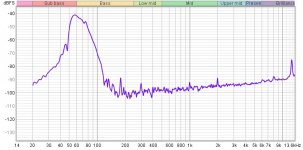

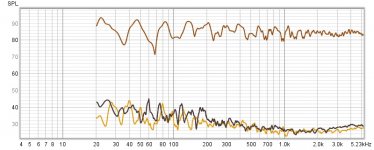

1. The side panel resonance of all three modules with no crossovers applied..

2. The side panel resonances with crossovers applied to specifically deal with the primary resonances of each..

It should also be noted that what is left is extraordinary low in level compared with the module outputs of 90db/1m

3. The subwoofer panel resonance will be a tougher nut to crack🙂

Have you tried two woofers opposing sides of the enclosure? Should reduce vibration a lot 🙂 with ~250Hz crossover drivers should be within about ~34cm from each other to still radiate as one.

Last edited:

How much are the side panels actually moving, I presume around 1/1,000 of an inch; does it become more and more difficult to markedly reduce the movement further, after all the thick walls, damping and struts. Would it be more practical to have an acoustic hood with holes in for the tweeter/mid bass, or a double skinned side panel with an air gap in between - although it's possible that the air pressure would couple both panels together. I've used to opposing drivers, and annoyingly the cabinet STILL vibrates. I've used foam, cork and felt under speakers, but only because I had such at the time.

Have you tried two woofers opposing sides of the enclosure? Should reduce vibration a lot 🙂 with ~250Hz crossover drivers should be within about ~34cm from each other to still radiate as one.

I have stereo subs with outstanding drivers that are no longer made. If I can't get these subwoofer panel vibrations lowered to an acceptable level, Then I have no choice but to make it my next project. The null method should be perfectly suited for subwoofer panel audibility, especially when the panels resonances "appear" to be so severe, relative to the fundamental, like the Dunlavy's I tested a little while back.

One thing I just discovered about the Behringer AD121, is that it becomes very microphonic when the vibration sensor is plugged into it. Having it anywhere near anything that's vibrating will screw up the measurement. Placing it as far as possible from what's being measured and between to thick pillows really helps, and I'm already getting much better measurements on everything including the subwoofer panel. This is one more thing that needs to be accounted for while taking measurements with this rig. Maybe everything that this extremely sensitive vibration sensor is plugged into will become microphonic. My next vibration sensor cable which I am assembling now, will use a double shielded mic cable with non microphonic sheathing. That may solve the problem completely. The electrical tape sheathing I'm using now is probably terrible when it comes to microphonics🙂

Last edited:

A hood is an excellent idea worth pursuing, especially on the subwoofer. My modular cabinet panel vibrations in their current situation are so quiet, that they have to be referenced to the noise floor of my electronics. When I remeasure after controlling for microphonics, they will probably be even lower than that.How much are the side panels actually moving, I presume around 1/1,000 of an inch; does it become more and more difficult to markedly reduce the movement further, after all the thick walls, damping and struts. Would it be more practical to have an acoustic hood with holes in for the tweeter/mid bass, or a double skinned side panel with an air gap in between - although it's possible that the air pressure would couple both panels together. I've used to opposing drivers, and annoyingly the cabinet STILL vibrates. I've used foam, cork and felt under speakers, but only because I had such at the time.

Last edited:

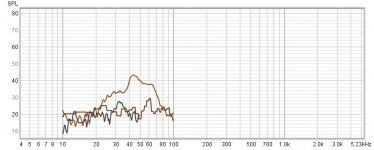

Microphonics of Behringer, with and without pillow sandwich, while analyzing cabinet. No crossover filters applied. It's very bad without the pillows. I'm glad I caught this.

Orange- pillow sandwich..

Fixing the mic cable will lower it even more, I'm sure. As you can see, I'm still getting the kinks out of this panel measurement setup.

Orange- pillow sandwich..

Fixing the mic cable will lower it even more, I'm sure. As you can see, I'm still getting the kinks out of this panel measurement setup.

Attachments

Last edited:

Strange, why would it be so microphonic? 5M input impedance can do odd things, but what in the Behringer could be turning vibration into sound?

Yeah, I can't figure it out, But I do know this, when the sensor cable is not plugged in, I can tap on the Behringer with the RTA going and it doesn't read, but when I Plug the mic cable in, the tiniest tap or brush on the Behringer will read perfectly on the RTA. A harder tap will send it sky high. That's how I discovered the problem, while playing around with the RTA on REW. I even tried gently blowing on it and it read on the rta. That's pretty bad. Two big couch pillows seem to kill the problem, and not playing the sweeps too loudly. 95db/1m is to high. 90db is good though.

Last edited:

I'm going to try this along with the Blu-Tak and sorbothane, for the loudspeaker/stand mounting test. It has some strange properties that might work well.

https://www.amazon.com/Length-1-18inch-Transparent-Traceless-Washable/dp/B08MFPBJBB

https://www.amazon.com/Length-1-18inch-Transparent-Traceless-Washable/dp/B08MFPBJBB

Yeah, I can't figure it out, But I do know this, when the sensor cable is not plugged in, I can tap on the Behringer with the RTA going and it doesn't read, but when I Plug the mic cable in, the tiniest tap or brush on the Behringer will read perfectly on the RTA. A harder tap will send it sky high. That's how I discovered the problem, while playing around with the RTA on REW. I even tried gently blowing on it and it read on the rta. That's pretty bad. Two big couch pillows seem to kill the problem, and not playing the sweeps too loudly. 95db/1m is to high. 90db is good though.

This is a long shot - and very unlikely, but could it be vibration transition down the cable to the piezo disc ? Perhaps blobs of blue tack along it's length might do something.

I completely rebuilt the sensor cable yesterday, with double shielded, non microphonic cable, and it does seem to be helping, but I need to play around with it some more just to make sure.

Last edited:

This is a long shot - and very unlikely, but could it be vibration transition down the cable to the piezo disc ? Perhaps blobs of blue tack along it's length might do something.

That could definitely happen and makes perfect sense. The thin film piezo is extremely sensitive. Vibrations on the Behringer could easily travel up the cable to the sensor, get converted to an electrical signal signal, and sent back down through the cable, this time electrically, to get processed by the electronics. Excellent call. I'm willing to bet that that's the entire problem in a nutshell.

So the pillow sandwich along with the new, non microphonic sensor cable with a brick mechanically grounding the cable to the concrete floor at the half way point should kill the mechanical feedback completely. Maybe even just the brick, and I can forget the pillows.

I'll test that theory today.

Once I get done with all of this complex trial and error, the protocol involved when using this setup should be very simple.

Last edited:

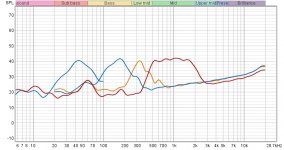

Now that I have the mechanical feedback problem under control, I tested the subwoofer again. It appears that what I originally thought was a bad panel resonance was actually just feedback gone wild🙂 I also lowered the sub crossover to 50hz to filter out the actual panel resonance even further. Totally normal now. Phew!

1.- Feedback on subwoofer panel measurement with noise floor.

2.- New subwoofer measurement with noise floor included.

3.- All three modules remeasured side panel resonances with subwoofer included. Crossovers are filtering out all primary resonances of each cabinet. What is left is very low in level compared to what was filtered out. That's the good thing about these Behringer dsp crossovers. It's extremely easy to make changes to the system on a whim, and I can do it wirelessly from my listening seat with the remote software that's downloaded from Behringer.

1.- Feedback on subwoofer panel measurement with noise floor.

2.- New subwoofer measurement with noise floor included.

3.- All three modules remeasured side panel resonances with subwoofer included. Crossovers are filtering out all primary resonances of each cabinet. What is left is very low in level compared to what was filtered out. That's the good thing about these Behringer dsp crossovers. It's extremely easy to make changes to the system on a whim, and I can do it wirelessly from my listening seat with the remote software that's downloaded from Behringer.

Attachments

Last edited:

System response at 50" after using the crossover to filter out panel resonances. Still good.

2nd and 3rd hd at 50" is also at acceptable levels.

2nd and 3rd hd at 50" is also at acceptable levels.

Attachments

Last edited:

Guitar cables can be microphonic and they aren't going into 5M. It's good that you have fixed it, but in future if you have problems maybe look to the lowest noise guitar cables.

Actually, my latest sensor cable iteration is made using an instrument cable specifically meant for plugging directly into a guitar. I said "Mic cable" on an earlier post, which was incorrect.

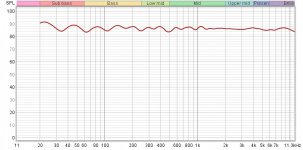

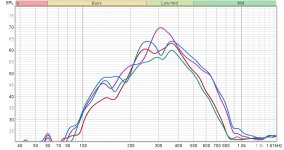

Speaker/stand damping compound contest, with loudspeaker sidewall measured for each..

Purple- Nothing

Red- Quarter sized blu-tak

Blue- 2cmx2cmx2mm Nano tape square

Green- 2cmx2cmx3mm Sorbothane

Absolute "spl" is not real, of course, but relative "spl" is.

Purple- Nothing

Red- Quarter sized blu-tak

Blue- 2cmx2cmx2mm Nano tape square

Green- 2cmx2cmx3mm Sorbothane

Absolute "spl" is not real, of course, but relative "spl" is.

Attachments

Last edited:

Perhaps you could get some washing machine anti vibration pads and test those under a speaker, after the test stick them under your washing machine, or valve amp.

A good analogy would be shock absorbers on a car. This is just a downsized version of that. There are also variables for each system that could change the results. For example, every different make of car needs it's own specific type of shock absorber that's tuned to it's specific situationWow! That's only by changing how the speaker is coupled the stand? 😱

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Accelerometers to measure panel vibrations?