Jacques

I am presently trying to fix my Alp selector on a 9711.

I have dismounted, it, cleaned it,

but I did not precisely note the alignment of the wheels.

Can any of you tell me how to mount the selector back, by providing precise informatio on the alignment, Are all the wheels align in the same way ?

What about the first one which is different from the others ?

Thanks for all

Jacques

Finally, I manage to align the wheels, after looking to

the service manual with the schematics.

But I broke one of the small axis of one of the wheels. Probably

the plastic got stiff with the age. As there remains two of the four

bits. I still put if back, with a spring in order to exert some pressure

to improve the contact.

After remounting, to my high surprise, it works.

Even the motorised command work, at least for most of the

selections (Pb with the Tape2 and Tape1), but this is more than

I need. This amplifier has been waiting for a fix for 10 years.

For the first time since, the sound is perfect.

Thanks for the information, that was really helpful.

http://www.diyaudio.com/forums/attachment.php?attachmentid=446483&stc=1&d=1414958817

the service manual with the schematics.

But I broke one of the small axis of one of the wheels. Probably

the plastic got stiff with the age. As there remains two of the four

bits. I still put if back, with a spring in order to exert some pressure

to improve the contact.

After remounting, to my high surprise, it works.

Even the motorised command work, at least for most of the

selections (Pb with the Tape2 and Tape1), but this is more than

I need. This amplifier has been waiting for a fix for 10 years.

For the first time since, the sound is perfect.

Thanks for the information, that was really helpful.

http://www.diyaudio.com/forums/attachment.php?attachmentid=446483&stc=1&d=1414958817

Attachments

I see that many have issues with the specific switch and i hope that the rather long post below might help a bit.

Sometime during the late 80's i bought a Yamaha AX-550 Stereo amplifier.

For about 15-20 years now it accompanies my computer and my turntable.

Since ages it has the expected ALPS input switch issues. Sometime long ago i opened the switch and i cleaned it with a contact cleaner spray with oil. It worked for sometime and although i didn't used it much the problems started again in all inputs making it... not really usable.

I also started to clean the wafer using a cheap fibreglass pencil. In the photos below the four wafer are visible with the top right cleaned with the "pen".

Then i changed my mind and decided that i didn't want it to fail after some time. Also i didn't want to go with hard gold plating of the wafers and the sliders.

A search for a replacement switch revealed a few things.

1) The specific switch will fail.

2) Yamaha (i don't know about other makers that were using the same part) sometime decided to use an improved part with gold contacts. The MTBF of that solution is unknown to me.

3) Both part are not available in the local Yamaha service center.

4) The "improved" input selector was found on-line but with a total cost of a bit over 80€ i thought that the price is too high.

So, i started to search what "other" input selector to buy, a cheap with 2-3€ or something better? It was clear from the beginning that there was going to be a no remote control selector. I don't mind, i don't even know where my original remote control is now.

To make the story short, the original switch has four "wafers", one for each channel, one for current position feedback to the micro-controller and one more that i think is for a muting of the audio during intermediate positions of the switch. One more wafer -not really exposed- is in the front side of the switch that has the sliders that provide power to the led.

In any case i decided to buy an ELMA switch that can handle 6 stereo inputs (2pole/6 way) with 30degrees step and is of a non shorting type, meaning that it first disconnects from an input and than makes connection the the neighbouring input while you are turning the knob. The price was about 30-32€ and as i bought some other parts the shipping didn't increased my total cost.

I didn't found a switch with the proper shaft type (D) that could accommodate the original Yamaha knob and even the switch i selected has a smaller diameter (3mm).

The good thing is that the solution to that problem was even better that i thought as i ended up maintaining the led indicator on the knob working.

The exact type of the switch doesn't really matter as the solution can be implemented with other types.

I will try to describe below what i did and then have the photos below continuing with a next post if necessary.

I had to increase the diameter of the hole in the rear side of the original switch where the original shaft was terminating making it large enough to fit the new switch.

A new small hole was needed to keep the switch from turning. That should make the shaft of the new switch concentric with the "shortened" shaft of the original ALPS switch.

There are two ways to join the two shafts together using couplers used in robotics projects and they are cheap. I preferred the one that could "forgive" differences of concentricity of the shaft axles from the simple copper coupler at the bottom of the respective photo. Have in mind that i used couplers for a 3mm and a 4mm shafts. they are available for a range of shaft diameters.

I made an estimation and i cut the ALPS shaft, then i measured how much i have to cut the shaft of the new switch and i did it in a few steps. The reason is that the shaft of the new switch happened to be made of steel and cutting it with the dremel was increasing the temperature of the shaft so i had to hold it firmly with pliers while cutting and give it some time to cool down in order not to melt any plastic part inside the main switch body.

Assembling of the parts is easy and it worked very well for me. I also oiled a bit the join of the coupler.

Then as the completed switch body was covering the connection points on the pcb i used other connection position that i had easily found using the DMM with a help of the service manual.

As the pcb is single sided it has several wire jumpers that most of them can be used as they carry the proper input signals. In total we need 14 connections, 12 for the 6 stereo inputs and two for the outputs. For about 4 connections i used the original holes under the switch body, for the rest i soldered a blob on the proper jumper wires. I didn't want to use long wire lengths and also some of the original soldering point under the pcb was destroyed after the second removal of the switch after first cleaning attempt.

In the photos there are a couple of L/R mixups with the wires connected as i was not careful enough during the wire identification during the soldering.

After one week of the above i can say that my amp works perfect. Of course the job can be done in a better was using a different switch with two wafer that probably has less crosstalk (not that i tested/noticed a difference) between the channels or using better/shorter connection wires.

Continuing in the next post with the remaining photos.....

Sometime during the late 80's i bought a Yamaha AX-550 Stereo amplifier.

For about 15-20 years now it accompanies my computer and my turntable.

Since ages it has the expected ALPS input switch issues. Sometime long ago i opened the switch and i cleaned it with a contact cleaner spray with oil. It worked for sometime and although i didn't used it much the problems started again in all inputs making it... not really usable.

I also started to clean the wafer using a cheap fibreglass pencil. In the photos below the four wafer are visible with the top right cleaned with the "pen".

Then i changed my mind and decided that i didn't want it to fail after some time. Also i didn't want to go with hard gold plating of the wafers and the sliders.

A search for a replacement switch revealed a few things.

1) The specific switch will fail.

2) Yamaha (i don't know about other makers that were using the same part) sometime decided to use an improved part with gold contacts. The MTBF of that solution is unknown to me.

3) Both part are not available in the local Yamaha service center.

4) The "improved" input selector was found on-line but with a total cost of a bit over 80€ i thought that the price is too high.

So, i started to search what "other" input selector to buy, a cheap with 2-3€ or something better? It was clear from the beginning that there was going to be a no remote control selector. I don't mind, i don't even know where my original remote control is now.

To make the story short, the original switch has four "wafers", one for each channel, one for current position feedback to the micro-controller and one more that i think is for a muting of the audio during intermediate positions of the switch. One more wafer -not really exposed- is in the front side of the switch that has the sliders that provide power to the led.

In any case i decided to buy an ELMA switch that can handle 6 stereo inputs (2pole/6 way) with 30degrees step and is of a non shorting type, meaning that it first disconnects from an input and than makes connection the the neighbouring input while you are turning the knob. The price was about 30-32€ and as i bought some other parts the shipping didn't increased my total cost.

I didn't found a switch with the proper shaft type (D) that could accommodate the original Yamaha knob and even the switch i selected has a smaller diameter (3mm).

The good thing is that the solution to that problem was even better that i thought as i ended up maintaining the led indicator on the knob working.

The exact type of the switch doesn't really matter as the solution can be implemented with other types.

I will try to describe below what i did and then have the photos below continuing with a next post if necessary.

I had to increase the diameter of the hole in the rear side of the original switch where the original shaft was terminating making it large enough to fit the new switch.

A new small hole was needed to keep the switch from turning. That should make the shaft of the new switch concentric with the "shortened" shaft of the original ALPS switch.

There are two ways to join the two shafts together using couplers used in robotics projects and they are cheap. I preferred the one that could "forgive" differences of concentricity of the shaft axles from the simple copper coupler at the bottom of the respective photo. Have in mind that i used couplers for a 3mm and a 4mm shafts. they are available for a range of shaft diameters.

I made an estimation and i cut the ALPS shaft, then i measured how much i have to cut the shaft of the new switch and i did it in a few steps. The reason is that the shaft of the new switch happened to be made of steel and cutting it with the dremel was increasing the temperature of the shaft so i had to hold it firmly with pliers while cutting and give it some time to cool down in order not to melt any plastic part inside the main switch body.

Assembling of the parts is easy and it worked very well for me. I also oiled a bit the join of the coupler.

Then as the completed switch body was covering the connection points on the pcb i used other connection position that i had easily found using the DMM with a help of the service manual.

As the pcb is single sided it has several wire jumpers that most of them can be used as they carry the proper input signals. In total we need 14 connections, 12 for the 6 stereo inputs and two for the outputs. For about 4 connections i used the original holes under the switch body, for the rest i soldered a blob on the proper jumper wires. I didn't want to use long wire lengths and also some of the original soldering point under the pcb was destroyed after the second removal of the switch after first cleaning attempt.

In the photos there are a couple of L/R mixups with the wires connected as i was not careful enough during the wire identification during the soldering.

After one week of the above i can say that my amp works perfect. Of course the job can be done in a better was using a different switch with two wafer that probably has less crosstalk (not that i tested/noticed a difference) between the channels or using better/shorter connection wires.

Continuing in the next post with the remaining photos.....

Attachments

Good pictures; the showed blue rotary switch unfortunately haven't a long live time and isn't make for opening (more expensive but not really better than the good known plastic switch from LORLIN). My favorite switch is the ELMA 04 - go to

Type 04 - versatile, super robust 24 positions selector switch

e. g.

https://www.don-audio.com/Elma-Dreh...ene-2-x-6-Nicht-Kurzschliessend-30-04-1264-20

unfortunately the needed space is too much in most cases. This means, an outdoor input selector device must be created. Examples are here:

http://www.goldpt.com/sw4_ang_4.jpg

found under

Tweakers' Asylum

or

http://i41.tinypic.com/90ppi8.jpg

but with the ELMA 04 instead the showed LORLIN low cost plastic switch.

Type 04 - versatile, super robust 24 positions selector switch

e. g.

https://www.don-audio.com/Elma-Dreh...ene-2-x-6-Nicht-Kurzschliessend-30-04-1264-20

unfortunately the needed space is too much in most cases. This means, an outdoor input selector device must be created. Examples are here:

http://www.goldpt.com/sw4_ang_4.jpg

found under

Tweakers' Asylum

or

http://i41.tinypic.com/90ppi8.jpg

but with the ELMA 04 instead the showed LORLIN low cost plastic switch.

Thank you for the suggestions, indeed the Type 04 switch is a nice one and I considered it as an option before selecting the blue one -mainly because it was cheaper- (still expensive though).

The maker claims a “Useful life > 25,000 switching cycles” for both switches so I hope it will last for long but In case I have issues again I will replace it with something cheap.

The external passive volume/input selector box is nice but I didn’t want to add one mode box.

Also it does not provide an easy solution for the Phono input that is the main reason I repairer that old amplifier.

The usage of the amplifier is at my home office using the following sources : Phono, Computer, Tuner.

I could use a Rec out to feed the external box but unfortunately the Rec out selector switch has some issues as well .

The maker claims a “Useful life > 25,000 switching cycles” for both switches so I hope it will last for long but In case I have issues again I will replace it with something cheap.

The external passive volume/input selector box is nice but I didn’t want to add one mode box.

Also it does not provide an easy solution for the Phono input that is the main reason I repairer that old amplifier.

The usage of the amplifier is at my home office using the following sources : Phono, Computer, Tuner.

I could use a Rec out to feed the external box but unfortunately the Rec out selector switch has some issues as well .

in cases of very tight space, the Cole S3900 series is a good choice for a replacement part - go to

http://www.cole-switches.com/pdfs/s3900.pdf

and to page 4 under

http://www.condoraudio.com/wp-conte...am-Alpha9-Amplifier-Upgrade-Switch-Repair.pdf

Please let me know suppliers in Europe - thank you very much.

http://www.cole-switches.com/pdfs/s3900.pdf

and to page 4 under

http://www.condoraudio.com/wp-conte...am-Alpha9-Amplifier-Upgrade-Switch-Repair.pdf

Please let me know suppliers in Europe - thank you very much.

externally hosted images aren't a good idea because we have a dead URL after several months. Can you upload the pictures here?Working on Onkyo a-9711 rotary switch cleaned with tooth paste and polished with tooth paste. And it works perfectly after.

More pictures on this URL's concerning this rotary Alps switch:

YAMAHA AX 890 mit Seltsamen Defekt, Elektronik (Stereo&Surround) - HIFI-FORUM

Elektronik Reparatur

Yamaha AX 870 - Netz- und Direct-schalter säubern, Elektronik (Stereo&Surround) - HIFI-FORUM

Hey everybody, I'm new here and forgive me if my question might be stupid. I own a Yamaha AX-470 amplifier which uses the same switch. the audio comes mainly from the right channel whereas the left channel is either silent or cracks when I wiggle the selector switch a bit. At times the sound seems stable and comes from both channels clearly, but most of the time the sound is distorted on the left channel and there's no way to get rid of it. I would like to fix this myself, but I don't want to mess things up. Am I correct in assuming that the whole unit (metal casing including sliding contact switches within the casing) should be desoldered from the PCB before cleaning? Any info on how I should proceed?

in the meantime I favor retrofitting an external resp. outdoor source selector (due better contact- and thus sonic quality).Hey everybody, I'm new here and forgive me if my question might be stupid. I own a Yamaha AX-470 amplifier which uses the same switch. the audio comes mainly from the right channel whereas the left channel is either silent or cracks when I wiggle the selector switch a bit. At times the sound seems stable and comes from both channels clearly, but most of the time the sound is distorted on the left channel and there's no way to get rid of it. I would like to fix this myself, but I don't want to mess things up. Am I correct in assuming that the whole unit (metal casing including sliding contact switches within the casing) should be desoldered from the PCB before cleaning? Any info on how I should proceed?

Both a commercial product and a diy project could be realized.

e. g.

https://www.instructables.com/DIY-Audio-Switch-HiFi/

equipped with ELMA 04 2x6 or DACT CT3-5-4 (excellent contact quality).

commercial products

https://goldpt.com/sw4.html

https://www.reussenzehn.de/de/hifi/zubehoer/hochpegel-switches.php

https://web.archive.org/web/20070206191733/http://www.redwineaudio.com:80/Signature_3S.html

(only available in used condition)

cheap version:

https://www.profitec.info/audio-video/umschalter/

More such input selectors (overview):

https://www.diyaudio.com/community/threads/rotary-source-selector-for-audio.202573/page-2

the only work on your amp is cutting the rails at one cinch input and add a separate wire from there to the actually input (= output pins on the faulty rotary switch). Unfortunately this is necessary due the absence of a TP/source switch.

If you want to use the existing switch again, you have to completely disassemble and carefully cleaning it.

Ah many thanks tiefbassübertr, I'll look into the links you have submitted. Anyway, I think I'll reuse the switch, this amp is very dear to me and I'd like to have it in it's original state as much as possible.in the meantime I favor retrofitting an external resp. outdoor source selector (due better contact- and thus sonic quality).

Both a commercial product and a diy project could be realized.

e. g.

https://www.instructables.com/DIY-Audio-Switch-HiFi/

equipped with ELMA 04 2x6 or DACT CT3-5-4 (excellent contact quality).

commercial products

https://goldpt.com/sw4.html

https://www.reussenzehn.de/de/hifi/zubehoer/hochpegel-switches.php

https://web.archive.org/web/20070206191733/http://www.redwineaudio.com:80/Signature_3S.html

(only available in used condition)

cheap version:

https://www.profitec.info/audio-video/umschalter/

More such input selectors (overview):

https://www.diyaudio.com/community/threads/rotary-source-selector-for-audio.202573/page-2

the only work on your amp is cutting the rails at one cinch input and add a separate wire from there to the actually input (= output pins on the faulty rotary switch). Unfortunately this is necessary due the absence of a TP/source switch.

If you want to use the existing switch again, you have to completely disassemble and carefully cleaning it.

- Home

- Amplifiers

- Solid State

- Alps Rotary Switch Dropout Issues for Input Select (e.g. Onkyo, Yamaha, Creek)