close, 0.137 mm away. Overall diaphragm is 30.1mm and throat is 30.374mm. This is a Bliesma T25B BTW.

- Does this resemble what you have?

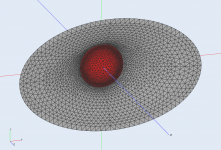

STL file attached.

STL file attached.

Attachments

Last edited:

Yes pretty much that. Except I can't see if you have small 0.5mm lip. Also the surround is concave.

You have it in the appendix as part of the dome source: P5 to WG0. Functionally the same as my lip seal. I agree at 0.5mm it won't do much, but I want to experiment with it.

Awesome, thank you! One more small request if I may LOL, could I get a version with OS contours so I can start comparing OS vs constant radius and can be confident I didn't screw something up copy/pasting?

In the meantime I ran the analysis - is this it? 🙂

- Ouch, same mistake again, I forgot to switch the velocity to axial - so this is wrong... OK, once again.

- Ouch, same mistake again, I forgot to switch the velocity to axial - so this is wrong... OK, once again.

Attachments

Simulations for the axial dome motion - it's not much better 🙂

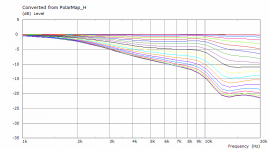

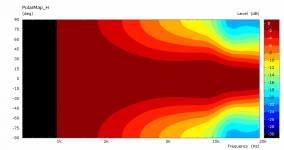

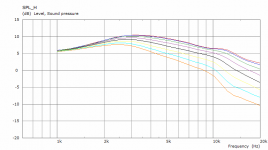

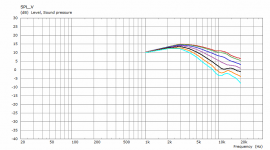

Raw horizontal polars (constant acceleration):

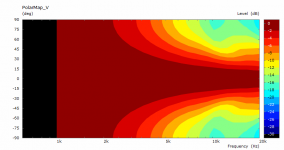

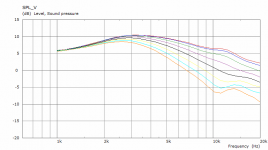

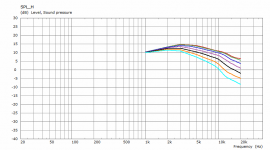

Vertical:

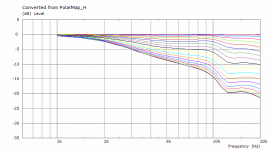

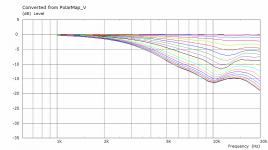

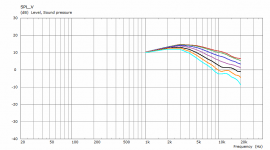

Attached also the normalized responses to 0 deg.

I'm really interested to see the measured data - how much are we off with this.

Raw horizontal polars (constant acceleration):

Vertical:

Attached also the normalized responses to 0 deg.

I'm really interested to see the measured data - how much are we off with this.

Attachments

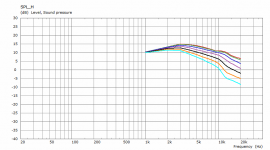

Here are my measured results, 0-60 degree in 10 degree steps, horizontally, followed my manufacturer's specs. What are the steps in ABEC?

Last edited:

You can set any step you need. This is for 0 - 60 / 10 for the raw polars ("SPL_H/V" charts). Polar maps are per 5 deg by default.

ABEC.SimType = 1 ; infinite baffle

ABEC.f1 = 1000 ; [Hz]

ABEC.f2 = 20000 ; [Hz]

ABEC.NumFrequencies = 20

ABEC.MeshFrequency = 1000 ; [Hz]

ABEC.Abscissa = 2 ; linear

ABEC.Polars.Dist = 1.5 ; mic distance - adjust this to your value [m]

ABEC.Polars.Step = 10 ; angular step [deg]

ABEC.Polars.Points = 7 ; # of polars

ABEC.Polars.Horizontal = 1

ABEC.Polars.Vertical = 1

ABEC.Polars.Diagonal = 0

ABEC.Polars.DiagonalInclination = 0.0

ABEC.Polars.PMapNorm = 10 ; polar map normalizing angle [deg]

I think the match is pretty good. There may still be differences due to the different radiating conditions. I work on finite baffles - that will be even closer.

BTW, this was calculated for 20 points only. Solved in 10 minutes.

ABEC.SimType = 1 ; infinite baffle

ABEC.f1 = 1000 ; [Hz]

ABEC.f2 = 20000 ; [Hz]

ABEC.NumFrequencies = 20

ABEC.MeshFrequency = 1000 ; [Hz]

ABEC.Abscissa = 2 ; linear

ABEC.Polars.Dist = 1.5 ; mic distance - adjust this to your value [m]

ABEC.Polars.Step = 10 ; angular step [deg]

ABEC.Polars.Points = 7 ; # of polars

ABEC.Polars.Horizontal = 1

ABEC.Polars.Vertical = 1

ABEC.Polars.Diagonal = 0

ABEC.Polars.DiagonalInclination = 0.0

ABEC.Polars.PMapNorm = 10 ; polar map normalizing angle [deg]

I think the match is pretty good. There may still be differences due to the different radiating conditions. I work on finite baffles - that will be even closer.

BTW, this was calculated for 20 points only. Solved in 10 minutes.

Attachments

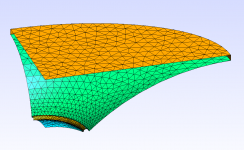

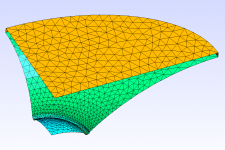

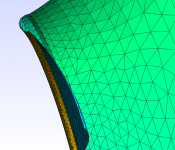

Looking more closely on your geometry, it seems that the vertical profile arc touches the baffle at slightly higher angle. When I checked my radiuses they were 74.6 and 25.5 mm, horizontally and vertically.

Maybe this will be a bit closer to what you have:

CircArc.TermAngle = 0.8 + 7*sin(p)^2

Now the radiuses are 73.9 and 30.5 mm. Updated STL attached.

Maybe this will be a bit closer to what you have:

CircArc.TermAngle = 0.8 + 7*sin(p)^2

Now the radiuses are 73.9 and 30.5 mm. Updated STL attached.

Attachments

Last edited:

Looking more closely on your geometry, it seems that the vertical profile arc touches the baffle at slightly higher angle. When I checked my radiuses they were 74.6 and 25.5 mm, horizontally and vertically.

Maybe this will be a bit closer to what you have:

CircArc.TermAngle = 0.8 + 7*sin(p)^2

Now the radiuses are 73.9 and 30.5 mm. Updated STL attached.

I'm not quite following, are the wall profile radiuses not 73.66 and 30.48 mm as I specified? Looking at the .cfg I see they are not even there, so some function with certain assumptions (tangent at baffle for example) must be calculating a best fit when given mouth size, throat size, depth, etc? Is there a way to direct code the radius?

If you think about it, it's not that easy - what's the radius on the diagonals and everywhere between? If you wanted to set the radii directly you would have to know this. I chose a different approach - you define the throat, the mouth outline (whatever that is) and the angle at which the arc should meet the baffle (=CircArc.TermAngle). The radii around the waveguide are simply calculated from that.

Good point, I wonder how Fusion360 does it? I only draw the four "guide" arcs you see in my pic a few posts ago and the Loft function interpolates the rest. Must be some standard formula?

It can be anything, there even don't have to be circular arcs anywhere else. I don't know the loft algorithm.

In my approach there are simply circular arcs everywhere.

In my approach there are simply circular arcs everywhere.

Forgive the naive question: what's the difference between constant velocity and constant acceleration simulation? When should one be used over the other?

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)