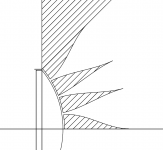

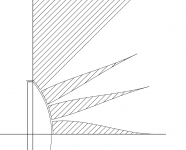

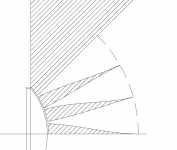

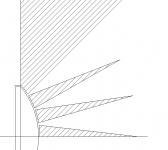

Maybe something like this? (Still just a basic sketch.)

The beams could be made longer to suppress a possible diffraction there, perhaps?

The beams could be made longer to suppress a possible diffraction there, perhaps?

Attachments

Last edited:

Last edited:

P. Bateman posted some interesting comments and quotes from Tom Danley on the diycaraudioforum about phaseplugs producing either a converging wave front at the exit, a plane wave, or a diverging wave front.

According to Tom Danley, a diverging wavefront (as emitted by drivers with annular diaphragms) is preferred for conical horns.

According to Tom Danley, a diverging wavefront (as emitted by drivers with annular diaphragms) is preferred for conical horns.

Last edited:

Sure, a diverging spherical wavefront of the corresponding radius is actually the perfect match for a conical waveguide (and the only one), even better than a flat wavefront is for an OS waveguide. There is no doubt about that. That's the reason I would like to try this out. Now I'm searching for any drawbacks. There must be some as I don't see this being done - actually I have never seen this done like that. Either it is too brilliant or too dumb 🙂

Last edited:

There's at least one 'minor' limitation, the actual produced wavefront depends on the diaphragm/phase plug interaction across the band.

If you had a pulsating spherical cap as a source you would not need any phase plug. The above might be a way how to shape the sound wave produced by axially oscillating dome to be approximately spherical. The question is if it would be any better in the end than a flat wavefront (as produced by majority of CDs) fed to na OS waveguide. Or if it would work as intended at all.

Last edited:

That's why the Chinese High End manufacturer (mentioned previously) puts 3" Beryllium dome tweeters in their monitor speakers (As well as ultra rigid Titanium cones that do not deform, even with a 100kg person dancing on top of it).

Last edited:

Now I'm not sure I follow. Are you saying that the more rigid diaphragm, the better? That is true in any case, I suppose.

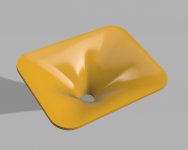

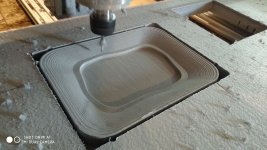

The test was done with foam (expanded polystyrene). I am a carpenter but absolutely a beginner with cnc. I finished mounting it this week.

The idea is to make it out of wood.

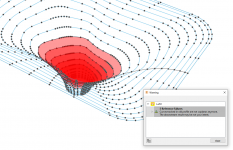

The import of the surface did not give me any problem, I do not understand the error message, I do not know what reference makes the old profile.

The idea is to make it out of wood.

The import of the surface did not give me any problem, I do not understand the error message, I do not know what reference makes the old profile.

BTW: foam vs hard surface - any measurable difference in SPL or just different vibration spectra? Many believes that hard smooth horn is better.

I have no answer for this

Another idea is to make a mold to make them in fiberglass with epoxy resin, it would be to machine the negative and use a vacuum infusion technique.

But this would be more complicated for prototype, it would be appropriate for series production.

Another idea is to make a mold to make them in fiberglass with epoxy resin, it would be to machine the negative and use a vacuum infusion technique.

But this would be more complicated for prototype, it would be appropriate for series production.

Sure, a diverging spherical wavefront of the corresponding radius is actually the perfect match for a conical waveguide (and the only one), even better than a flat wavefront is for an OS waveguide. There is no doubt about that. That's the reason I would like to try this out. Now I'm searching for any drawbacks. There must be some as I don't see this being done - actually I have never seen this done like that. Either it is too brilliant or too dumb 🙂

A converging wave front at the exit, a plane wave, or a diverging wave front can all be made by varying the path lengths in the phase plug from inner and outer portions of the diaphragm, regardless of whether the diaphragm is annular or dome shaped.

Drawbacks to your “in horn” rather than “in driver” phase plug proposal:

1)The level of machining (fractions of a millimeter) to make a good high frequency phase plug is such that incorporating it into the horn itself would not be cost effective for manufacturing.

2) Each different pattern horn would require a complete redesign of the phase plug portion.

3) Each section of the phase plug as illustrated is a “beamy” very high frequency horn, and as such would have HF “fingering” as multi-cell horns do.

4) Diffraction effects would be worse than standard phase plugs, as the slit exit dimensions are larger and spaced further apart.

Dave Gunness 2005 AES Convention paper “Improving Loudspeaker Transient Response with Digital Signal Processing”

https://web.archive.org/web/2012051...m/info/EAW/Technical_Papers/NT_Whitepaper.pdf

section 3.1 gives some insight into problems inherent in phase plug design.

Art

I agree with Art that I do see these proposals as being ones that integrate the phase plug into the whole waveguide design. I argued in one of my patents that this should be done and could be easily accommodated with replaceable phase plugs. To Art's points I would say:

1) If the phase plug were separated from the waveguide and replaceable then this is not an issue. With the way its being approached here it would be.

2)Absolutely true, but not really all that complex to achieve.

3) "as illustrated" perhaps, but if done correctly then this is not an issue.

4) This need not be the case, although it could be if things were not done correctly. However, again, if done correctly this is also not an issue.

1) If the phase plug were separated from the waveguide and replaceable then this is not an issue. With the way its being approached here it would be.

2)Absolutely true, but not really all that complex to achieve.

3) "as illustrated" perhaps, but if done correctly then this is not an issue.

4) This need not be the case, although it could be if things were not done correctly. However, again, if done correctly this is also not an issue.

Now I'm not sure I follow. Are you saying that the more rigid diaphragm, the better? That is true in any case, I suppose.

This is the case if the target is "an approximately spherical wave front emitted by an axially oscillating dome"

Thanks. That actually doesn't sound that discouraging. By drawbacks I meant mostly the acoustic flaws. This is DIY after all, much of what would be impractical or expensive in a serial production is almost a norm here.

So far I haven't thought much about any mounting or dividing into actual parts, this is to be left as the final step. I have some ideas though.

I suppose none of you are willing to disclose here what "done correctly" means and I guess I really should figure that out myself - just let me ask one quick question: Should the slits have straight sides?

So far I haven't thought much about any mounting or dividing into actual parts, this is to be left as the final step. I have some ideas though.

I suppose none of you are willing to disclose here what "done correctly" means and I guess I really should figure that out myself - just let me ask one quick question: Should the slits have straight sides?

Attachments

I agree with Art that I do see these proposals as being ones that integrate the phase plug into the whole waveguide design. I argued in one of my patents that this should be done and could be easily accommodated with replaceable phase plugs.

This would be the smartest thing to do IMHO, designing a phaseguide.

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)