Started an ATH based adventure here: https://www.diyaudio.com/community/threads/hornflower-2-way-point-source.386363/

//

//

Attachments

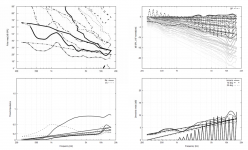

Does anyone know why my reports do this?

The traces are doubled and there's this weird zig zag pattern.

I have ATH installed on three machines and they all do this.

Here's the config file that produced this:

R-OSSE = {

R = 152 ; [mm]

r0 = 17 ; [mm]

a0 = 10 ; [deg]

a = 34.4836 ; [deg]

k = 1.6226 + 3.4566*abs(sin(p))^2.1429; []

r = 0.32683 ; []

b = 0.13157 ; []

m = 0.81285 ; []

q = 4.011 ; []

}

Source.Contours = {

zoff -2

point p1 4.68 0 2

point p2 0 14 0.5

point p3 1 15 0.5

point p4 0 16 0.5

point p5 0 17 1

cpoint c1 -18.59 0

cpoint c2 0 15

arc p1 c1 p2 1.0

arc p2 c2 p3 0.75

arc p3 c2 p4 0.25

line p4 p5 0

line p5 WG0 0

}

Mesh.LengthSegments = 36

Mesh.AngularSegments = 48

Mesh.ThroatResolution = 5

Mesh.MouthResolution = 9

Mesh.WallThickness = 8

Mesh.RearResolution = 20

Mesh.SubdomainSlices = 35

Mesh.InterfaceOffset = 25

Mesh.InterfaceDraw = 0

ABEC.MeshFrequency = 1000

ABEC.NumFrequencies = 32

ABEC.Abscissa = 1

ABEC.SimType = 2

ABEC.f1 = 500

ABEC.f2 = 12000

ABEC.Polars:SPL_H = {

MapAngleRange = 0,90,19

NormAngle = 0

}

ABEC.Polars:SPL_V = {

MapAngleRange = 0,90,19

NormAngle = 0

Inclination = 90

}

Output.ABECProject = 1

Output.STL = 1

Report = {

PolarData = "SPL_H"

NormAngle = 10

MaxAngle = 90

}

The traces are doubled and there's this weird zig zag pattern.

I have ATH installed on three machines and they all do this.

Here's the config file that produced this:

R-OSSE = {

R = 152 ; [mm]

r0 = 17 ; [mm]

a0 = 10 ; [deg]

a = 34.4836 ; [deg]

k = 1.6226 + 3.4566*abs(sin(p))^2.1429; []

r = 0.32683 ; []

b = 0.13157 ; []

m = 0.81285 ; []

q = 4.011 ; []

}

Source.Contours = {

zoff -2

point p1 4.68 0 2

point p2 0 14 0.5

point p3 1 15 0.5

point p4 0 16 0.5

point p5 0 17 1

cpoint c1 -18.59 0

cpoint c2 0 15

arc p1 c1 p2 1.0

arc p2 c2 p3 0.75

arc p3 c2 p4 0.25

line p4 p5 0

line p5 WG0 0

}

Mesh.LengthSegments = 36

Mesh.AngularSegments = 48

Mesh.ThroatResolution = 5

Mesh.MouthResolution = 9

Mesh.WallThickness = 8

Mesh.RearResolution = 20

Mesh.SubdomainSlices = 35

Mesh.InterfaceOffset = 25

Mesh.InterfaceDraw = 0

ABEC.MeshFrequency = 1000

ABEC.NumFrequencies = 32

ABEC.Abscissa = 1

ABEC.SimType = 2

ABEC.f1 = 500

ABEC.f2 = 12000

ABEC.Polars:SPL_H = {

MapAngleRange = 0,90,19

NormAngle = 0

}

ABEC.Polars:SPL_V = {

MapAngleRange = 0,90,19

NormAngle = 0

Inclination = 90

}

Output.ABECProject = 1

Output.STL = 1

Report = {

PolarData = "SPL_H"

NormAngle = 10

MaxAngle = 90

}

Attachments

Here is what I got.Does anyone know why my reports do this?

The traces are doubled and there's this weird zig zag pattern.

I have ATH installed on three machines and they all do this.

Here's the config file that produced this:

R-OSSE = {

R = 152 ; [mm]

r0 = 17 ; [mm]

a0 = 10 ; [deg]

a = 34.4836 ; [deg]

k = 1.6226 + 3.4566*abs(sin(p))^2.1429; []

r = 0.32683 ; []

b = 0.13157 ; []

m = 0.81285 ; []

q = 4.011 ; []

}

Source.Contours = {

zoff -2

point p1 4.68 0 2

point p2 0 14 0.5

point p3 1 15 0.5

point p4 0 16 0.5

point p5 0 17 1

cpoint c1 -18.59 0

cpoint c2 0 15

arc p1 c1 p2 1.0

arc p2 c2 p3 0.75

arc p3 c2 p4 0.25

line p4 p5 0

line p5 WG0 0

}

Mesh.LengthSegments = 36

Mesh.AngularSegments = 48

Mesh.ThroatResolution = 5

Mesh.MouthResolution = 9

Mesh.WallThickness = 8

Mesh.RearResolution = 20

Mesh.SubdomainSlices = 35

Mesh.InterfaceOffset = 25

Mesh.InterfaceDraw = 0

ABEC.MeshFrequency = 1000

ABEC.NumFrequencies = 32

ABEC.Abscissa = 1

ABEC.SimType = 2

ABEC.f1 = 500

ABEC.f2 = 12000

ABEC.Polars:SPL_H = {

MapAngleRange = 0,90,19

NormAngle = 0

}

ABEC.Polars:SPL_V = {

MapAngleRange = 0,90,19

NormAngle = 0

Inclination = 90

}

Output.ABECProject = 1

Output.STL = 1

Report = {

PolarData = "SPL_H"

NormAngle = 10

MaxAngle = 90

}

There are 3 fields for the impedance it might be the issue?

What tweeter did you model?

BTW, it seems that the far off-axis diffraction products in the horizontal plane can be reduced by making the mouth slightly elliptical, i.e. to set the R to something like this:

R = 152 - E*sin(p)^2 ; [mm]

; E = "eccentricity factor" [mm]

R = 152 - E*sin(p)^2 ; [mm]

; E = "eccentricity factor" [mm]

You shouldn't do that, i.e. to normalize both H and V independently to any other angle than 0 deg. You can do that on paper but it's physically impossible and can lead to misleading results.Probably what you were looking for (normalized to 10deg)

- What could be done instead is to normalize e.g. the horizontals to 10 deg and apply the same "EQ" on the verticals.

I'm no expert on chemistry but it sticks pretty well 🙂Does the PU adhere chemically well to the printed pa? Or do you need mechanical interlocking (rough surface; printed mini-hooks;….). At least this kind of PU has minor shrinkage….

I agree, thats why I didn't use 10deg so far fpr assim. devices, I did it just because it was specified 10deg in the script...You shouldn't do that, i.e. to normalize both H and V independently to any other angle than 0 deg. You can do that on paper but it's physically impossible and can lead to misleading results.

- What could be done instead is to normalize e.g. the horizontals to 10 deg and apply the same "EQ" on the verticals.

thats also why I buy into anything other than 0deg in general

Maybe LW could work

For round devices normalizing to whatever off-axis angle is completely valid of course. On-axis (0 deg) is seldom the best curve to choose but for an asymmetric device that's the only reasonable option (besides the approach I mentioned but that's more than just a normalization).

It should adhere well to PLA, PET, ABS, PC, and other common 3d printing plastics. According to two sources I found (one and two), polyurethane resins will generally adhere well to substrates with high surface energy (>40 dynes/cm), which includes all the plastics I listed.Does the PU adhere chemically well to the printed pa?

@maiky76 ..of course measuring at a non-zero H and non-zero V where they meet at one point is OK. You can use that response measurement for creating a directivity index (which is not that dissimilar to what's being discussed with normalising, except there are limitations in how things are getting measured). You could choose a non-zero vertical and run a new set of horizontals on that plane..

..not all horns are the same in this respect, however, for the same reason that measuring at 0 degrees horizontal and 0 degrees vertical isn't always enough information.

..not all horns are the same in this respect, however, for the same reason that measuring at 0 degrees horizontal and 0 degrees vertical isn't always enough information.

Sure, but that's something completely different...of course measuring at a non-zero H and non-zero V where they meet at one point is OK.

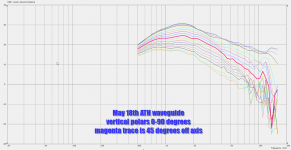

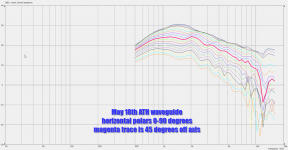

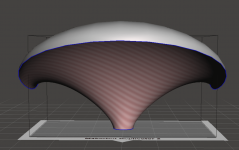

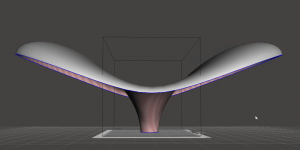

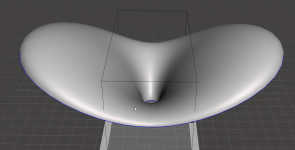

I took some of the R-OSSE designs that Mabat created, and messed around with them, yielding the attached results.

One of the interesting/unexpected results was that horizontal directivity was narrower than vertical directivity, even though the angle of the waveguide is larger. I think that's due to diffraction, basically the horizontal dimension is a small fraction of the vertical dimension.

Because the horizontal dimension is smaller, I think the wavefront is transitioning from a state where it's radiating into 90 degrees, then 180 degrees, then 360 degrees, as frequencies get lower. This has the effect of "shading" the output on the horizontal axis.

One of the interesting/unexpected results was that horizontal directivity was narrower than vertical directivity, even though the angle of the waveguide is larger. I think that's due to diffraction, basically the horizontal dimension is a small fraction of the vertical dimension.

Because the horizontal dimension is smaller, I think the wavefront is transitioning from a state where it's radiating into 90 degrees, then 180 degrees, then 360 degrees, as frequencies get lower. This has the effect of "shading" the output on the horizontal axis.

Attachments

-

2022-05-19 09_21_53-squaft - TightVNC Viewer.png79.6 KB · Views: 171

2022-05-19 09_21_53-squaft - TightVNC Viewer.png79.6 KB · Views: 171 -

2022-05-19 09_19_37-squaft - TightVNC Viewer.png84.8 KB · Views: 159

2022-05-19 09_19_37-squaft - TightVNC Viewer.png84.8 KB · Views: 159 -

2022-05-19 08_17_42-squaft - TightVNC Viewer.png122.5 KB · Views: 149

2022-05-19 08_17_42-squaft - TightVNC Viewer.png122.5 KB · Views: 149 -

2022-05-19 08_16_47-squaft - TightVNC Viewer.png75.7 KB · Views: 163

2022-05-19 08_16_47-squaft - TightVNC Viewer.png75.7 KB · Views: 163 -

2022-05-19 08_17_07-squaft - TightVNC Viewer.png132.7 KB · Views: 158

2022-05-19 08_17_07-squaft - TightVNC Viewer.png132.7 KB · Views: 158

Here's the configuration file:

R-OSSE = {

R = 150 + 100 * abs(sin(p))^2 ; [mm]

r0 = 17 ; [mm]

a0 = 15 ; [deg]

a = 45 ; [deg]

k = 1.6226 + 6*abs(sin(p))^2.1429; []

r = 0.32683 ; []

b = 0.13157 ; []

m = 0.81285 ; []

q = 4.011 ; []

}

Source.Contours = {

zoff -2

point p1 4.68 0 2

point p2 0 14 0.5

point p3 1 15 0.5

point p4 0 16 0.5

point p5 0 17 1

cpoint c1 -18.59 0

cpoint c2 0 15

arc p1 c1 p2 1.0

arc p2 c2 p3 0.75

arc p3 c2 p4 0.25

line p4 p5 0

line p5 WG0 0

}

Mesh.LengthSegments = 36

Mesh.AngularSegments = 48

Mesh.ThroatResolution = 5

Mesh.MouthResolution = 9

Mesh.WallThickness = 8

Mesh.RearResolution = 20

Mesh.SubdomainSlices = 35

Mesh.InterfaceOffset = 25

Mesh.InterfaceDraw = 0

ABEC.MeshFrequency = 1000

ABEC.NumFrequencies = 48

ABEC.Abscissa = 1

ABEC.SimType = 2

ABEC.f1 = 500

ABEC.f2 = 16000

ABEC.Polars:SPL_H = {

MapAngleRange = 0,90,19

}

ABEC.Polars:SPL_H_NORM = {

MapAngleRange = 0,90,19

NormAngle=10

}

ABEC.Polars:SPL_V = {

MapAngleRange = 0,90,19

Inclination = 90

}

Output.ABECProject = 1

Output.STL = 1

Report = {

PolarData = "SPL_H"

NormAngle = 10

MaxAngle = 90

}

R-OSSE = {

R = 150 + 100 * abs(sin(p))^2 ; [mm]

r0 = 17 ; [mm]

a0 = 15 ; [deg]

a = 45 ; [deg]

k = 1.6226 + 6*abs(sin(p))^2.1429; []

r = 0.32683 ; []

b = 0.13157 ; []

m = 0.81285 ; []

q = 4.011 ; []

}

Source.Contours = {

zoff -2

point p1 4.68 0 2

point p2 0 14 0.5

point p3 1 15 0.5

point p4 0 16 0.5

point p5 0 17 1

cpoint c1 -18.59 0

cpoint c2 0 15

arc p1 c1 p2 1.0

arc p2 c2 p3 0.75

arc p3 c2 p4 0.25

line p4 p5 0

line p5 WG0 0

}

Mesh.LengthSegments = 36

Mesh.AngularSegments = 48

Mesh.ThroatResolution = 5

Mesh.MouthResolution = 9

Mesh.WallThickness = 8

Mesh.RearResolution = 20

Mesh.SubdomainSlices = 35

Mesh.InterfaceOffset = 25

Mesh.InterfaceDraw = 0

ABEC.MeshFrequency = 1000

ABEC.NumFrequencies = 48

ABEC.Abscissa = 1

ABEC.SimType = 2

ABEC.f1 = 500

ABEC.f2 = 16000

ABEC.Polars:SPL_H = {

MapAngleRange = 0,90,19

}

ABEC.Polars:SPL_H_NORM = {

MapAngleRange = 0,90,19

NormAngle=10

}

ABEC.Polars:SPL_V = {

MapAngleRange = 0,90,19

Inclination = 90

}

Output.ABECProject = 1

Output.STL = 1

Report = {

PolarData = "SPL_H"

NormAngle = 10

MaxAngle = 90

}

Yeah, the somewhat narrowed horizontal directivity caught my attention already in the measurements Dkalsi showed. That was ST260-KVAR vs ST260 which are both about the same size (i.e. ~260 mm). That's definitely an interesting outcome -

https://www.diyaudio.com/community/...-design-the-easy-way-ath4.338806/post-7015019

https://www.diyaudio.com/community/...-design-the-easy-way-ath4.338806/post-7015019

Last edited:

These are the ST260 (brass at the back), 1.4" KVAR (the big one) and its 1:2 scale model in grey.

The ST260 is the old petal construction (quite laborous), the KVAR is assembled from 5 pieces (base + 4 petals, pretty easy) and the small one is made from just two pieces (throat +mouth).

The ST260 is the old petal construction (quite laborous), the KVAR is assembled from 5 pieces (base + 4 petals, pretty easy) and the small one is made from just two pieces (throat +mouth).

Finally working on a full-3D report. In a general case we need to calculate the radiated power properly -

Here's an equally-spaced sampled sphere (100 a 200 points).

Here's an equally-spaced sampled sphere (100 a 200 points).

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)